Electrochemical separation and recovery method for gold and silver in copper matte

A technology of separation and recovery and electrochemistry, which is applied in the fields of optics, improvement of process efficiency, photographic process, etc., can solve the problems of large investment in matte fire treatment, difficulty in leaching in wet treatment, long treatment cycle, etc., and achieve the treatment process Short, good product purity, and the effect of accelerating the leaching speed

Active Publication Date: 2010-12-01

ZIJIN MINING GROUP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a method for electrochemical separation and recovery of gold and silver in matte, which can solve the problems of large investment, long treatment period, many procedures and difficulty in wet treatment and leaching of matte.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

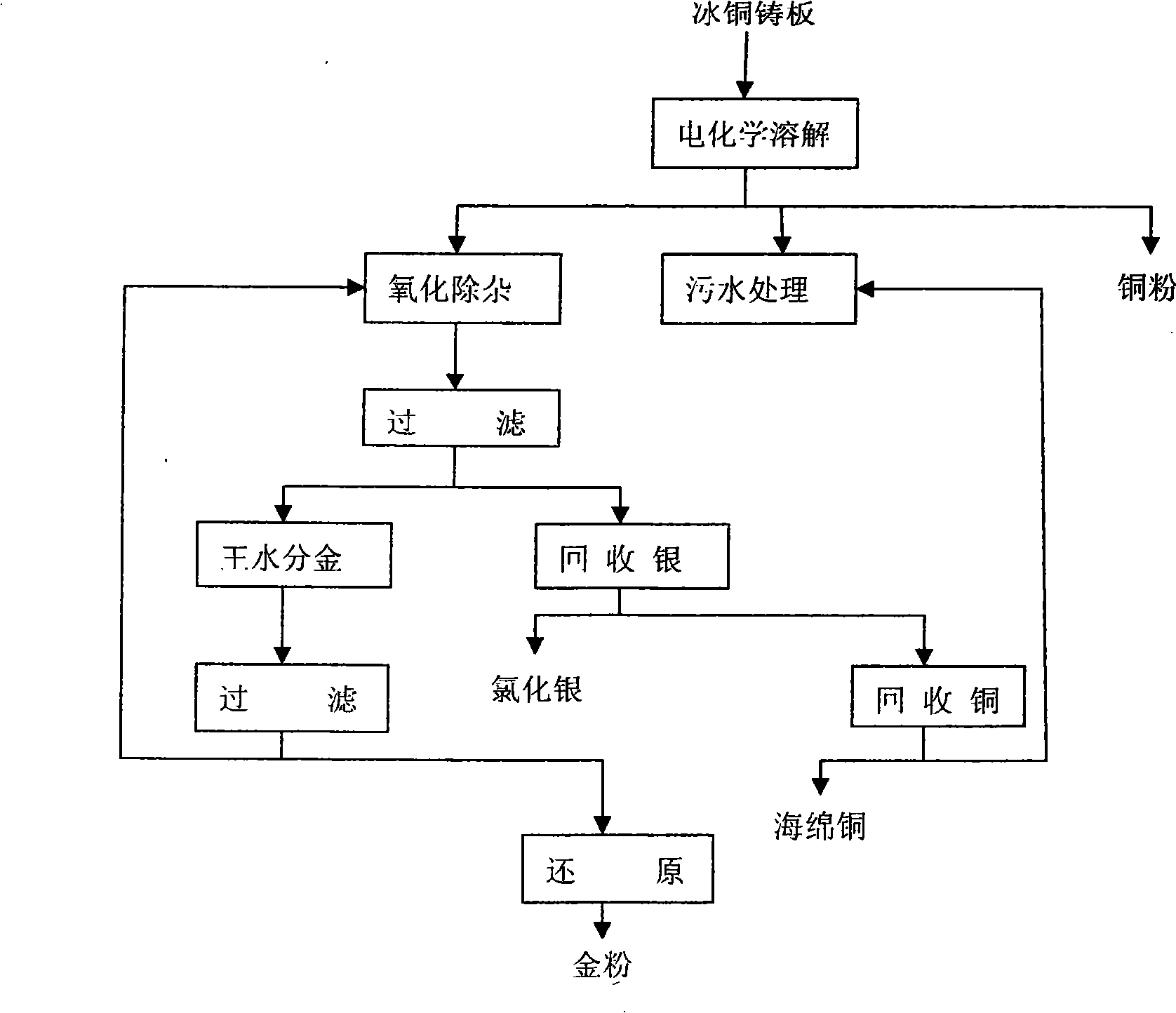

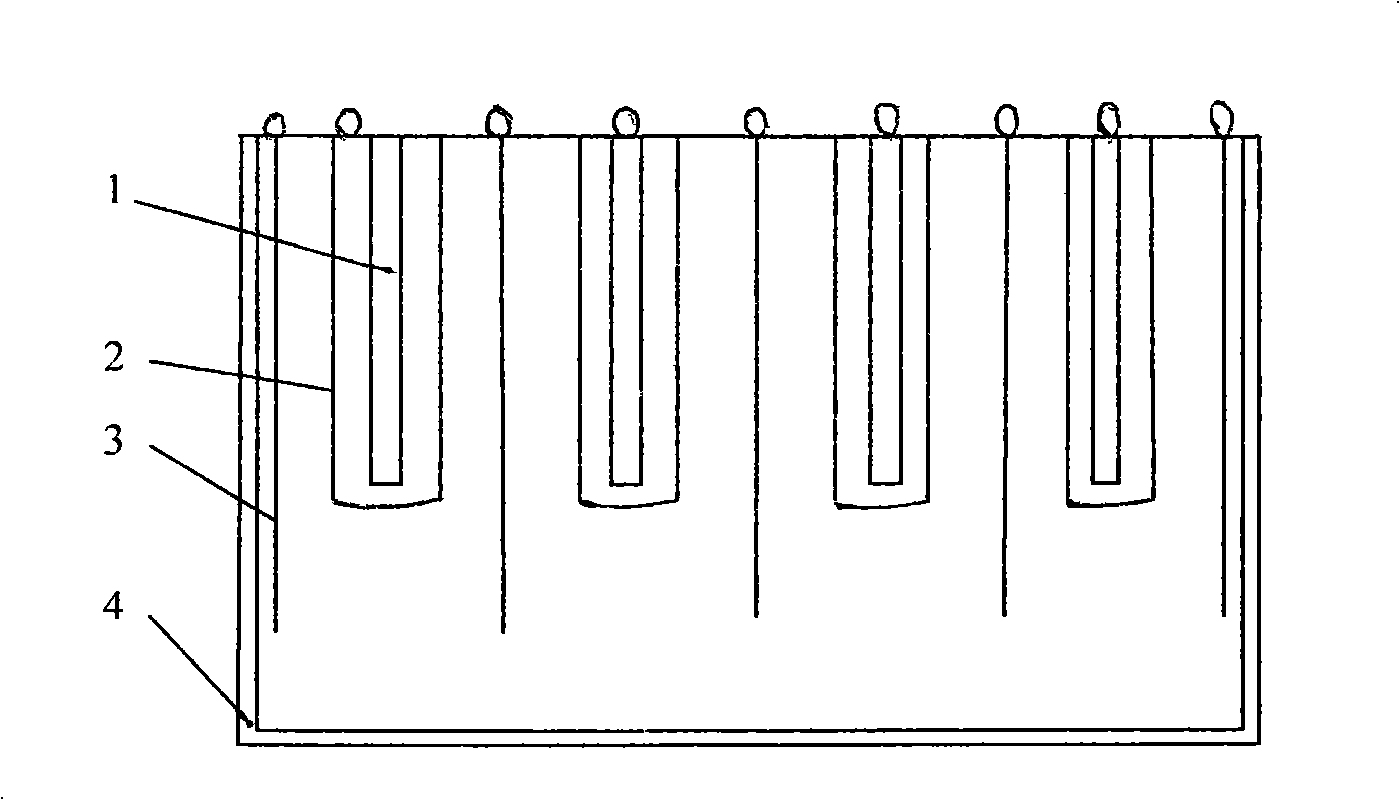

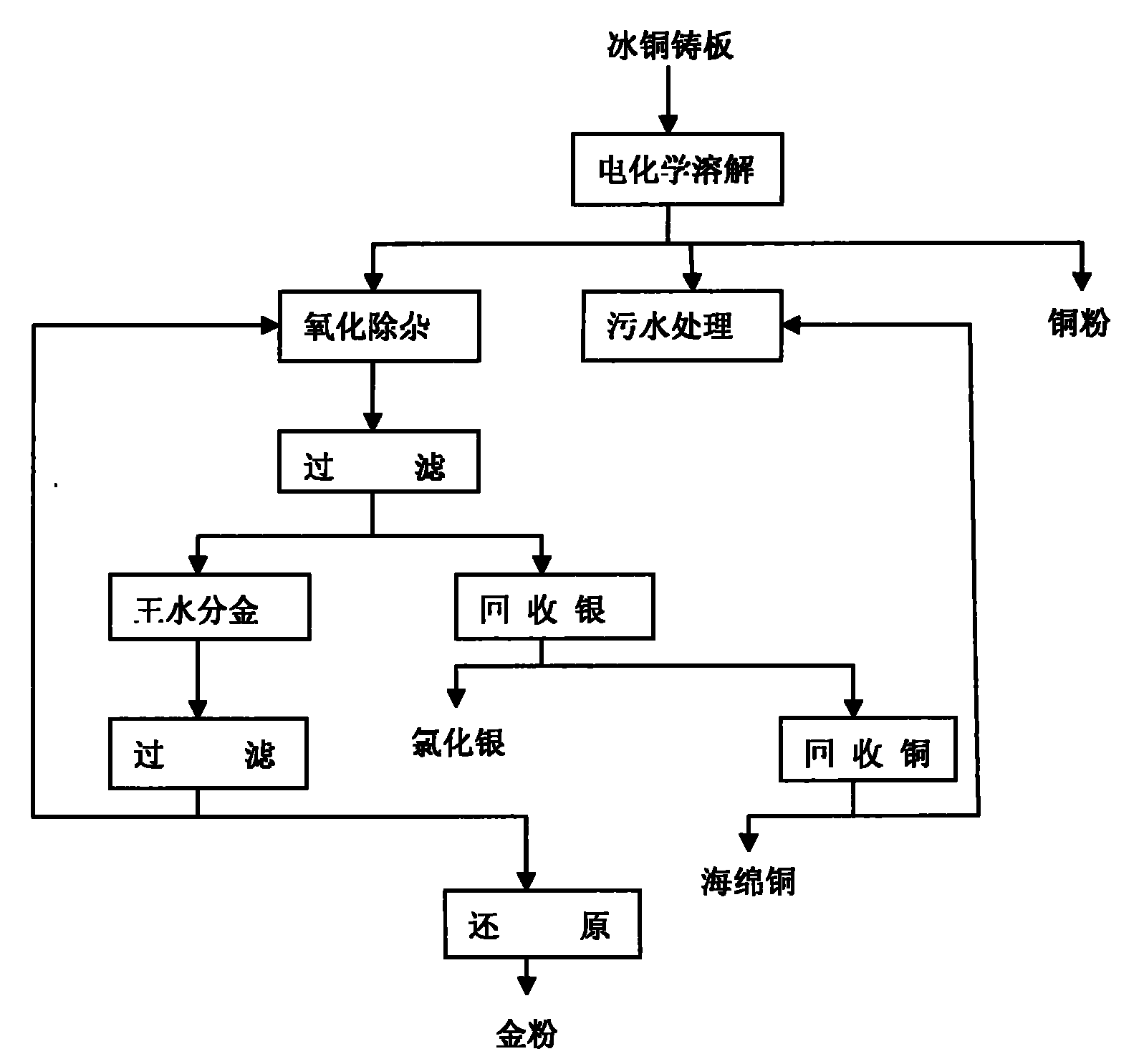

