Method for preparing vanadium battery solution or adjusting capacity and special device thereof

A vanadium battery and electrolysis device technology, which is applied to fuel cell components, secondary batteries, regenerative fuel cells, etc., can solve the problems of difficult to obtain vanadium compounds, reduce electrolysis efficiency, and necessary dissolution pools, etc., and achieve simple equipment and electrolysis High efficiency and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

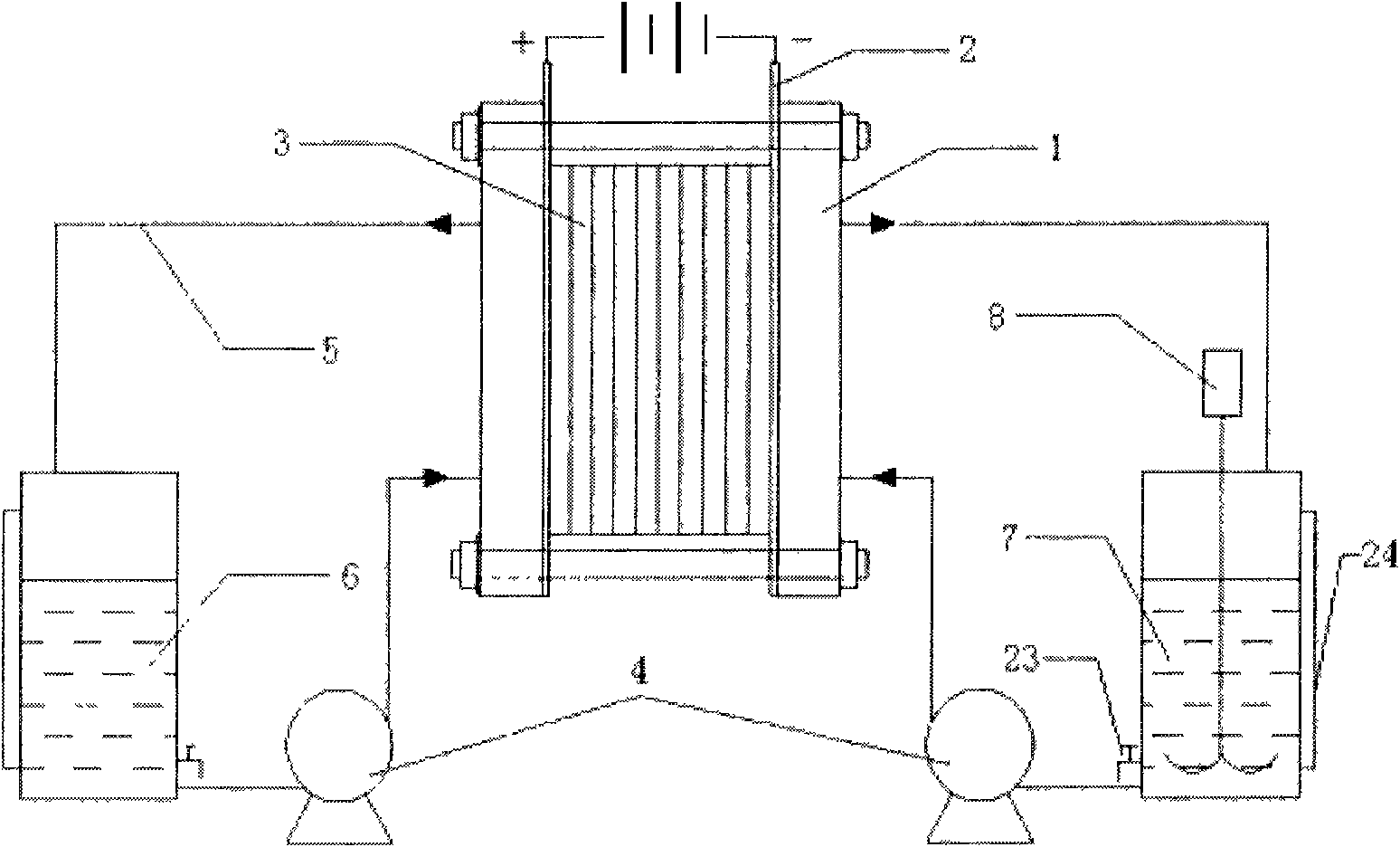

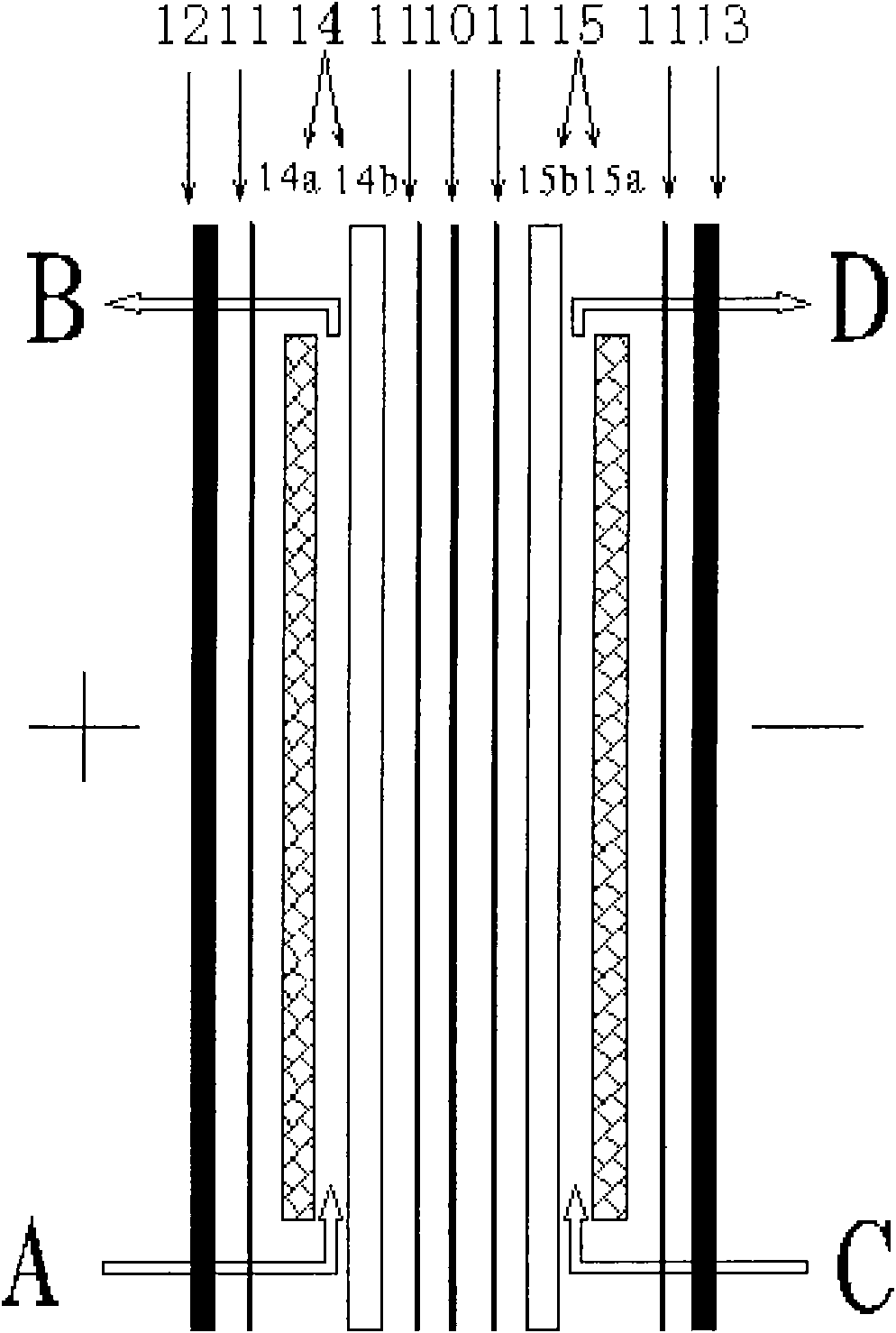

[0065] Using the electrolytic device of the present invention, the flow rate of the electrolyte in the electrolytic cell is 0.1 cms -1 , The temperature during electrolysis is 0℃, the pressure difference between the inlet and outlet of the electrolytic cell module is 0.01MPa, and the structure of the electrolytic cell is as follows:

[0066] Number of sections of electrolytic cell: 2 sections

[0067] Solution distribution: series

[0068] Circuit connection mode: series ( Figure 4 structure)

[0069] Anode: Stainless steel mesh

[0070] Cathode: carbon felt

[0071] Area: 100cm 2

[0072] Membrane: Anion exchange membrane

[0073] Frame: PVC

[0075] Anode current collecting plate: graphite plate

[0076] Cathode collector plate: graphite plate

[0077] End plate: PVC

[0078] Concentration of vanadium solution: 1.35molL -1 , Of which pentavalent vanadium 1.33molL -1 , Tetravalent vanadium 0.2mo1L -1 , Take 15L vanadium solution into the cathode of the electrolytic cell...

Embodiment 2

[0080] Using the electrolytic device of the present invention, the flow rate of the electrolyte in the electrolytic cell is 5 cms -1 , The temperature of the electrolyte is about 50℃, the pressure difference between the inlet and outlet of the electrolytic cell module is 0.3MPa, and the structure of the electrolytic cell is as follows:

