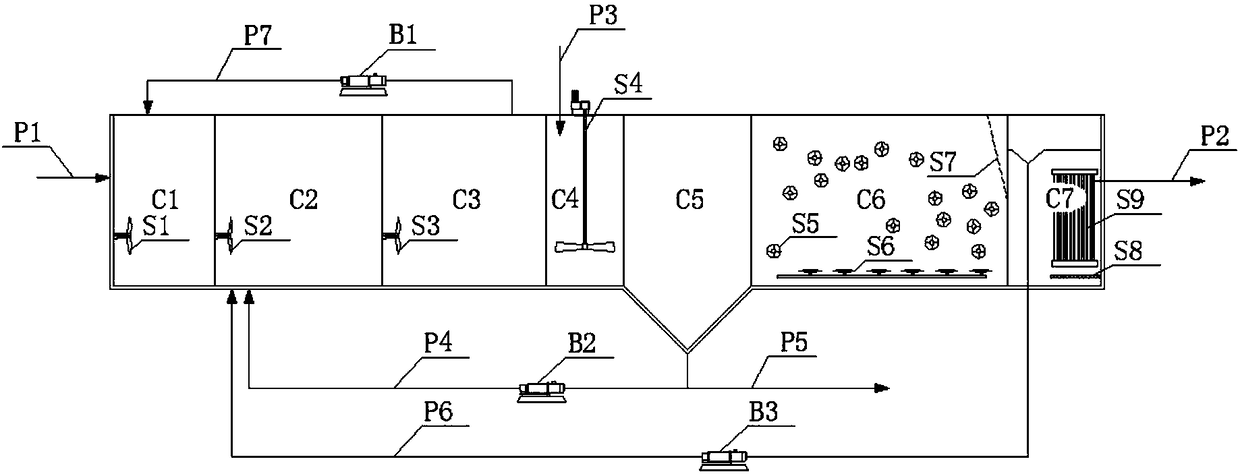

MBBR (Moving Bed Biofilm Reactor) sewage treatment system and treatment process

A sewage treatment system and sewage treatment technology, applied in the field of MBBR sewage treatment, can solve the problems of poor phosphorus and phosphorus removal effects, achieve good results, reduce wear and tear, and improve resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The effluent of the primary sedimentation tank of a city sewage treatment plant is used as the system inlet water, with a water volume of 8.3m 3 / h, pH average 6.90, influent COD concentration 120-300mg / L, BOD concentration 60-125mg / L, TN concentration 32-45mg / L, ammonia nitrogen concentration 25-40mg / L, TP concentration 2-6mg / L, SS The concentration is 120-200mg / L. High-efficiency sewage treatment process The residence time of the anaerobic zone is 1.5h; the anoxic zone 1 is 1.5h; the anoxic zone 2 is 1.5h; the surface load of the sedimentation zone is 8m 3 / m 2 / h; the residence time in the biofilm area is 2.5h, and the specific surface area of the suspension carrier used is 800m 2 / m 3 , The filling rate is 45%; the effluent area adopts submerged ultrafiltration membrane modules and negative pressure suction filtration.

[0067] During operation, the reflux ratio of the nitrifying liquid from the biofilm zone to the anoxic zone 1 is 240%, the reflux ratio from ...

Embodiment 2

[0071] The effluent from the regulating tank of a township sewage treatment station is used as the system inflow, with a water volume of 4.2m 3 / h, pH average 6.90, influent COD concentration 100-400mg / L, BOD concentration 50-225mg / L, TN concentration 25-45mg / L, ammonia nitrogen concentration 20-40mg / L, TP concentration 3-8mg / L, SS The concentration is 150-250mg / L. The residence time in the anaerobic zone is 1.5h; the anoxic zone 1 is 1.0h; the anoxic zone 2 is 1.5h; the surface load in the sedimentation zone is 8m 3 / m 2 / h; the residence time in the biofilm area is 3h, and the specific surface area of the suspension carrier used is 800m 2 / m 3 , The filling rate is 50%; the submerged membrane module is set in the water outlet area, and the negative pressure suction filter is used.

[0072] During operation, the reflux ratio of the nitrifying liquid from the biofilm area to the anoxic zone 1 is 200%, the reflux ratio from the anoxic zone 2 to the anaerobic zone is 150%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com