Printing and dyeing sewage classification treatment process

A technology for printing and dyeing sewage and treatment process, which is applied in water/sewage treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc., and can solve the problems of insufficient physical and chemical treatment, increased operating costs, and high physical and chemical costs. Achieve the effect of saving oxygen demand, saving operating cost and overcoming short flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

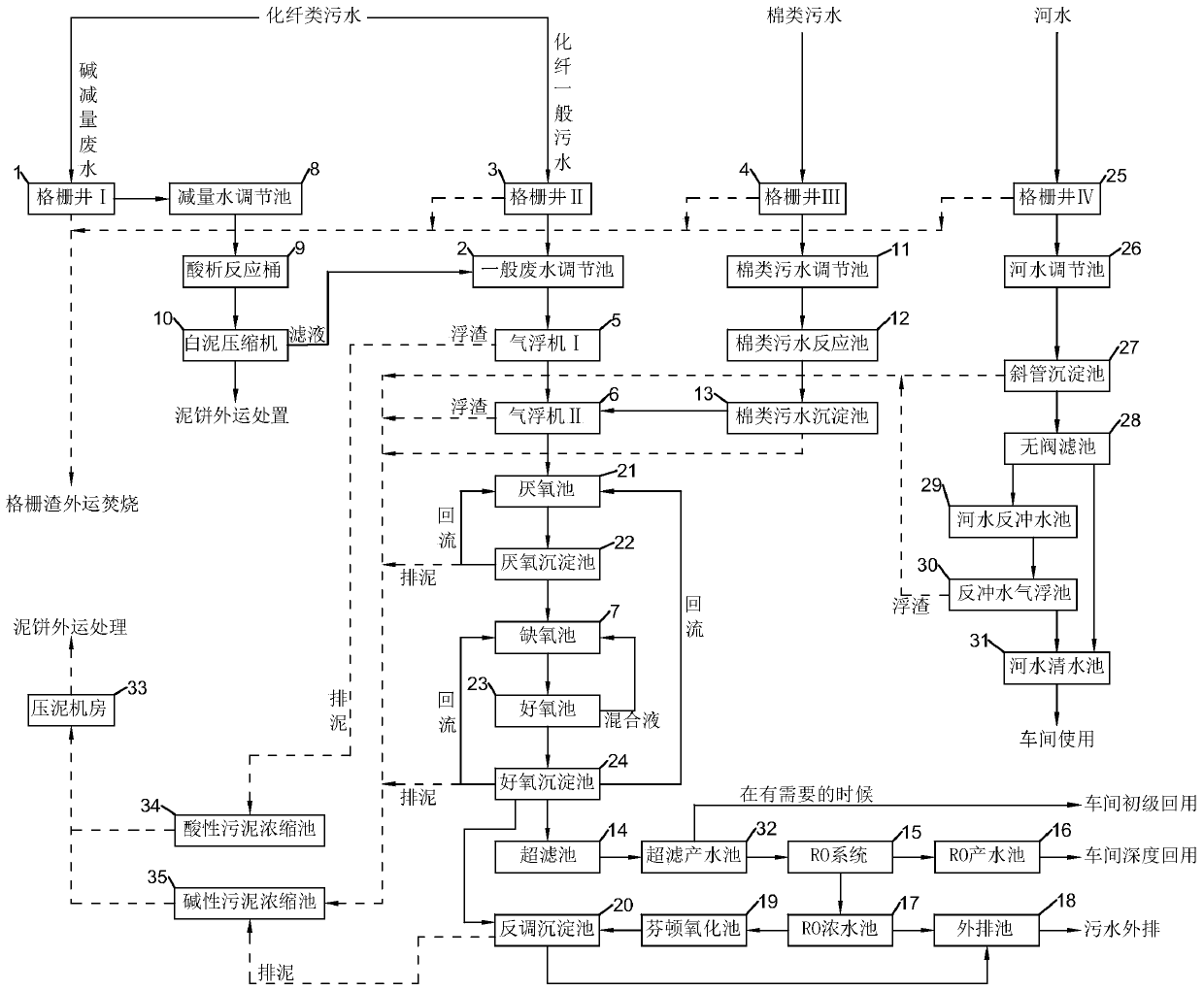

[0037] refer to figure 1 Embodiments of the present invention will be further described.

[0038] A classification treatment process for printing and dyeing sewage. First, the printing and dyeing sewage is divided into two major categories: chemical fiber sewage and cotton comprehensive sewage, and chemical fiber sewage is divided into two subcategories: alkali reduction sewage and chemical fiber general sewage, and then treated; Proceed as follows:

[0039] a. Pass the alkali reduction sewage first through the grid well I1 and then undergo acid treatment to obtain the alkali reduction filtrate and then inject it into the general wastewater adjustment tank 2;

[0040] Pass the chemical fiber ordinary sewage through the grid well II3 to obtain the chemical fiber ordinary filtrate, and then inject it into the ordinary wastewater regulating tank 2;

[0041] After the printing and dyeing sewage is passed through the grid well III4, the cotton filtrate is obtained after physical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com