Short process iron-making device and coke-free saltpeter-free energy-saving environmental short process iron-making method thereof

A short process and taphole technology, applied in the field of metallurgy, can solve problems such as complex equipment, large investment, and limited environmental pollution, and achieve the effect of reducing flue gas emissions and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

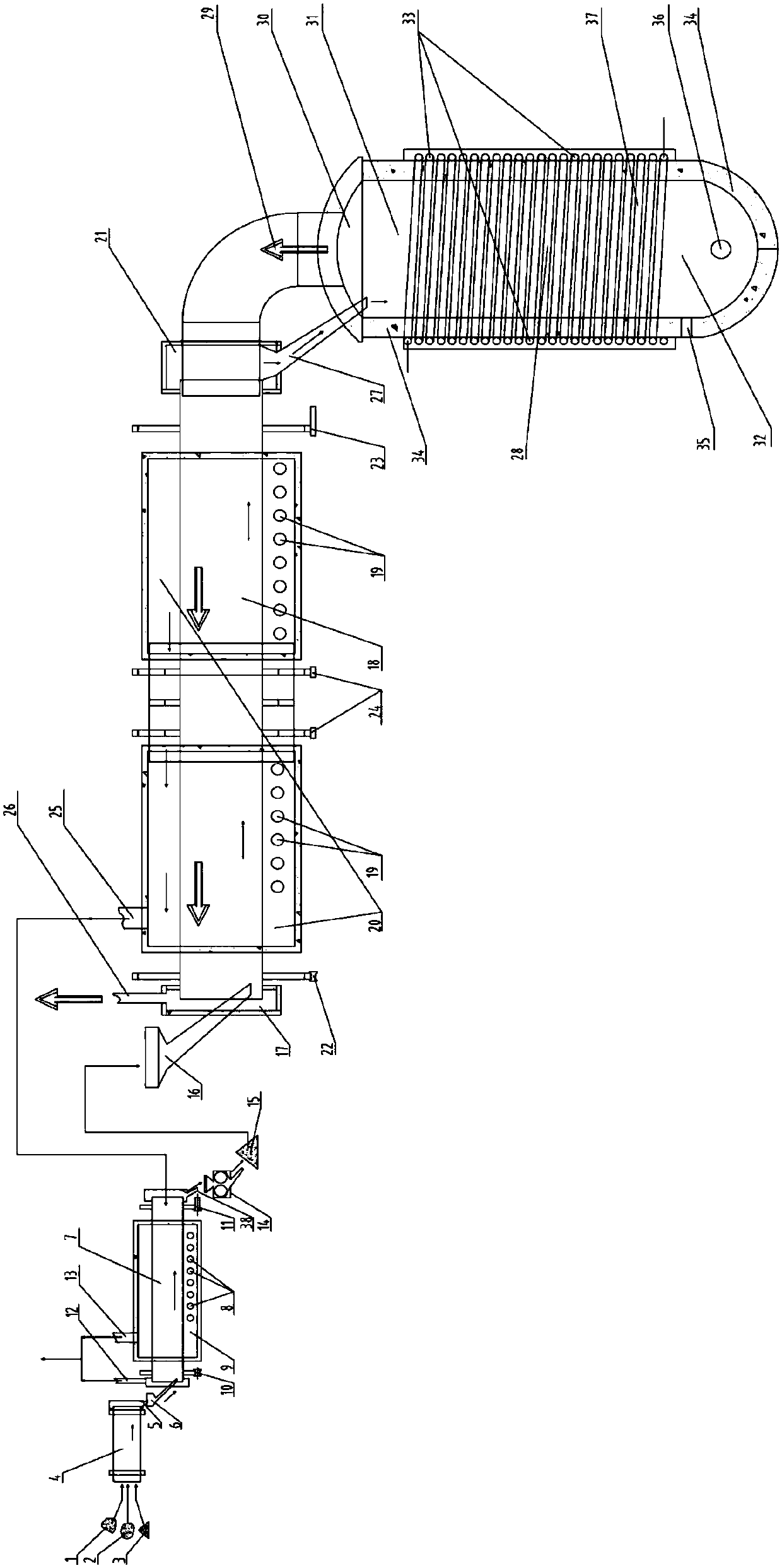

[0067] A short-flow ironmaking device, comprising a mixing mill 4, a preheating muffle rotary kiln 7, a ball press 14, a pre-reduction muffle rotary kiln 18 and an induction shaft furnace 28 connected in sequence;

[0068] The preheating muffle rotary kiln is supported and rotated by the rear supporting drive mechanism 10 of the preheating muffle rotary kiln and the front support driving mechanism 11 of the preheating muffle rotary kiln; the preheating muffle rotary kiln is provided with a preheating insulation Flame rotary kiln feed hopper 6 and preheating muffled rotary kiln discharge hopper 38; the kiln tail of said preheating muffled rotary kiln is provided with water vapor outlet 12 and preheating muffled rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com