A method for measuring heavy component content in black oil

A technology of mass percentage content and heavy components, which is applied in the direction of measuring devices, material separation, and analysis materials, can solve problems such as inability to calculate, retention, and non-publication, and achieve the effect of improving the accuracy and effectiveness of reservoir numerical simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be explained in detail below in conjunction with the accompanying drawings and embodiments.

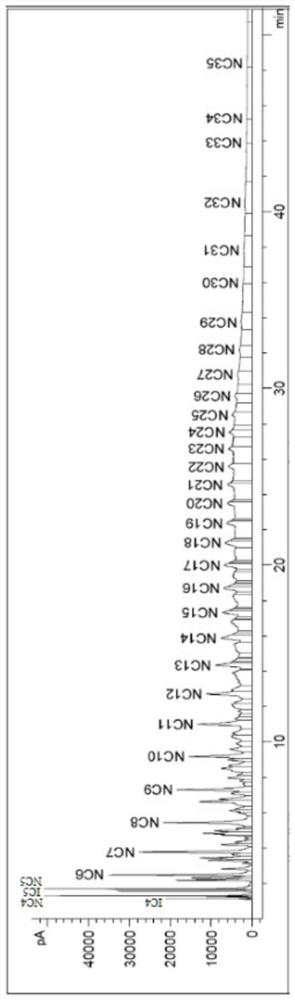

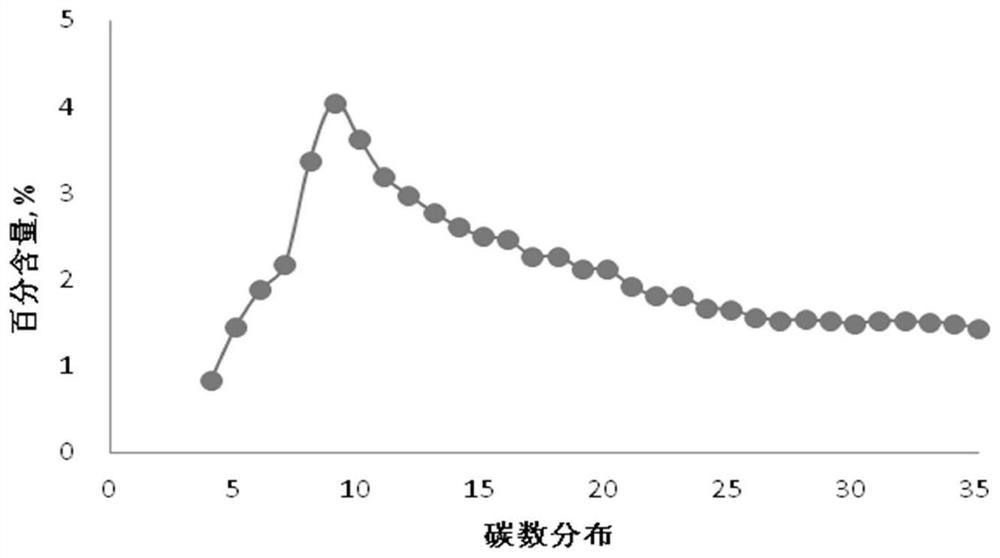

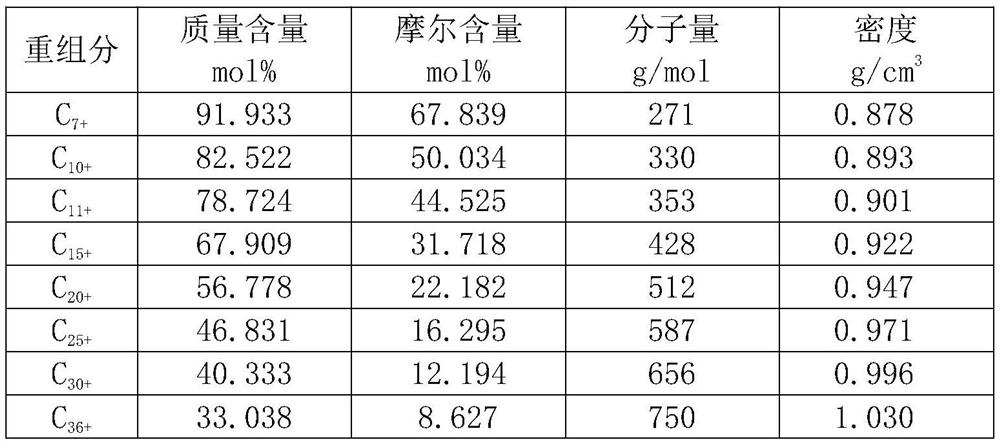

[0025] Well Ismail-1 in a northern oilfield is a black oil well. In order to clarify the reservoir fluid parameters and structural reserves, a PDS sampler was used to sample downhole at 2810m. The nozzle was controlled before sampling, and the surface pressure and production were stable. The rough side bubble point pressure of field analysis is 2860psia, which is lower than the opening pressure of the sample of 3660psia and the bottom hole sampling pressure of 3228psia, indicating that the sample is a single phase during the sampling period, and no composition changes have occurred. The flash test can be carried out for qualified samples . Strictly control the sample injection conditions through sample mixing and sample transfer pre-treatment operations to ensure that the components are consistent throughout the process. Finally, 92ml of black oil sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com