Patents

Literature

932results about How to "Reduce generation cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

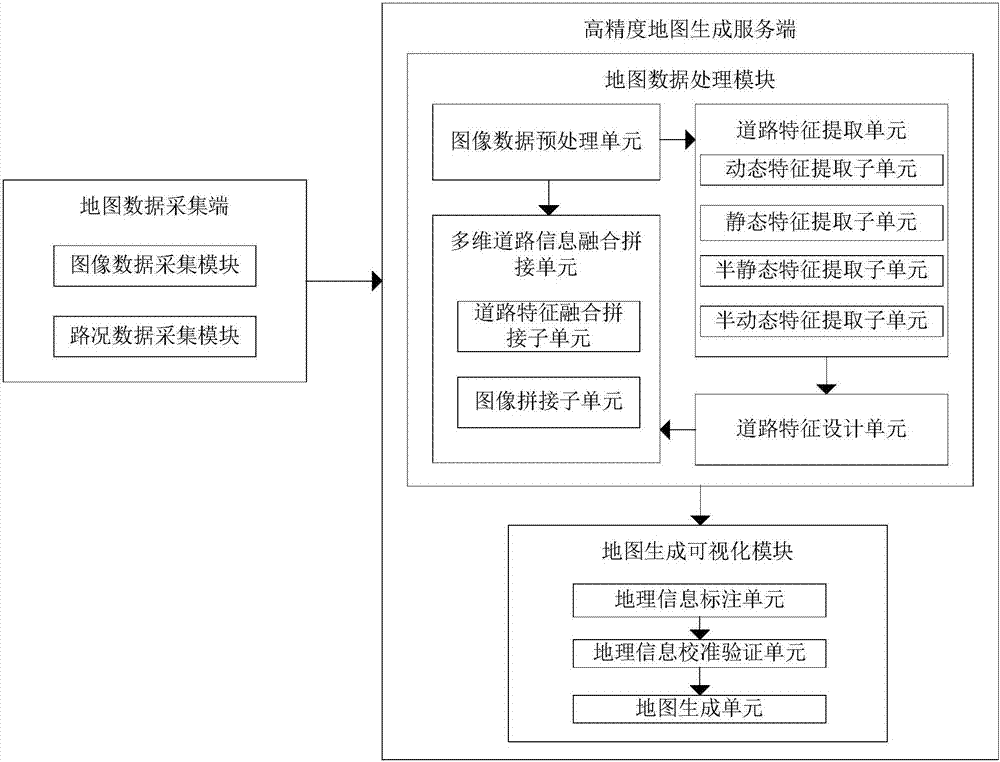

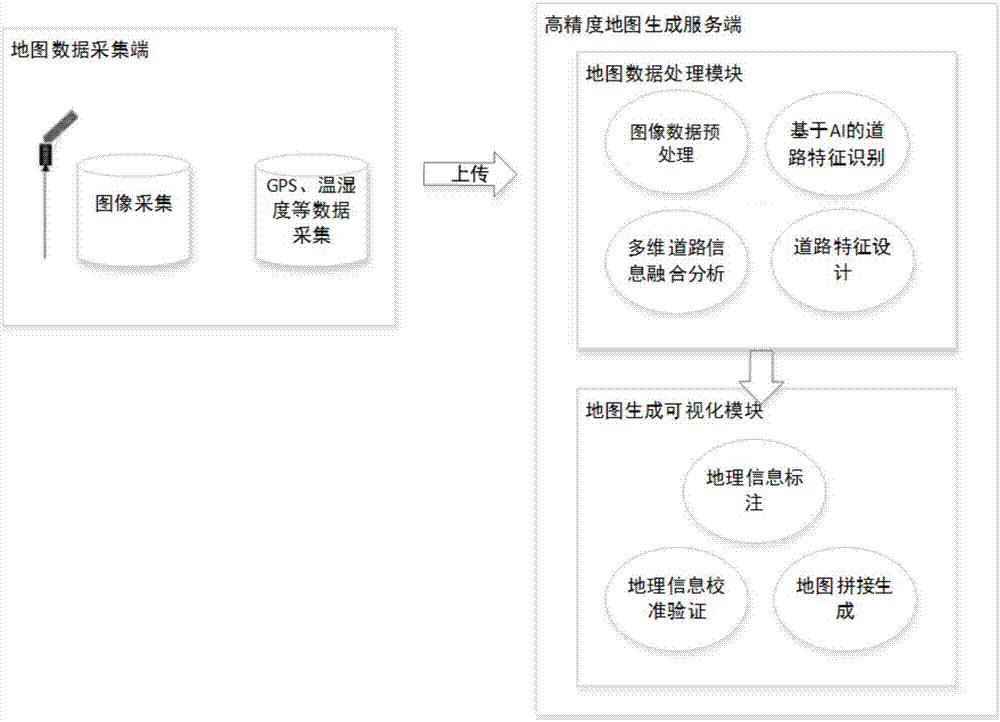

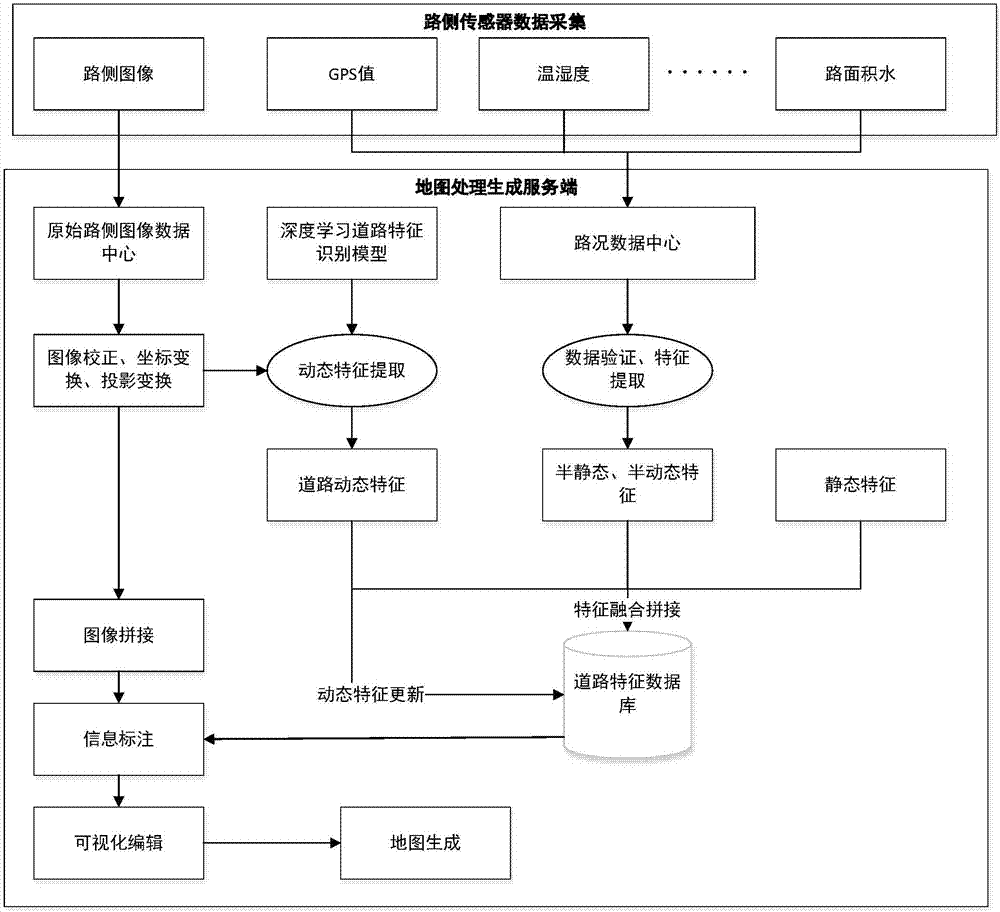

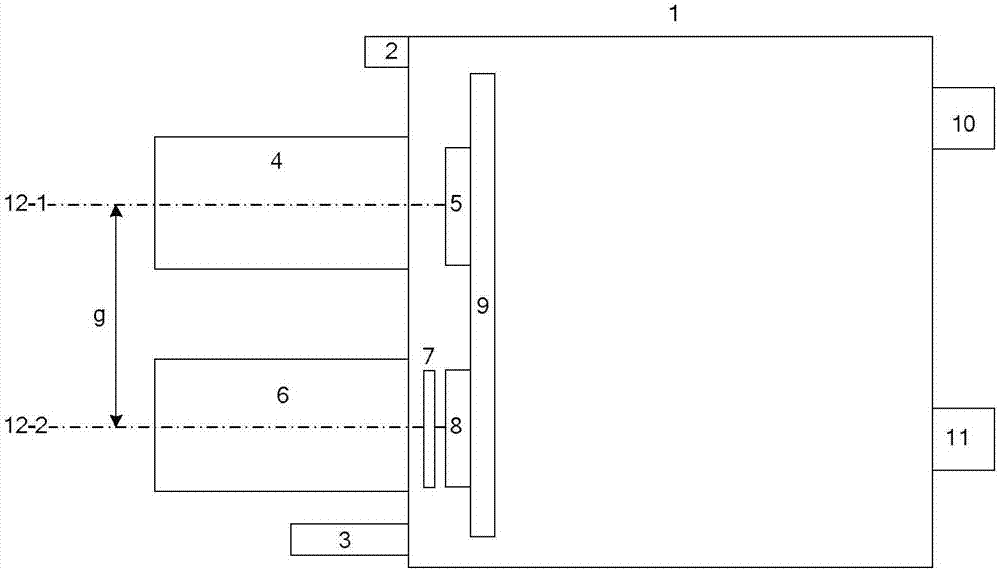

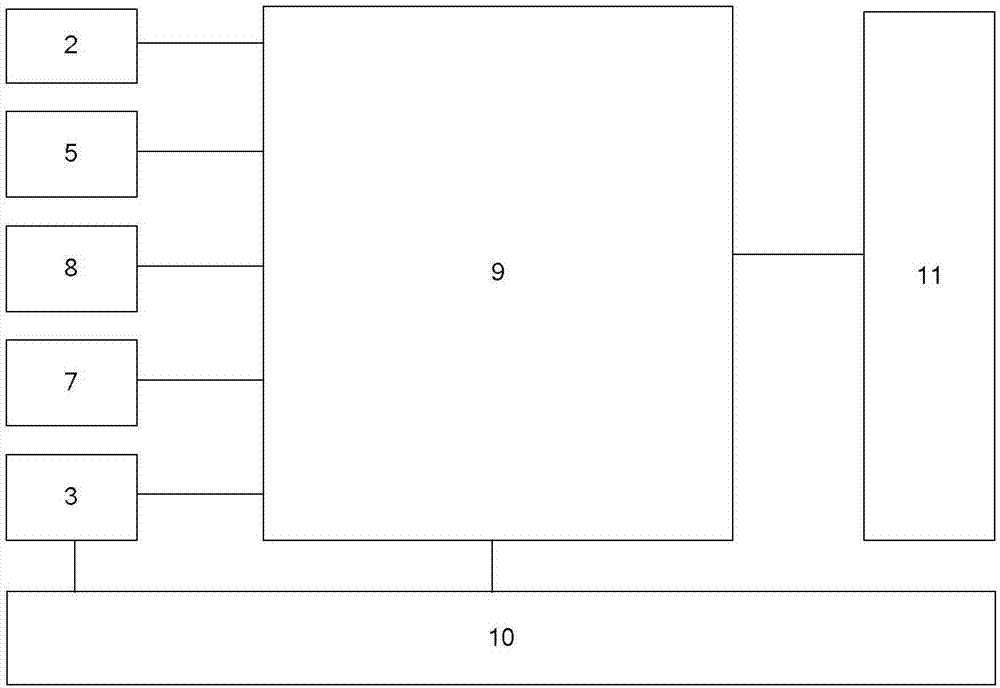

High-precision dynamic map data processing system and method based on road side sensors

ActiveCN107229690AWith real-time validityReal-time acquisitionRoad vehicles traffic controlCharacter and pattern recognitionData processing systemFeature extraction

The invention discloses a high-precision dynamic map data processing system and method based on road side sensors. The high-precision dynamic map data processing system comprises a map data acquisition terminal and a high-precision map generation service terminal. The map data acquisition terminal provides a bulk of diversified map road original data for the high-precision map generation service terminal; the high-precision map generation service terminal comprises a map data processing module and a map generation visual module; the map data processing module is used for extracting road features from the map road original data and carrying out hierarchical design on all the road features, splicing information of the same road, completing road feature data fusion on the road feature aspect first, finally completing image splicing on the image aspect, and generating a road downward projection drawing in dependence on the splicing result; and the map generation visual module is used for marking road information on the downward projection drawing, the marked road information and the downward projection drawing commonly form map data of a high-precision map, visual editing is carried out on the map data, and a high-precision dynamic map is generated. According to the invention, the generation cost of the high-precision map can be reduced, and the high-precision dynamic map can be updated quickly.

Owner:INST OF SOFTWARE APPL TECH GUANGZHOU & CHINESE ACAD OF SCI

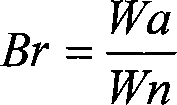

Method for preparing high-activity silicon collidal sol formed from superfine silicon dioxide particles

InactiveCN101070161AEvenly distributedOvercome the disadvantage of uneven sizeSilicaSilicic acidIon exchange

The invention discloses a kind of preparation method of silica sol of high activity. For this kind of silica sol, the particle is tiny and grain size of it is distributed narrowly. It is characterized in that it takes sodium silicate as raw material, natrium ion is took out using method of exchanging ion and then get active silicic acid solution, prepare silica sol of high activity whose grain size is 6-12 nm, content of silicon dioxide is accounting for 10-30%,content of sodium monoxide is accounting for 0.2-0.3%, and PH value is between 8.5 and 10.5,through controlling proportion, pH value of reaction and heating temperature of active silicic acid solution. Silica sol prepared using this method can satisfy needs of spinning sizing, organic polymerization catalysis and modifying technology. Compared to common ion-exchanging method, preparation method of the invention has advantages of tiny particle, equal granularity, synchronizing dehydration and purification and low energy wasting, and it can control size of particle according to needs of actual utilization.

Owner:LUDONG UNIVERSITY +1

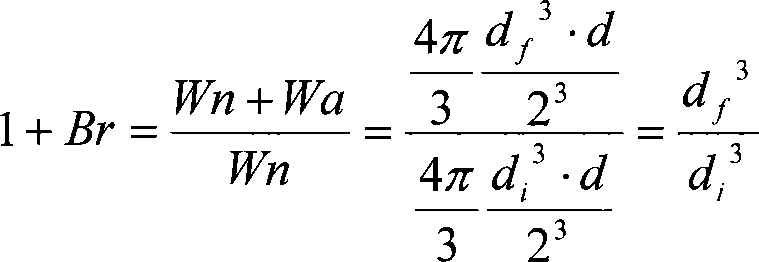

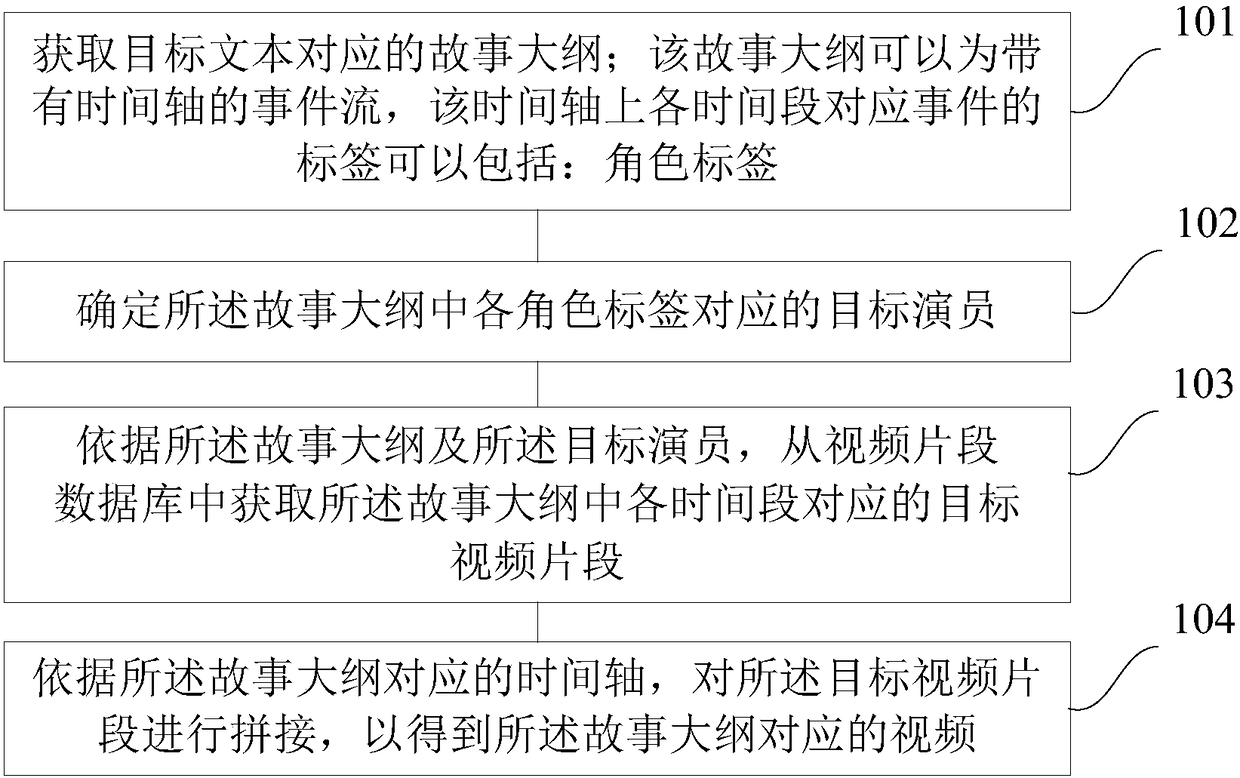

Video generation method and device

ActiveCN108933970AReduce generation costSave human effortCharacter and pattern recognitionData miningTarget textEvent stream

The embodiments of the invention provide a video generation method and device. The method comprises the following steps of acquiring a story outline corresponding to a target text, wherein the story outline is an event stream with a time shaft, and the label of an event corresponding to each time period on the time shaft includes a role label; determining a target actor corresponding to each character label in the story outline; acquiring a target video segment corresponding to each time period in the story outline from a video clip database according to the story outline and the target actor;and splicing the target video segment according to the time shaft corresponding to the story outline to obtain a video corresponding to the story outline. In the embodiments of the invention, for thetarget text, the corresponding video is automatically generated, and the generation cost of the video is effectively reduced.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

Catalyst for converting alcohols and ethers into aromatic hydrocarbons as well as preparation method and use method thereof

ActiveCN103007985ASmall particle sizeEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenAlcohol

The invention discloses a catalyst for converting alcohols and ethers into aromatic hydrocarbons, as well as a preparation method and a use method of the catalyst, and belongs to the technical field of chemical engineering. The preparation method comprises the steps as follows: at first, taking a template agent, kaolin, sodium hydroxide and water as raw materials for preparing a hydrogen type nanoscale ZSM-5 molecular sieve, and then directly preparing the catalyst; or based on the hydrogen type nanoscale ZSM-5 molecular sieve, preparing the two-component, three-component or four-component catalyst with metal and / or a structure enhancer and / or a stabilizing additive. The catalyst comprises the following components in percentage by mass: 30-100% of the needle-like nanoscale ZSM-5 molecular sieve, 0-10% of the metal, 0-50% of the structure enhancer and 0-10% of the stabilizing additive. The invention further provides a method for enabling the catalyst to be used for converting alcohols and ethers into aromatic hydrocarbons. The catalyst is small in particle size, high in catalytic efficiency and low in use cost; the preparation method is simple and efficient; and the use method is reasonable and efficient.

