Novel vortex spinning equipment and spinning method thereof

A vortex spinning, a new type of technology, applied to new vortex spinning equipment and its spinning field, can solve the problems of difficulty in greatly improving the yarn forming performance, loose yarn structure, low yarn strength, etc., and achieves improved torsion performance. , The effect of increasing the yarn strength and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

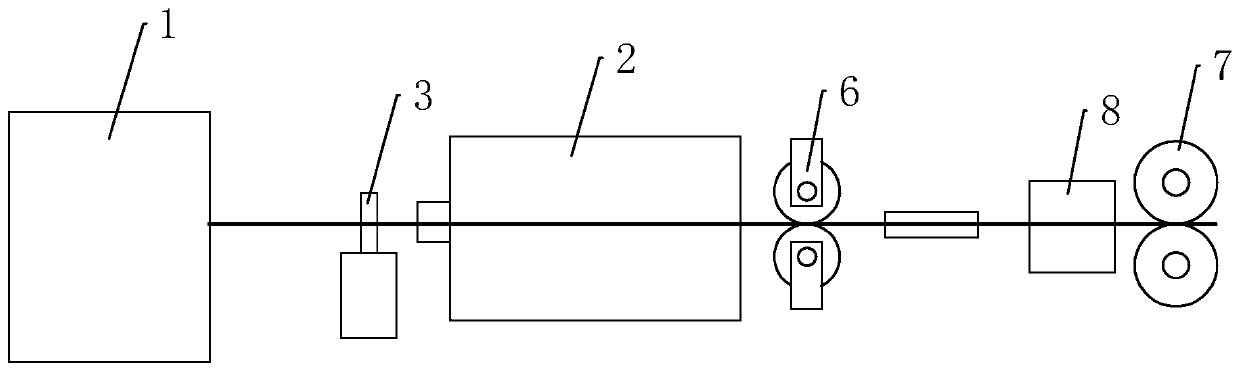

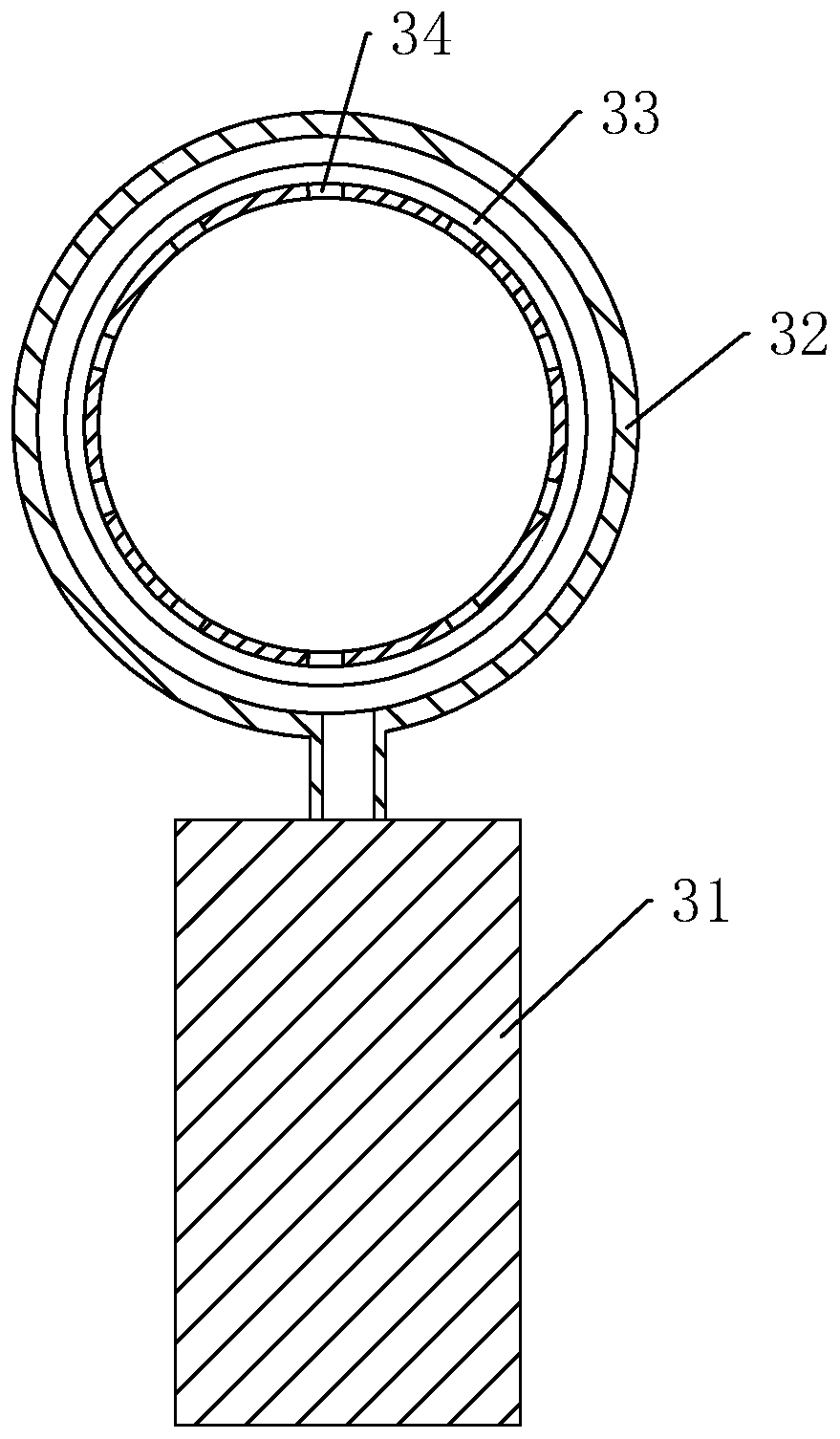

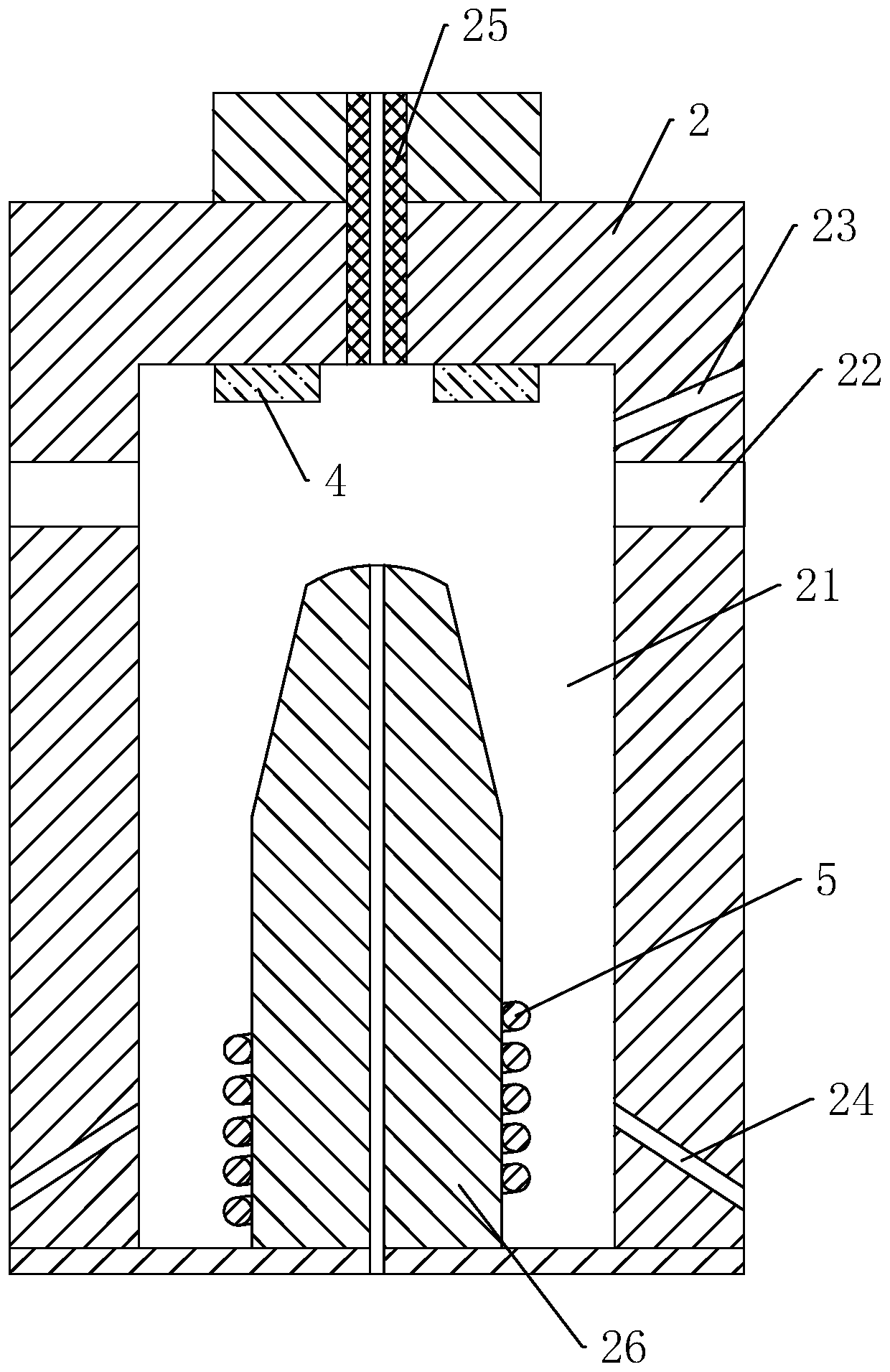

[0036] A new type of vortex spinning equipment, such as Figure 1 to Figure 5 As shown, it includes: a yarn output device 1 for conveying spinning fiber raw materials; a vortex tube 2 for vortex spinning. The air inlet 22 that is connected with each other, one side of the air inlet 22 is provided with the steam inlet 23, the rear section of the vortex tube 2 is provided with the air extraction hole 24, the front section of the vortex tube 2 is provided with the fiber guide 25, and the vortex tube 2 is provided with a fiber guide There is a spindle 26 aligned with the axis of the fiber guide 25; a softening device 3 arranged at the front end of the fiber guide 25, and the softening device 3 is used to heat and humidify the spinning fiber raw material; a heater 4 arranged inside the vortex tube 2 The heating wire 5 that is arranged on the spindle 26 in a spiral ring; the drying and shaping device 6 arranged at the front end of the spindle 26, the drying and shaping device 6 incl...

Embodiment 2

[0043] A vortex spinning method, the spinning method of this embodiment is based on the spinning equipment described in Embodiment 1, specifically comprising:

[0044] Step 1: The fiber raw material is output from the yarn output device 1, and the fiber raw material is heated and humidified by the softening device 3 for the first softening treatment. The heating temperature of the softening device 3 is 90-110°C.

[0045] Step 2: Introduce the fiber material into the vortex tube 2 through the fiber guide 25, twist the fiber material into yarn in the vortex tube 2, and simultaneously pass steam into the vortex tube 2 through the steam inlet 23, and the steam temperature is 120-160°C , and the fiber raw material is heated by the heater 4 during the yarn forming process, and the second softening treatment is performed, and the heating temperature of the heater 4 is 120-150° C.

[0046] Step 3: the yarn is led out through the center of the spindle 26, and the yarn is heated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com