Treatment method and device for waste water containing greasy dirt

A technology of treatment method and treatment device, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of multiple process links, control, inability to effectively remove emulsified oil and organic matter, etc. problems, to achieve the effect of increasing the contact area, high processing efficiency, and enhancing the oxidation processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

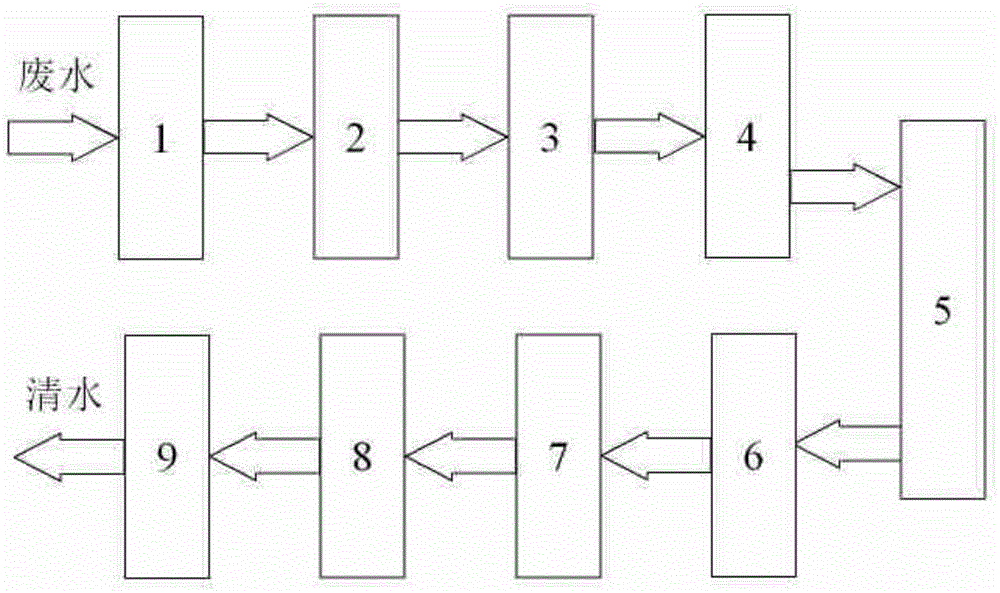

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] The present invention proposes a kind of processing method of oily waste water, it is characterized in that comprising the following steps:

[0026] Step 1: Oil-water separation treatment, the waste water is discharged into the degreaser, the lipophilic and hydrophobic medium in the degreaser absorbs the oil, when the adsorption force of the medium decreases below the adsorption threshold, the oil absorbed on the medium is treated by extraction and other treatment methods Recycling, the separated waste water is discharged into the next processor;

[0027] Step 2: send the separated wastewater to the air flotation treatment mechanism for air flotation treatment, and remove the insoluble impurities in the wastewater from step 1 in the form of suspension and emulsification;

[0028] Step 3: High-pressure oxidation treatment, sending the discharged wastewater in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com