Owner:TSINGHUA UNIV

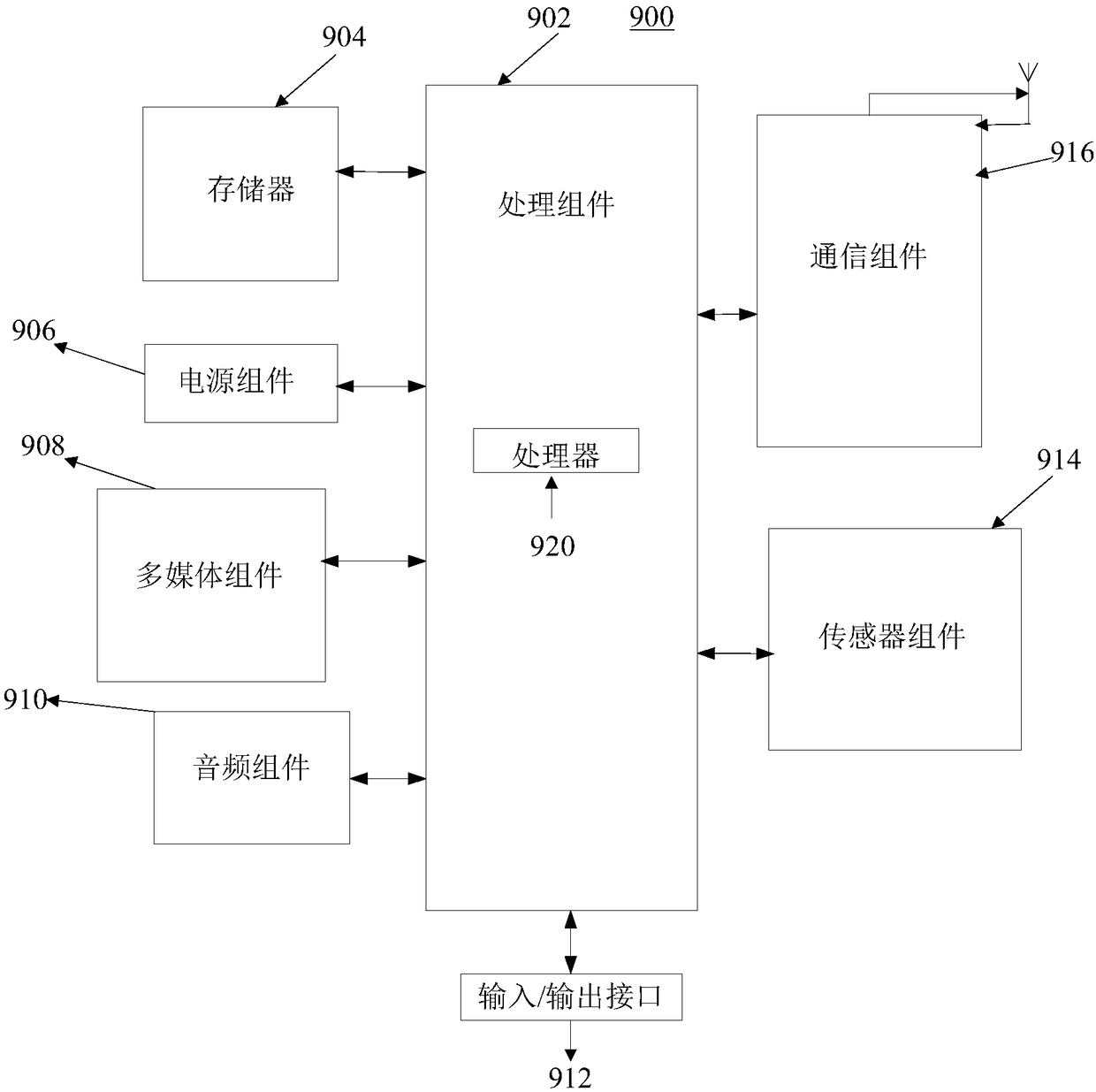

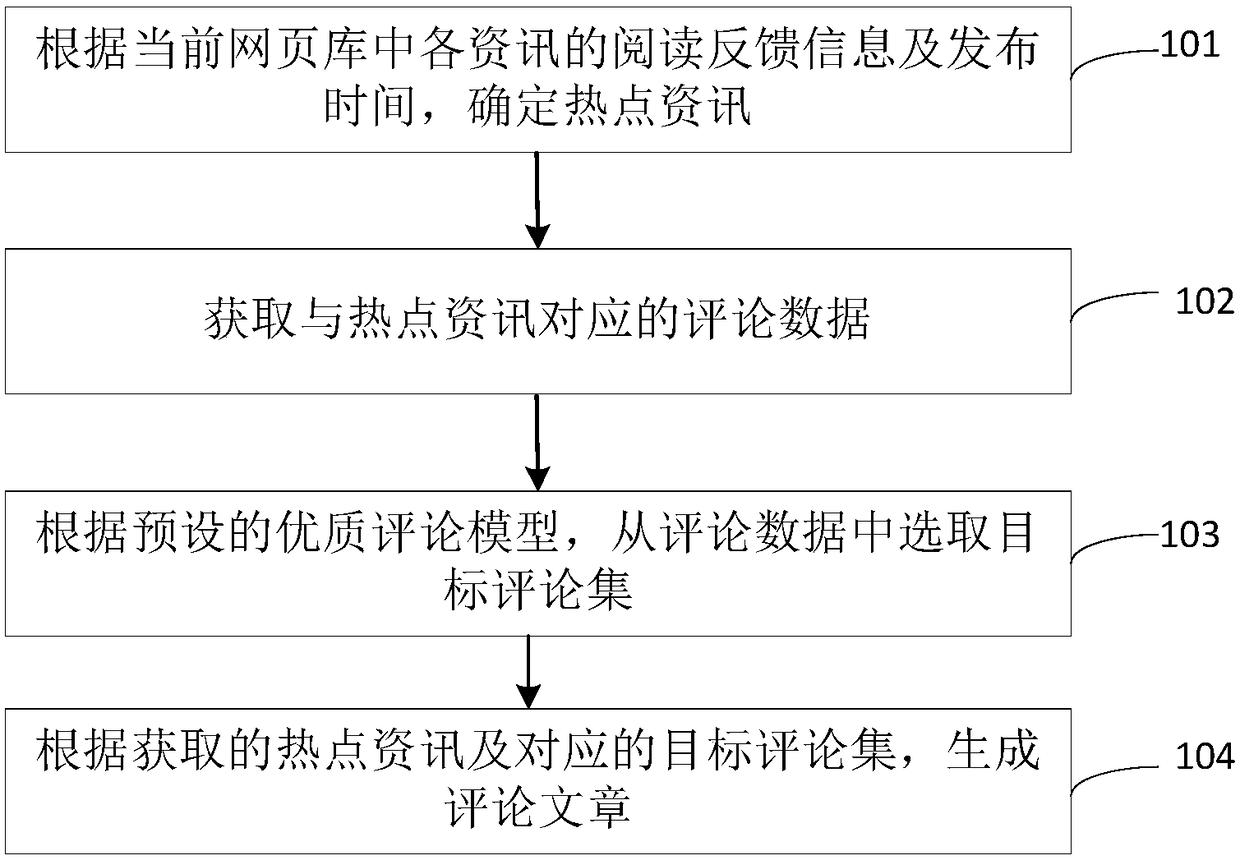

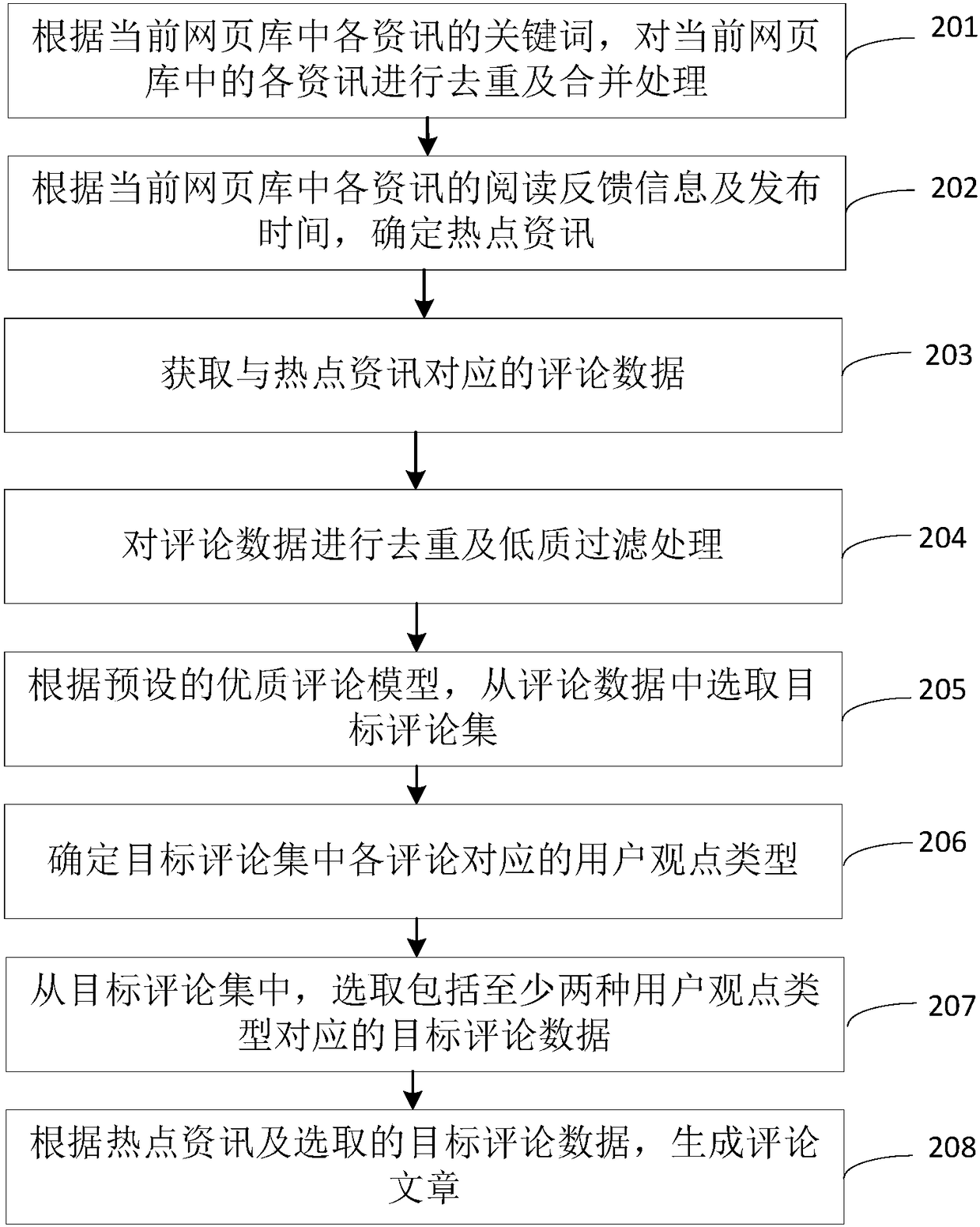

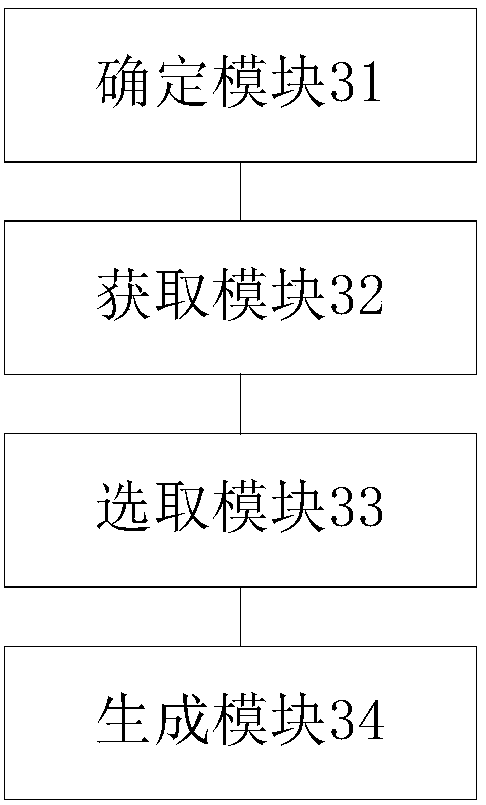

HoTSpot information review article generation method, device and terminal equipment

ActiveCN108153723AReduce generation costIncrease generation speedNatural language translationSemantic analysisTerminal equipmentComputer terminal

The invention provides a hoTSpot information review article generating method, device and terminal equipment. The method comprises the steps that hoTSpot information is determined according to readingfeedback information and publishing time of each information in the current webpage library; comment data corresponding to the hoTSpot information is obtained; a target comment set is selected from the comment data according to a preset high-quality comment model; a review article is generated according to the obtained hot spot information and the corresponding target comment set. Thereby, it isrealized that the hot news information review article is automatically generated according to the webpage library, the article generation cost is reduced, the article generation speed and timeliness are improved, and the user experience is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

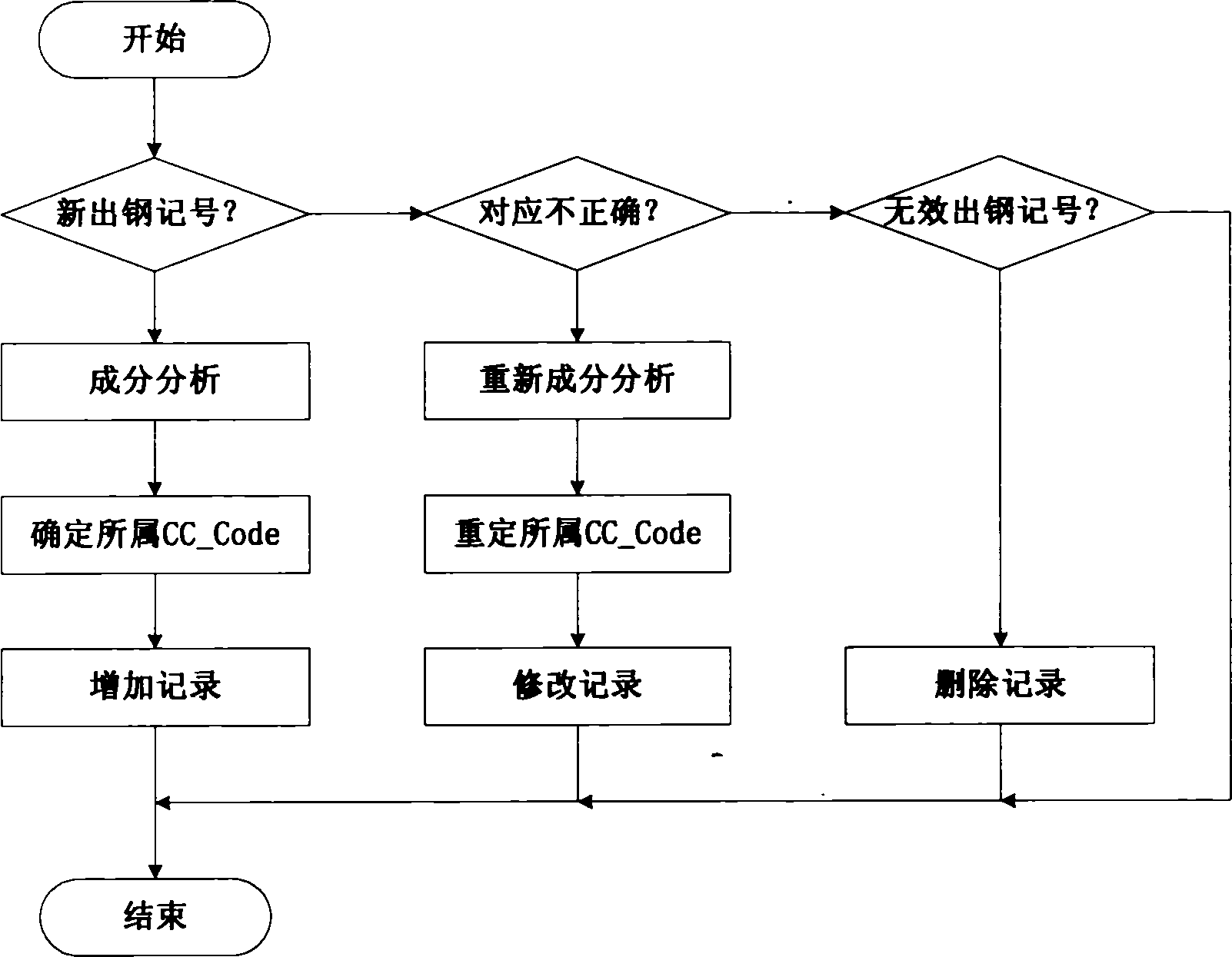

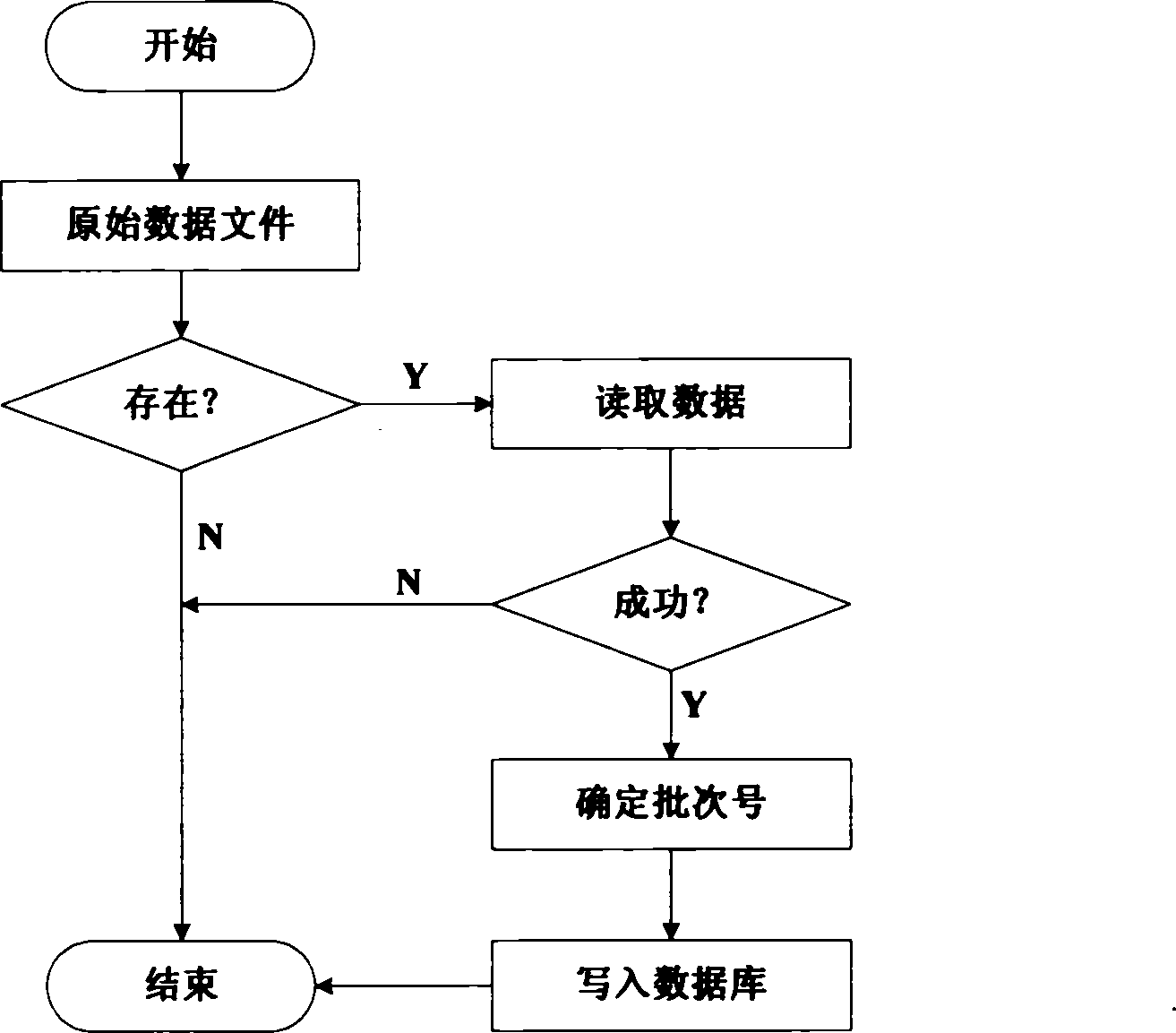

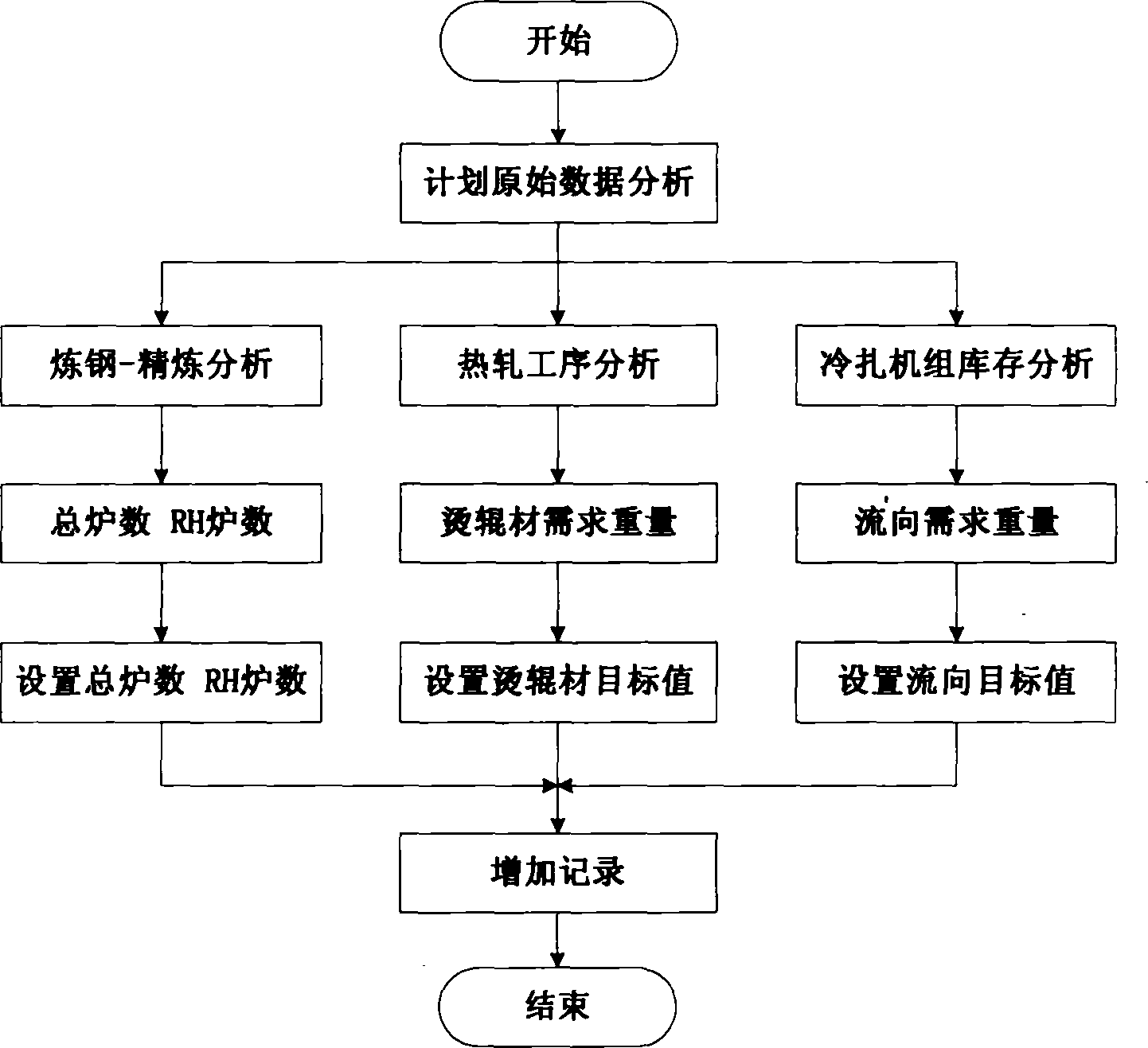

Steelmaking-continuous casting tundish batch plan method and system

The invention relates to a steel-smelting-continuous casting middle pack batch plan and relative system, wherein said system comprises arc static parameter setting module, original data download module, batch plan demand setting module, model algorism parameter setting module, middle pack batch plan automatic generating module, plan index stat display module, plan result stat display module, producing plan artificial adjusting module, and producing plan upload module. And said method uses middle pack batch plan math model, uses two-stage multi nearby field forbidden search algorism, to fix how the furnace time is batched into the middle pack to realize multi-furnace continuous casting, to maximize the casting number, and reduce the cost. The invention can improve the plan efficiency, reduce labor density, improve plan quality and optimize production.