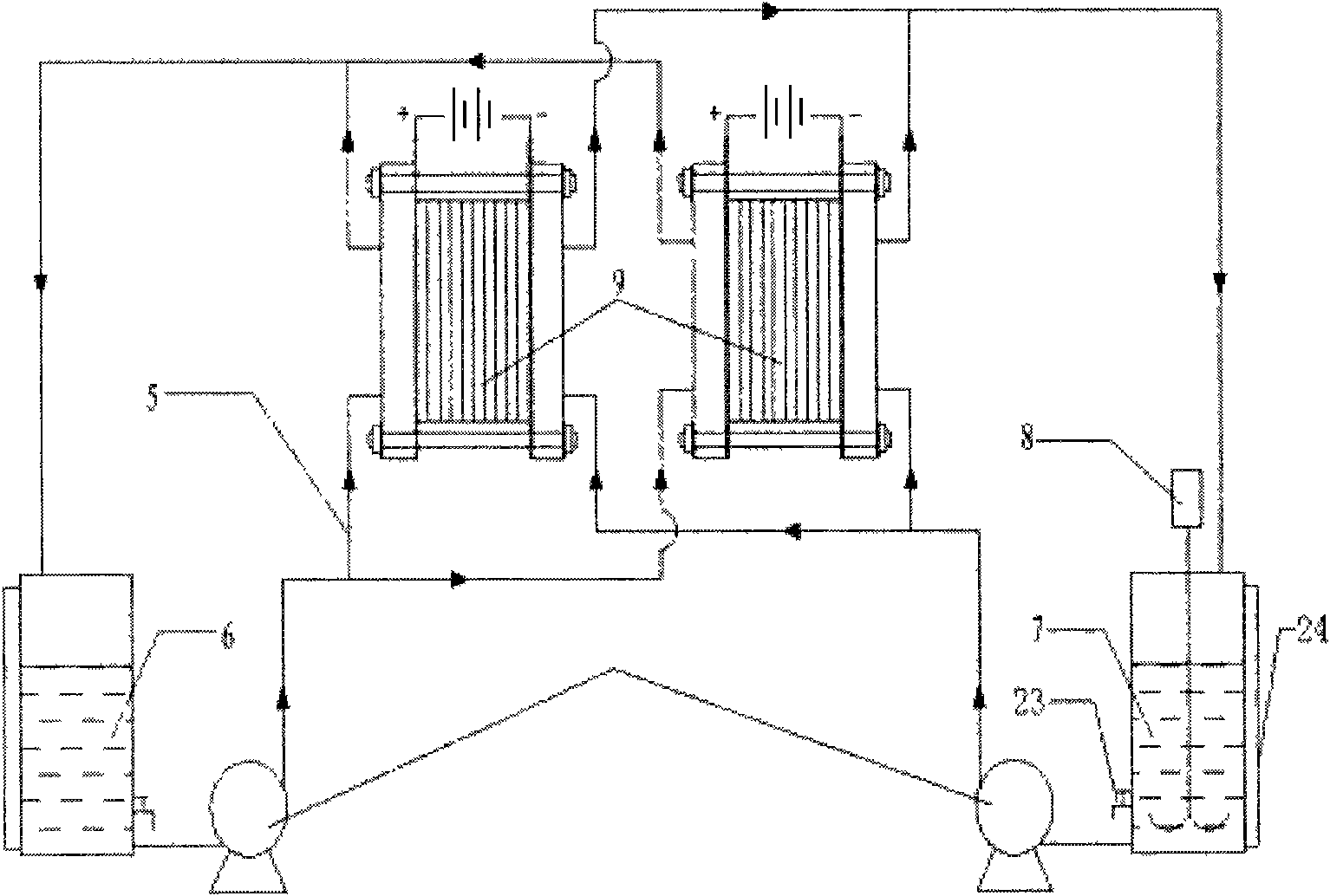

[0081] Number of sections of electrolytic cell: 12 sections

[0082] Solution distribution: series and parallel

[0083] Circuit connection mode: series ( Figure 5 structure)

[0084] Partition: PVC board

[0086] Cathode: carbon felt

[0087] Area: 2000cm 2

[0088] Membrane: Cation exchange membrane

[0089] Frame: PVC

[0091] Anode current collecting plate: nickel plate

[0092] Cathode collector plate: graphite plate

[0093] End plate: Bakelite

[0094] Concentration of vanadium solution: 4.9molL -1 , Of which pentavalent vanadium 0.01molL -1 , Tetravalent vanadium 4.89molL -1 , Take 200L vanadium solutio...

Embodiment 3

[0096] Using the electrolytic cell of the present invention, the flow rate of the electrolyte in the cell is 2 cms -1 , The electrolyte temperature is 40℃, the pressure difference between the inlet and outlet of the electrolytic cell module is 0.1MPa, and the structure of the electrolytic cell is as follows:

[0097] Number of sections of electrolytic cell: 12 sections

[0098] Solution distribution: parallel

[0099] Circuit connection mode: parallel ( Image 6 structure)

[0100] Anode: Titanium mesh

[0101] Cathode: Titanium foam

[0102] Area: anode 300cm 2 , Cathode 500cm 2

[0103] Membrane: Anion exchange membrane

[0104] Frame: Teflon

[0106] Anode current collecting plate: titanium plate

[0107] Cathode collector plate: titanium plate

[0108] End plate: Bakelite

[0109] Concentration of vanadium solution: 0.11molL -1 , Of which 0.1molL of pentavalent vanadium -1 , Tetravalent vanadium 0.01molL -1 , Take 20L vanadium solution into the cathode of the electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com