Anti-radiation building putty powder and preparation method thereof

A radiation protection and putty powder technology, which is applied in the field of radiation protection materials, can solve problems such as volume expansion of the putty layer, reduce radiation shielding and safety, and segregation of building putty components, so as to improve shielding performance and realize harmless disposal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

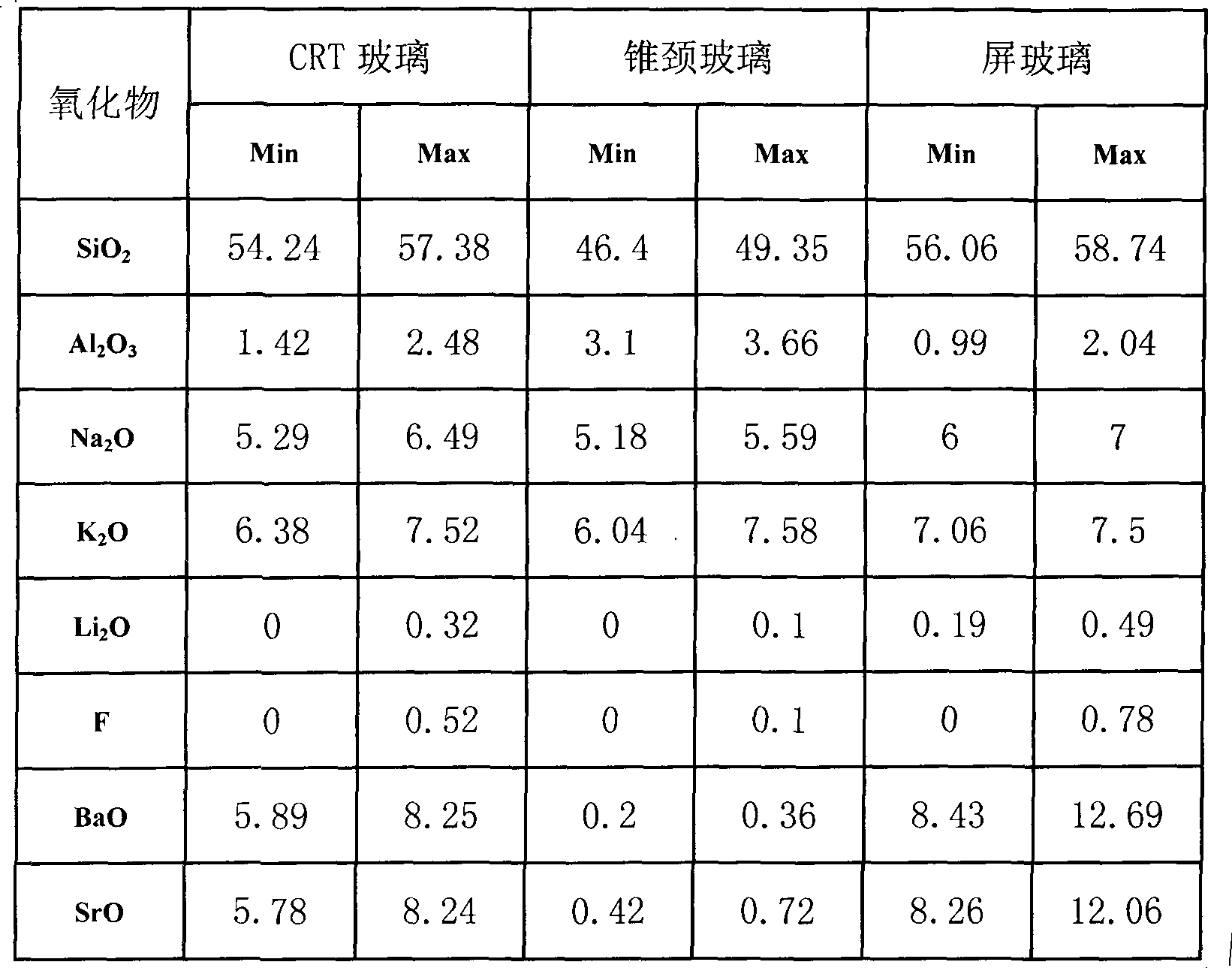

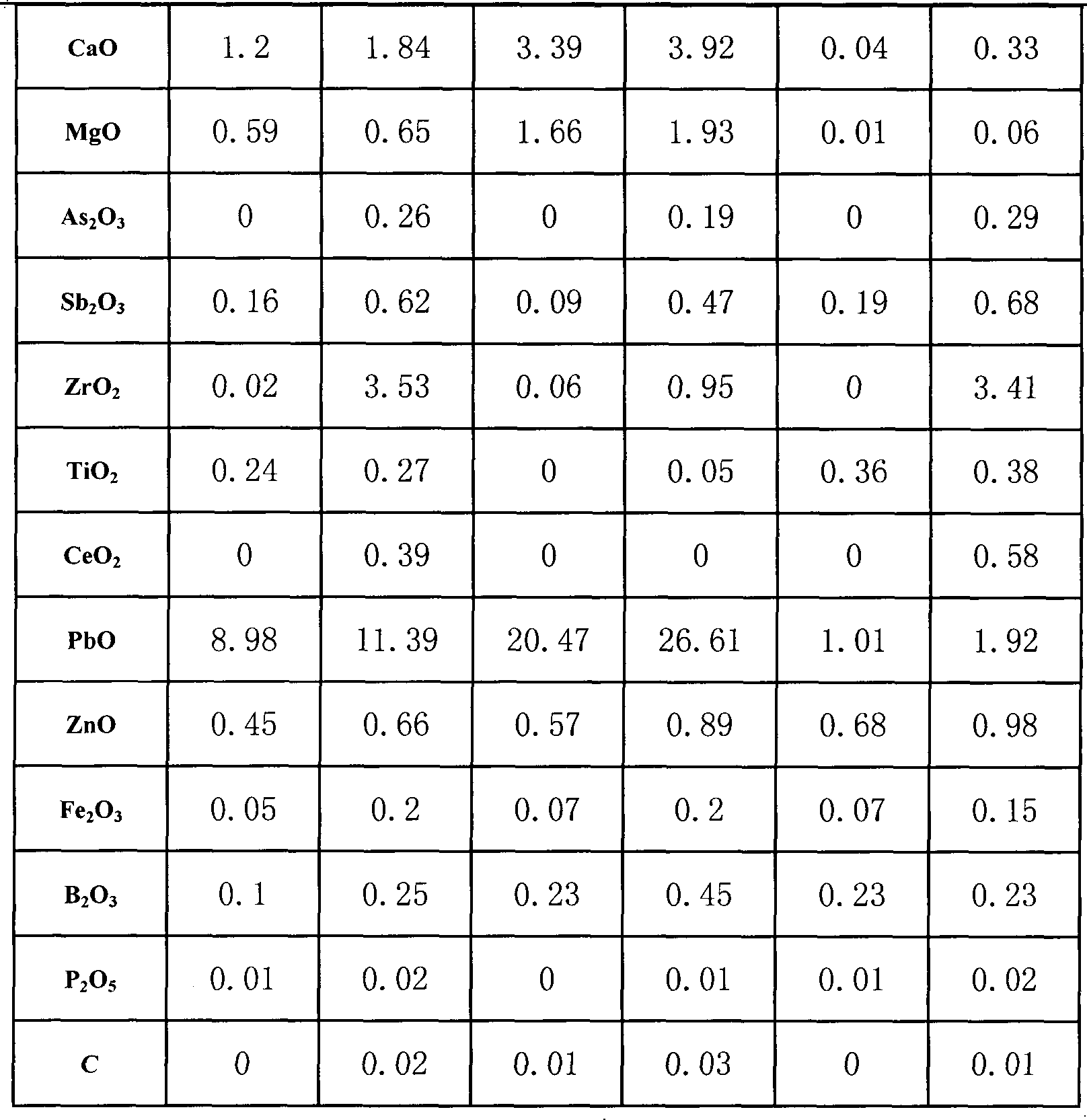

Embodiment 1

[0024] Dry-mill the CRT glass in a ball mill; pass through a 60-mesh sieve to obtain fine powder, and mix it with 30 parts of ordinary construction cement to obtain a ground radiation-proof construction putty; main properties: density 2.641g / cm 3 , the line attenuation coefficient (1 / cm) corresponding to the ray energy of 30KeV~200KeV is 17.09~0.66; the specific lead equivalent (mmPb / mm) corresponding to 80KeV and 100KeV is 0.072 and 0.03 respectively.

Embodiment 2

[0026] Send the ground powder in Example 1 into a rotary kiln, heat up to 550°C for calcination and keep warm for 230 minutes for mineralization; then leave the kiln and cool down to below 100°C; then send it into a ball mill for dry ball milling; pass through a 100-mesh sieve, Obtain fine powder; mix evenly with 30 parts of ordinary construction cement to obtain sintered anti-radiation construction putty; main properties: density is 2.631g / cm 3 , the line attenuation coefficient (1 / cm) corresponding to the ray energy of 30KeV~200KeV is 17.09~0.66; the specific lead equivalent (mmPb / mm) corresponding to 80KeV and 100KeV is 0.08 and 0.04 respectively.

Embodiment 3

[0028]Dry-mill the conical-neck glass in a ball mill; pass through a 100-mesh sieve to obtain a fine powder; mix it with 40 parts of ordinary construction cement to obtain an abrasive radiation-proof construction putty; main properties: density 2.61g / cm 3 , the linear attenuation coefficient (1 / cm) corresponding to the ray energy of 30KeV~200KeV is 26.29~1.04; the specific lead equivalent (mmPb / mm) corresponding to 80KeV~100KeV is 0.09 and 0.06 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com