Mesoporous SiO2 microsphere lithium ion battery diaphragm and lithium ion battery

A mesoporous silica and ion battery technology, which is applied in secondary batteries, battery components, circuits, etc., can solve the problems of ceramic coatings with insufficient liquid absorption and liquid retention capabilities, and impacts on battery performance and cycle performance. Achieve the effects of safety performance and cycle performance improvement, large loading capacity, strong absorption and retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of mesoporous silica microspheres:

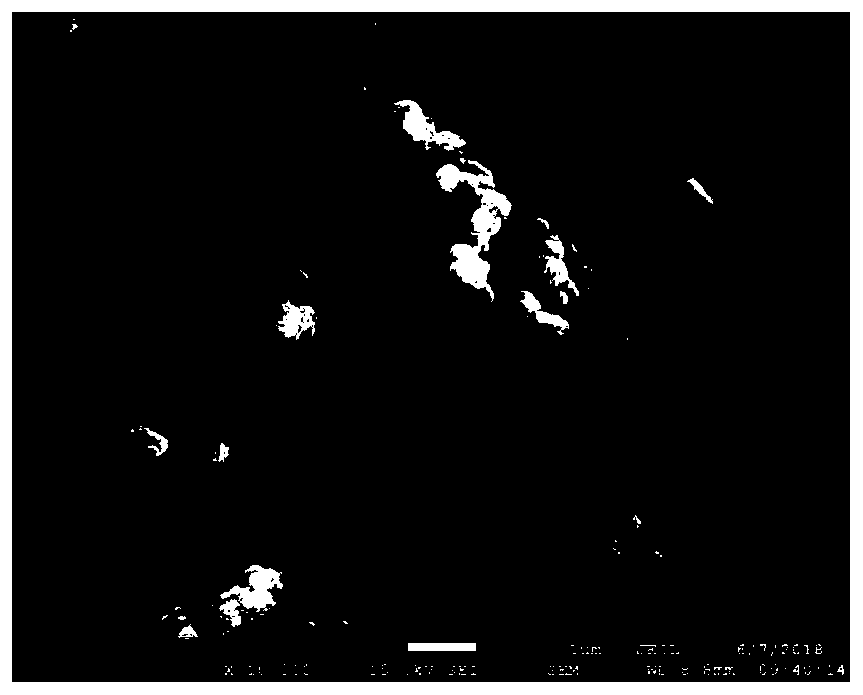

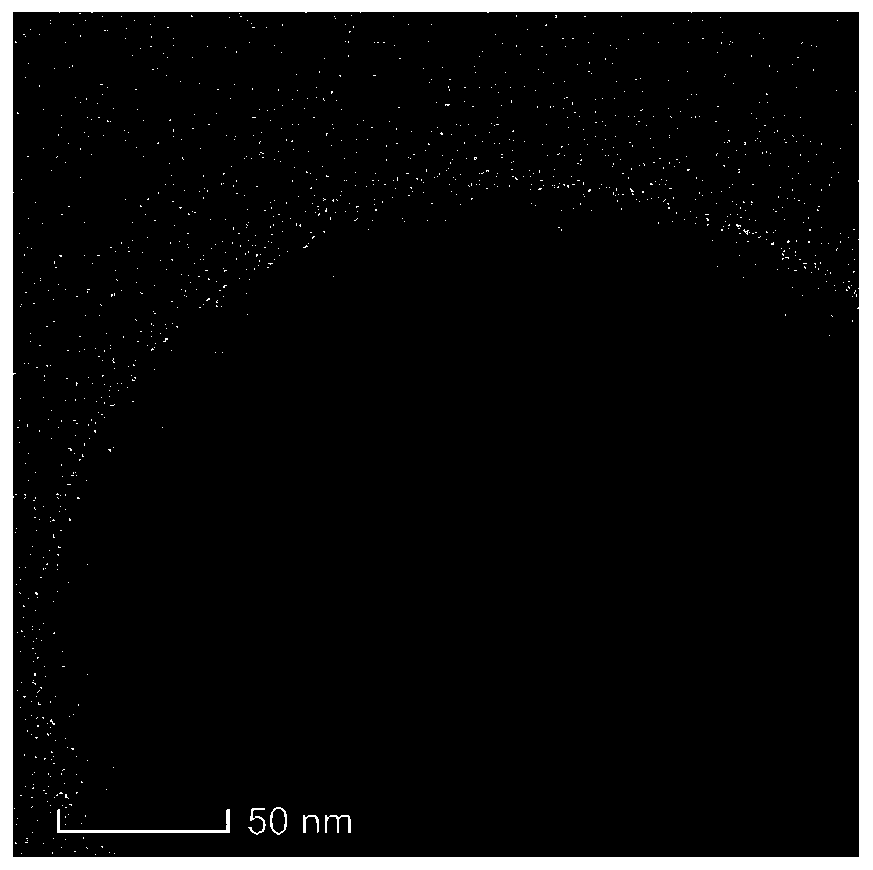

[0028] Under rapid magnetic stirring, add 1.5g of cetyltrimethylammonium bromide (CTAB) to the mixture of 132mL of acetone, 36ml of deionized water, 1.5g of PVP and 2mol / L sodium hydroxide, and then quickly add 8ml For tetraethyl orthosilicate (TEOS), continue to keep stirring slowly, and the solution system becomes milky white turbid 15 minutes after the addition is completed, and the reaction solution is allowed to stand at 30°C for 2-3 hours. Thereafter, the reaction solution was centrifuged and ultrasonically dispersed and cleaned, and repeated several times to obtain a wet powder of silica microspheres, and then the powder was freeze-dried for 6 to 8 hours, and finally the dried powder was roasted in a high-temperature furnace at 550°C for 5 hours to remove CTAB template, the specific surface area is 420 ~ 430m 2 / g, the pore volume is 0.2~0.25cm 3 / g, mesoporous silica microspheres with a pore size of 1-4nm.

[0...

Embodiment 2

[0039] The difference with embodiment 1 is:

[0040] Preparation of diaphragm:

