Glass fiber reinforced plastic cable bridge and machining method thereof

A cable tray and glass fiber reinforced plastic technology, applied in electrical components and other directions, can solve the problems of cable breakage, harsh working environment, cracking at the bulge, etc., to reduce the cost of raw materials, improve processing stability, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

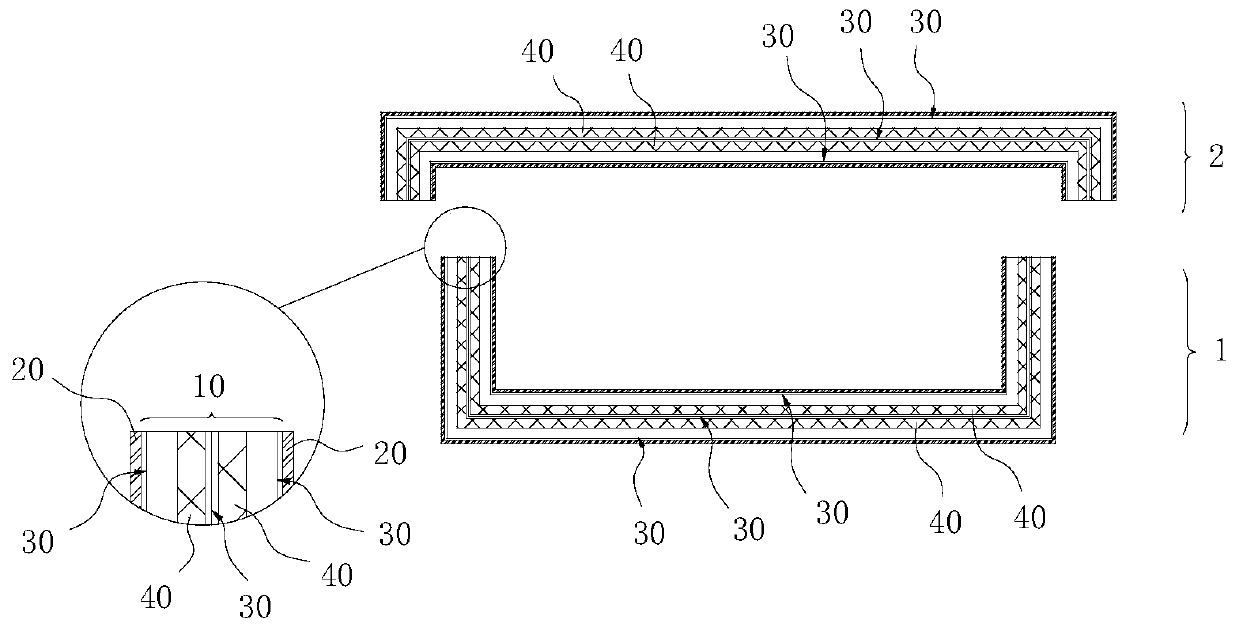

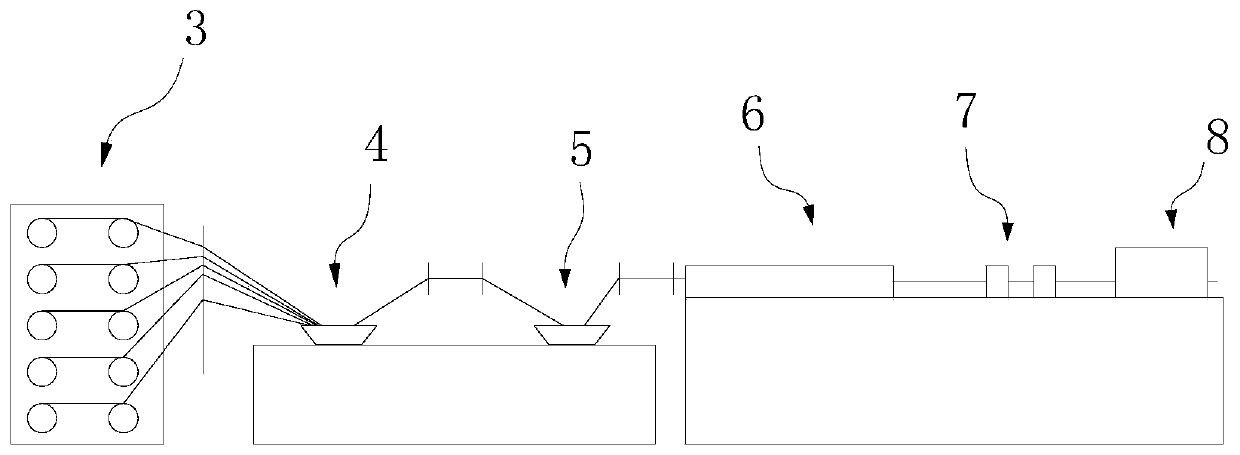

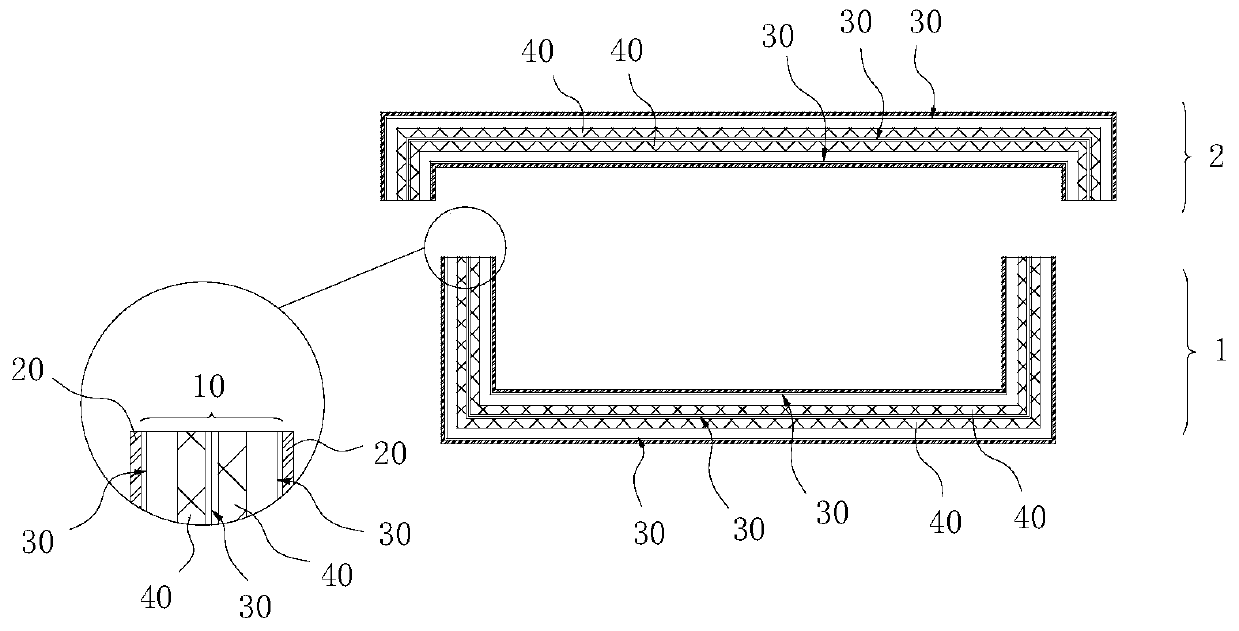

[0061] A processing method for a fiberglass cable tray, comprising the following steps:

[0062] S1: Raw material preparation and preform layout

[0063] First place two layers of 4800Tex alkali-free glass fiber yarn 40 and three layers of continuous mat 30 on the designated position of the creel 3, and thread the yarn from the creel 3 on the designated position of the large yarn board; first place the two layers of 4800Tex non-alkali The alkali-free glass fiber yarn 40 is arranged on the dry and wet glue tank board, and then passed to the designated position of the preformed board according to the area position, and all the alkali-free glass fiber yarn 40 is drawn through the mold cavity in layers, and finally the three-layer continuous mat 30 is guided through the mold cavity, and the E-glass fiber yarn 40 and the continuous mat 30 are stitched together to complete the production preparation;

[0064] S2: batching, melt kneading to obtain a melt mixture,

[0065] The melt ...

Embodiment 2

[0080] The processing method of the FRP cable tray provided in Example 1 is different in that the core layer includes 85% polyethylene terephthalate, 9.2% alkali-resistant glass fiber, 2.3% polytetrafluoroethylene fiber, 2.5% of styrene-butadiene thermoplastic elastomer, 1% of epoxy polymer chain extender, and the percentage is by weight;

[0081] The rest remain unchanged, and the cable tray profile is obtained by providing a processing method according to Example 1.

Embodiment 3

[0083] The processing method of FRP cable bridge as provided in Example 1, the difference is that the core layer includes polyethylene terephthalate 85%, alkali-resistant glass fiber 7.7%, polytetrafluoroethylene fiber 3.8%, 2.5% of styrene-butadiene thermoplastic elastomer, 1% of epoxy polymer chain extender, and the percentage is by weight;

[0084] The rest remain unchanged, and the cable tray profile is obtained by providing a processing method according to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com