Patents

Literature

439 results about "Cobalt metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt naturally occurs in nickel-bearing laterites and nickel-copper sulfide deposits and, thus, is most often extracted as a by-product of nickel and copper. According to the Cobalt Development Institute, about 48% of cobalt production originates from nickel ores, 37% from copper ores and 15% from primary cobalt production.

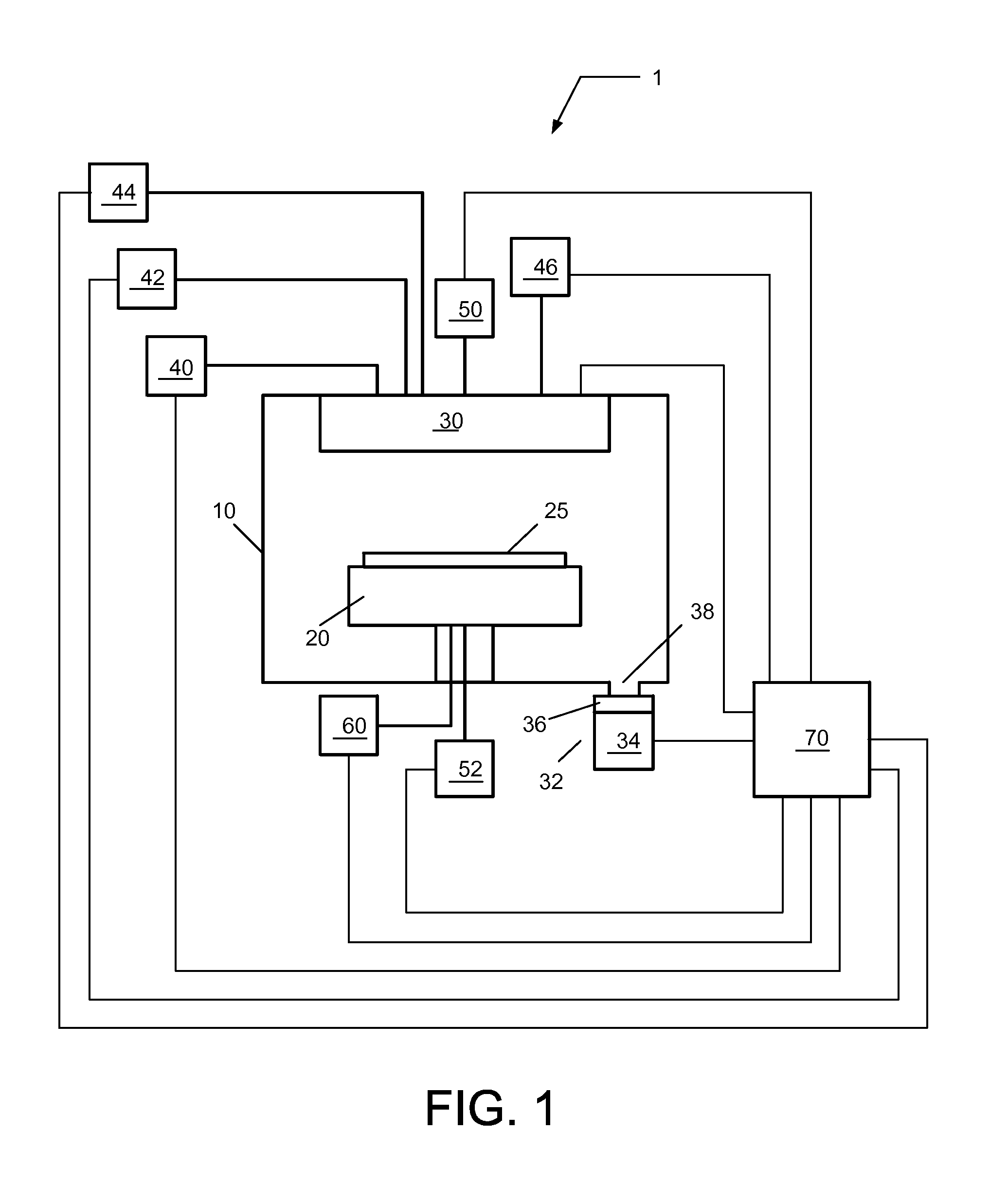

