Technique for processing garbage leachate

A technology for landfill leachate and treatment process, applied in the field of high-concentration organic leachate treatment technology, can solve the problems of immature process methods and unsatisfactory effects, and achieve the effects of easy control, low treatment costs, and reduced investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The process of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

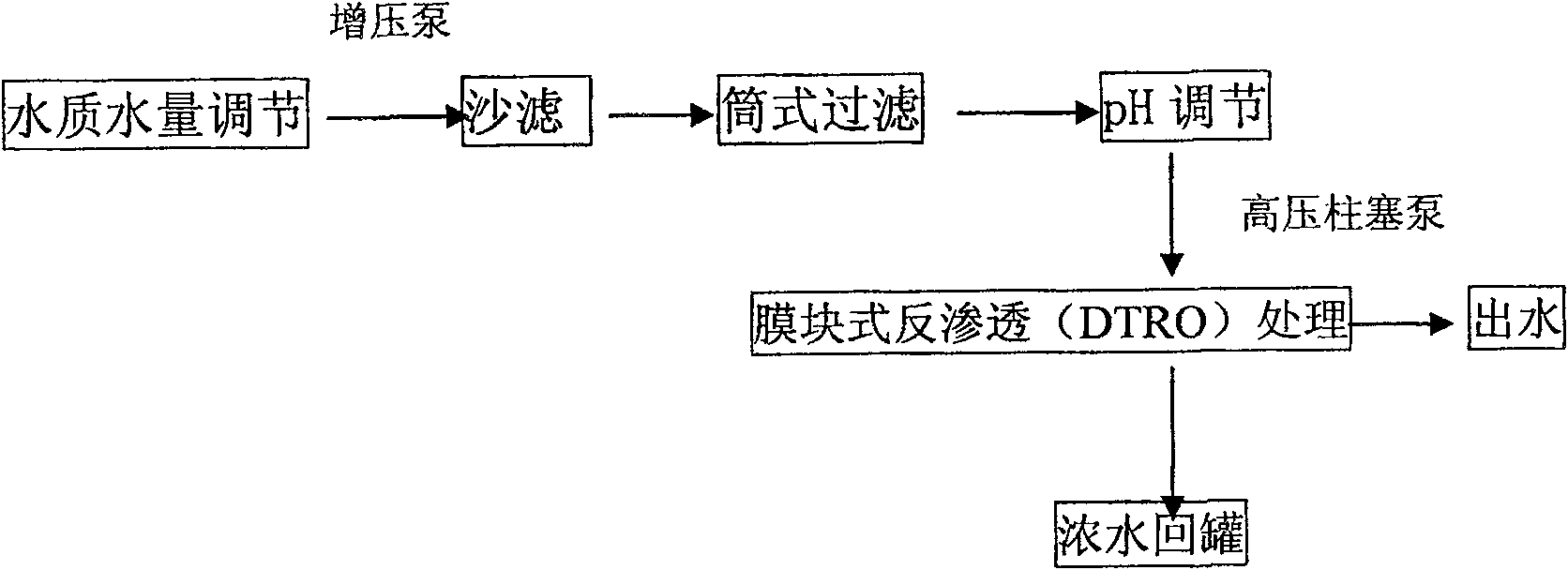

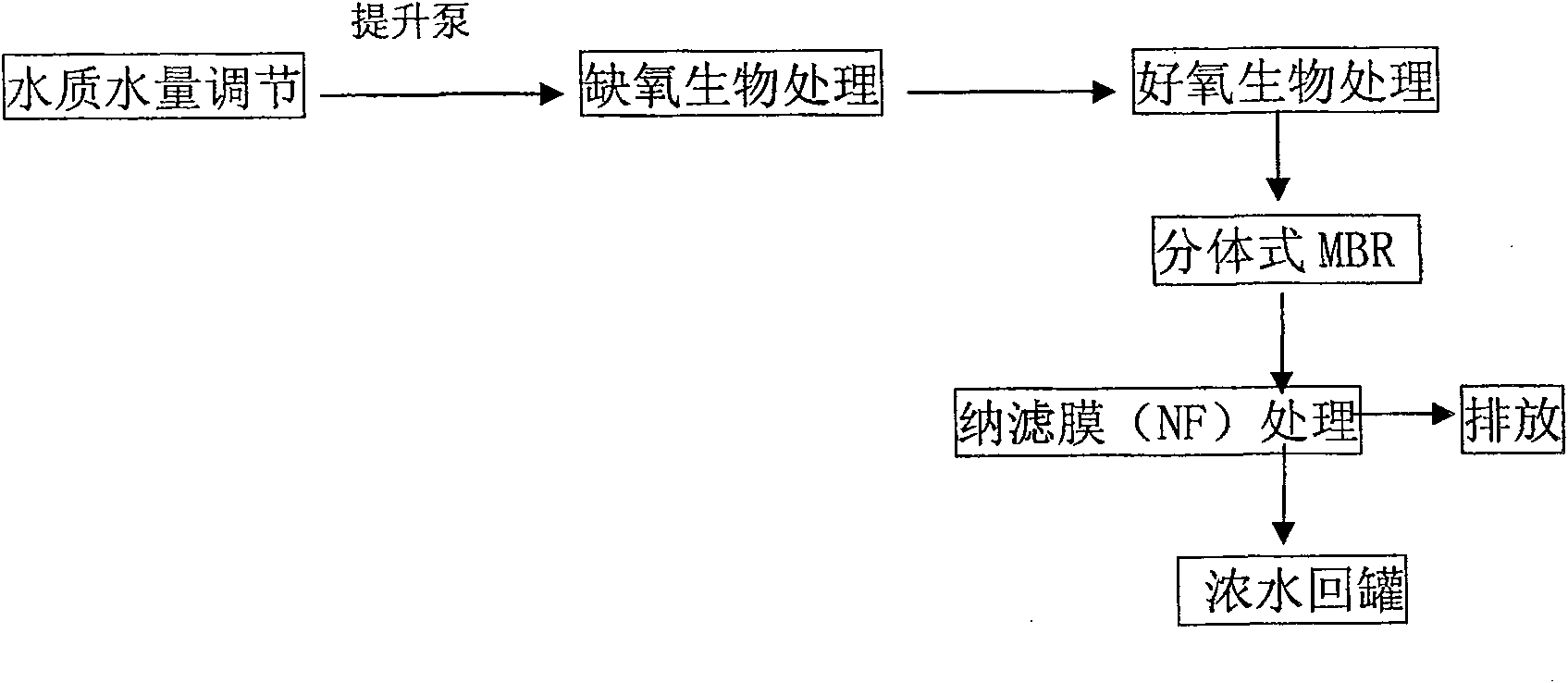

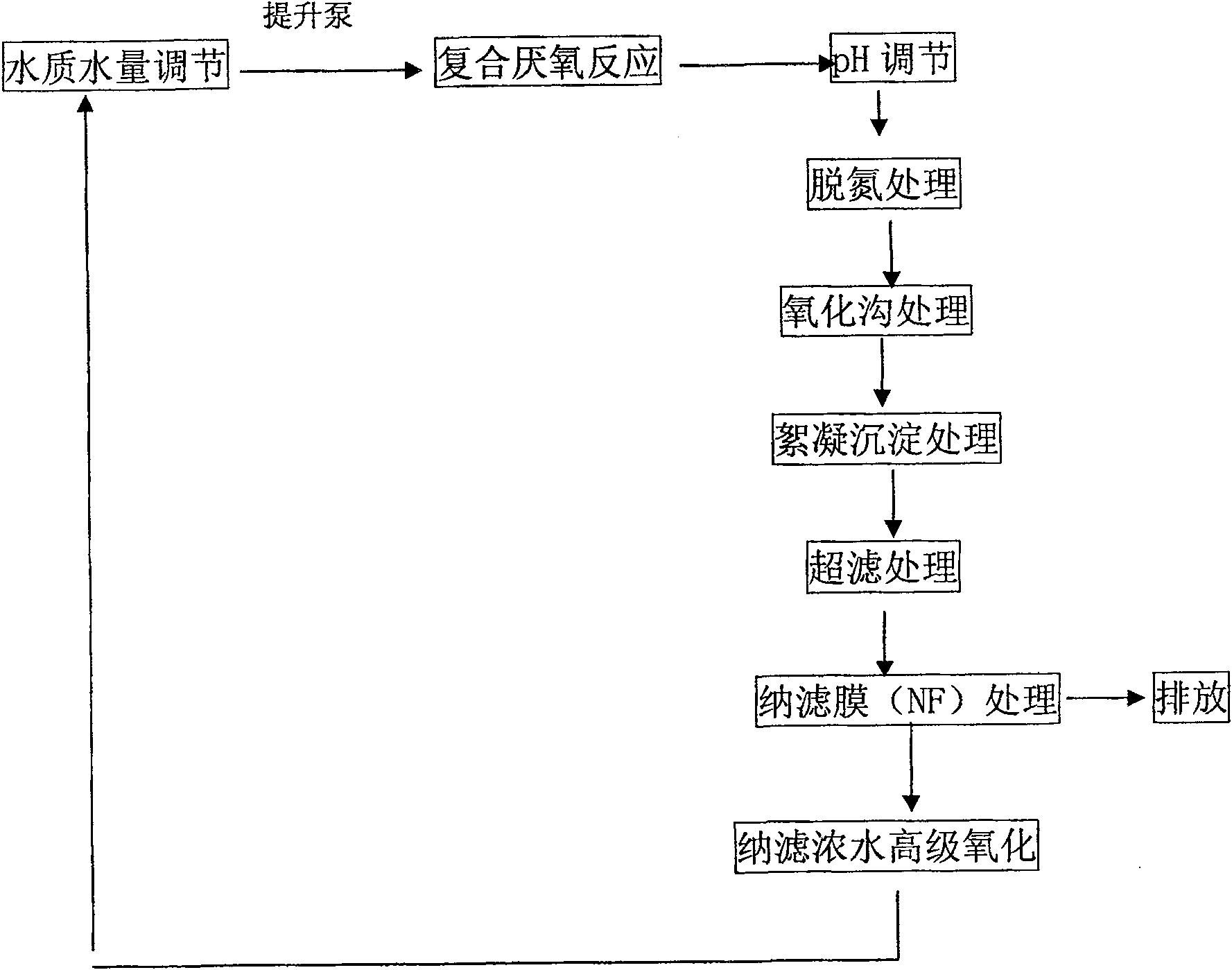

[0025] Such as Figure 5 Shown, the present invention handles landfill leachate and comprises the following processes:

[0026] 1. Regulate the water quality and quantity of landfill leachate in a regulating tank. The water quality regulation is to remove bulky impurities in the landfill leachate through the grid, and the water volume regulation is to concentrate a large amount of landfill leachate in the regulating tank so that it can be transported to the next step by the water pump for treatment.

[0027] 2. Send the leachate treated in step 1) into an anaerobic tank, and perform anaerobic treatment at 25°C to 45°C (choose different treatment temperatures depending on the concentration and type of pollutants in the leachate). Oxygen treatment time is 50-100 hours (it varies depending on the concentration of pollutants in the leacha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com