Treatment method and device for oil sludge

A treatment method and sludge technology, which are used in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve the problems of unrecoverable sludge, waste of resources, and high disposal costs, and achieve simple treatment methods, good economic benefits, and good society. The effect of efficiency and environmental protection and energy saving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

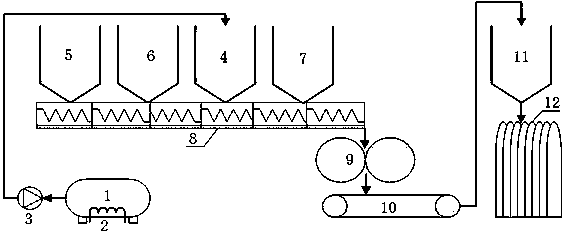

[0023] use figure 1 The treatment device for oily sludge produced by the treatment of oily wastewater includes a sludge storage tank 1, a steam heating device 2 is installed in the sludge storage tank 1, a transfer pump 3 is connected to a sludge silo 4, and a mixing mixer 8 is provided under the sludge silo 4, and the mixing mixer The 8 inlets are respectively connected to the coking coal silo 5, the dust removal ash silo 6, the oil sludge silo 4, and the tar residue silo 7, and the outlet of the mixing mixer 8 is connected to the counter-roller briquetting machine 9, which is connected to the counter-roller briquetting machine 9 through a belt conveyor 10 The coke coal storage bin 11 for entering the furnace is connected with the coke oven 12 .

[0024] In the above device, distributors are respectively provided at the joints of the coking coal silo 5, dedusting ash silo 6, oil sludge silo 4, tar residue silo 7 and mixing mixer 8 to control the amount of various raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com