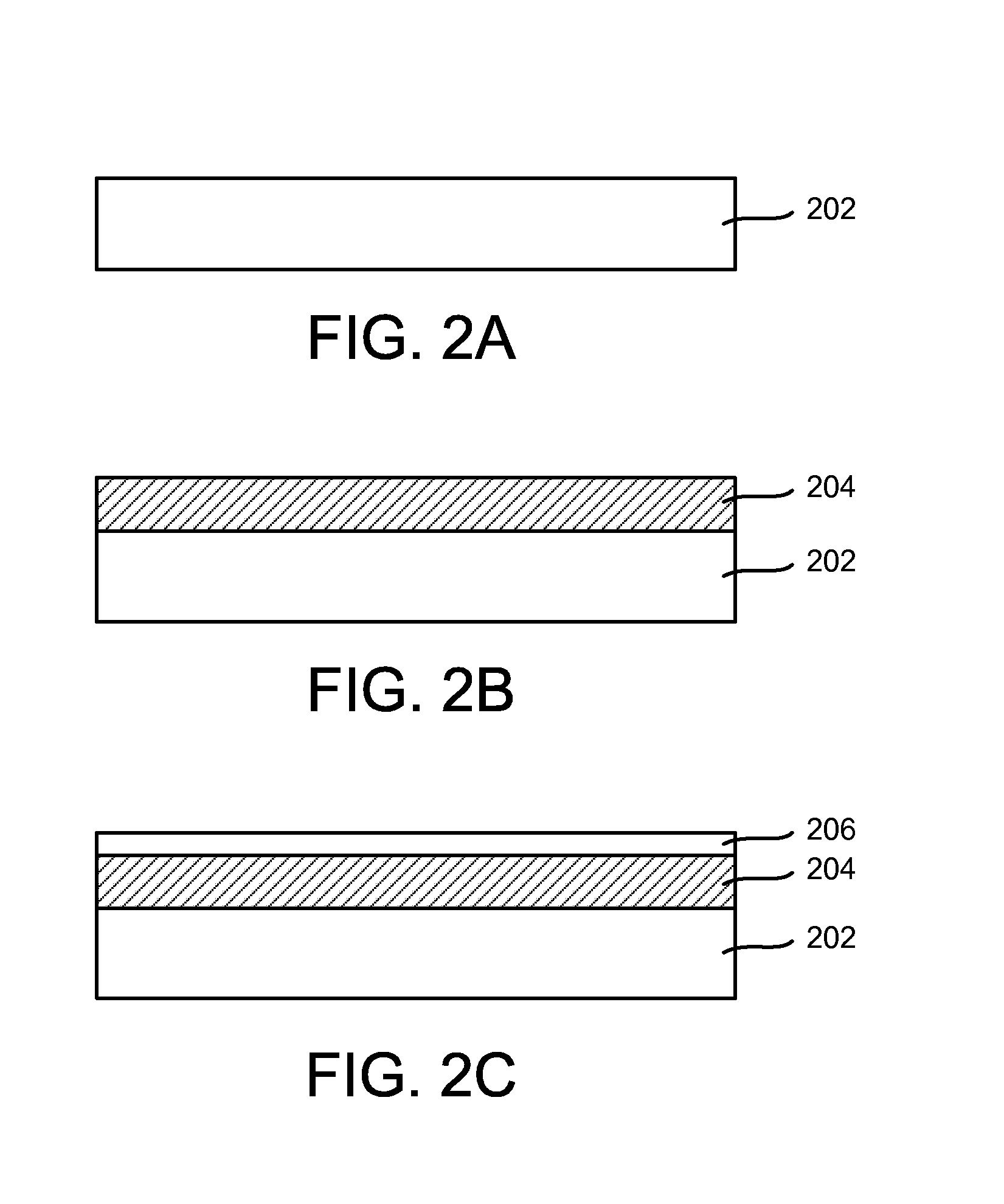

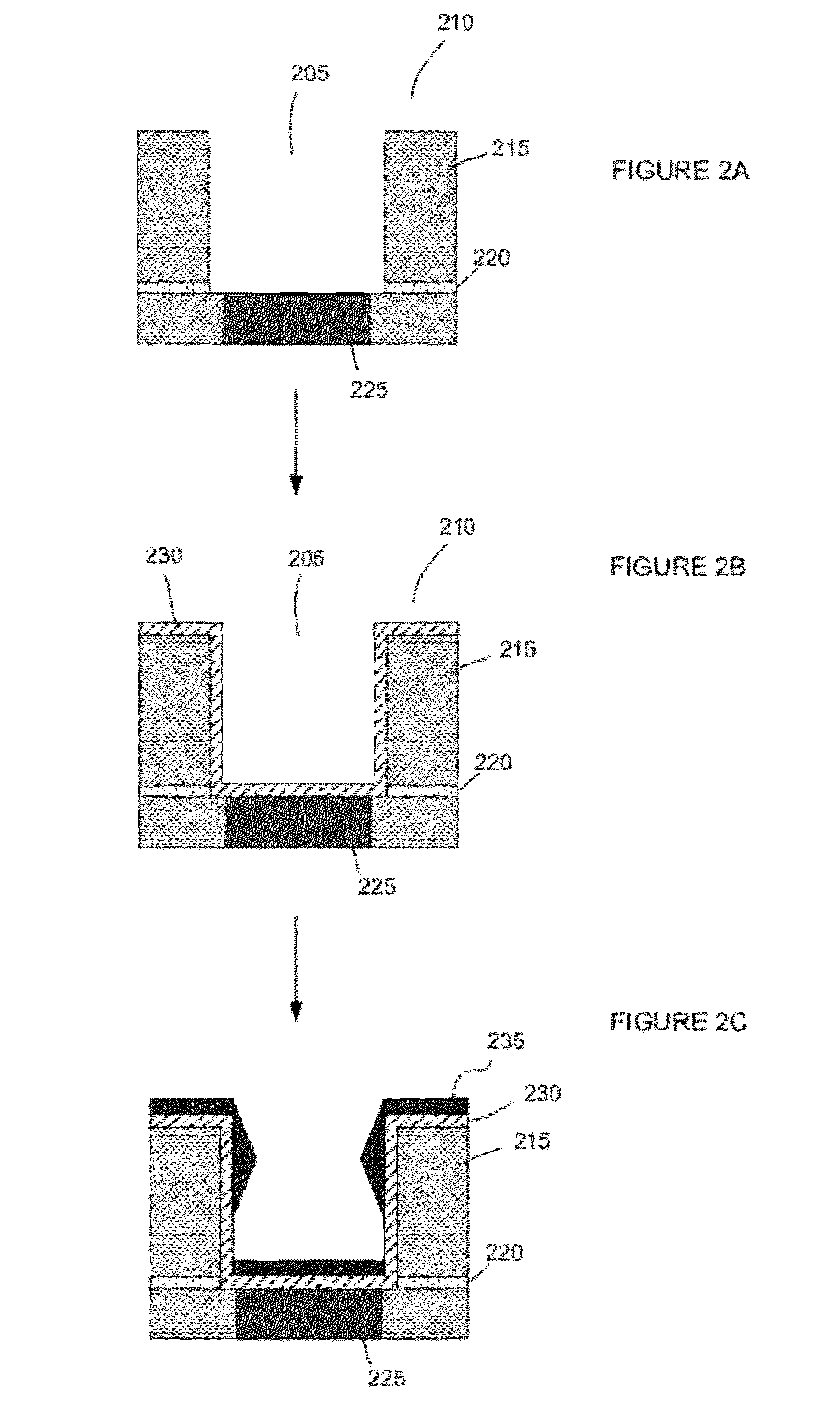

Method of forming a cobalt metal nitride barrier film

InactiveUS20090246952A1Improve the immunitySemiconductor/solid-state device detailsSolid-state devicesCobalt metalNitride

A method is provided for forming a cobalt metal nitride barrier film on a substrate for semiconductor devices. According to one embodiment of the invention, the method includes depositing a plurality of metal nitride layers on the substrate, and depositing a cobalt layer between each of the plurality of metal nitride layers. According to another embodiment of the invention, the method includes simultaneously exposing the substrate to a metal nitride precursor or a metal precursor, a cobalt precursor, and a reducing gas, nitriding gas, or a combination thereof. Embodiments for integrating a cobalt metal nitride barrier film into semiconductor devices are described.

