Electrochemical separation and recovery method for gold and silver in copper matte

A separation and recovery, electrochemical technology, applied in optics, process efficiency improvement, photographic technology and other directions, can solve the problems of large investment in matte fire treatment, difficult leaching in wet treatment, long treatment period, etc., and achieve good product purity. , the effect of reducing the dosage and speeding up the leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

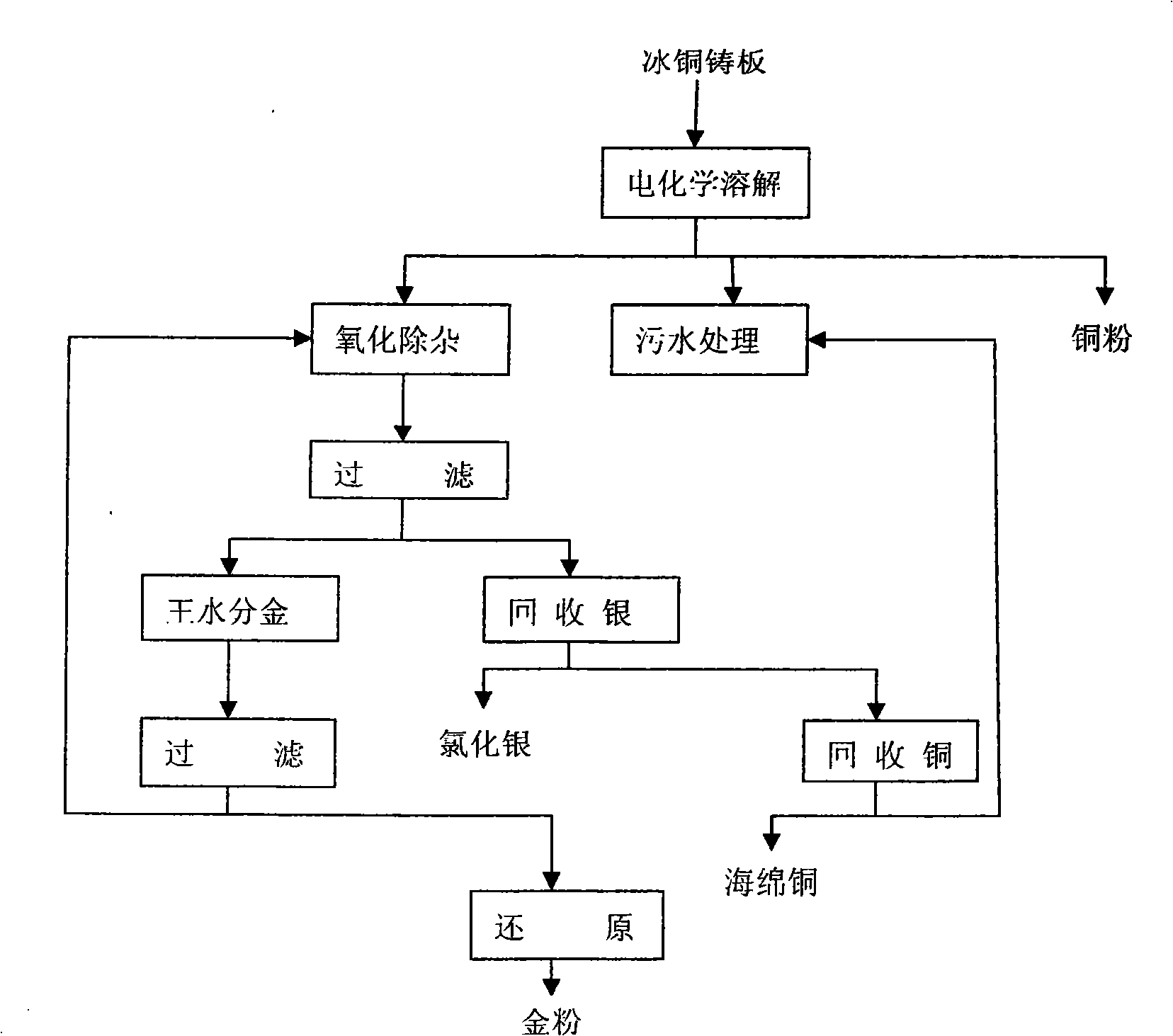

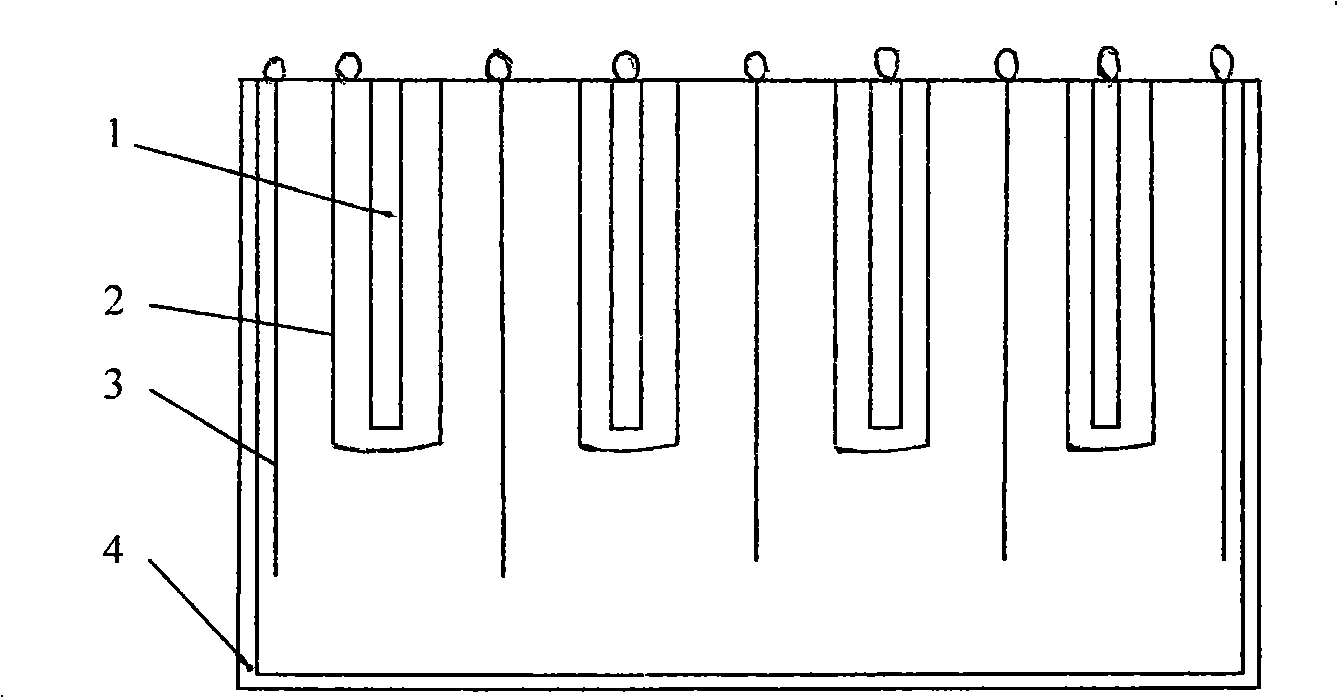

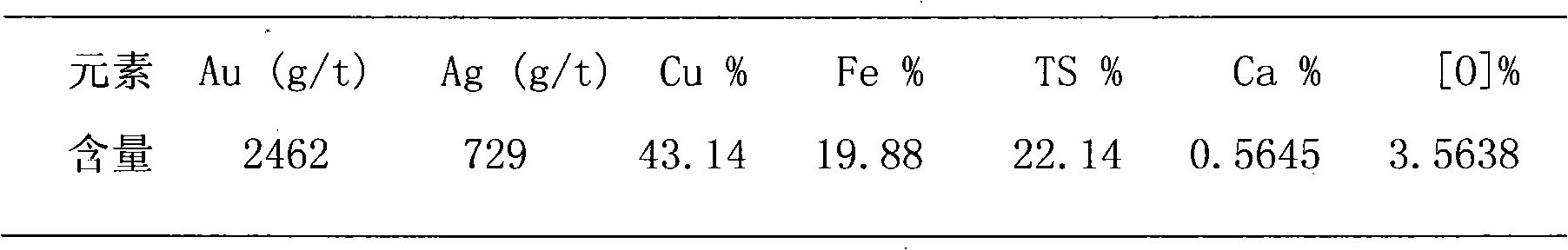

[0034] Such as figure 1 , figure 2 Shown, the electrochemical separation and recovery method of gold and silver in matte, the method comprises the following process steps:

[0035] a. Electrochemical dissolution, place the matte cast plate of the outer cover anode bag (2) as the anode plate (1) and the copper cathode plate (3) at equal intervals in the electrochemical dissolution tank filled with 5-15% concentration of sulfuric acid solution In the tank body (4), pass direct current at a current density of 80-200Am -2 , Electrochemical dissolution is carried out under the process conditions of cell voltage 1-5V and temperature 20-50°C;

[0036] b. Oxidation and impurity removal, adding 20 to 50% concentration of nitric acid solution to the electrochemically dissolved matte anode slime for oxidation and impurity removal;

[0037] c. Filtration, filtering the matte anode slime after oxidation and removal of impurities, filtering out the filtrate and filter cake, adding sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com