Treatment process suitable for rapidly oxidizing magnesium sulfite to magnesium sulfate

A magnesium sulfite and treatment process technology, applied in the direction of magnesium sulfate, chemical recovery, etc., can solve the problems of not being able to reduce the content of slightly soluble salt magnesium sulfite, not being suitable for catalytic oxidation of magnesium sulfite, and reducing the possibility of system fouling, etc. Achieve the effect of realizing recycling, increasing oxidation rate and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

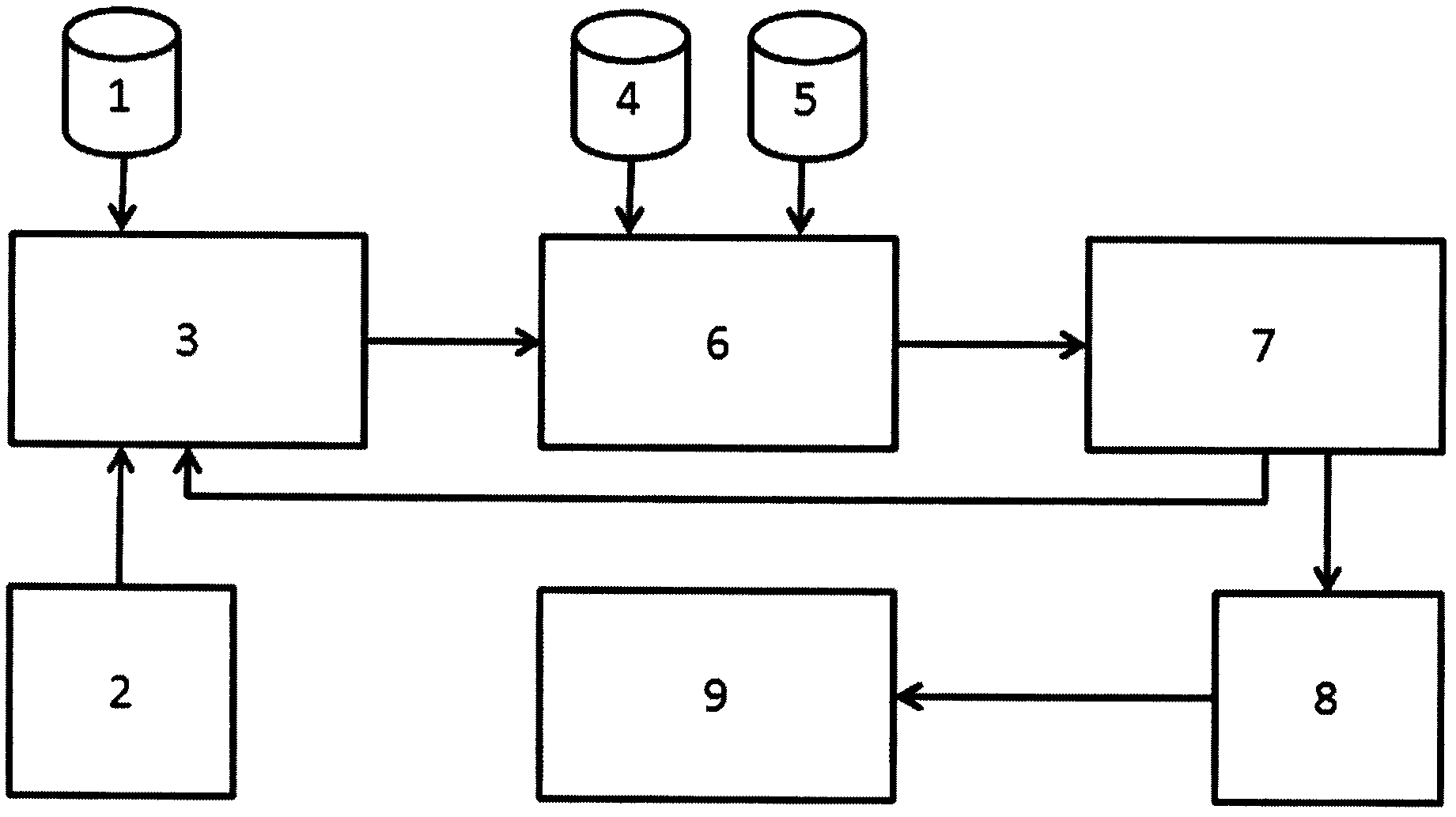

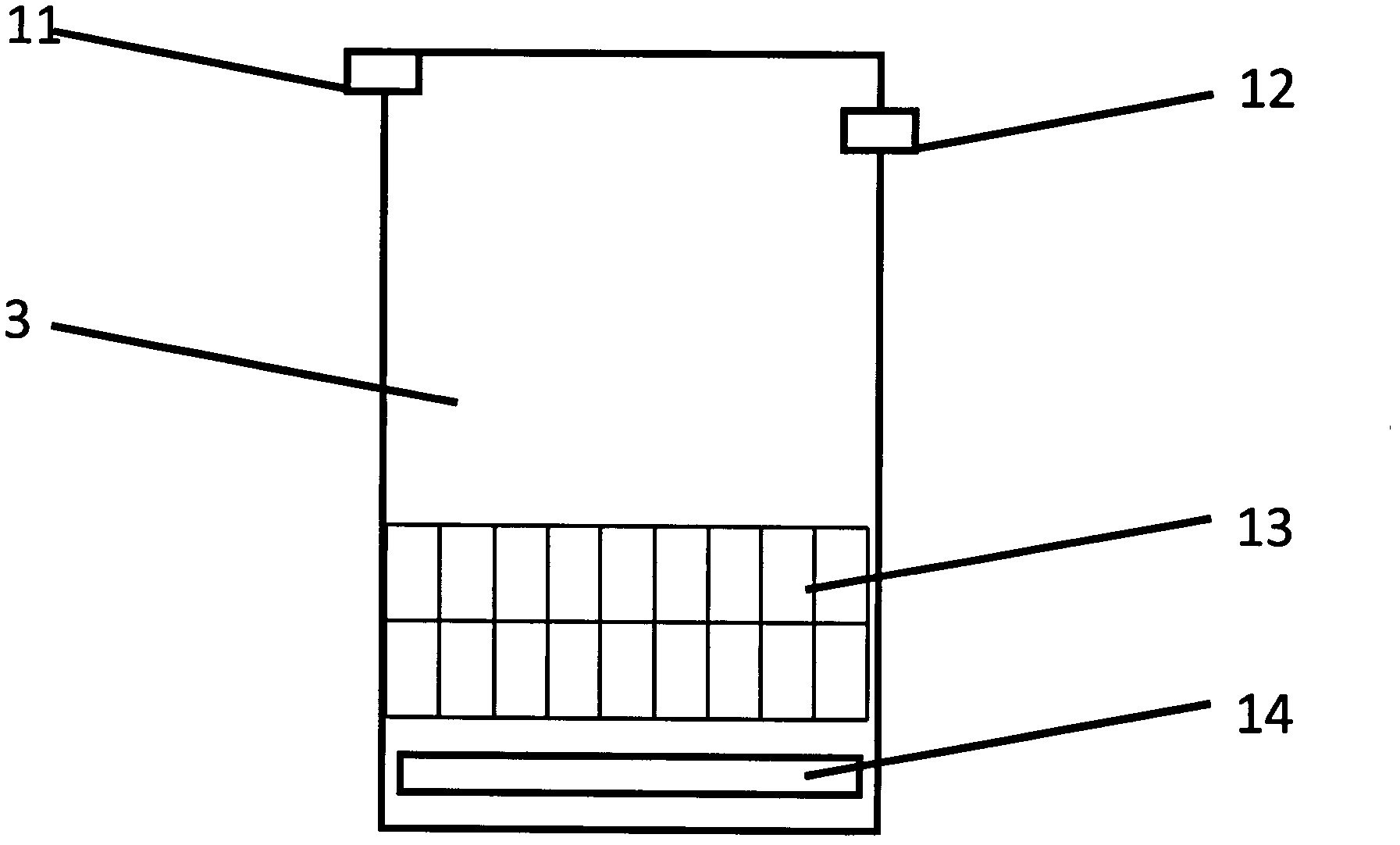

[0022] Such as figure 1 As shown, the treatment device of the present invention includes a catalyst supply tank 1, an oxygen supply system 2, a high-efficiency oxidizer 3, a coagulant supply device 4, a coagulant aid supply device 5, a coagulation reactor 6, a purifier 7, and a buffer tank 8 , Evaporation and concentration system 9. Its treatment process steps include oxidation, condensation, purification, evaporation and concentration, specifically:

[0023] (1) Put a certain concentration of magnesium sulfite slurry into the high-efficiency oxidizer, add 0.001-0.003mol / L catalyst into the high-efficiency oxidizer, and introduce oxygen at the same time, after 1 hour of oxidation, the magnesium sulfite solid in the desulfurization slurry Basically completely oxidized to become magnesium sulfite and magnesium sulfate slurry;

[0024] (2) Send it to the coagulation reactor, add coagulant and coagulant aid, and stir, so that unoxidized magnesium sulfite and silicon dioxide in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com