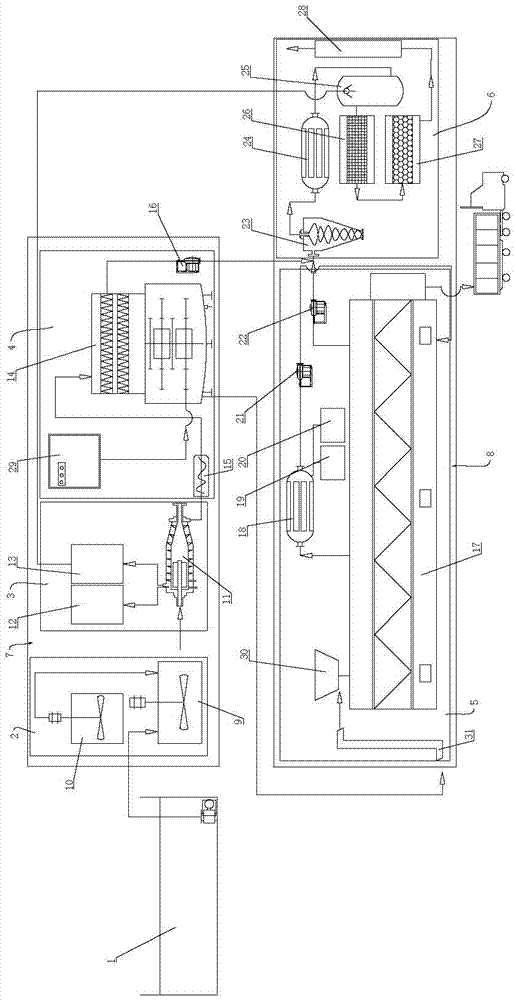

Refinery oily sludge disposal system and method

A disposal system and technology of oily sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem that the total amount of sludge has not been greatly reduced, environmental and health hazards, and high disposal costs cost and other issues, to achieve the effect of convenient transportation in different places, elimination of harm to the environment, and strong adaptability to the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: This embodiment is to repair the oily sludge in the refinery homogeneous pool with an oil content of 62300ppm, a water content of 85.20%, and a solid content of 8.57%. The sludge disposal volume is 3900t. Quality tank, add demulsifier through the dosing tank: flocculant = 0.1-1%: 0.1-0.5%, the sludge after dosing and stirring enters the decanter centrifuge for oil, water and mud three-phase separation, and the liquid content of the sludge is ≤ 80%, the degree of reduction ≥ 57%, the mud cake enters the granulation and drying machine through the high-viscosity screw conveyor, and the sludge becomes sludge particles with a particle size of 2-15mm after granulation, and the moisture content is controlled at 20-30 %, the reduction degree of sludge is ≥89%. After drying, the sludge changes from mud cake to sediment state. It enters the thermal cracking main equipment through the hoist for indirect heating. The heating temperature is 400-550°C to reduce the moist...

Embodiment 2

[0044] Embodiment 2: In this embodiment, the oil content is 140210ppm, the water content is 78.71%, the solid content is 7.269%, and the sludge at the bottom of the refinery tank is repaired. The sludge disposal volume is 3000t. Add demulsifier through the dosing tank: gel breaker: flocculant = 0.1-1%: 0.5-2%: 0.1-0.5%, the sludge after dosing and stirring enters the decanter centrifuge for oil, water and mud three-phase separation, The oil product in the tempering and centrifugal stage is ≥80%, the liquid content of the sludge is ≤75%, and the reduction degree is ≥70%. The mud cake enters the granulation and drying machine through the high-viscosity mud screw conveyor, and the sludge becomes 2 For sludge particles with a particle size of -15mm, the moisture content is controlled at 20-30%, and the reduction degree of sludge is ≥90%. After drying, the sludge changes from mud cake to sediment state, and enters the thermal cracking main equipment directly through the elevator He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com