Process for treating restaurant-kitchen garbage by utilizing Hermitia illucens

A technology of food waste and black soldier flies, which is applied in the field of environmental protection, can solve the problems of limiting the value of promotion, ignoring the efficiency and cost of food waste treatment, and achieving the effects of improving treatment efficiency, avoiding pollution risks, and reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

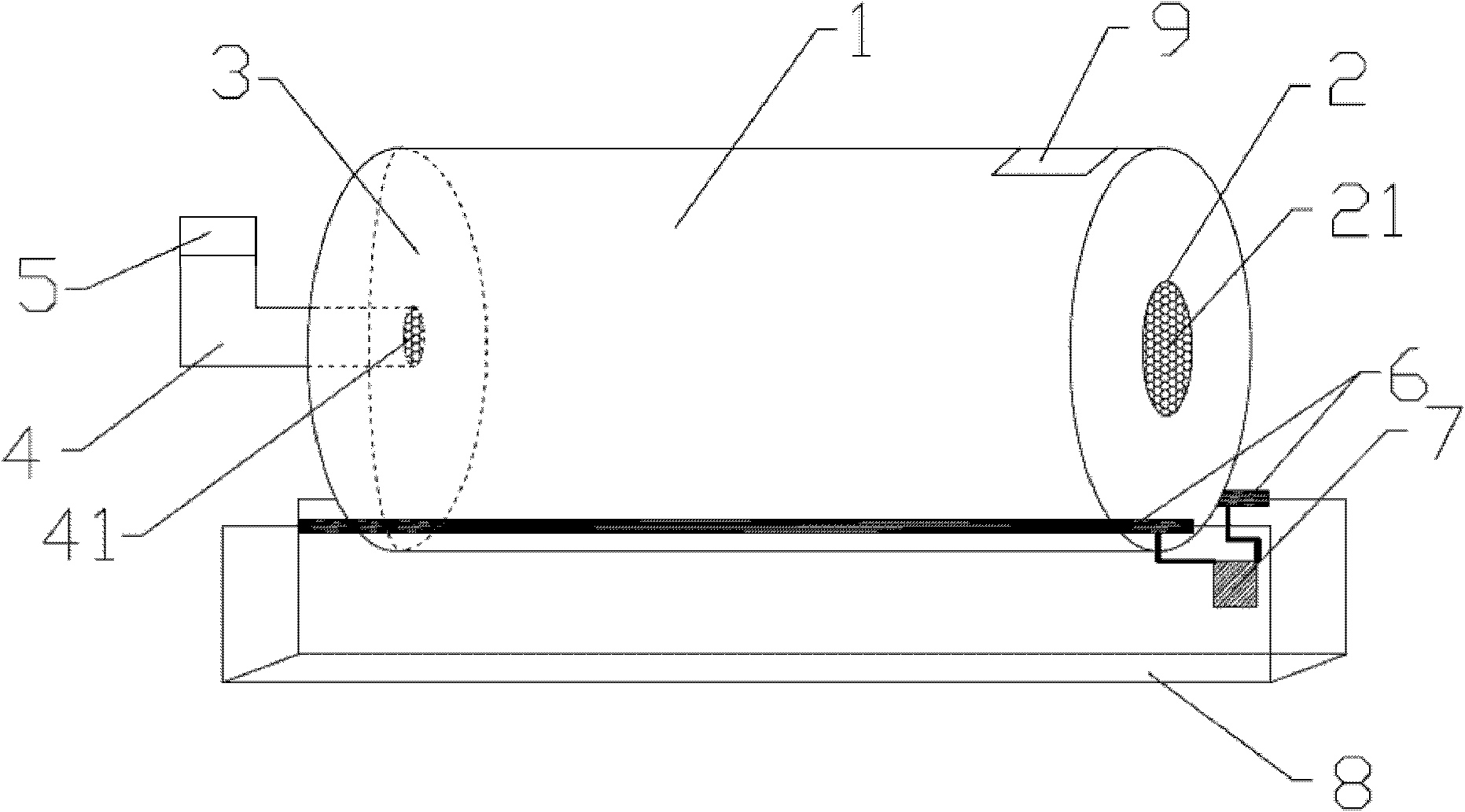

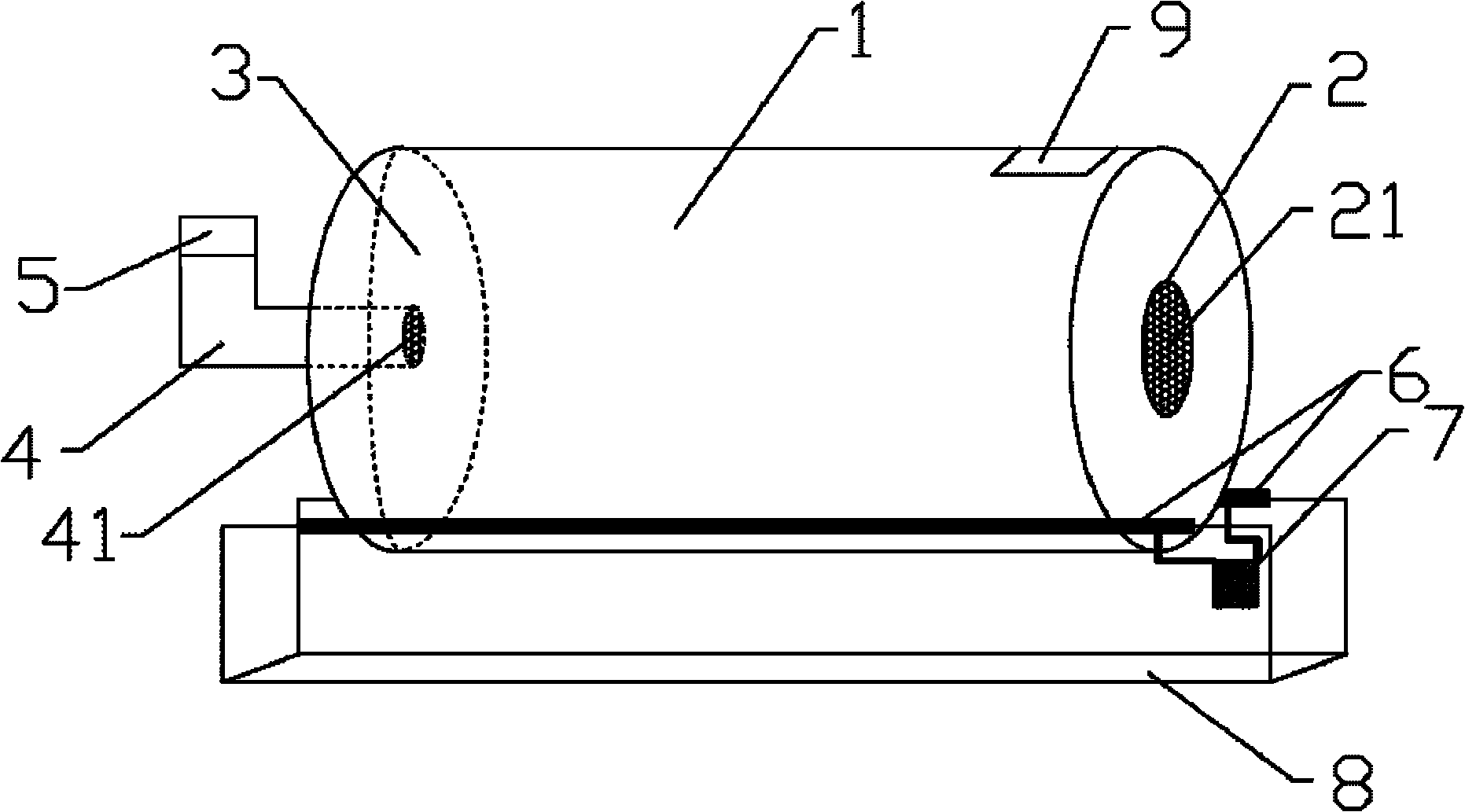

Embodiment 1

[0025] The collected food waste is separated from solid and liquid, so that the water content of the separated food waste is 65%, and then it is broken into particles with a particle size of 2 to 50 mm. The food waste: wheat bran mass ratio is 1:0.25 Add wheat bran to the kitchen waste to form a treatment material, then add 12 million 3-6 day-old black soldier fly larvae to each ton of the treatment material, and then add EM bacteria powder to form a mixture; mix The material is loaded into the drum from the feed port 9, and the feed port 9 is closed. Turn on the exhaust fan 4 to generate an air flow inside the drum 1, and the extracted air is filtered by the air filter 5 and discharged, and every hour, the drive device 7 (motor) is turned on to drive the roller 6 to rotate, and the roller 6 is driven by friction. Drum 1 rotates slowly and evenly, and the rotation time is about 10 minutes, which can fully mix the black soldier fly larvae, auxiliary materials and kitchen waste,...

Embodiment 2

[0027] The collected kitchen waste is subjected to solid-liquid separation, so that the moisture content of the separated food waste is 85%, and then it is broken into particles with a particle diameter of 2 to 50 mm, and the food waste: (wood chips+wheat bran ) at a mass ratio of 1:1, add wood chips and wheat bran (mixed at a mass ratio of 1:1) to kitchen waste to form treatment materials, and then add 5 million 3-6-day-old black soldier flies to each ton of treatment materials Larva, then EM bacteria, forms mixture; Mixture enters in the drum type bioprocessor according to the mode of embodiment 1 and handles, and the temperature of control mixture is 32~42 ℃, and relative humidity is 35~75%, handles 24 After 1 hour, you can add an appropriate amount of mixture to increase the processing capacity. The number of additional additions should not exceed 2 times, with an interval of 24 hours. After 5 days, the treatment is completed, unloading, and then sifted to separate the blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com