Steelmaking-continuous casting tundish batch plan method and system

A continuous casting tundish and tundish technology, applied in the field of information, can solve problems such as low efficiency of manual production scheduling, and achieve the effects of improving the level of planning, solving low efficiency of manual production scheduling, and improving scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

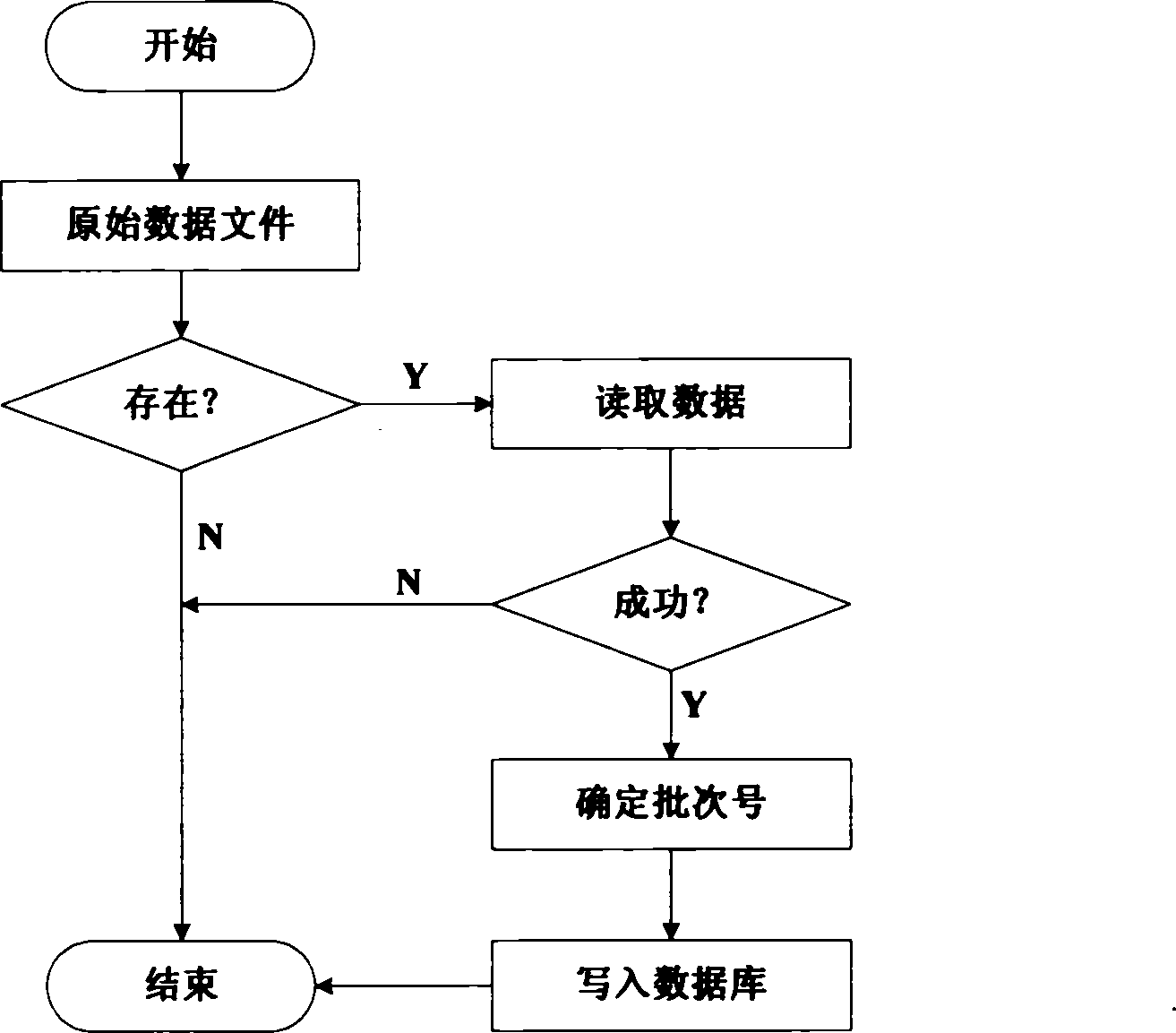

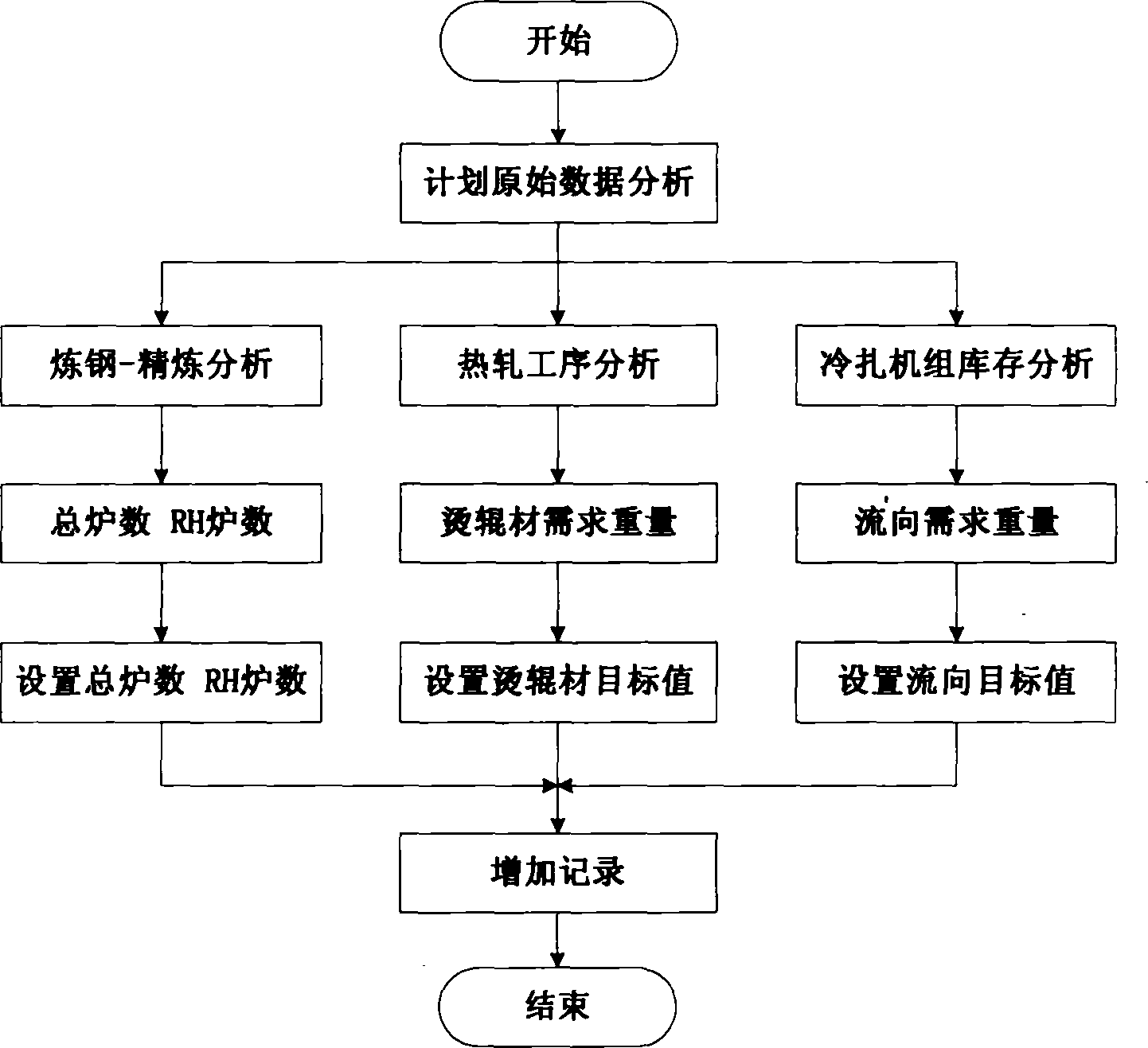

[0200] The tundish batch planning optimization system of the present invention is based on the information platform of iron and steel enterprises, but it is a relatively independent local system. The system has its own database, front-end display interface, and mathematical model-based planning optimization algorithm. Functional modules include: Process static parameter setting module, raw data download module, model algorithm parameter setting module, batch planning requirement setting module, production plan automatic generation module, production plan manual adjustment module, plan indicator statistical display module, and plan result statistical display module.