Owner:NORTHEASTERN UNIV

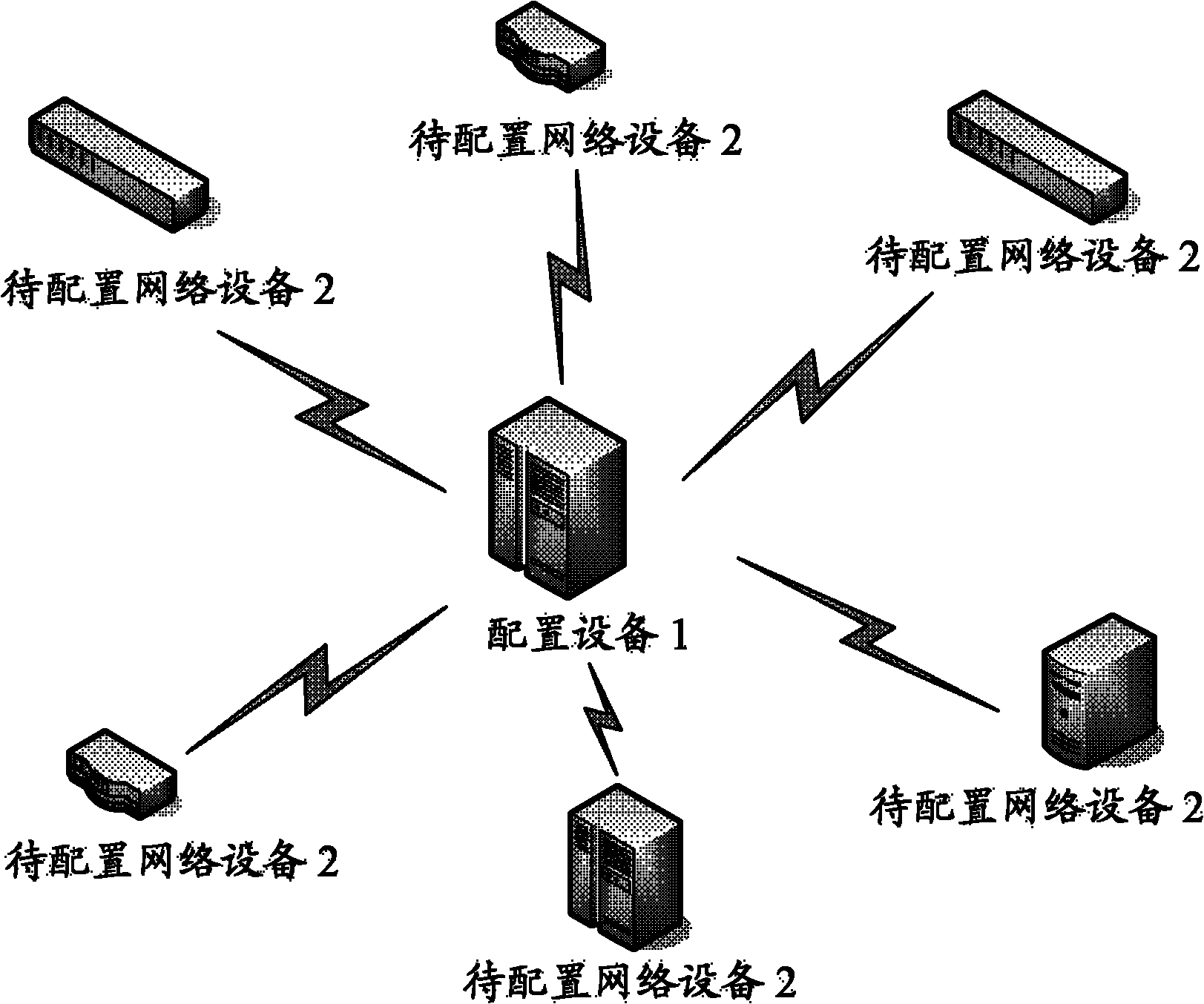

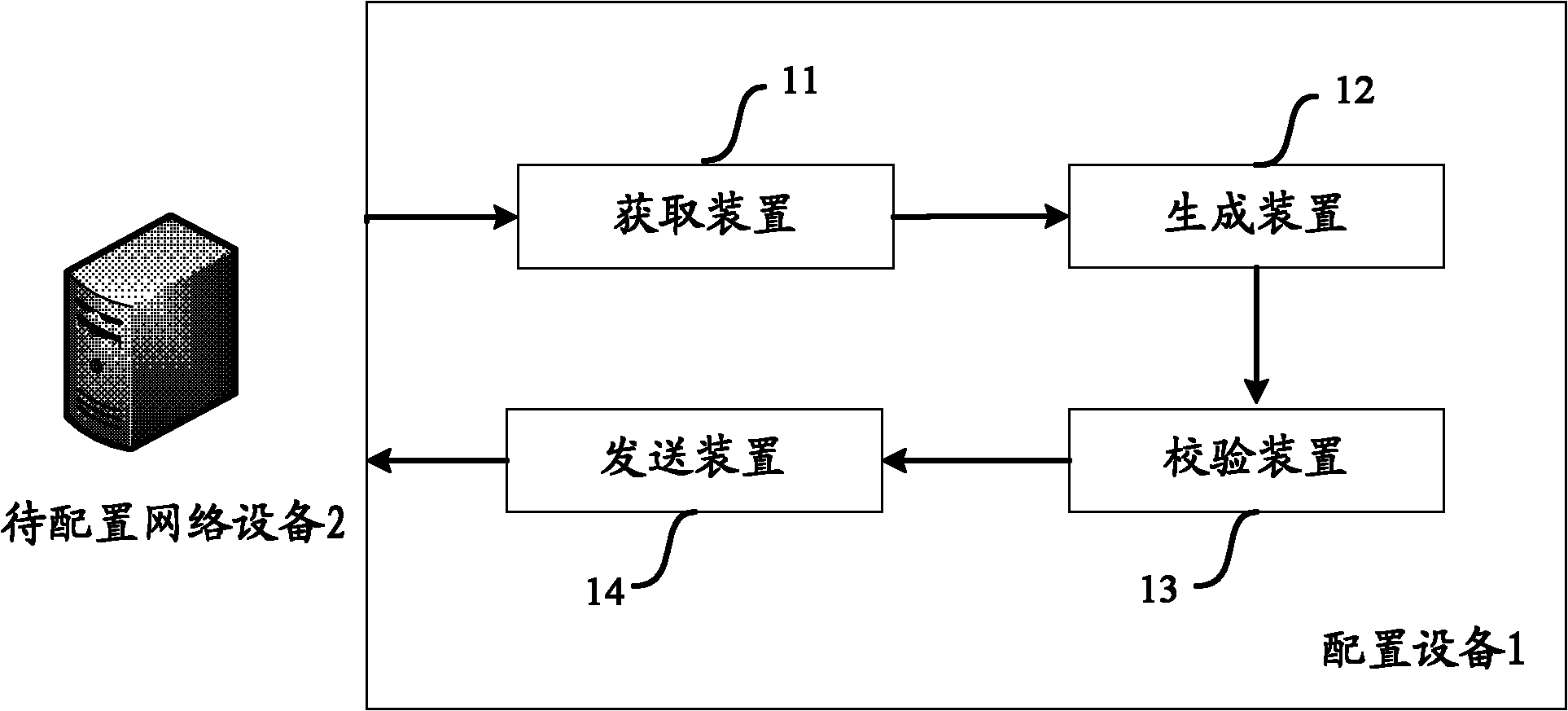

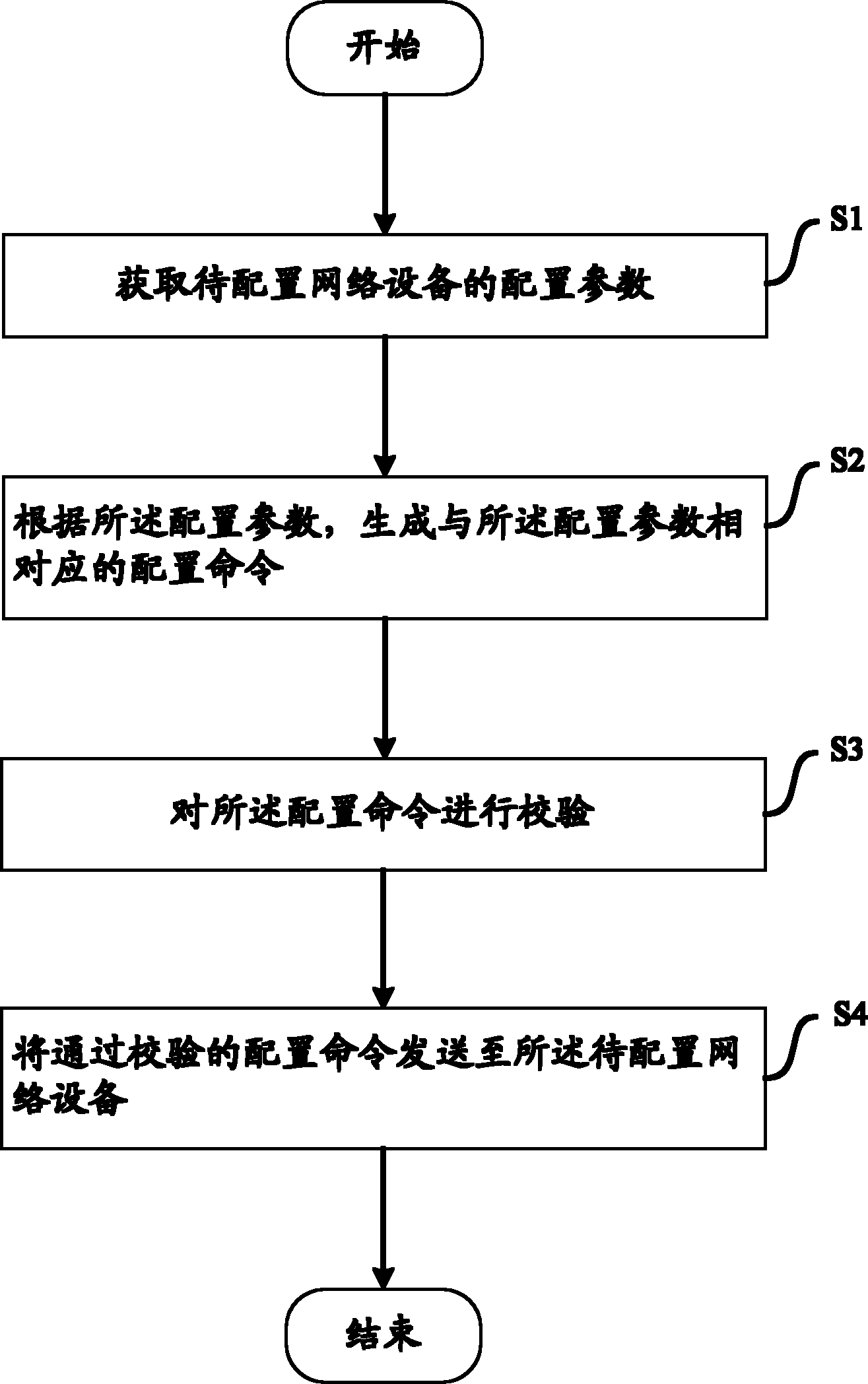

Configuration parameter based Method and configuration equipment for configuring network equipment

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

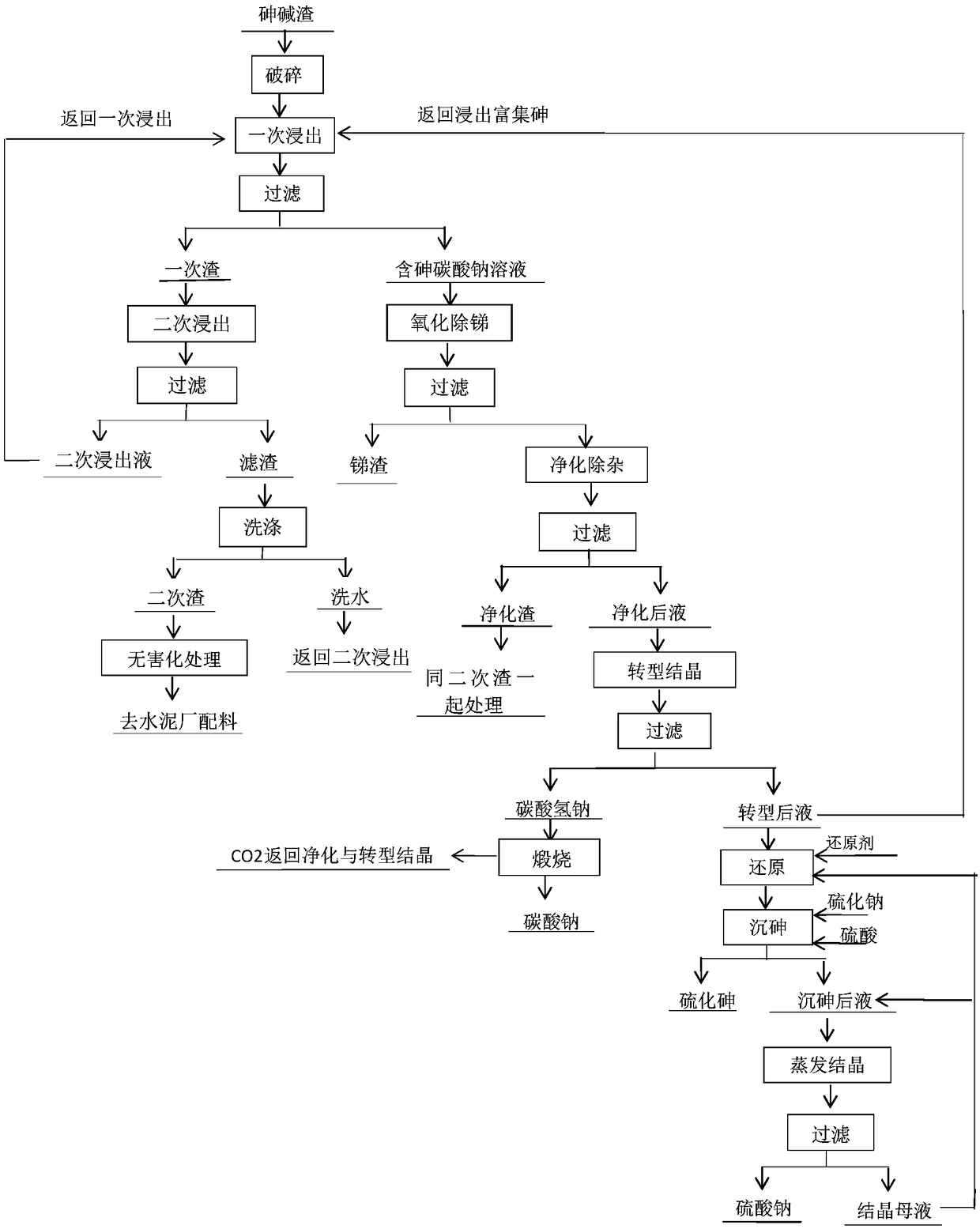

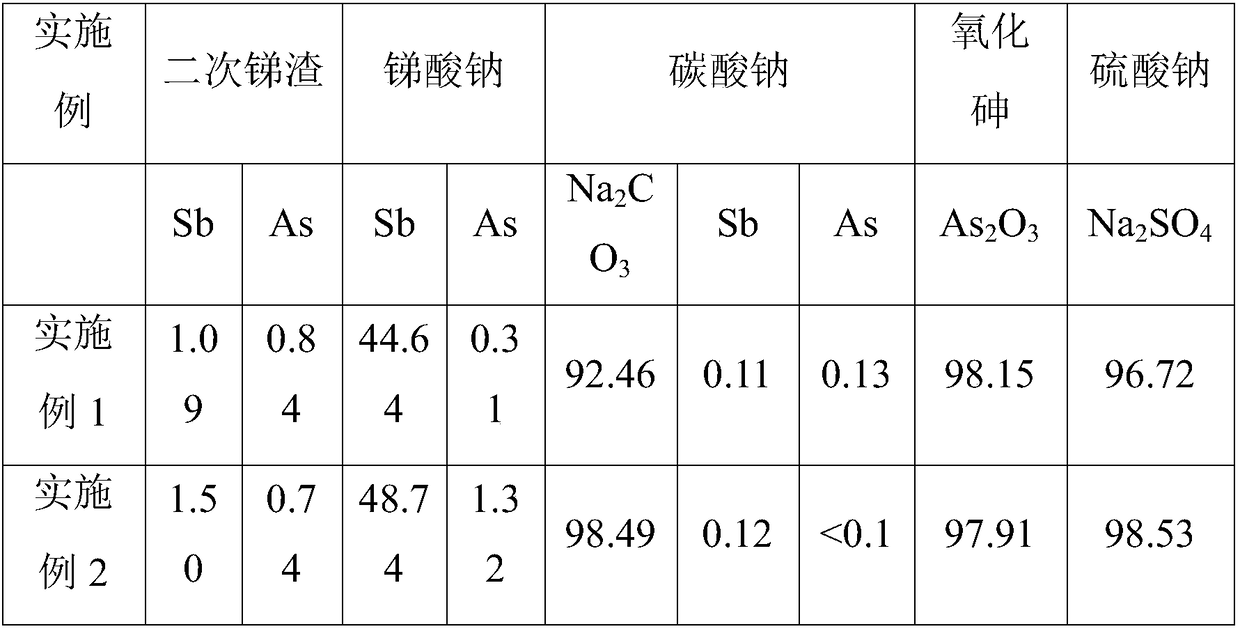

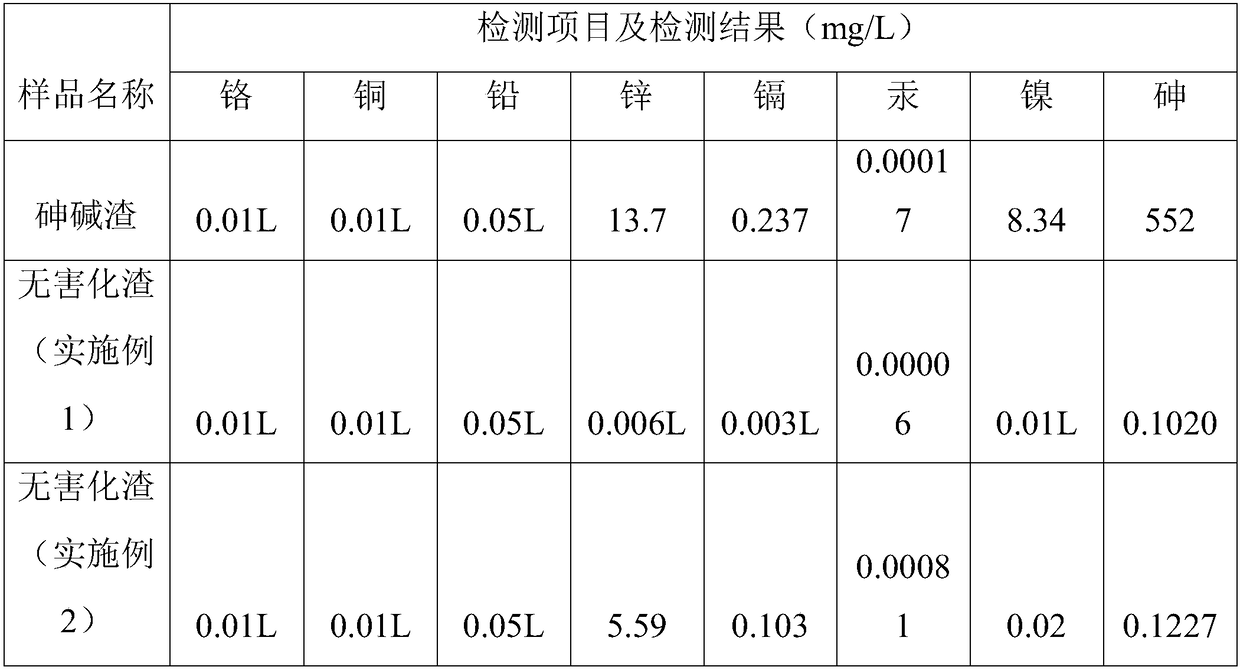

Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

PendingCN108441642ARealize green and clean cycle productionHigh recovery rateSolid waste disposalAlkali metal sulfite/sulfate purificationWastewaterImpurity

The invention belongs to the field of antimony smelting arsenic alkali residue treatment and particularly discloses a wet-method recycling and harmless treatment process for antimony smelting arsenicalkali residue. The process adopts a whole-wet-method treatment process and mainly comprises the eight working procedures of breaking, dissolving for leaching, oxidation for antimony outlet, purification for impurity removing, transition for crystallizing, reduction for arsenic sinking, evaporative crystallization and secondary residue harmless treatment. Recycling and harmless treatment of the arsenic alkali residue, zero emission of waste residue and waste water and up-to-standard discharge of exhaust gas are thoroughly achieved, the long-term plagued arsenic alkali residue environmental pollution problem in the antimony smelting industry in China is thoroughly solved, and the environmental risk caused by stacking the arsenic alkali residue is eliminated; and meanwhile, separation, enrichment and effective recovering of valuable elements are achieved.

Owner:CHENZHOU YANGTAO CHEM

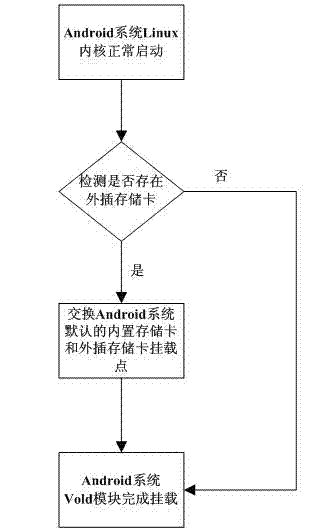

Memory card of handheld equipment and dynamic mounting method of memory card

InactiveCN102902488AMeet general needsSave resourcesInput/output to record carriersSubstation equipmentHand held devicesMemory cards

The invention discloses a memory card of handheld equipment. Based on an Android system, the memory card comprises an internally-arranged memory card; the internally-arranged memory card is divided into a first storage region and a second storage region; the first storage region is an ROM (Read Only Memory); a system program and / or an application program of the handheld equipment are / is stored in the ROM; and the second storage region belongs to a user storage space, is mainly used for storing relative data for a user and can also be used for mounting the application program. A dynamic mounting method of the memory card is used for dynamically selecting mounting between the second storage region of the internally-arranged memory card and an externally-inserted T card. According to the memory card of handheld equipment, the mounting path of the second storage region of the internally-arranged memory card and the externally-inserted T card is replaced, so that the utilization efficiency of a cell phone is improved and the cost is saved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

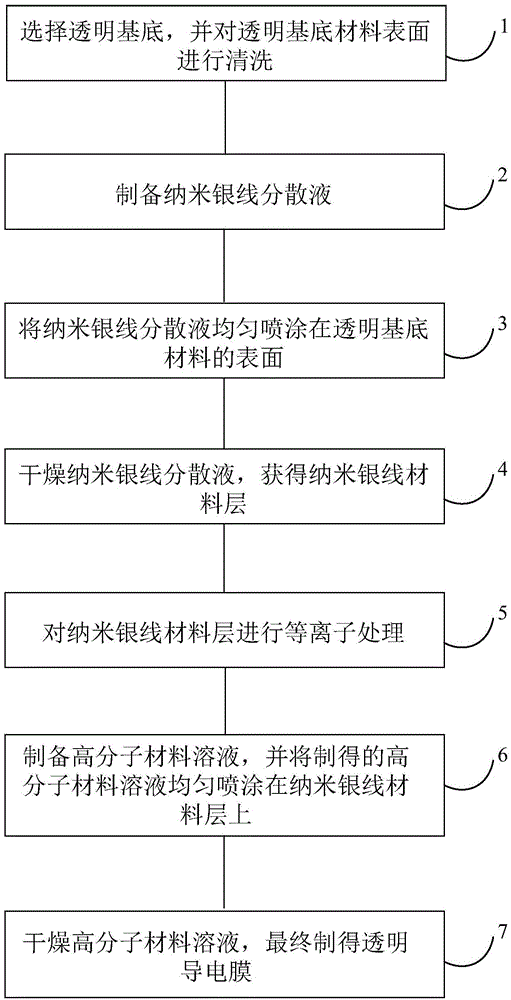

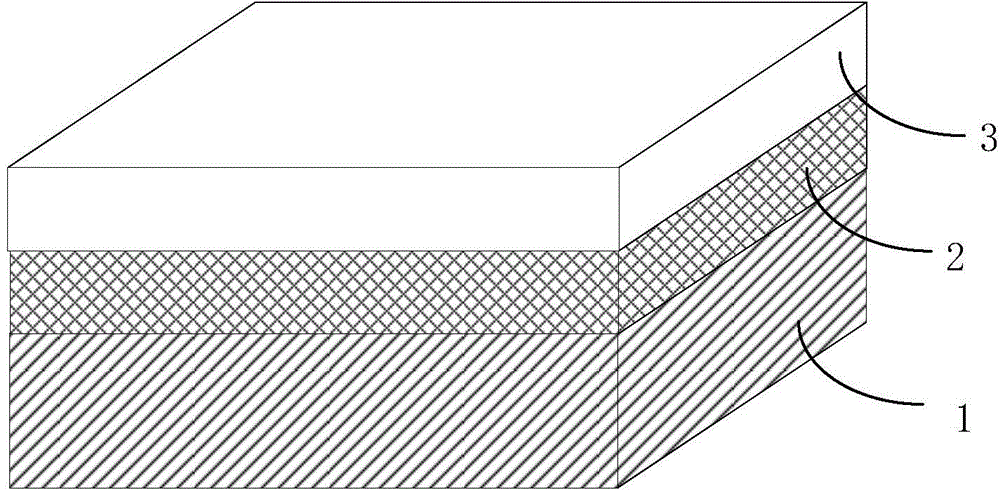

Manufacturing method of transparent conducting film and transparent conducting film

ActiveCN103985434ALow costImprove stabilityConductive layers on insulating-supportsCable/conductor manufactureOptoelectronicsTransparent conducting film

The invention discloses a manufacturing method of a transparent conducting film and the transparent conducting film. The manufacturing method includes the following steps that (1) a transparent base is selected, and the surface of the transparent base material is washed; (2) nano silver wire dispersion liquid with the concentration being 0.01-10 mg / mL is prepared; (3) the nano silver wire dispersion liquid prepared in the step (2) is sprayed on the surface of the transparent base material; (4) the nano silver wire dispersion liquid is dried to obtain a nano sliver wire material layer overlaid on the surface of the transparent base material; (5) radio-frequency tubes with the power being 10-5000 W are used for generating plasmas, and plasma treatment is conducted on the nano silver wire material layer for 30 seconds to 30 minutes. According to the manufacturing method, a specific plasma treatment mode is used for treating the nano silver wire material layer, and therefore the electrical conductivity of the transparent conducing film can be improved. Meanwhile, according to the manufacturing method, the washing purification process of nano silver wire raw materials is omitted, high-standard transparent base materials are not needed, therefore, the technology is simple, and the cost is lower.