[0041] 1) First mix 30 parts of silica mesoporous microspheres, 10 parts of water-based binder, 1 part of dispersant, 1 part of thickener and 50 parts of water, ball mill, then add 8 parts of water-based binder, and continue ball milling Disperse to obtain silica mesoporous microsphere slurry;

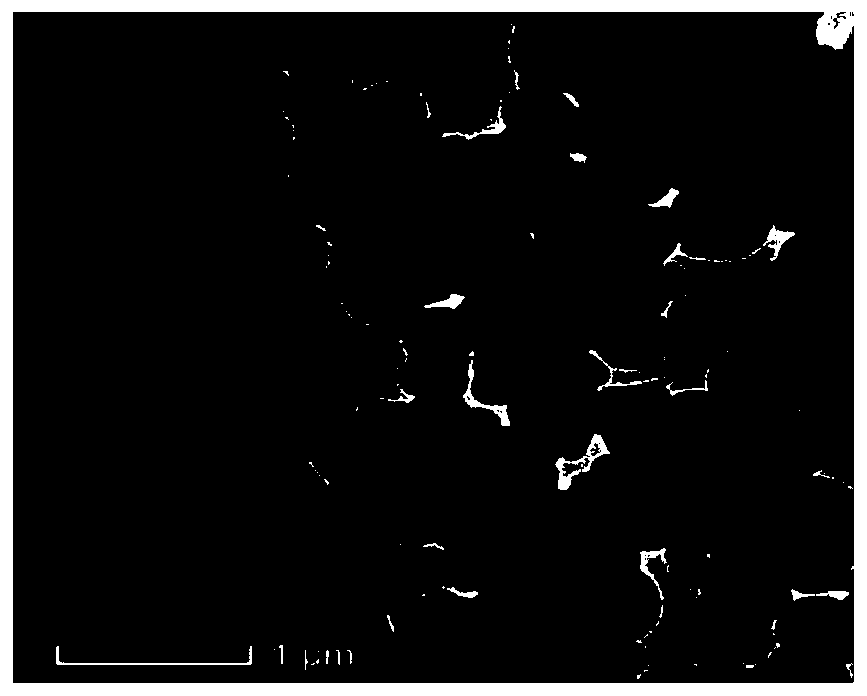

[0042] 2) Using a PE microporous membrane with a porosity of 42% and a pore diameter of 0.5-1.5 μm as the diaphragm substrate, evenly coat the mesoporous silica microsphere slurry on the diaphragm substrate at a coating speed of 20 m / min and then baked at 60°C for 3 minutes to obtain a coating with a thickness of 1 μm and a surface density of 12 g / m 2 Li-ion battery separator with mesoporous silica microsphere layer.

[0043] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0045] The difference with embodiment 1 is:

[0046] Preparation of diaphragm:

[0047] 1) First mix 50 parts of silica mesoporous microspheres, 5 parts of water-based binder, 0.3 parts of dispersant, 0.2 parts of thickener and 40 parts of water, ball mill, then add 4.5 parts of water-based binder, continue ball milling Disperse to obtain silica mesoporous microsphere slurry;

[0048] 2) Using a PE microporous membrane with a porosity of 52% and a pore diameter of 0.5-1.5 μm as the diaphragm substrate, evenly coat the mesoporous silica microsphere slurry on the diaphragm substrate at a coating speed of 50 m / min and then baked at 80°C for 1 min to obtain a coating with a thickness of 3 μm and a surface density of 13 g / m 2 Li-ion battery separator with mesoporous silica microsphere layer.

[0049] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com