[0201] Taking the experimental production data of a steel factory in a certain iron and steel company as an example, using the method of the present invention to carry out tundish batch planning mainly follows the steps below:

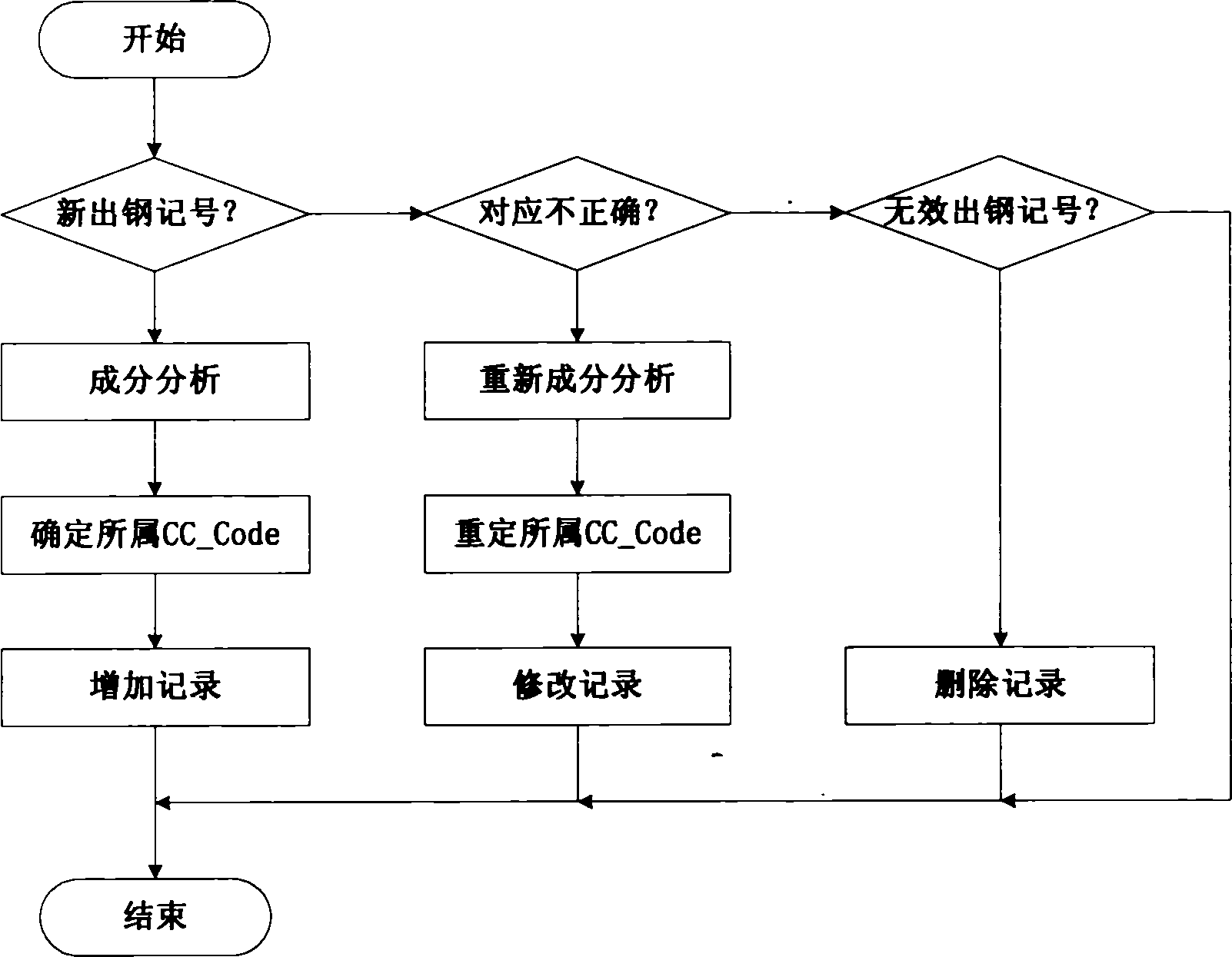

[0202] (1) Set the static parameters of the process, that is, the CC_Code setting, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com