Spraying production line

A technology of production line and spraying line, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of occupying a large production space, low equipment utilization rate, and huge spraying production line, etc., to reduce the use space , high degree of automation, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

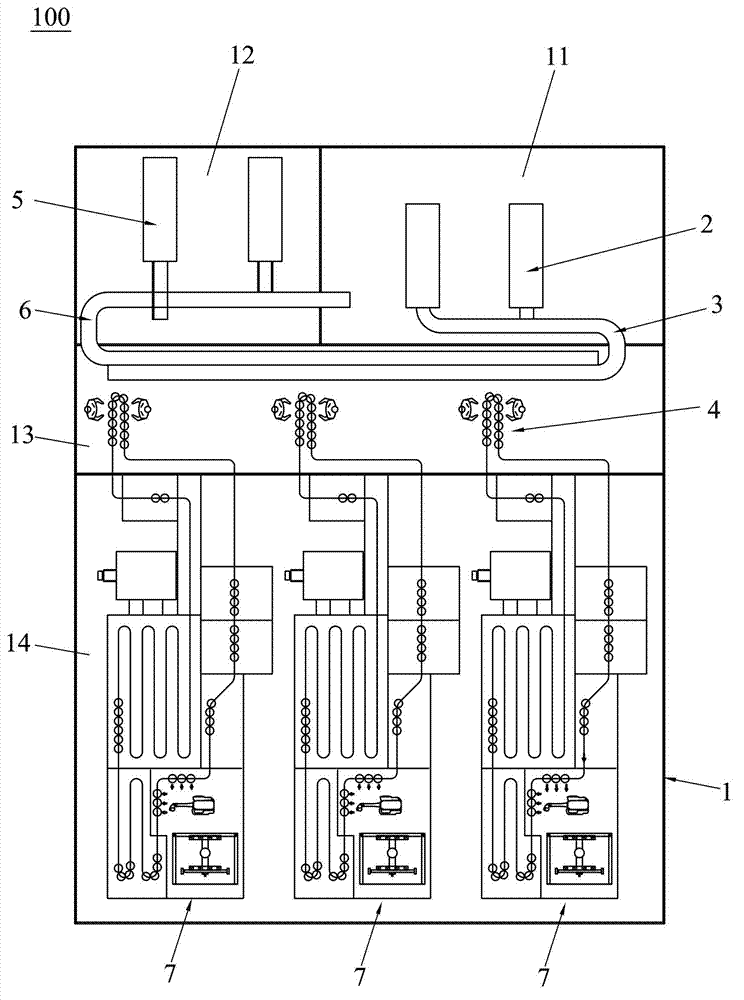

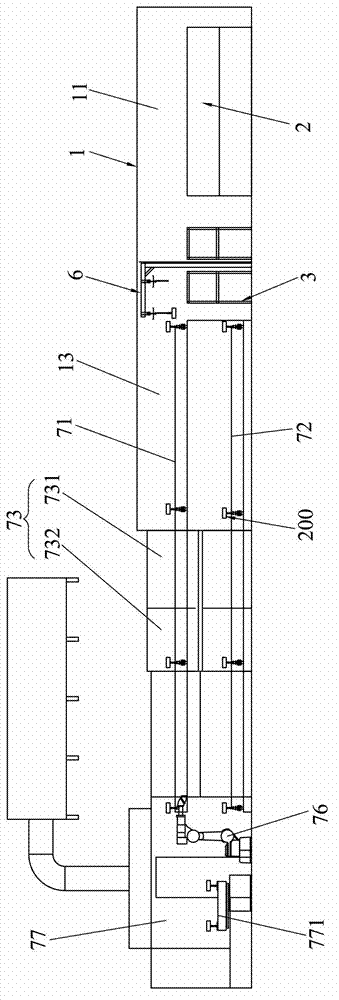

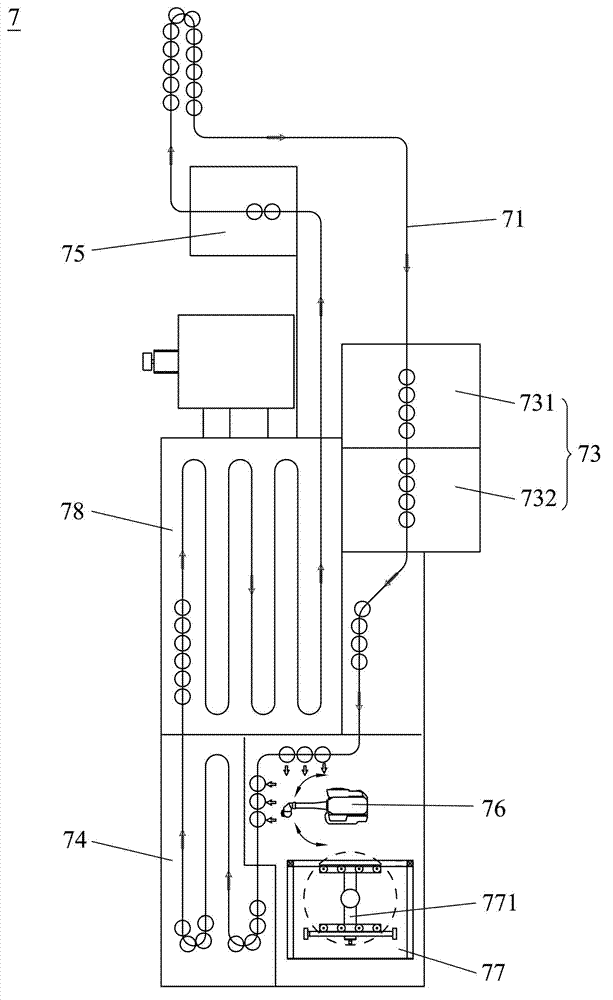

[0021] like figure 1 , figure 2 As shown, the spraying production line 100 of the present invention is suitable for carrying out color-changing spraying on the workpiece clamped on the workpiece fixture 200, including a container 1, a delivery line 2, an upper transport chain 3, an upper and lower area 4, an inspection line 5, The lower conveying chain 6, three sets of spraying lines 7 and control systems (not shown in the figure), the three sets of spraying lines 7 are arranged side by side, and the control system controls the conveying line 2, the upper conveying chain 3, the inspection The operation of the wrapping wire 5, the conveying chain 6 of the next part and the spraying line 7.

[0022] see figure 1 , the container 1 includes a first isolation area 11, a second isolation area 12, a third isolation area 13 and a fourth isolation area 14, the first isolation area 11 accommodates the delivery line 2, the second isolation area The isolation area 12 accommodates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com