Combined split mold once extrusion forming method with large flange middle through body

A technology of extrusion forming and combining molds, applied in the field of metal plastic forming, can solve the problems of high energy consumption, complex structure, folding defects, etc., and achieve the effects of accurate product size, simple mold structure, and no demoulding slope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

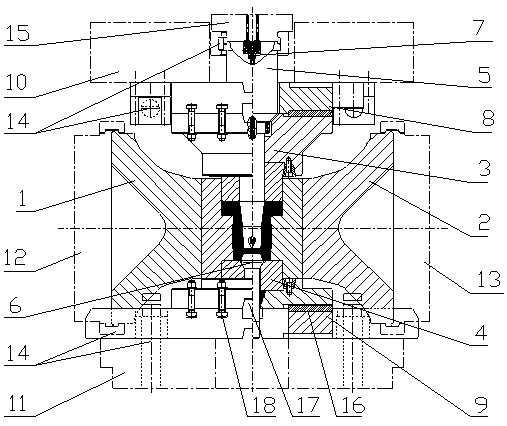

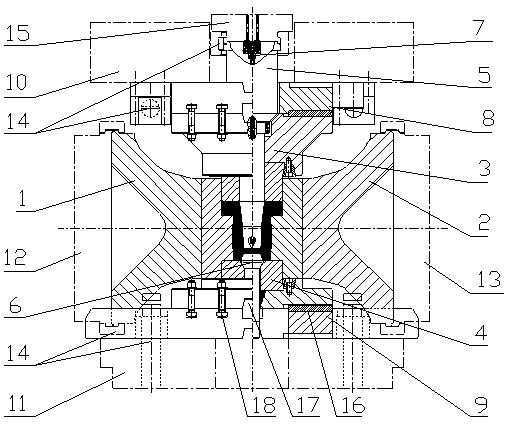

[0024] figure 1 It is a schematic diagram of the combined die after the extrusion of the product of the present invention. It can be seen from the accompanying drawings that the vertical double-action extrusion combined die with a large flange and a whole body combined parting mainly includes: a left horizontal die 1, a right horizontal die Die 2, upper extrusion die 3, lower extrusion die 4, upper vertical perforation tool 5, lower vertical perforation tool 6, inner water cooling device for perforation needle 7, upper die bottom plate 8, lower die bottom plate 9, movable beam backing plate 10. Mobile table 11, left horizontal master cylinder plunger 12, right horizontal master c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com