Dry cylinder liner preparation technology

A technology for preparing technology and cylinder liners, which is applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve problems such as unreasonable process layout and long process flow, and achieve the effect of lean equipment layout, low comprehensive cost and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

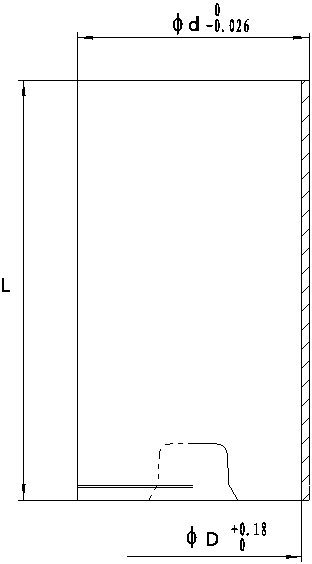

[0029] Such as figure 1 As shown, a preparation process of a Euro VI dry cylinder liner comprises the following steps:

[0030] (1) Cylinder liner castings are prepared by metal-type wet coating centrifugal casting process, and then the cylinder liner castings are sawn into individual cylinder liner blanks by high-precision sawing machine and subjected to heat treatment. The heat treatment refers to stress-relief annealing at 530°C for 3 hours; The total length of the blank workpiece is 158-158.5mm and the runout of the end surface is less than 0.8mm;

[0031] (2) Boring the inner hole: use the three-jaw boring tool to clamp the outer circle of the workpiece for high-speed boring inner hole; use a CNC lathe (model: T65 / 750, manufacturer: Zhejiang Headman Intelligent Equipment Co., Ltd.), the machining allowance 3mm, divided into 3 passes, the speed S is 1200 rpm, the feed rate F is 0.3-0.5mm / rotation, and the inner hole size is 81.1±0.09mm, the machining accuracy is 0.005mm, ...

Embodiment 2

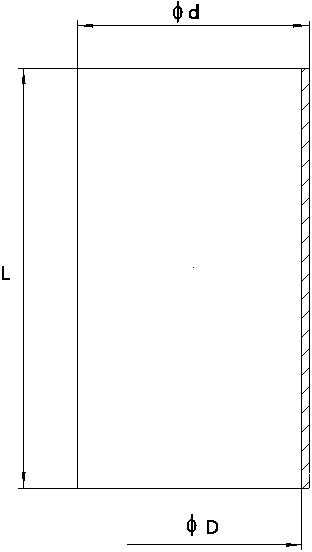

[0036] Such as figure 2 Shown, a kind of preparation technology of dry type cylinder liner comprises the following steps:

[0037] (1) Cylinder liner castings are prepared by centrifugal casting process of steel pipe or metal mold wet paint, and then the cylinder liner castings are cut into individual cylinder liner blanks by high-precision sawing machine and heat treated. The heat treatment refers to stress relief annealing at 530°C for 3 hours ;The total length of the workpiece conforming to the design is 134.3-134.8mm and the runout of the end surface is less than 0.8mm;

[0038] (2) Boring the inner hole: use the three-jaw boring tool to clamp the outer circle for high-speed boring inner hole; use a CNC lathe (model: T65 / 750, manufacturer: Zhejiang Heideman Intelligent Equipment Co., Ltd.), machining allowance 2 -3mm, divided into 2-3 passes, the speed S is 1000-1500 rpm, the feed rate F is 0.3-0.6 mm / rotation, and the inner hole size is 90.74±0.09mm, the machining accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com