Owner:深圳市善柔科技有限公司

Method for directly preparing metal oxide/silver nanowire composite conductive network

InactiveCN104575864AHigh mechanical strengthHigh visible light transmittanceCable/conductor manufactureOxygen plasmaElectrostatic coating

The invention relates to a method for directly preparing a metal oxide / silver nanowire composite conductive network, belongs to the technical field of transparent conductive thin films and anti-static coating layers, and aims to solve the technical problem that the technology for preparing a silver nanowire / inorganic metal oxide composite conductive thin film by two steps in the prior art is complicated. The method comprises the following steps: preparing a soluble metal oxide precursor solution; mixing the prepared metal oxide precursor solution with dispersion liquid of a silver nanowire to obtain soluble metal oxide / silver nanowire mixing dispersion liquid, and forming a film on the upper surface of a substrate by a wet processing technology; finally performing high-temperature annealing, ultraviolet ozone irradiation or oxygen plasma treatment to obtain the metal oxide / silver nanowire composite conductive network. According to the method, the metal oxide / silver nanowire composite conductive network is prepared in one step, so that the preparation technology is greatly simplified, and the production cost is reduced; the prepared composite conductive network is high in mechanical strength, higher in visible light transmittance and lower in square resistivity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

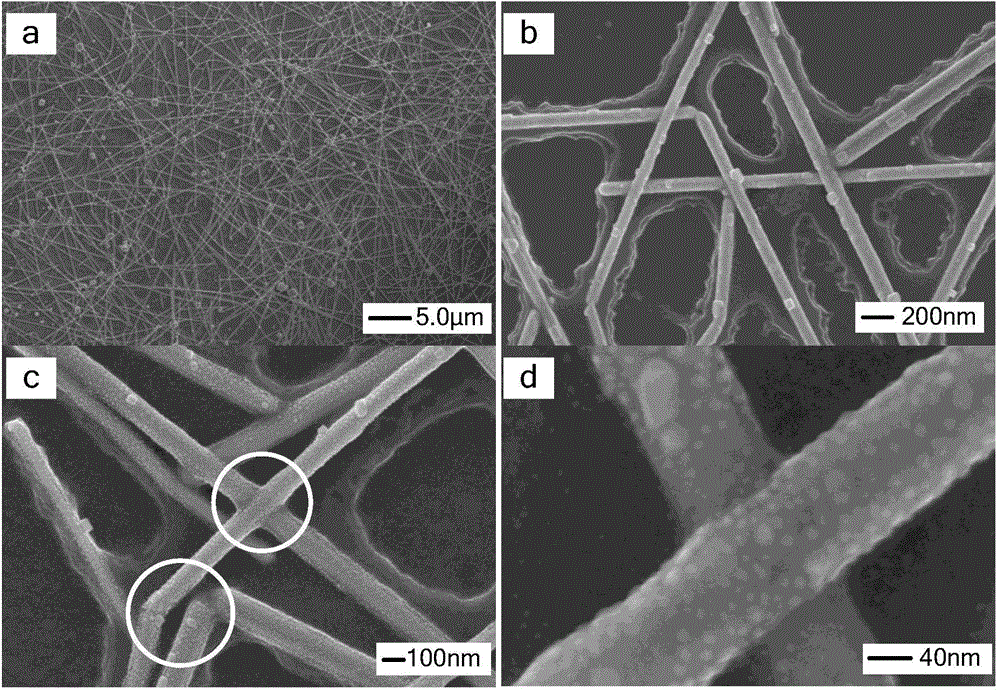

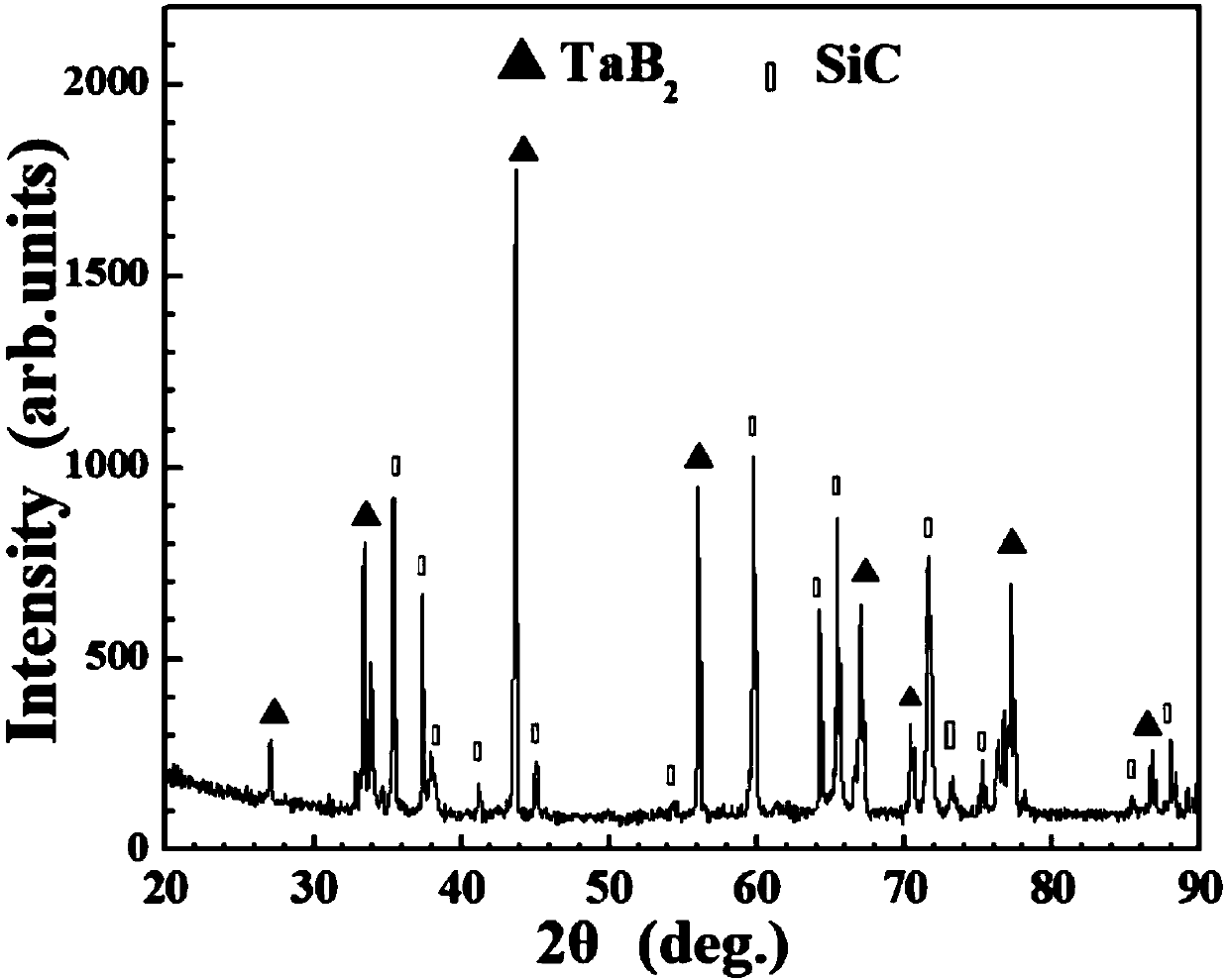

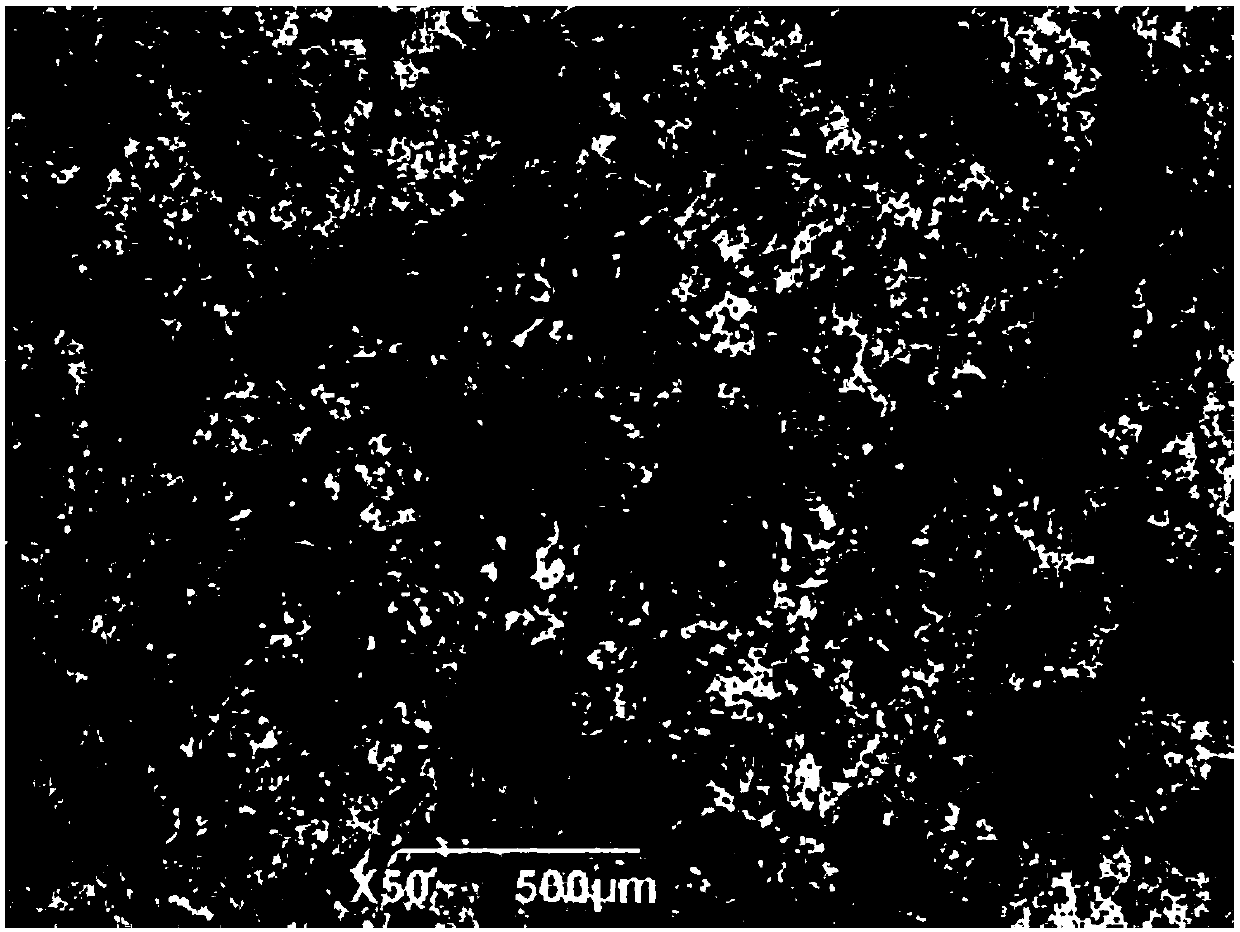

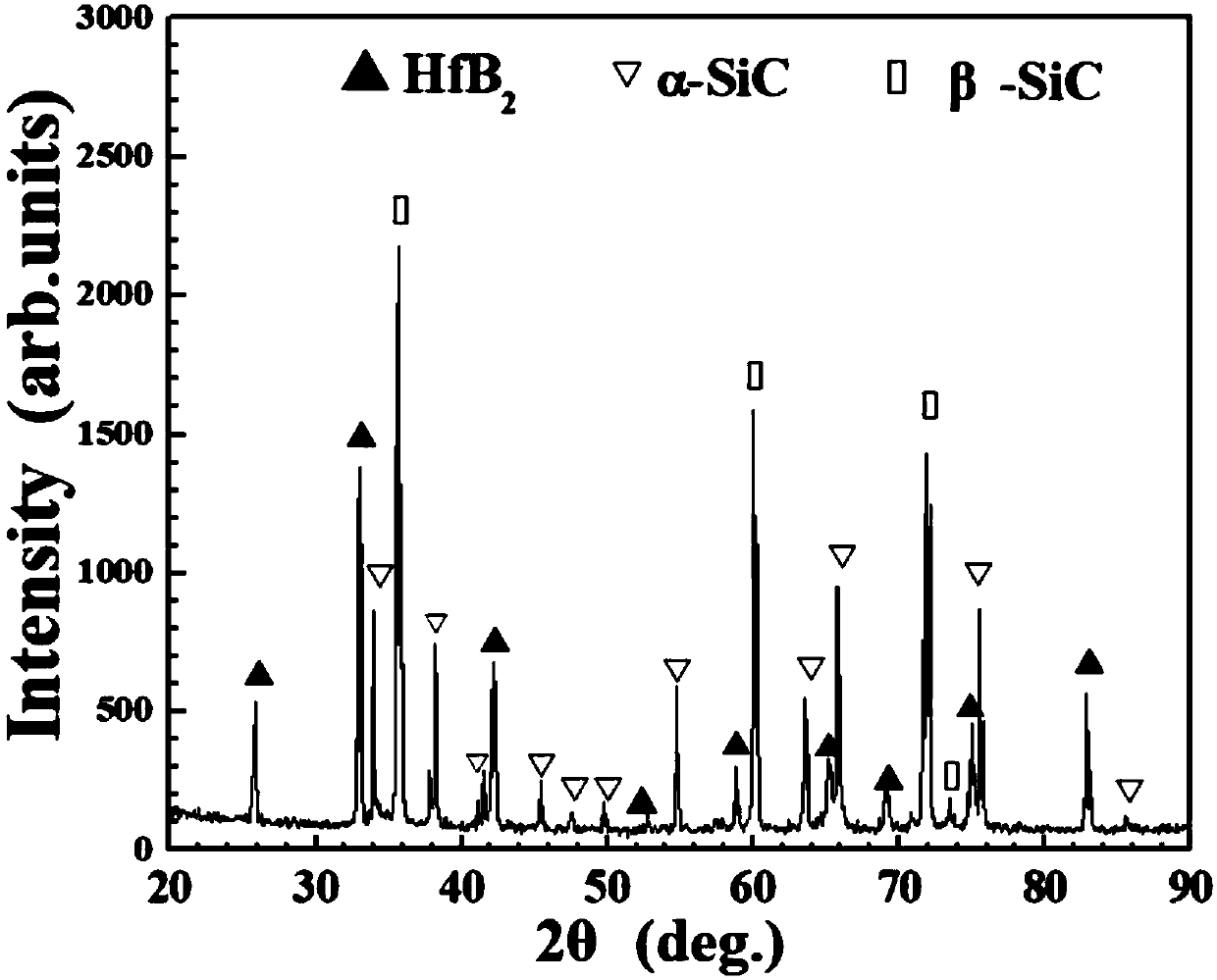

Preparation method of carbon material surface boride-modified silicon-based antioxidation coating layer

The invention relates to a preparation method of a carbon material surface boride-modified silicon-based antioxidation coating layer, and belongs to a preparation method of a carbon material surface high-temperature antioxidation coating layer. The preparation method of the antioxidation coating layer comprises the following steps of firstly, preparing a boride MB2 slurry with controllable content, wherein M in MB2 is Zr (zirconium), Ta (tantalum) or Hf (hafnium); brushing, impregnating or spraying a preset layer of MB2 slurry to the surface of a carbon material substrate with an SiC (siliconcarbide) inner coating layer; after the preset layer is obtained, performing superhigh-temperature heat treatment sintering, so as to obtain the coating layer. The preparation method is characterizedin that by regulating, controlling and designing a proportional ratio of the slurry powder of composite ceramic, the content of component in the MB2-SiC (M is Zr, Ta or Hf) coating layer can be controlled; by controlling the brushing, impregnating or spraying times, the thickness of the MB2-SiC (M is Zr, Ta or Hf) coating layer can be controlled; the preset layer is subsequently subject to superhigh-temperature sintering heat treatment, so that the density of the coating layer is improved, and the bonding strength of interface of the inner coating layer is improved. The preparation method hasthe advantages that the preparation technology is simple, the coating layer is dense and uniform, the production cost is lower, and the preparation method is suitable for carbon material parts with various shapes and sizes.

Owner:CHINA UNIV OF MINING & TECH

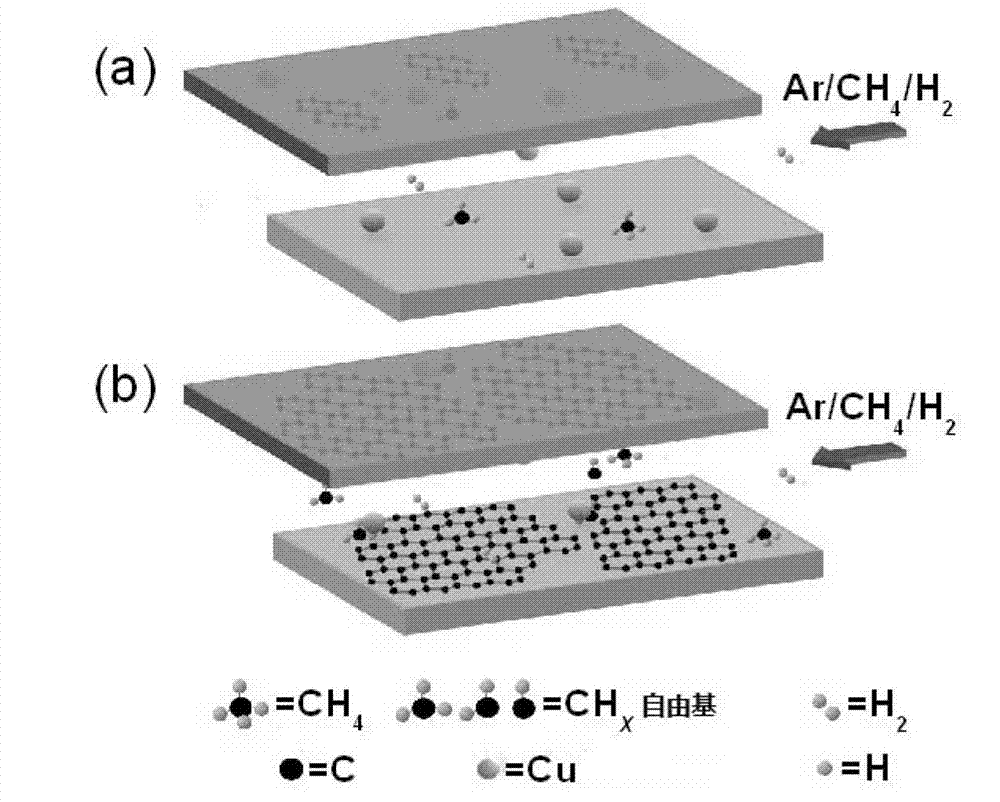

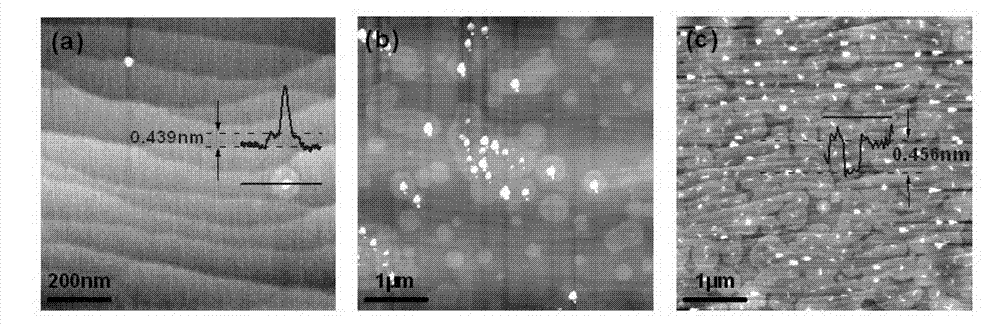

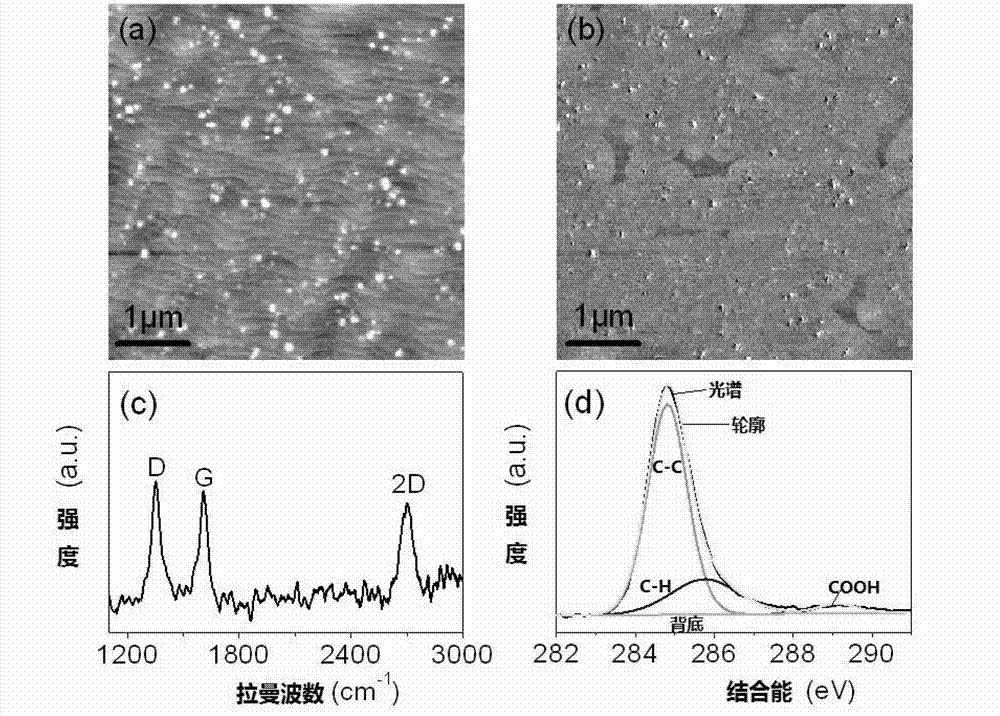

Method for growing large-area graphene on insulating substrate

The invention discloses a method for growing large-area graphene on an insulating substrate. According to the method, a growing substrate is taken as an insulating material, a copper foil is taken as a catalyst and a carbon source, nitrogen and protective gas are taken as source gases, and the large-area graphene is grown on the insulating substrate by adopting a two-step (low-pressure growth and high-pressure growth) chemical vapor deposition method and using the short-range catalytic effect of the copper coil through face-to-face contact of the insulating substrate and the copper foil. The method disclosed by the invention is simple in operation of the whole process and low in cost; and the sample preparation is very high in repeatability and is less interfered by external world. The prepared single-layer graphene can be made into a large-area circuit device by using an exposure method without needing a complex transfer technology.

