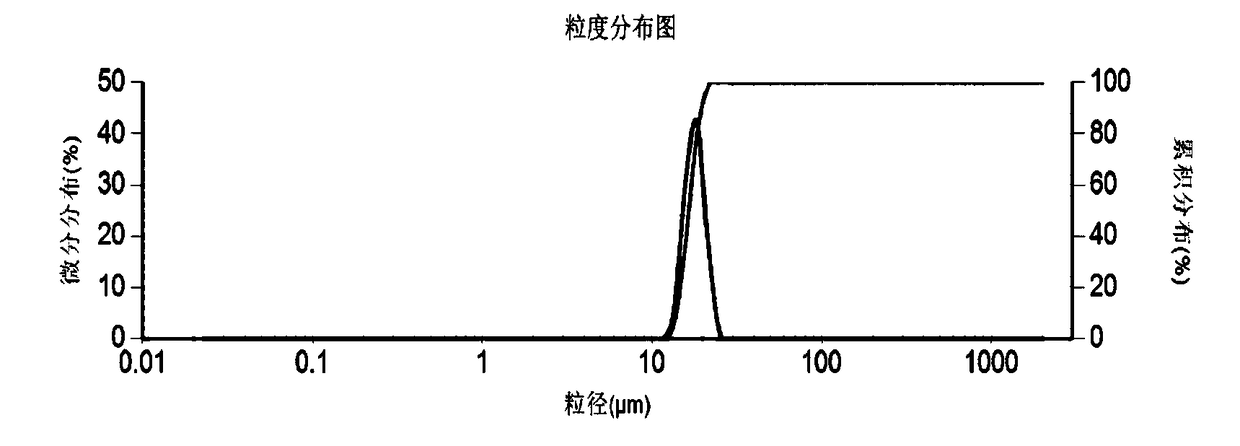

Preparation method of large-particle-size aluminum-doped cobalt trioxide

A technology of tricobalt tetroxide and large particle size, which is applied in the direction of cobalt oxide/cobalt hydroxide, electrical components, battery electrodes, etc., which can solve the problems of low recovery rate of cobalt metal, non-continuous production, and low work efficiency, and achieve high sphericity, The effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of almost spherical aluminum-doped cobalt carbonate seed crystals

[0039] 1.1 Preparation of aluminum salt solution

[0040] at 3m 3 Add 2m to the aluminum salt preparation tank 3 The pure water is heated through the built-in steam coil, the temperature is heated to 80-85°C, the stirring speed is turned on, and the motor speed is controlled to 400r / min. Add a certain amount of aluminum sulfate hexadecahydrate solid into the hot water in the preparation tank, stir for about 1 hour to dissolve it, turn off the stirring, let it stand for 30 minutes, and take a sample to detect that the concentration of aluminum ions is 8.0-8.5g / L.

[0041] 1.2 Preparation of Al-Co solution

[0042] Accurately add 10m 3 Cobalt chloride solution with a concentration of 145-150g / L, and then accurately add the prepared aluminum salt to 1.14m through a mass flow meter 3 Aluminum salt solution, turn on the stirring of the aluminum-cobalt preparation tank, control the stirrin...

Embodiment 2

[0058] 1. Preparation of almost spherical aluminum-doped cobalt carbonate seed crystals

[0059] 1.1 Preparation of aluminum salt solution

[0060] at 3m 3 Add 2m to the aluminum salt preparation tank 3 The pure water is heated through the built-in steam coil, the temperature is heated to 80-85°C, the stirring speed is turned on, and the motor speed is controlled to 400r / min. Add a certain amount of aluminum sulfate hexadecahydrate solid into the hot water in the preparation tank, stir for about 1 hour to dissolve it, turn off the stirring, let it stand for 30 minutes, and take a sample to detect that the concentration of aluminum ions is 8.0-8.5g / L.

[0061] 1.2 Preparation of Al-Co solution

[0062] Accurately add 10m 3 Cobalt chloride solution with a concentration of 145-150g / L, and then accurately add the prepared aluminum salt to 1.14m through a mass flow meter 3 Aluminum salt solution, turn on the stirring of the aluminum-cobalt preparation tank, control the stirrin...

Embodiment 3

[0078] 1. Preparation of almost spherical aluminum-doped cobalt carbonate seed crystals

[0079] 1.1 Preparation of aluminum salt solution

[0080] at 3m 3 Add 2m to the aluminum salt preparation tank 3 The pure water is heated through the built-in steam coil, the temperature is heated to 80-85°C, the stirring speed is turned on, and the motor speed is controlled to 400r / min. Add a certain amount of aluminum sulfate hexadecahydrate solid into the hot water in the preparation tank, stir for about 1 hour to dissolve it, turn off the stirring, let it stand for 30 minutes, and take a sample to detect that the concentration of aluminum ions is 8.0-8.5g / L.

[0081] 1.2 Preparation of Al-Co solution

[0082] Accurately add 10m 3 Cobalt chloride solution with a concentration of 145-150g / L, and then accurately add the prepared aluminum salt to 1.14m through a mass flow meter 3Aluminum salt solution, turn on the stirring of the aluminum-cobalt preparation tank, control the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com