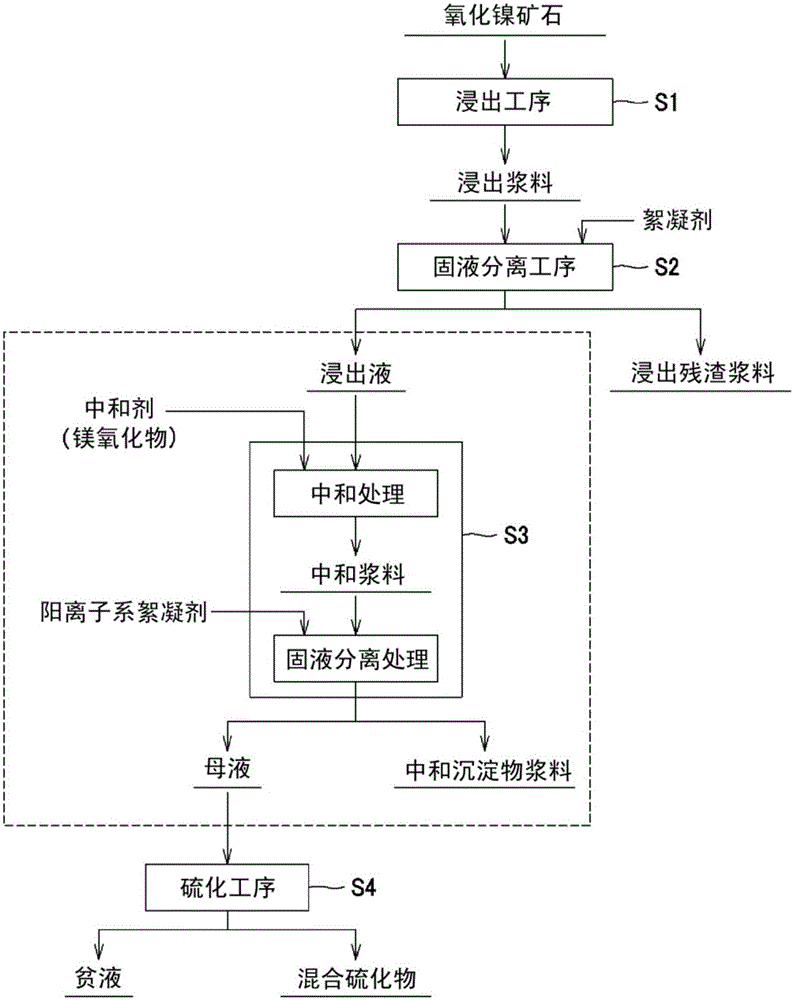

Settling separation method for nuetralized slurry and wet smelting method for nickel oxide ore

A technology of sedimentation separation and nickel oxide, which is applied in the field of sedimentation separation of neutralized slurry and wet smelting of nickel oxide ore. It can solve the problems of poor filtration of filter cloth, reduction of filtration speed, and poor filtration, so as to suppress poor filtration, Effect of SS concentration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Hereinafter, examples of the present invention will be described, but the present invention is not limited to the following examples.

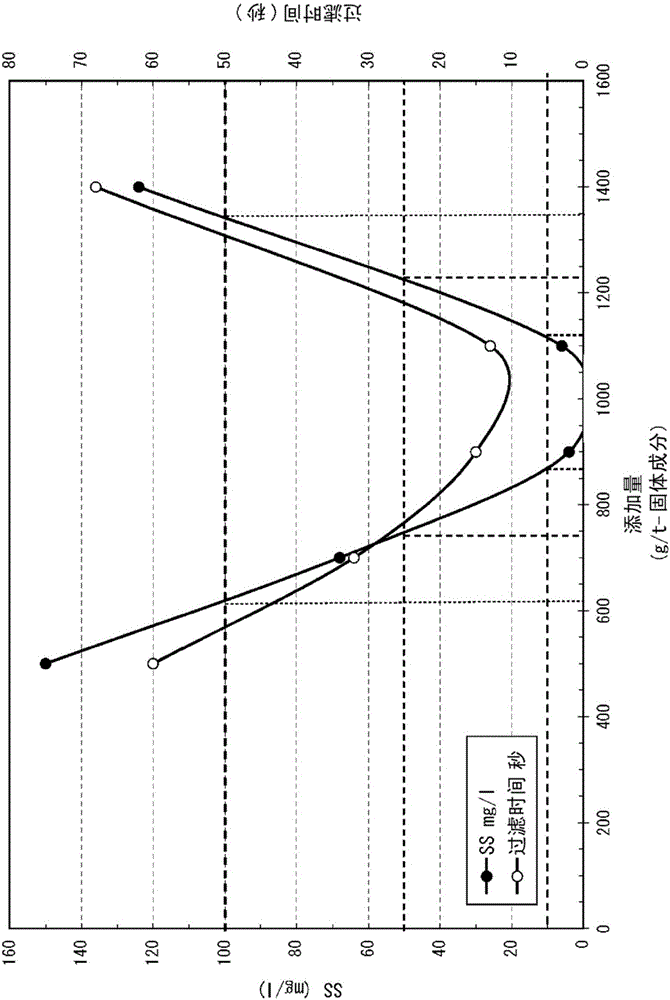

[0072] [Study on Sedimentation Separation Effect of Neutralized Sediment]

[0073] Nickel oxide ore is leached with sulfuric acid by the HPAL method, and the leach solution obtained by solid-liquid separation is neutralized with magnesium oxide (magnesium silicate and magnesium hydroxide) to neutralize the remaining acid and impurity components in the leach solution hydroxide removal. Through this neutralization treatment, a neutralized slurry containing a mother liquor and a neutralized precipitate is obtained.

[0074] Then, 100 ml of the obtained neutralized slurry was transferred to a graduated cylinder with a scale of 100 ml, and the flocculants listed in the following Table 1 were added at the level (addition amount) shown in the following Table 2, and three times of up and down After shaking, it was left to stand for solid-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com