Owner:PEKING UNIV

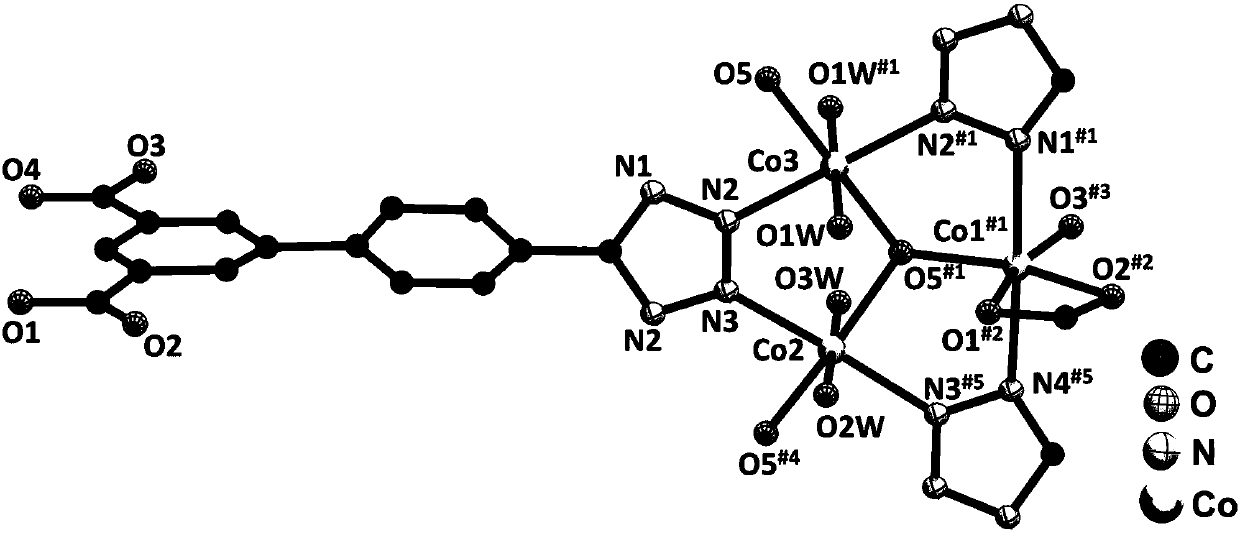

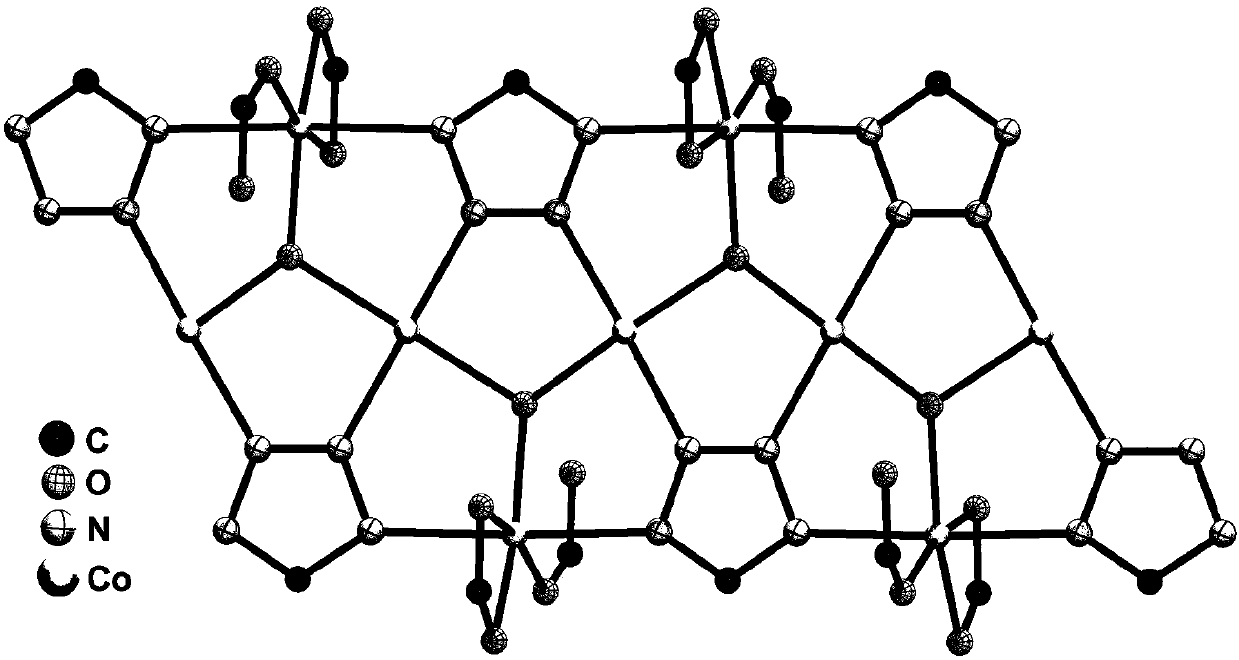

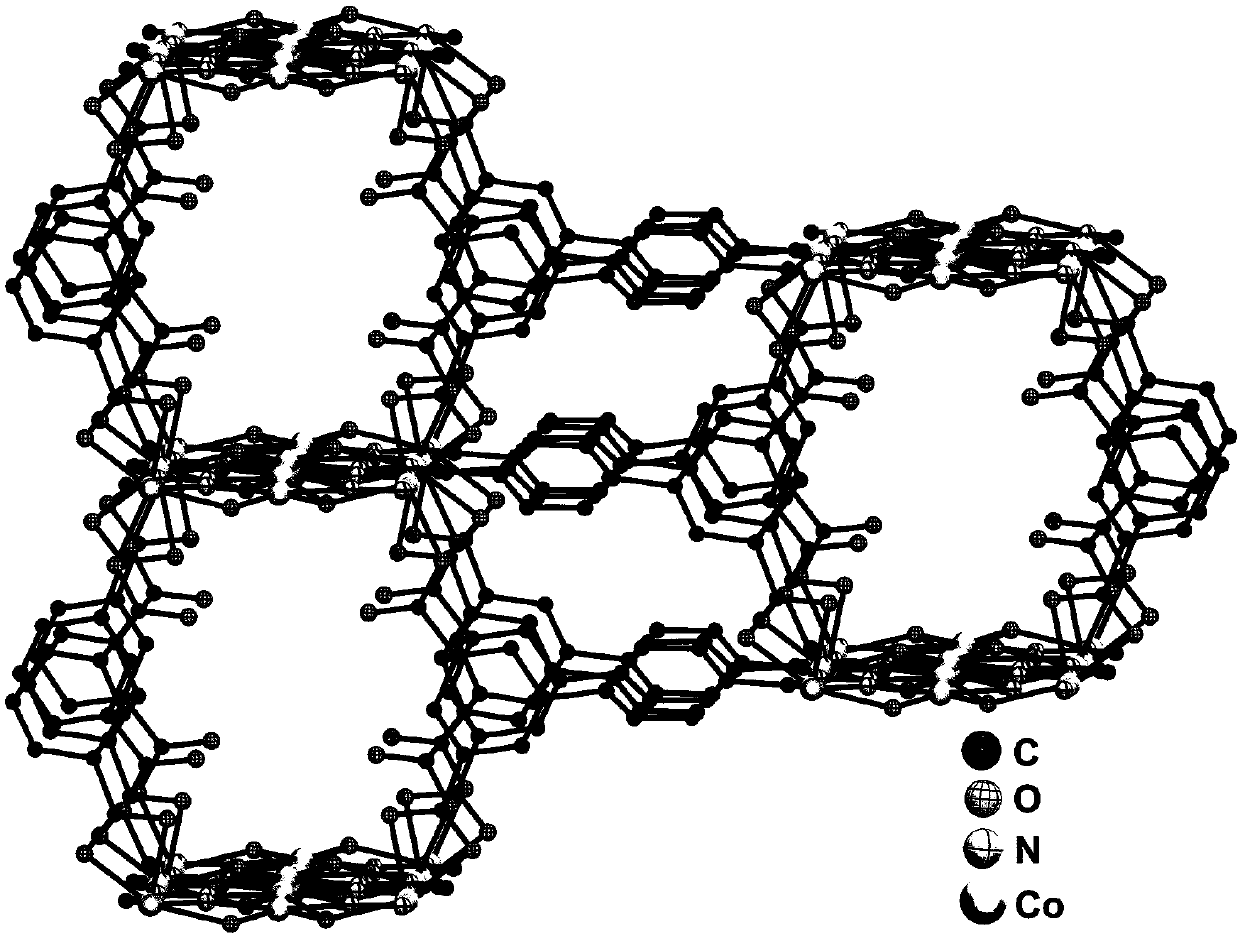

Preparation method and application of metal-organic framework material

InactiveCN106699817ASimple preparation processEasy to operateProductsGas treatmentN dimethylformamideMetal-organic framework

The invention relates to a preparation method and application of a metal-organic framework material. The preparation method of the metal-organic framework material comprises the following steps: (1) adding cobalt nitrate hexahydrate and 5-(4-(5-tetrazyl) phenyl)m-phthalic acid into a mixed solvent of N,N-dimethylformamide and water, and stirring evenly to obtain mixed liquid; (2) putting the mixed liquid into an airtight high pressure reaction still, heating to 110 to 110 DEG C, preserving heat, and then cooling to room temperature to obtain a reaction product; (3) filtering the obtained reaction product to obtain a red blocky crystal; (4) exchanging the red blocky crystal with methyl alcohol, and then vacuum heating at 220 DEG C for 5 to 7 hours, thus obtaining the metal-organic framework material. The metal-organic framework material is used for selective adsorption separation on CO2 in a gas mixture of CO and the CO2.

Owner:NORTHWEST UNIV(CN)

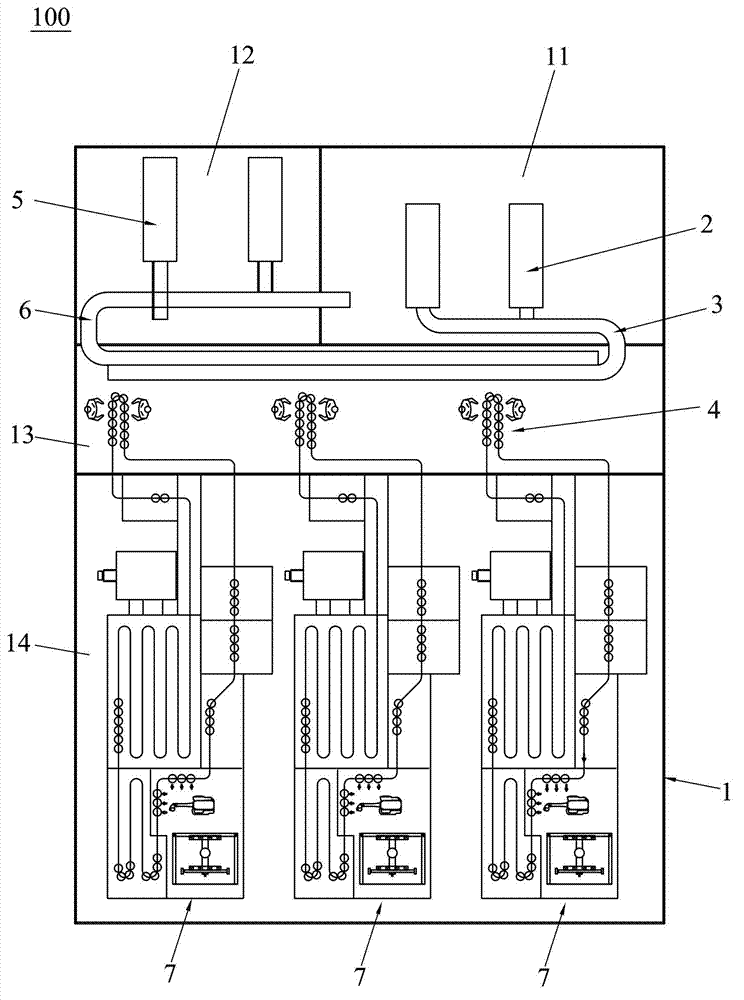

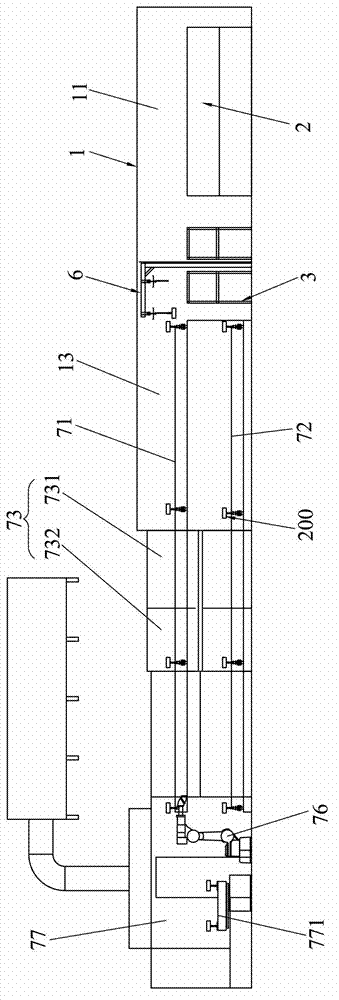

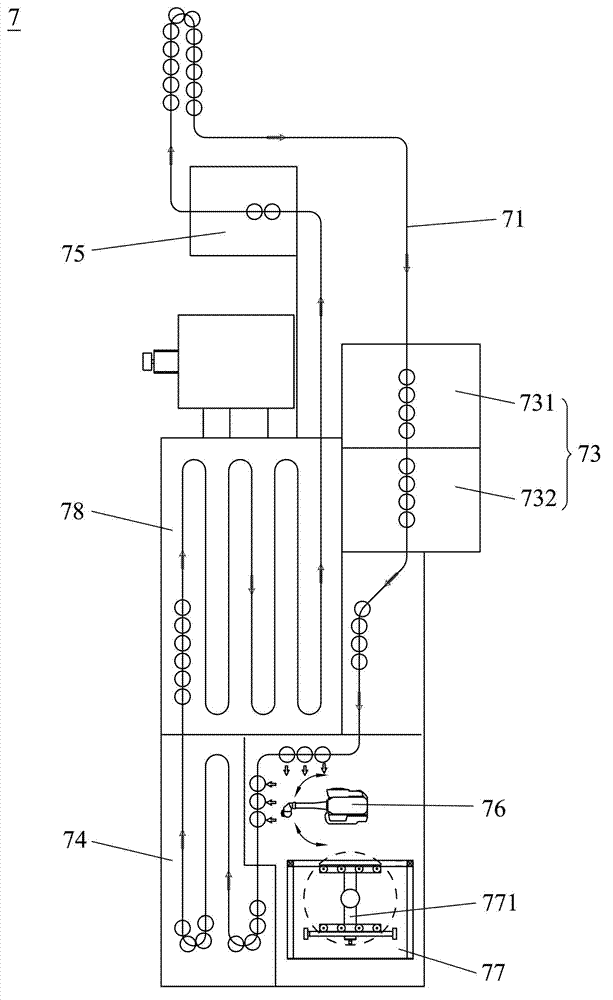

Spraying production line

InactiveCN102847630AQuick color change paintingReduce in quantitySpraying apparatusPretreated surfacesProduction lineEngineering

The invention discloses a spraying production line, which is applicable to conducting spraying on a workpiece clamped on a workpiece holder and comprises at least one spraying line. The spraying line comprises at least two circulation conveying chains, a dust removing chamber, a leveling chamber, a baking oven, as well as a manipulator and a spraying room that are used by the first and second circulation conveying chains together; the circulation conveying chains are arranged vertically; the workpiece holder enters the dust removing chamber, the spraying chamber, the leveling room and the baking oven in the conveying direction sequentially; the manipulator can seize or place the workpiece holder on the circulation conveying chains and the spraying room; the spraying room is provided with a color changing system and at least two spray guns; and the color changing system controls the spray guns to conduct color changing and spraying on the conveyed workpiece in turns. The spraying production line has the advantages that color changing and spraying are quick; the area occupied by equipment is reduced; the equipment utilization rate is increased; and the production efficiency is improved.