The invention relates to an electrochemistry parting method of bullion in matte, which comprises procedures as follows: (1) electrochemistry dissolving: the matte anode plate and the copper negative plate of an outer housing anode bag are arranged at intervals in an electrochemistry dissolving tank containing sulphuric acid for the electrochemistry dissolving, and the byproduct of copper powder is produced; (2) oxidation and impurity removal: nitric acid is added into matte anode mud dissolved by the electrochemistry for oxidation and impurity removal; (3) filtration: after being oxidized andedulcorated , the matte anode mud is filtered; and sodium chloride is added into filtered liquor to generate depositional silver chloride; (4) aqua regia parting: filtered filter mass is put into theaqua regia for the aqua regia parting; (5) filtration: after the aqua regia parting, the filter mass is filtered; and (6) deoxidization: sodium sulfite is added into the filtered liquor containing gold and the filtered liquor is deoxidized into gold powder. The electrochemistry parting method solves the dynamic problem of matte extraction and has the characteristics of rapid extraction speed, little treating solution, short process, low investment, high comprehensive rate, good product purity, etc.

Description

Electrochemical separation and recovery method of gold and silver in matte copper 1. Technical field The invention relates to an electrochemical separation and recovery method for gold and silver in matte copper. 2. Background technology Matte is a product of fire smelting pond mud calcined sand. The chemical composition of matte is shown in the table below: It can be seen from the table that the copper matte contains Cu43.14%, Fe19.88%, S22.14%, which is basically the same as the composition of the process product matte of the copper smelter. It is a kind of copper sulfide, ferrous sulfide, etc. A co-melt of sulfides. Matte is a good carrier for precious metals like gold and silver. At present, the main method for processing and recycling gold and silver in matte copper is: firstly, the matte copper is blown into blister copper by fire method, then the blister copper is electrolyzed, and finally the copper anode slime is wet-processed to recover precious metal gold ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25C1/20C22B11/00

CPCY02P10/20

Inventor 简椿林林志坚张新振蓝雄刘亚建陈期生

Owner ZIJIN MINING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com