Method for improving performances of yarns formed by vortex spinning

A vortex spinning and performance technology, applied in the field of textile processing, can solve the problems of reducing fiber stiffness, yarn structure relaxation, and high cost, reducing fiber modulus and bending stiffness, improving yarn tightness, and improving yarn performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

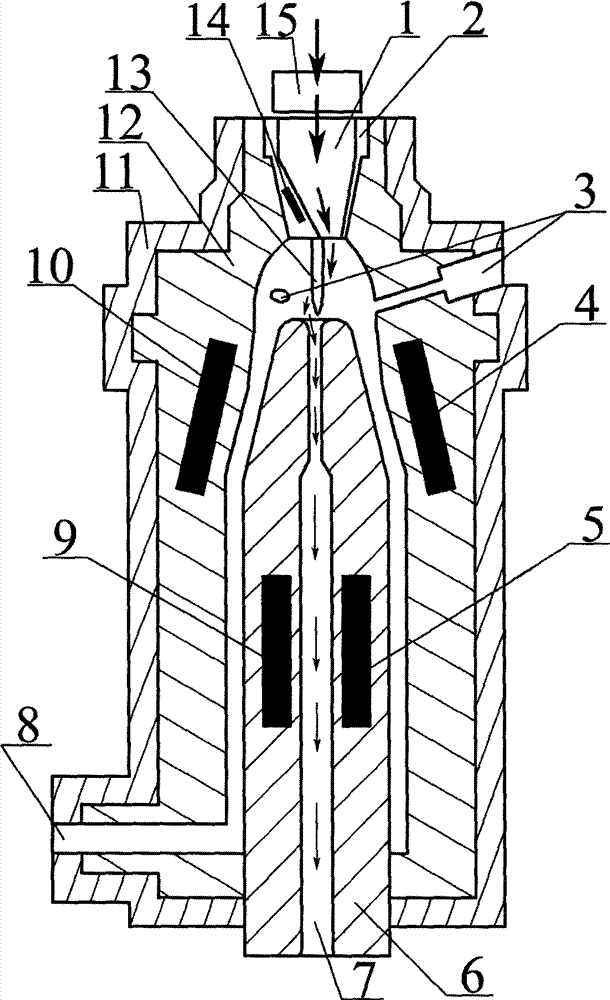

[0016]Embodiment 1: the method for improving vortex spinning yarn performance is carried out vortex spinning to cotton fiber, and arrow pointing is the running direction of cotton fiber in vortex spinning process in the accompanying drawing, adopts each vortex spinning on vortex spinning machine On the device, the fiber strands output by the drafting mechanism first pass through the heat and humidity treatment device 15 arranged at the front end of the feeding port 1 of the vortex spinning device. The heat and humidity treatment device 15 adopts a heat humidifier or a humidifier and a heating The combination of humidifiers, wherein the humidifier adopts the "spinning positioning humidification device" disclosed by the China Intellectual Property Office on May 11, 2011, and the publication number is the humidification device involved in CN201826076U. The strips are subjected to heat-moisture softening pretreatment, the heat-moisture treatment temperature adopted by the heat-mois...

Embodiment 2

[0017] Embodiment 2: the method for improving vortex spinning yarn performance is carried out vortex spinning to hemp fiber, and arrow pointing is the running direction of hemp fiber in vortex spinning process in the accompanying drawing, adopts each vortex spinning on the vortex spinning machine On the device, the hemp fiber strands output by the drafting mechanism first pass through the heat and humidity treatment device 15 arranged at the front end of the feeding port 1 of the fiber delivery pipeline 1 of the vortex spinning device. The heat and humidity treatment device 15 adopts a heat humidifier or a humidifier and The combination of heaters, wherein the humidifier adopts the "spinning positioning humidification device" disclosed by the China Intellectual Property Office on May 11, 2011. The publication number is the humidification device involved in CN201826076U, and the ramie fiber before feeding the vortex spinning device The strips are subjected to heat-moisture softe...

Embodiment 3

[0018] Embodiment 3: the method for improving vortex spinning yarn performance is spun vortex wool yarn, and the arrow in the accompanying drawing points to the running direction of the wool fiber in the vortex spinning process, adopting each vortex spinning device on the vortex spinning machine Above, the wool fiber strands output by the drafting mechanism first pass through the heat and humidity treatment device 15 arranged at the front end of the feeding port 1 of the fiber delivery pipeline 1 of the vortex spinning device. The heat and humidity treatment device 15 adopts a heat humidifier or a humidifier and heating The combination of humidifiers, wherein the humidifier adopts the "spinning positioning humidification device" disclosed by the China Intellectual Property Office on May 11, 2011, and the publication number is the humidification device involved in CN201826076U. Carry out hot-moisture softening pretreatment, the heat-humidity treatment temperature that heat-wet t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com