Owner:东莞丰裕电机有限公司

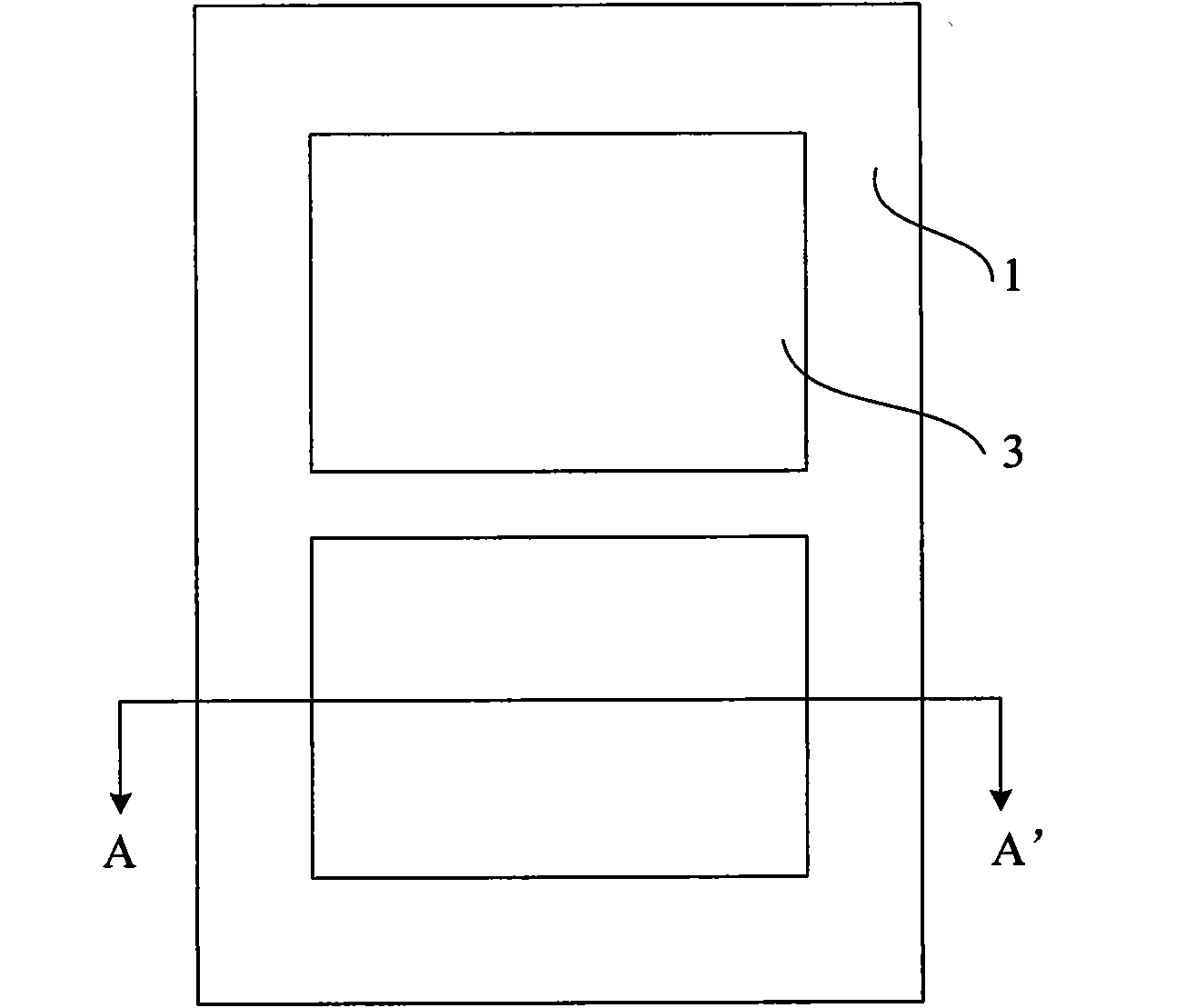

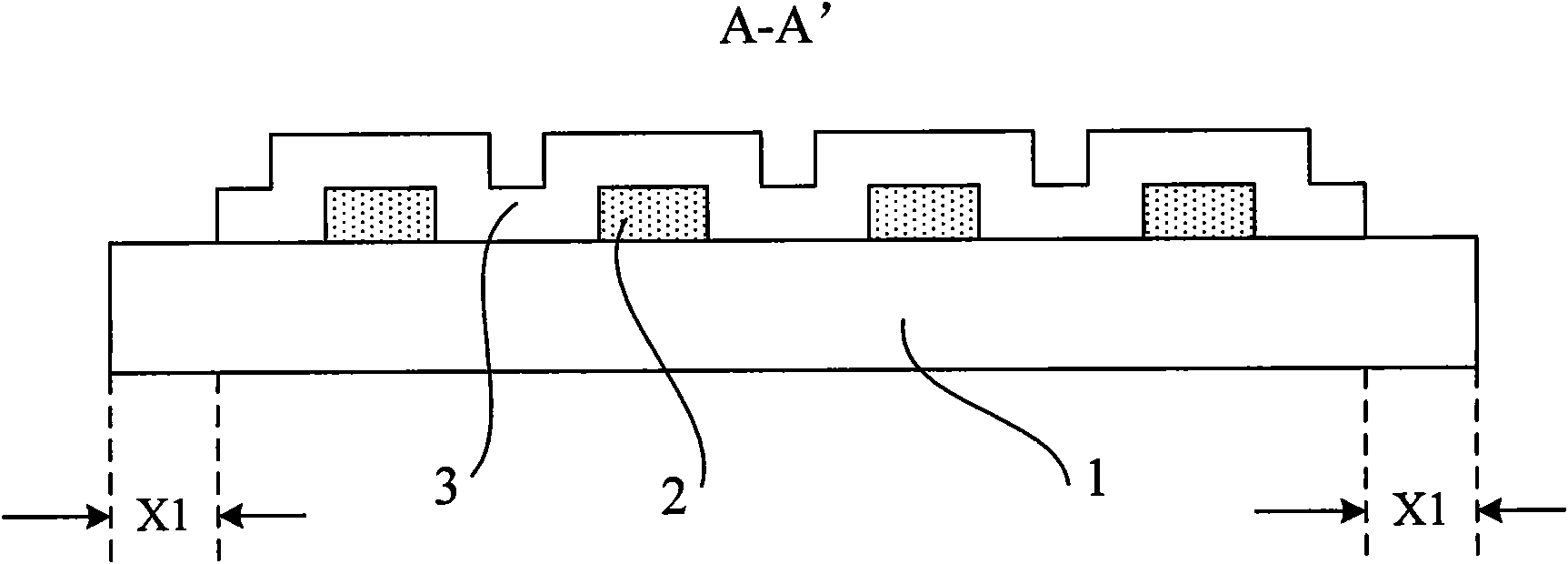

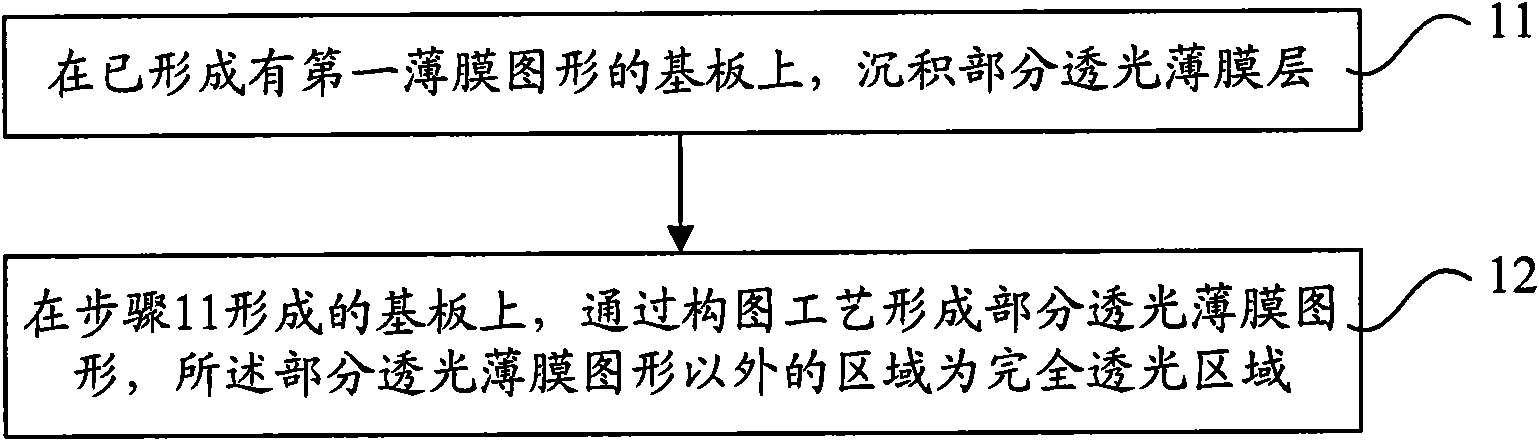

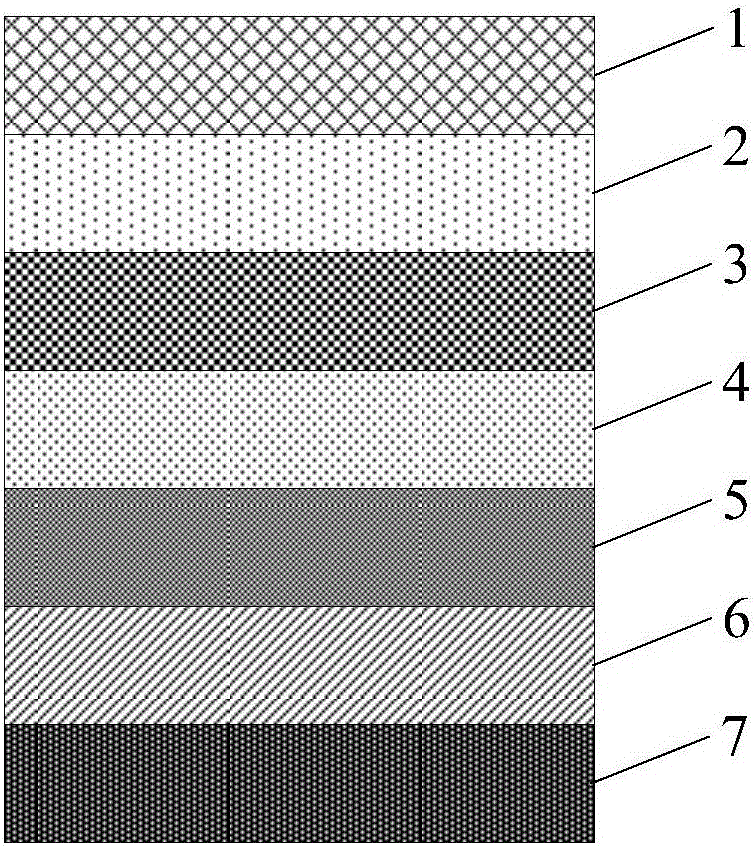

Mask and preparation method thereof

ActiveCN101995762ARealize the composition functionRealize functionOriginals for photomechanical treatmentMultiplexingMedicine

The invention relates to a mask and a preparation method thereof. The mask comprises a substrate, wherein a first film graph and a partially light-transmitting film graph are formed on the substrate; the partially light-transmitting film graph is positioned above or below the first film graph; and regions except for the partially light-transmitting film graph are completely light-transmitting regions. The mask of the invention can be prepared based on the conventional composition mask. The mask of the invention can realize composition function of the conventional composition mask and can realize light-blocking and light-transmitting functions of the conventional ultraviolet (UV) mask. In the process of preparing a thin film transistor liquid crystal display (TFT-LCD) by using the mask of the invention, the multiplexing of the masks required by a composition process and a box-aligning process can be realized, so the production cost of the TFT-LCD is reduced.

Owner:BOE TECH GRP CO LTD +1

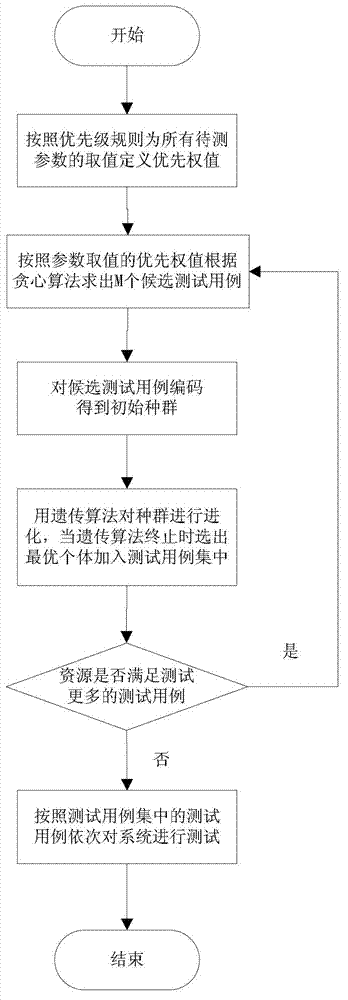

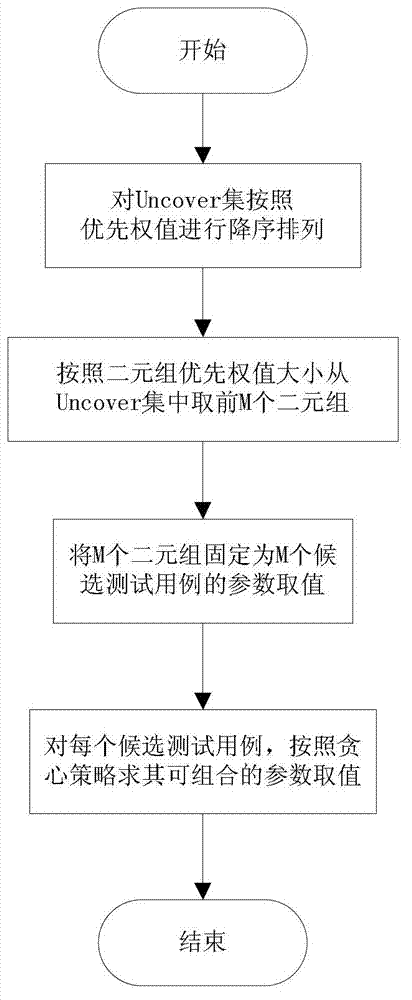

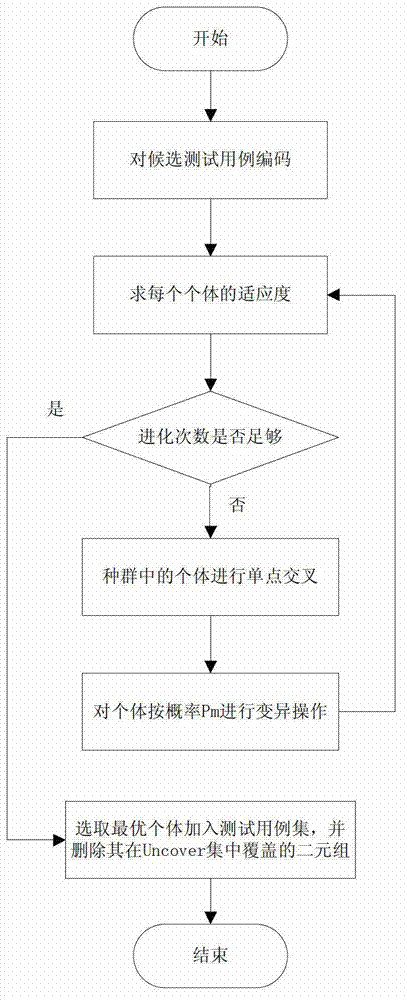

Pair-wise test method based on priority

ActiveCN102855185APromote generationReduce generation costSoftware testing/debuggingLimited resourcesGreedy algorithm

The invention discloses a pair-wise test method based on priority and belongs to the technical field of software testing. The method includes steps that rules are determined through the priority, and a priority value of a dereferencing of each parameter to be tested is defined; a greedy algorithm is utilized to obtain M candidate test cases according to an one dimensional expansion strategy and the priority of the dereferencing of each parameter to be tested; the candidate test cases are coded so that an initial population can be obtained, then the initial population is evolved by a provided genetic algorithm, when the genetic algorithm stops, optimum individual is selected among the initial population, and the optimum individual is added into a test case set; and certain times of executing the steps are limited according to test conditions, and the testing is performed according to the sequence of test cases obtained in the test case set during testing. By means of the method, problems that under the condition of limited resources, the key parameters and combination can not be fully tested, the time of generating the test cases is excessively long, the defect detection rate can not be passed and the like are solved.

Owner:HOHAI UNIV

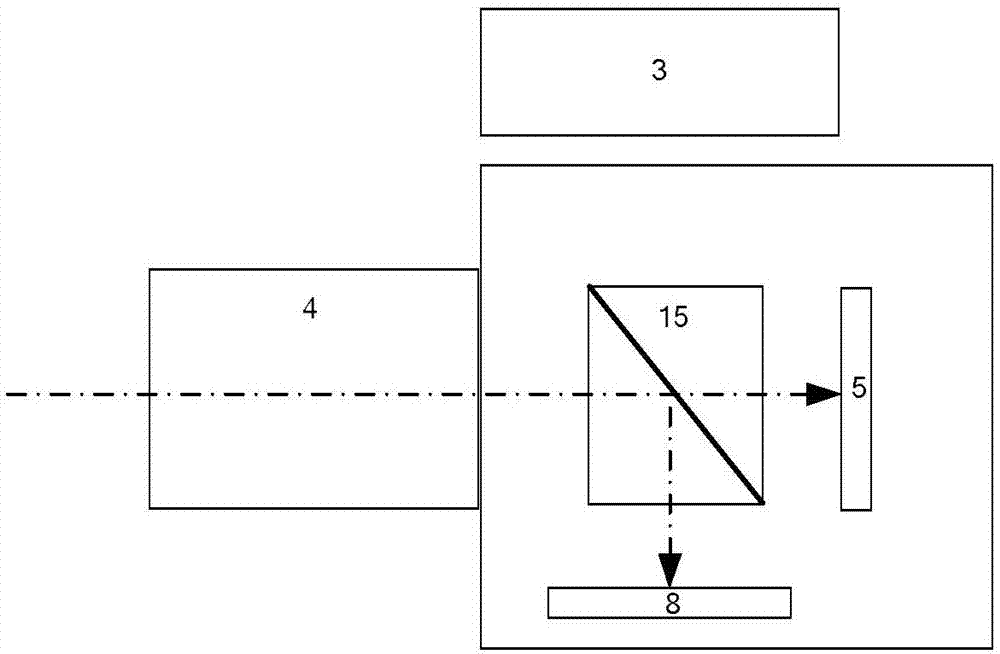

Dual-lens black light camera

PendingCN107580163AImprove signal-to-noise ratioImprove color imaging qualityTelevision system detailsColor signal processing circuitsColor imageInfrared

The invention discloses a dual-lens black light camera, which belongs to the technical field of low-illumination color imaging, and is used for solving the problem of poor nighttime color image quality of an existing low-illumination camera. The dual-lens black light camera adopts near-infrared light-supplementing illumination in case of low illumination, adopts a near-infrared anti-reflection lens and a single-color image sensor for photographing a near-infrared+visible light grayscale image, adopts a visible light lens parallel to an optical axis of the near-infrared anti-reflection lens anda color image sensor for photographing a visible light color image, performs denoising on the color image by taking the grayscale image as a guide, and then performs image detail and color fusion onthe grayscale image and the color image in a color and brightness separation space so as to obtain a low-illumination color image. The dual-lens black light camera can effectively improve the low-illumination color imaging quality and reduce the manufacturing cost of the camera.

Owner:四川精视科技有限公司

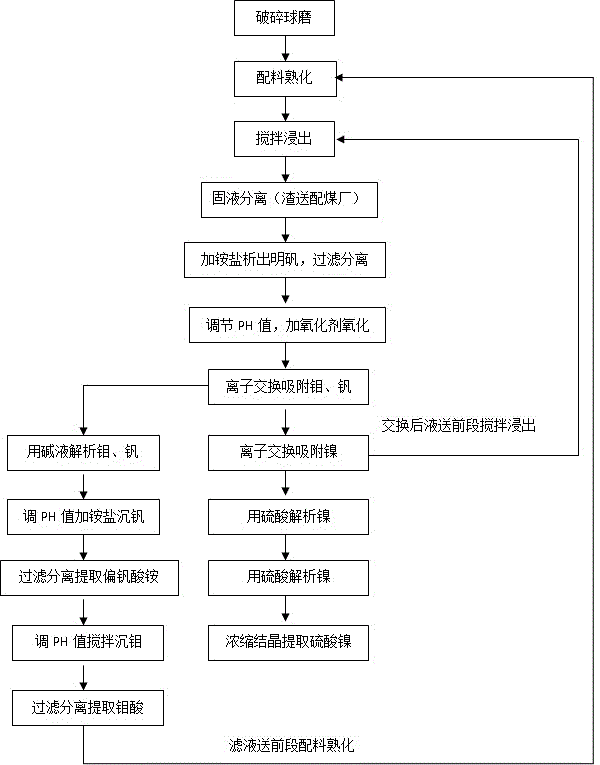

Production process for extracting elements such as aluminum, vanadium, molybdenum and nickel from black shale

InactiveCN104152687AReduce consumptionReduce generation costProcess efficiency improvementIonIon exchange

The invention discloses a production process for extracting elements such as aluminum, vanadium, molybdenum and nickel from black shale. The production process comprises the following steps: carrying out crushing and fine grinding on ores, adding an additive, water and concentrated sulfuric acid, uniformly stirring and then, sealing for storage and curing; stirring and leaching cured materials in water to obtain a solution of aluminum sulfate, nickel sulfate, molybdenum acyl sulfate and vanadium acyl sulfate, and carrying out liquid-solid separation; adding an ammonium salt or a potassium salt into filtrate to produce alum crystals, and carrying out filtering separation; regulating the PH value of the filtrate, then carrying out oxidization, then, adsorbing by using anion resin and desorbing by using an lkali liquor; regulating the PH value of the desorbing liquor, adding the ammonium salt to produce vanadate, and carrying out filtering separation; re-regulating the PH value of the filtrate to produce molybdate crystals, and carrying out filtering separation; adsorbing nickel from ion-exchanged liquor by using amino phosphate rein, and generating nickel sulfate by virtue of elution, evaporation and concentration of the sulfuric acid, and carrying out crystallizing separation on the nickel sulfate; and returning the filtrate for use.

Owner:罗侣旦

Preparation method of large-particle-size aluminum-doped cobalt trioxide

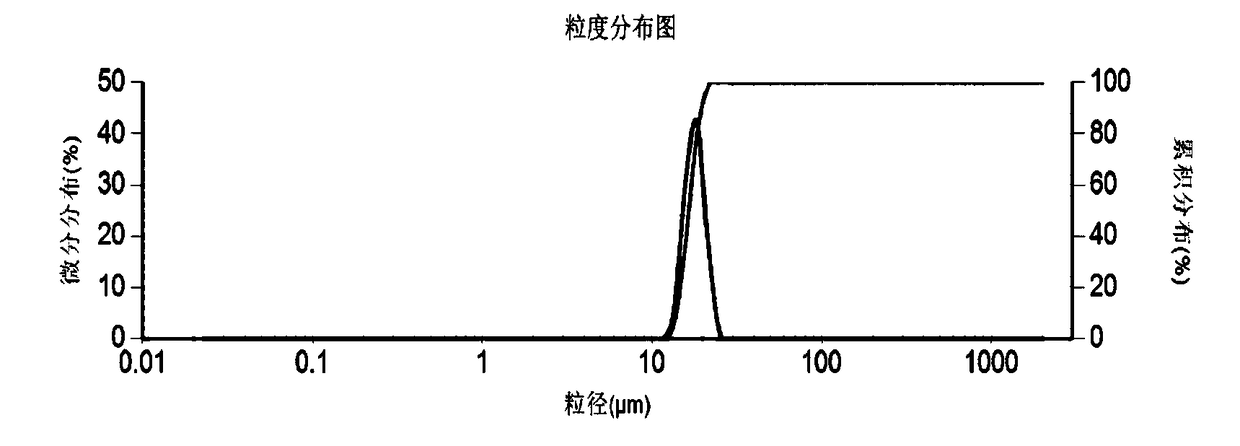

ActiveCN108649219AIncrease productivityReduce generation costCell electrodesLi-accumulatorsCobalt oxideChemistry

The invention provides a preparation method of large-particle-size aluminum-doped cobalt trioxide, which adopts a continuous production method, and simultaneously removes supernatant containing no material while performing a neutralization precipitation reaction to obtain aluminum-contained cobalt carbonate seed crystal having a particle diameter D50 of 10 to 14.5 [mu]m; further, an aluminum cobalt solution and an ammonium hydrogen carbonate solution are added to the seed crystal for neutralization precipitation reaction until large particle diameter aluminum-doped cobalt carbonate having a particle diameter D50 of 18 to 21 [mu]m is obtained; the obtained aluminum-doped cobalt carbonate is subjected to iron removal, dehydration, washing and drying, and sectional thermal decomposition to obtain a black powdery aluminum-doped cobalt oxide product having a particle size D50 of 17.5-19 [mu]m. The cobalt trioxide doped aluminum obtained by the method of the invention is more uniform, the final product stably obtained by the stable reaction system is relatively stable, and the cobalt carbonate does not appear in the form of small particles or blocks; continuous production can be realized; and the production efficiency is higher.

