High-temperature resistant micropore thin film material and application thereof

A technology of microporous film and high temperature resistance, which is applied in the direction of electrical components, circuits, battery pack parts, etc., can solve the problems of poor liquid absorption and liquid retention capacity, poor high temperature resistance, low mechanical strength, etc., to reduce battery life. Effects of internal resistance, improved safety performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The fiber and inorganic powder materials are compounded according to weight ratio: ceramic fiber diameter is 0.6μm, length 5mm; PET fiber diameter is 3μm, length 6mm; cellulose fiber diameter is 0.3μm, length 3mm; the required weight of nano zirconia powder 90% of the above fibers and zirconia nano-powders are made by wet papermaking process, after beating, molding, dehydration, and then coated with a coating solution prepared by zirconia powder and PVDF, rolling, drying, pressing Rolled to make a thickness of 30μm and a surface density of 20g / m 2 A high-temperature-resistant microporous film material, in which the content of various materials is: 32% ceramic fiber, 45% PET fiber, 10% cellulose fiber, 6% nano-zirconia powder, and 7% PVDF.

Embodiment 2

[0027] The fiber and inorganic powder materials are compounded according to the weight ratio: that is, the ultrafine glass fiber has a diameter of 0.6 μm and a length of 5 mm; PET fiber has a diameter of 3 μm and a length of 6 mm; cellulose fiber has a diameter of 0.3 μm and a length of 3 mm; 90% of the weight is required. The above-mentioned fibers and alumina nano-powder are made by wet papermaking process, beaten, shaped, dehydrated, and then coated with a coating solution prepared from alumina powder and acrylate, rolled, and baked. Dry, rolled, the thickness is 45μm, the surface density is 25g / m 2 A high-temperature-resistant microporous film material, in which the content of various materials is: 30% ultrafine glass fiber, 40% PET fiber, 12% cellulose fiber, 8% nano-alumina powder, and 10% acrylate.

Embodiment 3

[0029] The fiber and inorganic powder materials are compounded according to the weight ratio: that is, the diameter of alumina fiber is 0.6 μm, and the length is 5 mm; the diameter of PET fiber is 3 μm, and the length is 6 mm; the diameter of cellulose fiber is 0.3 μm, and the length is 3 mm; 90% by weight, the above-mentioned fiber and magnesium oxide nano-powder adopt wet papermaking process, after beating, forming, dehydration, and then use the coating solution prepared by magnesium oxide powder and cellulose binder to coat, rolling, in Drying, rolling, the thickness is 60μm, the surface density is 36g / m 2 A high-temperature-resistant microporous film material, in which the content of various materials is: 31% alumina fiber, 48% PET fiber, 10% cellulose fiber, 5% nano-magnesia powder, and 6% cellulose binder.

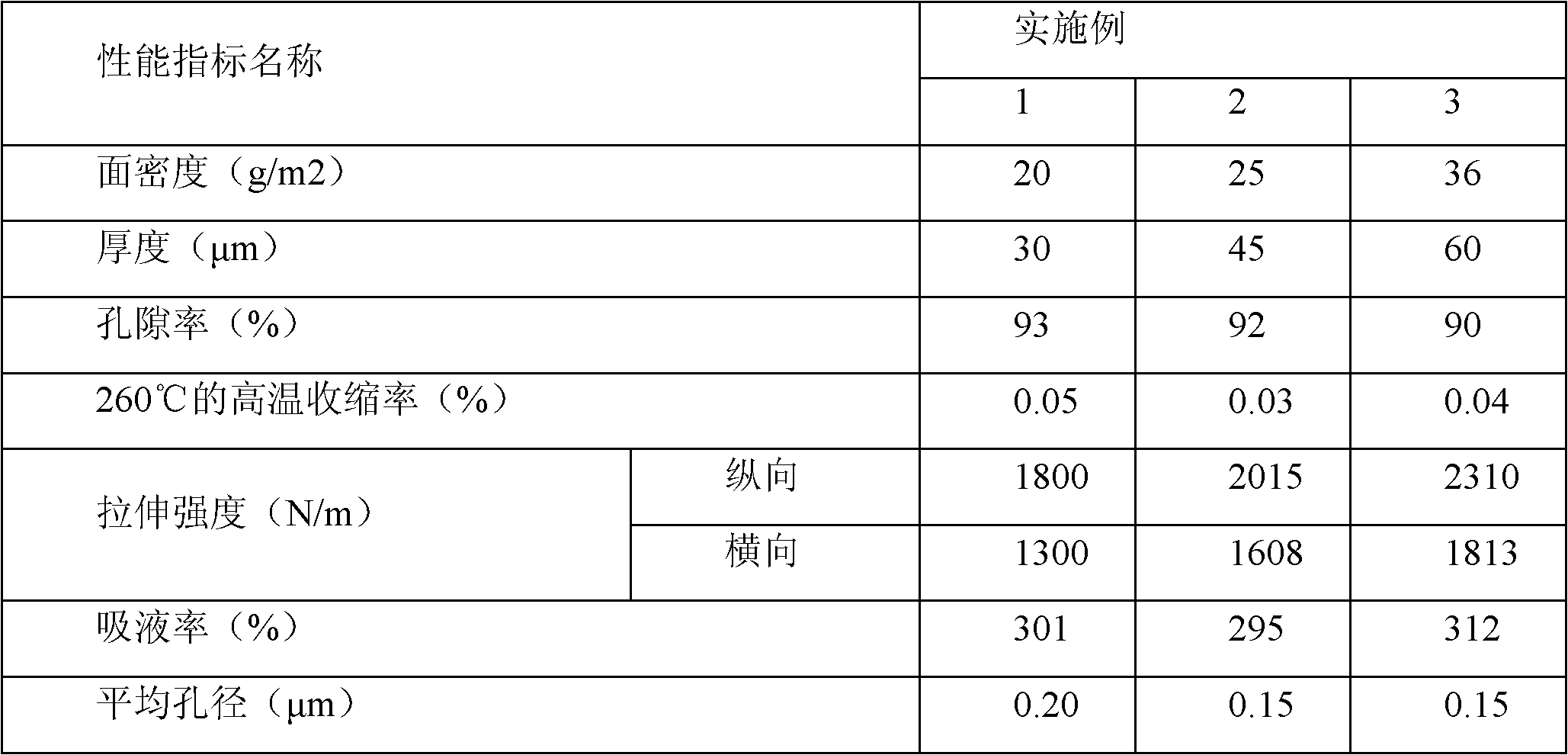

[0030] Using the above batching conditions and treatment methods, the performance indicators of the prepared high temperature resistant microporous film material are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com