Owner:JINGMEN GEM NEW MATERIAL

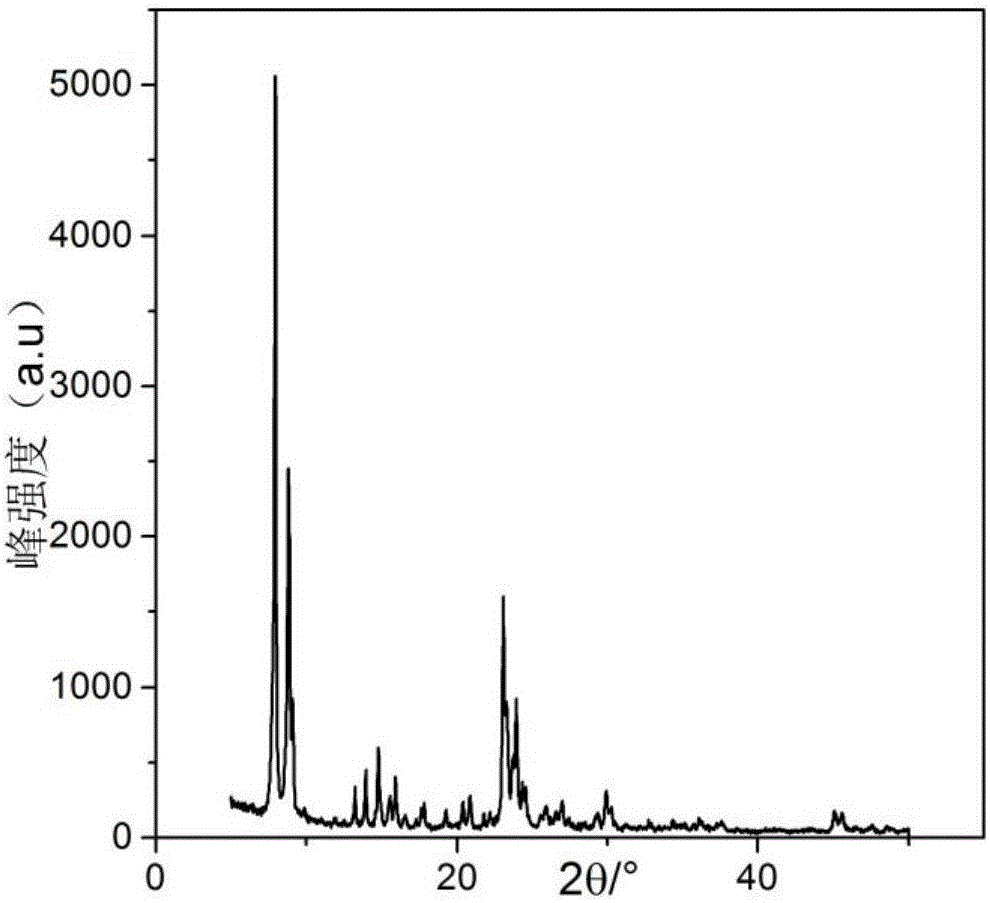

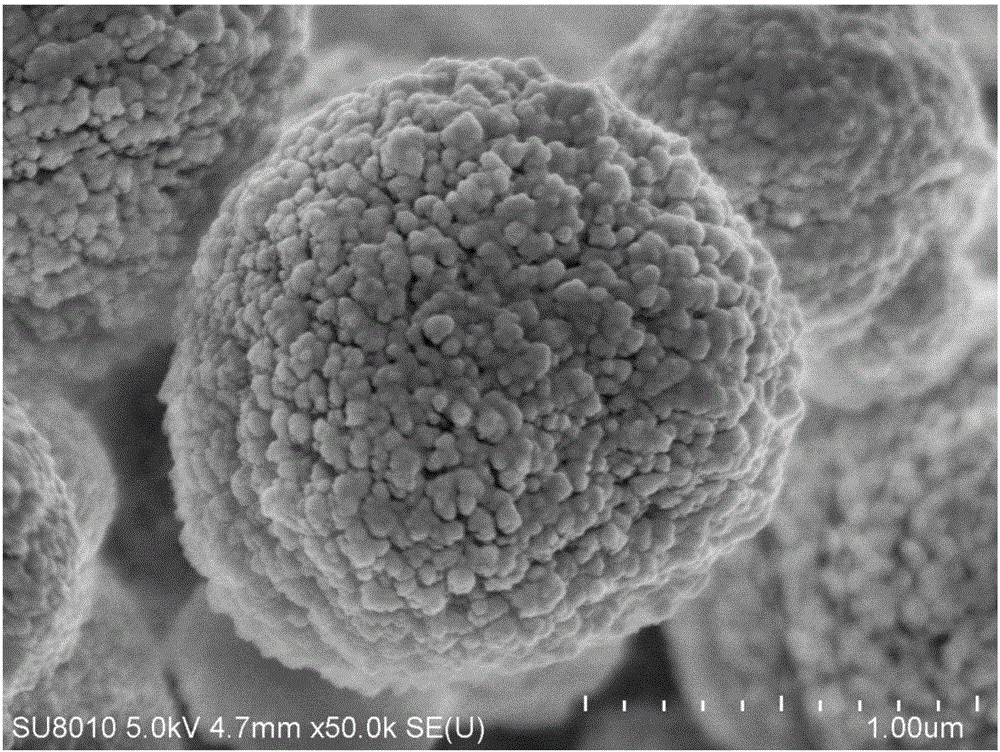

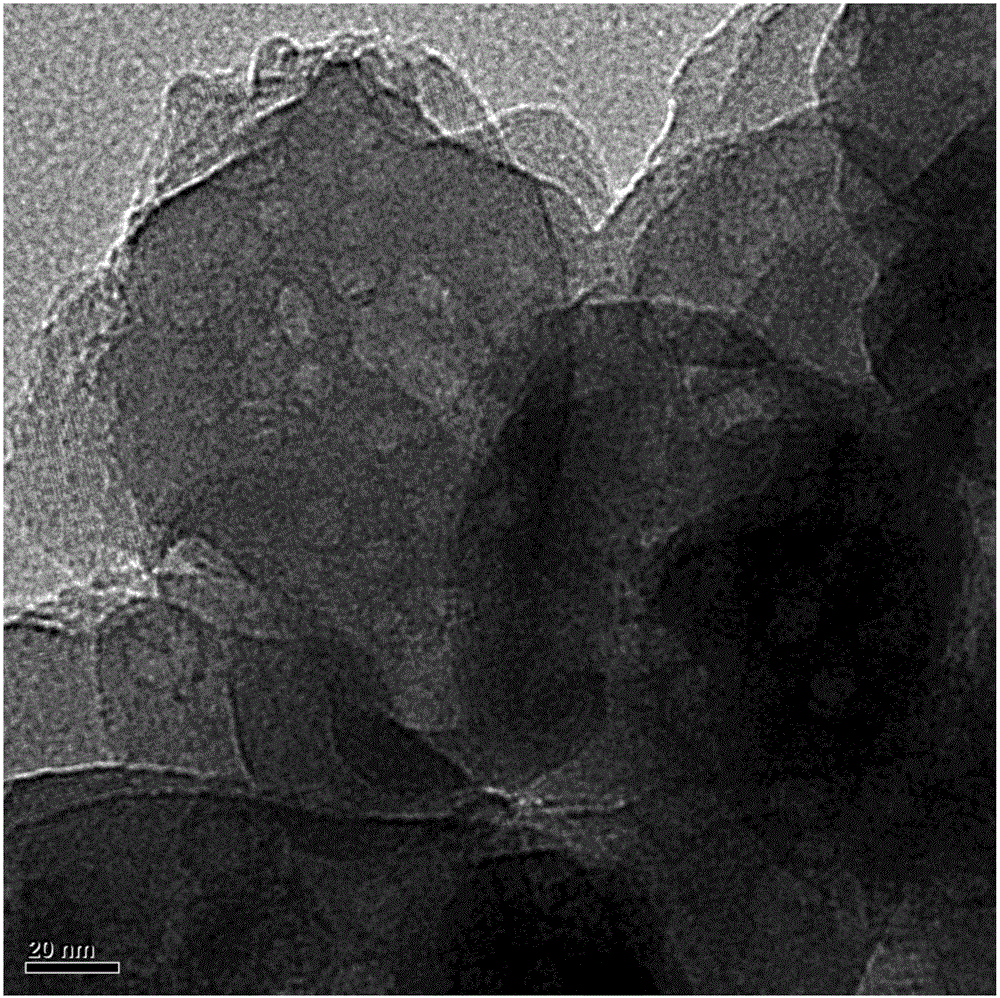

Multilevel structure ZSM-5 zeolite molecular sieve, as well as synthetic method and application thereof

ActiveCN106673008AImprove diffusion abilityHigh catalytic activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSide reaction

The invention relates to a synthesized multilevel structure ZSM-5 zeolite molecular sieve with intracrystalline meso pores and intercrystalline meso pores, as well as a synthetic method and an application thereof. Except micropores of the zeolite structure, the multilevel structure ZSM-5 zeolite molecular sieve comprises the intracrystalline mesoporous and intercrystalline mesoporous structure, wherein primary nanometer crystal grain size is 40-500nm, and secondary accumulated particle size is 500nm-5[mu]m. The structure greatly improves diffusion performance and the catalyst activity of the molecular sieve, reduces possibility of generation of side reaction and carbon deposit, improves carbon accommodating capability of the molecular sieve catalyst, and prolongs life of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

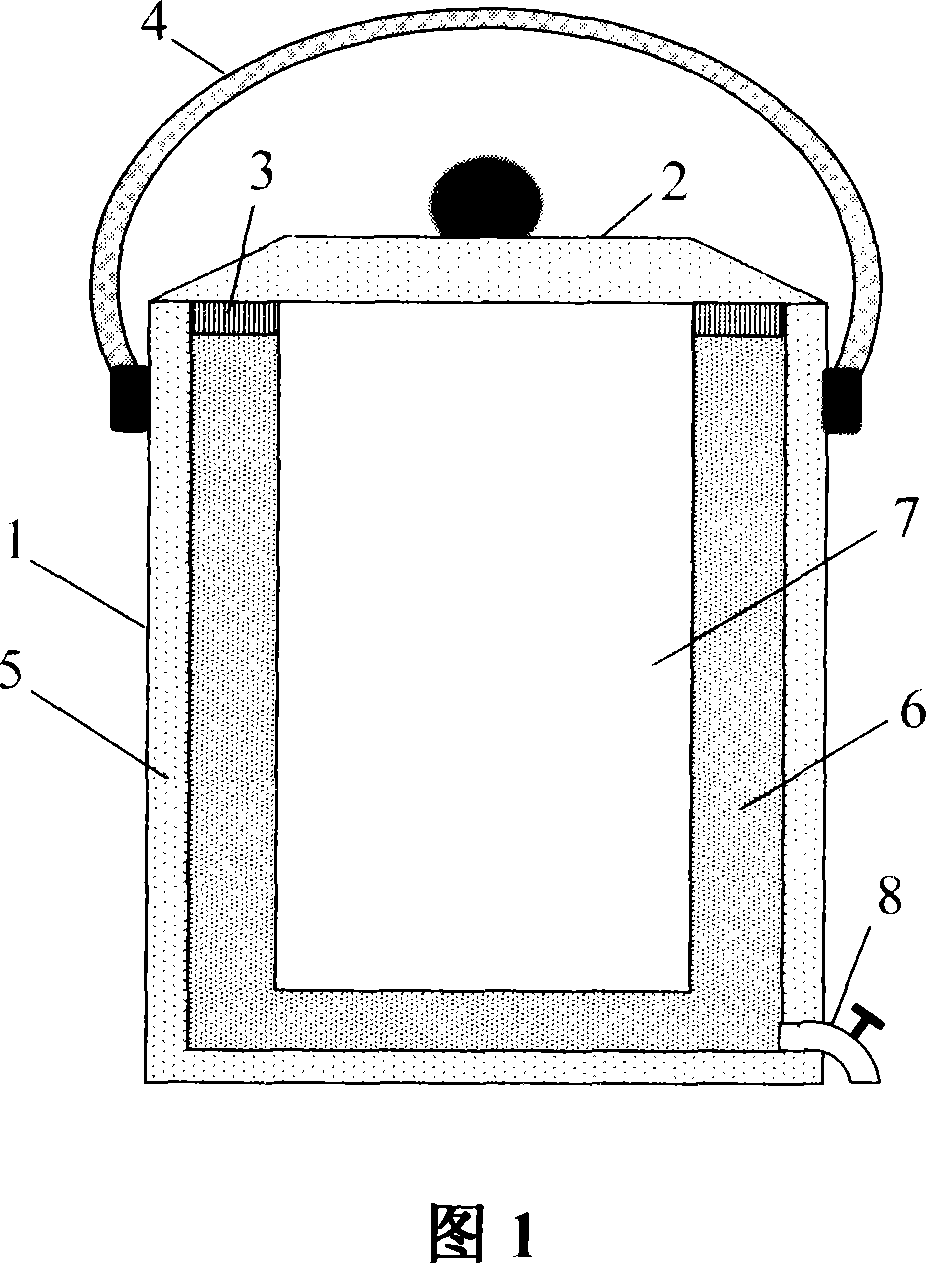

Non-electric environment friendly energy-saving portable freezing box

InactiveCN101196359ANo pollutionLow costDomestic cooling apparatusLighting and heating apparatusElectricityCooling chamber

The invention relates to an environmental protection energy-saving portable cooling chamber without using electricity, which comprises a chamber body 1, a heat preservation cover 2 and a heat preservation layer 5. The invention is characterized in that: the heat preservation layer 2 has a freezing layer 6 internally filled with refrigerant. The freezing layer 6 has a freezing room 7 internally, which has a sealing ring 3 at the opening of the chamber body 1 at upper section; the sealing ring 3 is tightly adhered to the freezing room 7 and the heat preservation layer 5 to seal the freezing layer 6. A lifting handle 4 is arranged on external wall at upper section of the chamber body 1, which is convenient for carry when going out. By applying normal ice and salt as the refrigerant without using electricity, the invention has low cost and is able to be recovered and reused without polluting any environment. The technology is realized by adopting common technology as adding refrigeration layer in the heat preservation box, the invention has quick refrigeration effect and is able to keep the low temperature environment for long time, which has the advantages of low producing cost, light and easy for promotion, thereby being a revolutionary product in refrigeration industry.

Owner:赵忠华

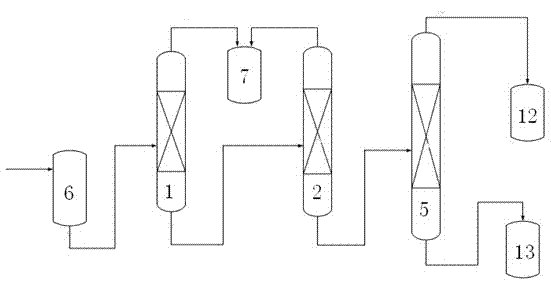

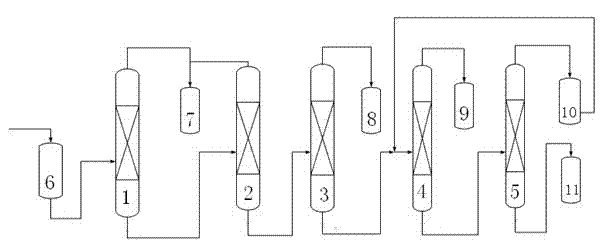

Ethylene glycol rectification device system and rectification technique in industry of producing ethylene glycol by synthesis gas

ActiveCN103193595AIncrease productionIncrease incomeOrganic compound preparationHydroxy compound preparationHydrogenation reactionProcess engineering

The invention discloses an ethylene glycol rectification device system in industry of producing ethylene glycol by synthesis gas. The ethylene glycol rectification device system comprises a primary dealcoholization tower, a secondary dealcoholization tower, an ethylene glycol refining tower, wherein the primary dealcoholization tower is connected with a hydrogenation reaction product tank by a pipeline, the secondary dealcoholization tower is connected with the primary dealcoholization tower by a pipeline, the ethylene glycol refining tower is connected with the secondary dealcoholization tower, an ethanol removal tower and a butylenes glycol removal tower which are connected by a pipeline are arranged on the pipeline between the secondary dealcoholization tower and the ethylene glycol refining tower, the top of the ethanol removal tower is connected with an ethanol tank, and the top of the butylenes glycol removal tower is connected with the butylenes glycol tank. The invention further discloses a rectification technique in industry of producing ethylene glycol by synthesis gas. According to the ethylene glycol rectification device system in industry of producing ethylene glycol by synthesis gas, the steam consumption can be reduced, the energy consumption can be saved, the purity of the methanol can be improved, the output of premium grade products can be increased, the production cost can be greatly lowered, and the enterprise benefits can be increased.

Owner:PUJING CHEM IND SHA

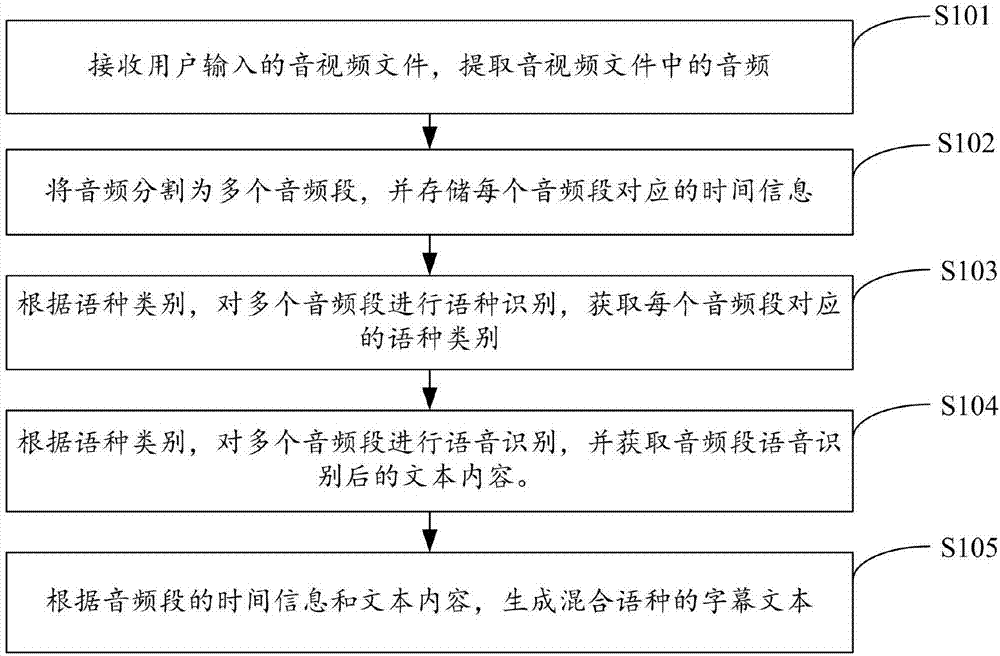

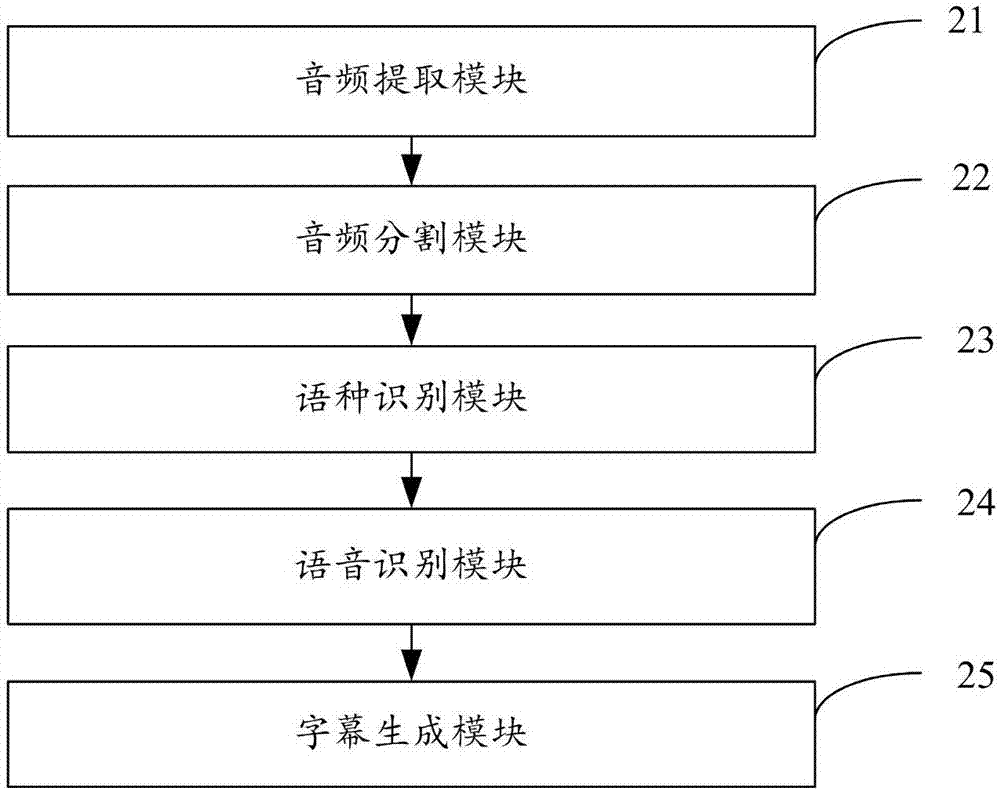

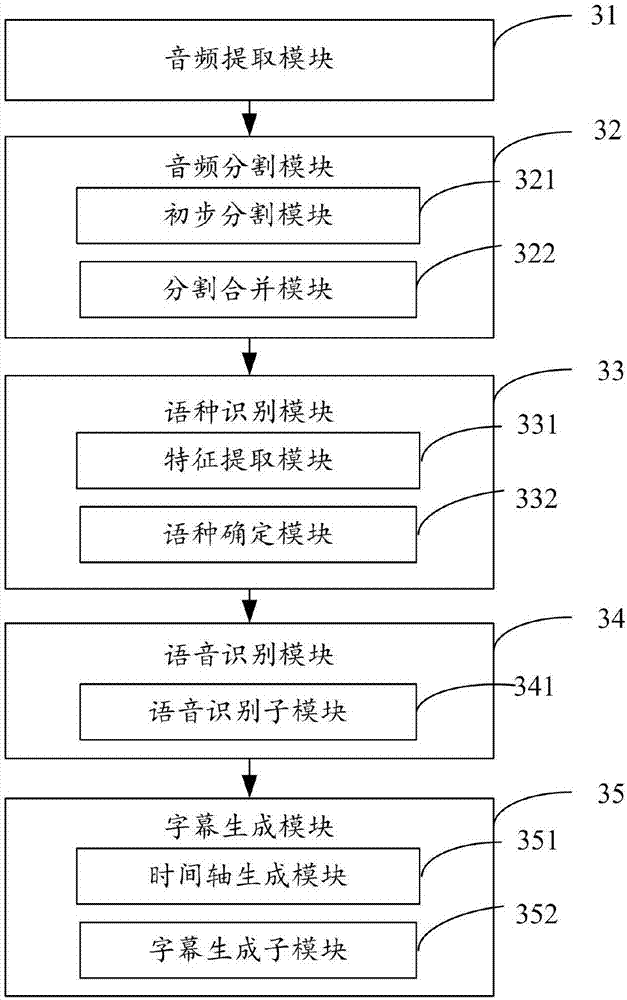

Method and apparatus for generating mixed-language-based subtitle file

InactiveCN106878805AImprove production efficiencyReduce generation costSelective content distributionTime informationUser input

The invention, which is applicable to the field of the computer technology, provides a method and apparatus for generating a mixed-language-based subtitle file. The method comprises: receiving an audio / video file inputted by a user and extracting an audio part in the audio / video file; segmenting the audio part into a plurality of audio segments and storing time information corresponding to each audio segment; carrying out language identification on the plurality of audio segments to obtain the language types corresponding to the audio segments; according to the language types, carrying out voice identification on the plurality of audio segments and obtaining text contents after the voice identification of the audio segments; and according to the time information of the audio segments and the text contents, generating a mixed-language-based subtitle file. Therefore, on the basis of language identification and voice identification, automatic generation of a mixed-language-based subtitle file can be realized, so that the accuracy of mixed-language voice recognition and the generation efficiency of the mixed-language-based subtitle file can be improved and the generation cost of the mixed-language-based subtitle file can be reduced.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Environment-friendly nanometer formaldehyde purification scavenger

InactiveCN103537164AReduce the ratioImprove clearanceDispersed particle separationScavengerPowder mixture

The invention discloses an environment-friendly nanometer formaldehyde purification scavenger which comprises the following components in percentage by weight: 1-3 percent of natural plant extract, 15-30 percent of nanometer TIO2 sol, 1-3 percent of sodium dodecyl benzene sulfonate and the balance of deionized water. The natural plant extract is amino acids which are extracted from powder mixture of more than two of tea, aloe, chlorophytum comosum and hedera helix through a supercritical method. The natural plants are used in the components of the environment-friendly nanometer formaldehyde purification scavenger; therefore, the percentage of other chemical materials is correspondingly reduced and secondary pollution caused by the air purifying agent can be reduced. The environment-friendly nanometer formaldehyde purification scavenger has strong absorption, good purifying effect and high clearance rate for harmful gas such as benzene series substances with weak polarity or non-polarity. When the environment-friendly nanometer formaldehyde purification scavenger is prepared, the production process is simple, and the production cost is low.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

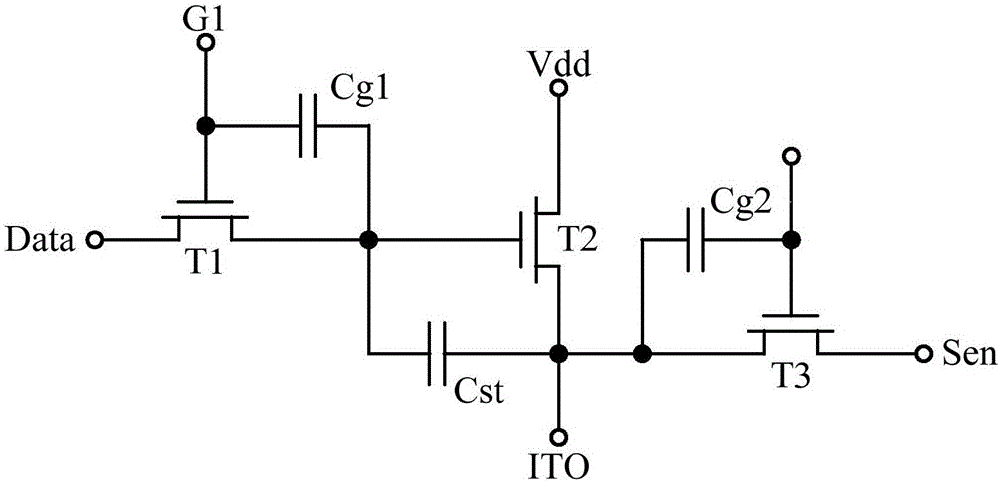

Method of testing driving circuit

The invention discloses a method of testing a driving circuit, and belongs to the field of display. The method comprises the following steps: inputting a data signal, a gate line scanning signal, a voltage signal, and a first control signal of a first level to a data input end, a gate scanning input end, a power end and a sensing voltage end of a driving circuit respectively; making a pixel storage capacitor perform charging by inputting a second control signal of a second level to a sensing scanning input end of the driving circuit, and measuring a first voltage at the anode end of an organic light emitting diode OLED of the driving circuit; making the pixel storage capacitor perform discharging by inputting a third control signal of a third level to the sensing scanning input end of the driving circuit, and measuring a second voltage at the anode end of the OLED of the driving circuit; and determining whether the driving circuit is abnormal according to the first voltage and the second voltage. The cost of production can be reduced.

Owner:BOE TECH GRP CO LTD

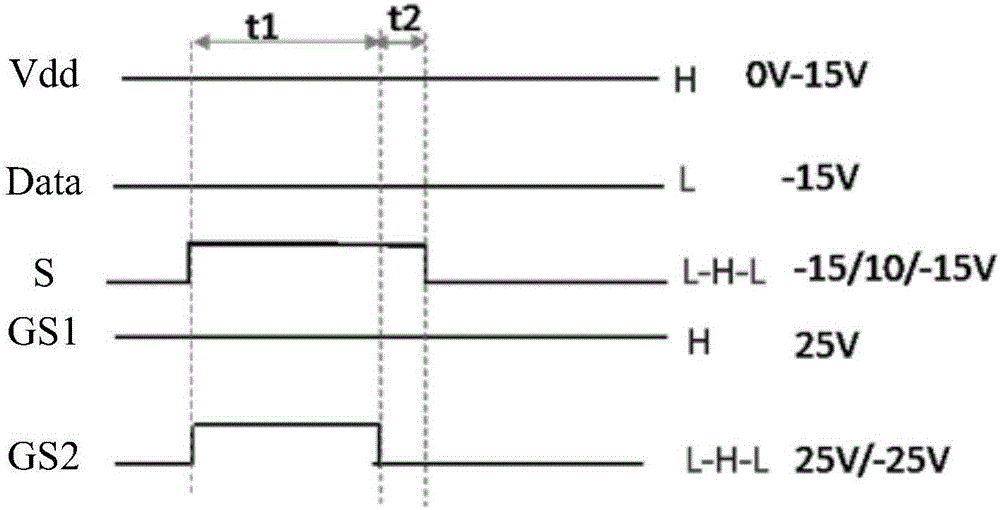

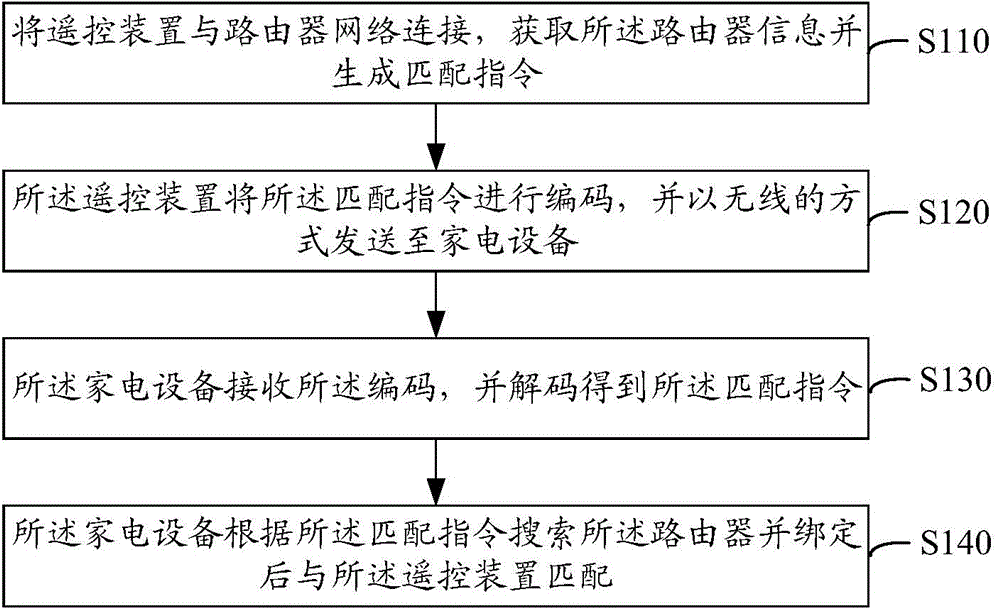

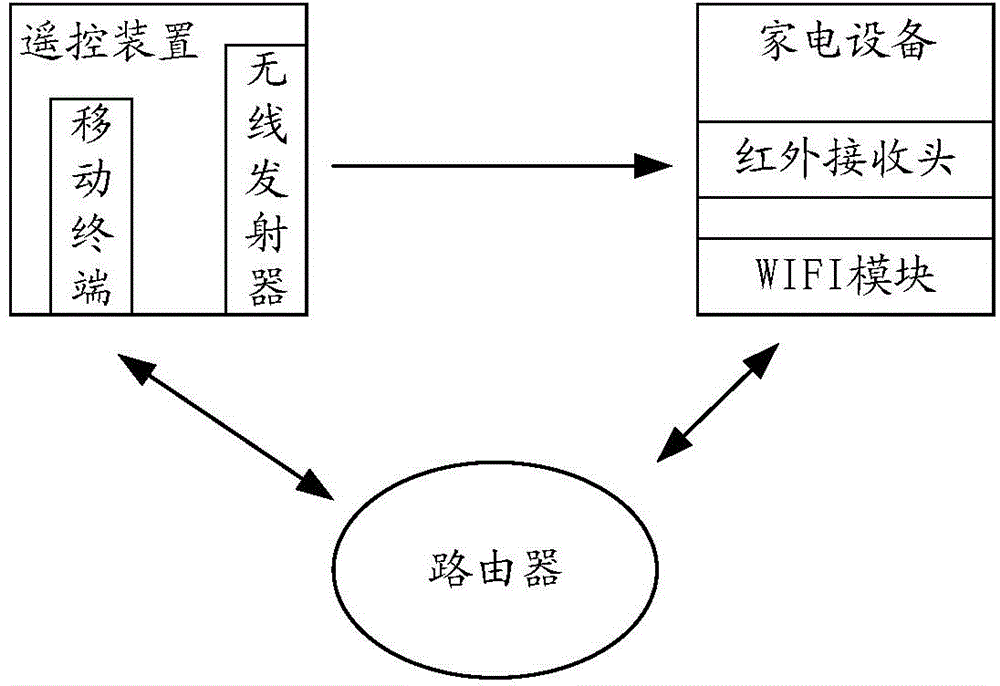

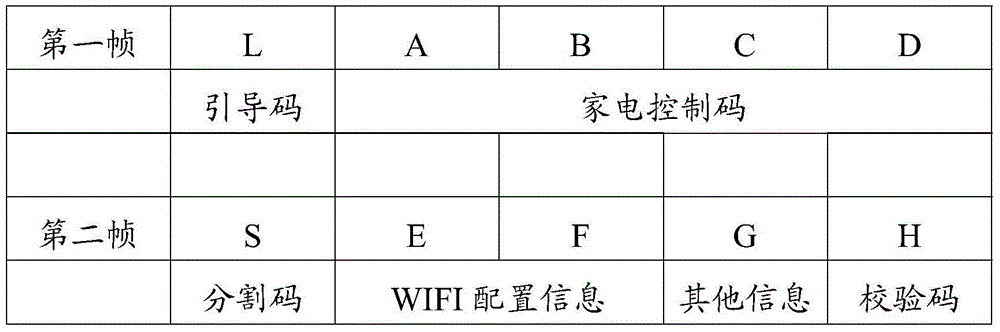

Remote control device matching method and system for household appliance

ActiveCN104574929ASimple and efficient operationReduce generation costNon-electrical signal transmission systemsEmbedded systemRemote control

The invention discloses a remote control device matching method and a remote control device matching system for a household appliance. The method comprises the following steps: connecting a remote control device with a router by a network to acquire router information and generate a matching instruction; encoding the matching instruction by virtue of the remote control device and sending the codes to the household appliance in a wireless manner; receiving the codes by the household appliance and decoding to acquire a matching instruction; searching the router by the household appliance according to the matching instruction, binding and matching with the remote control device. By utilizing the remote control device, the matching instruction is sent to the household appliance by a common remote control signal, and the household appliance achieves the binding with the router according to the instruction and is matched with the remote control device. The matching method is easy, convenient and quick to operate; matching marks such as two-dimension codes are not needed to be set on the household appliance, so that the production cost is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

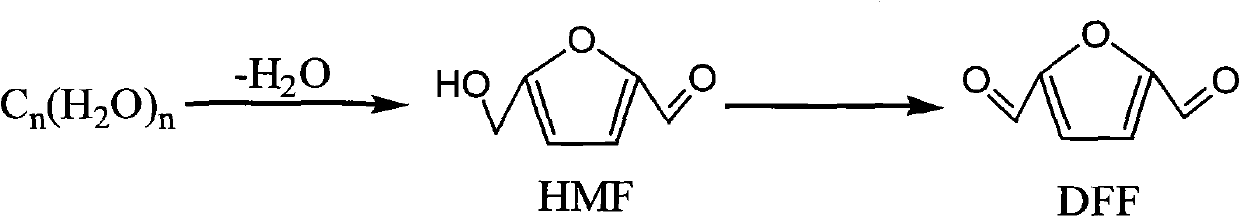

Method for catalysis-synthesizing 2,5-dicarbaldehyde by carbohydrate

The invention relates to a method for catalysis-synthesizing 2,5-dicarbaldehyde by carbohydrate; carbohydrate is used as raw material, N,N-dimethylacetylamide is used as reaction medium, sodium bromide is used as additive, 5-hydroxymethylfurfural is dehydrated under acid catalysis, vandic salt is added as the catalyst, and air flows in under normal pressure to carry out oxidizing reaction, so as to synthesize 2,5-dicarbaldehyde; in the method, the reaction condition is mild, the raw materials and the catalyst are obtained easily, the method has high 2,5-dicarbaldehyde yield and the reaction process is easily operated.

Owner:SICHUAN UNIV

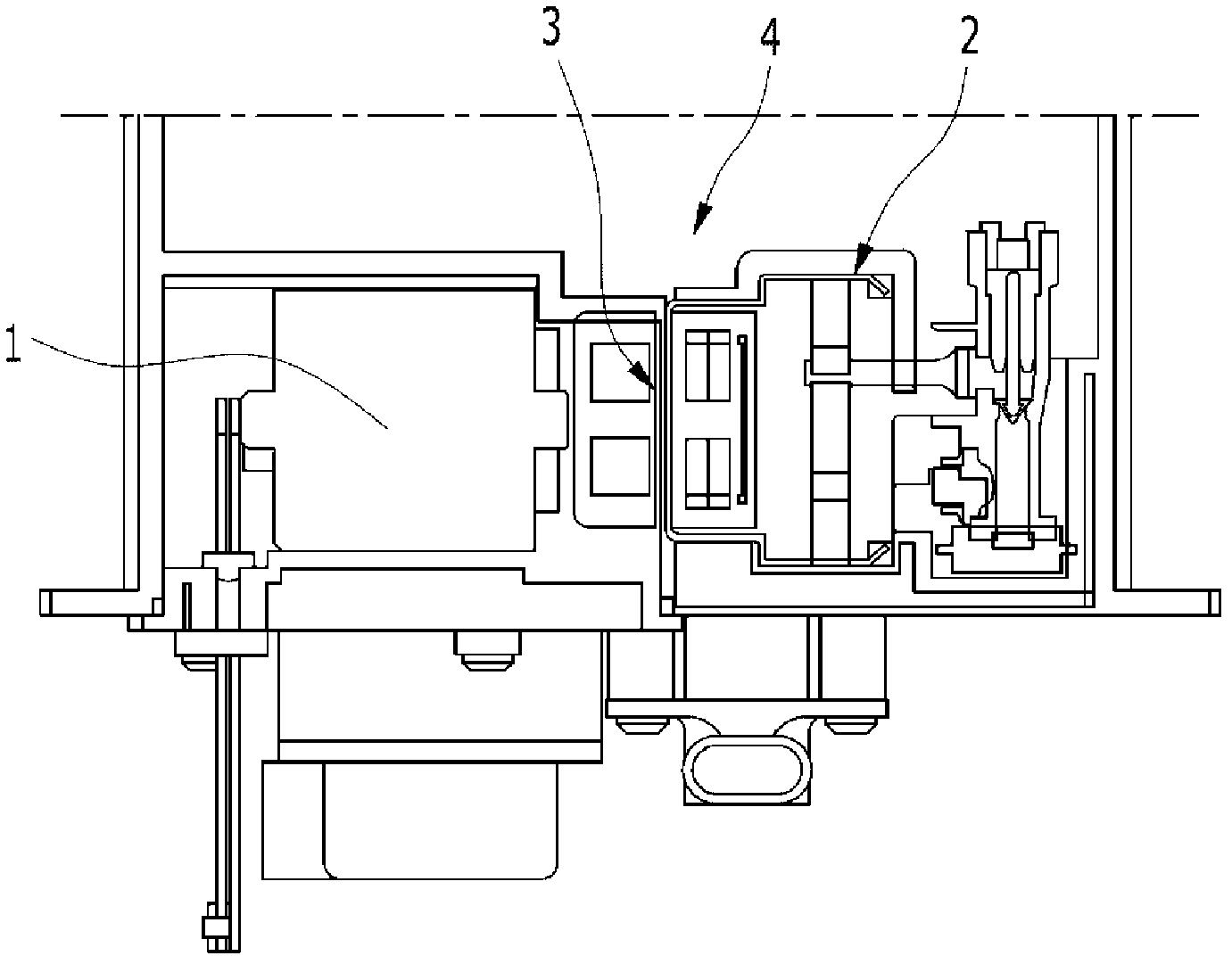

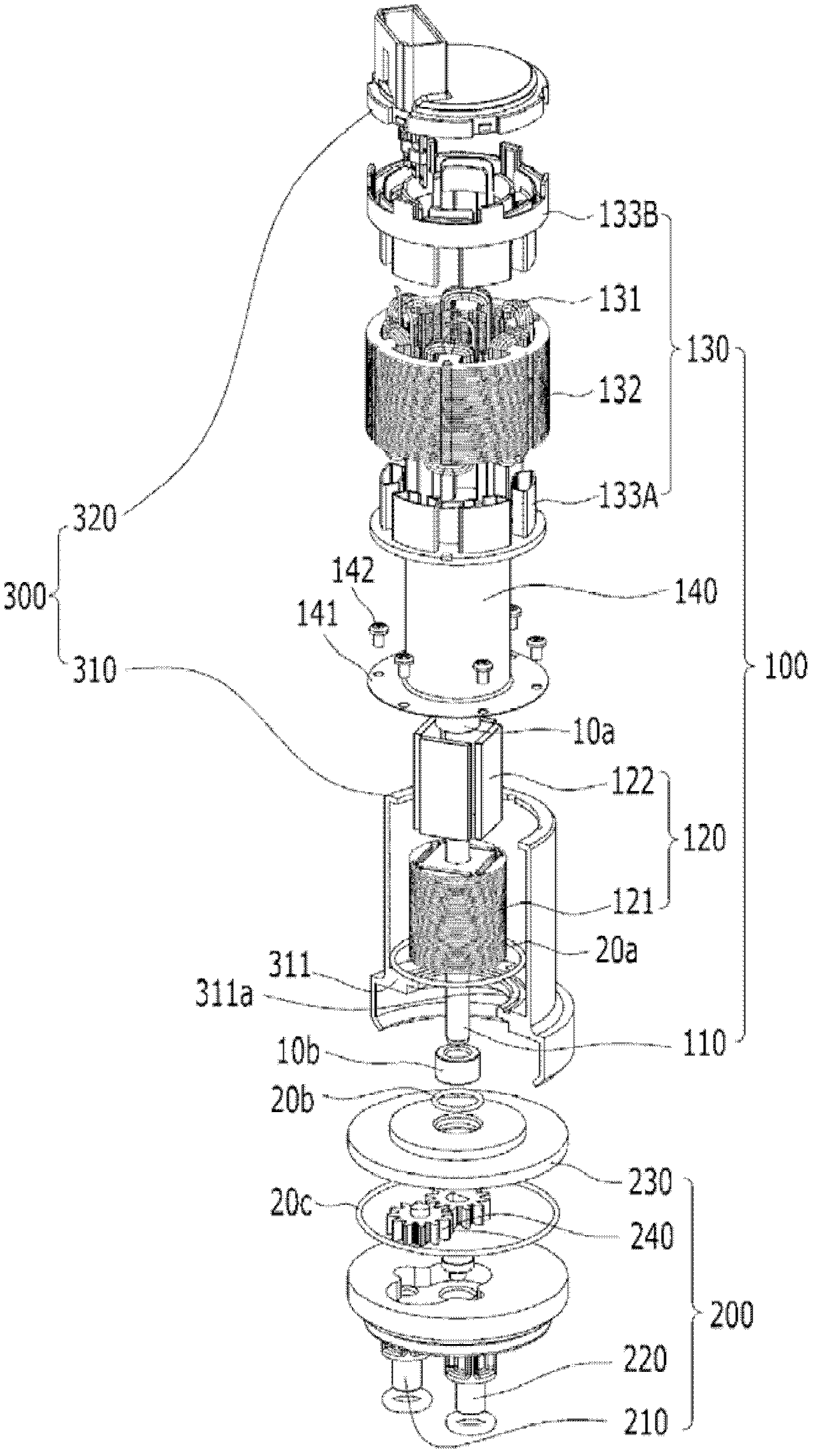

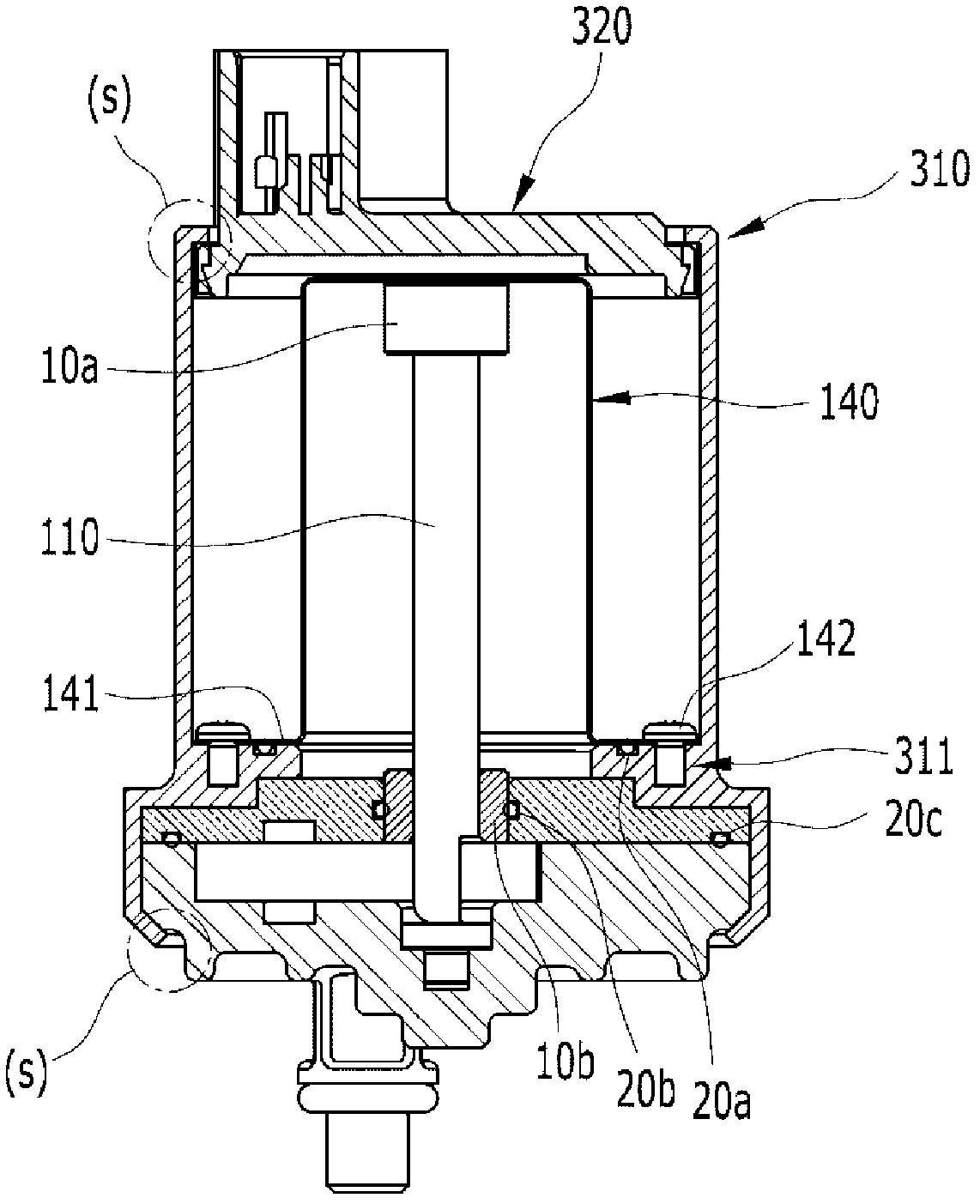

Pump structure for urea SCR system

InactiveCN103016338AReduce generation costReduce noiseExhaust apparatusDispersed particle separationEngineeringMechanical engineering

The invention discloses a pump structure for a urea SCR system and discloses a pump unit for a urea SCR system. A pump unit for a urea-SCR system may use a fuel pump of a vehicle engine and may have a case portion surrounding a motor portion and a pump portion. The motor portion may include a barrier wall surrounding a rotator so as to separate the rotator from a stator of the motor portion, and the pump portion includes a shield in which a suction hole and a supply hole for fluid are formed and that is disposed between the pump portion and the motor portion so as to prevent fluid from leaking into the motor portion, so the motor is protected from the urea solution to prevent corrosion thereof, manufacturing cost is reduced, and noise caused by the vibration is reduced.

Owner:HYUNDAI MOTOR CO LTD +1

A kind of preparation method of feed additive-amino acid trace element chelate

InactiveCN102258123ASimple processReduce generation costAnimal feeding stuffAccessory food factorsFood additiveManganese

The invention discloses a preparation method of a feed additive-amino acid trace element chelate. The product of the invention is a high-tech feed additive, which contains not only amino acids but also trace elements easily absorbed by animals. The prepared The feed has good palatability, high absorption rate, and is easy to transport. It can strengthen the activity of enzymes in animals, improve the utilization rate of protein, fat and vitamins, and thus improve the growth performance of animals. It is suitable for both animals and fish. The raw materials used in the production of this product are: amino acids (methionine, lysine, L-tryptophan), inorganic salts (ferrous sulfate, copper sulfate, manganese sulfate, zinc sulfate), 10% aqueous sodium hydroxide solution, absolute ethanol .

Owner:陈士安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com