Owner:TOKYO ELECTRON LTD

Electrodeposited metallic-materials comprising cobalt

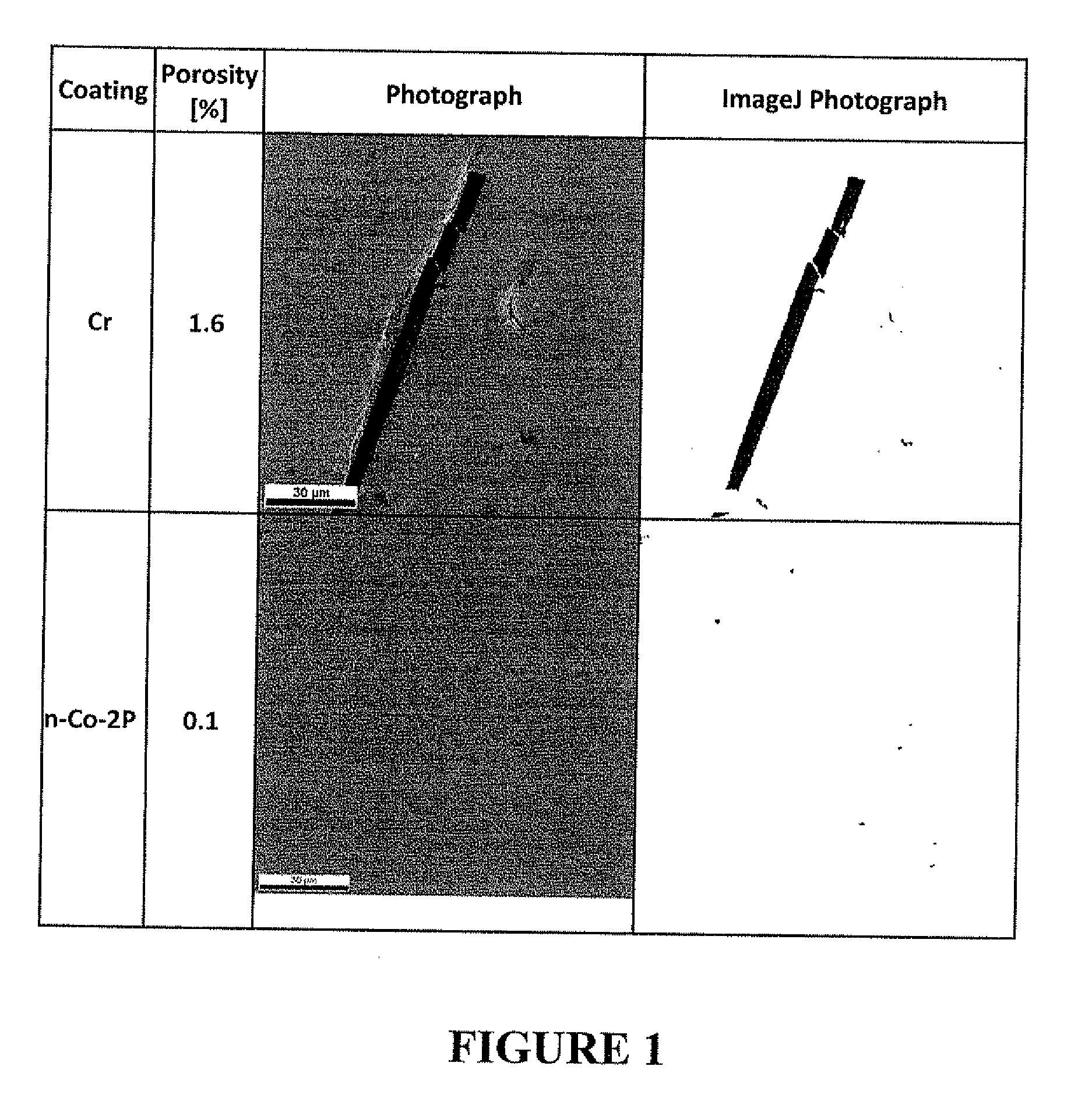

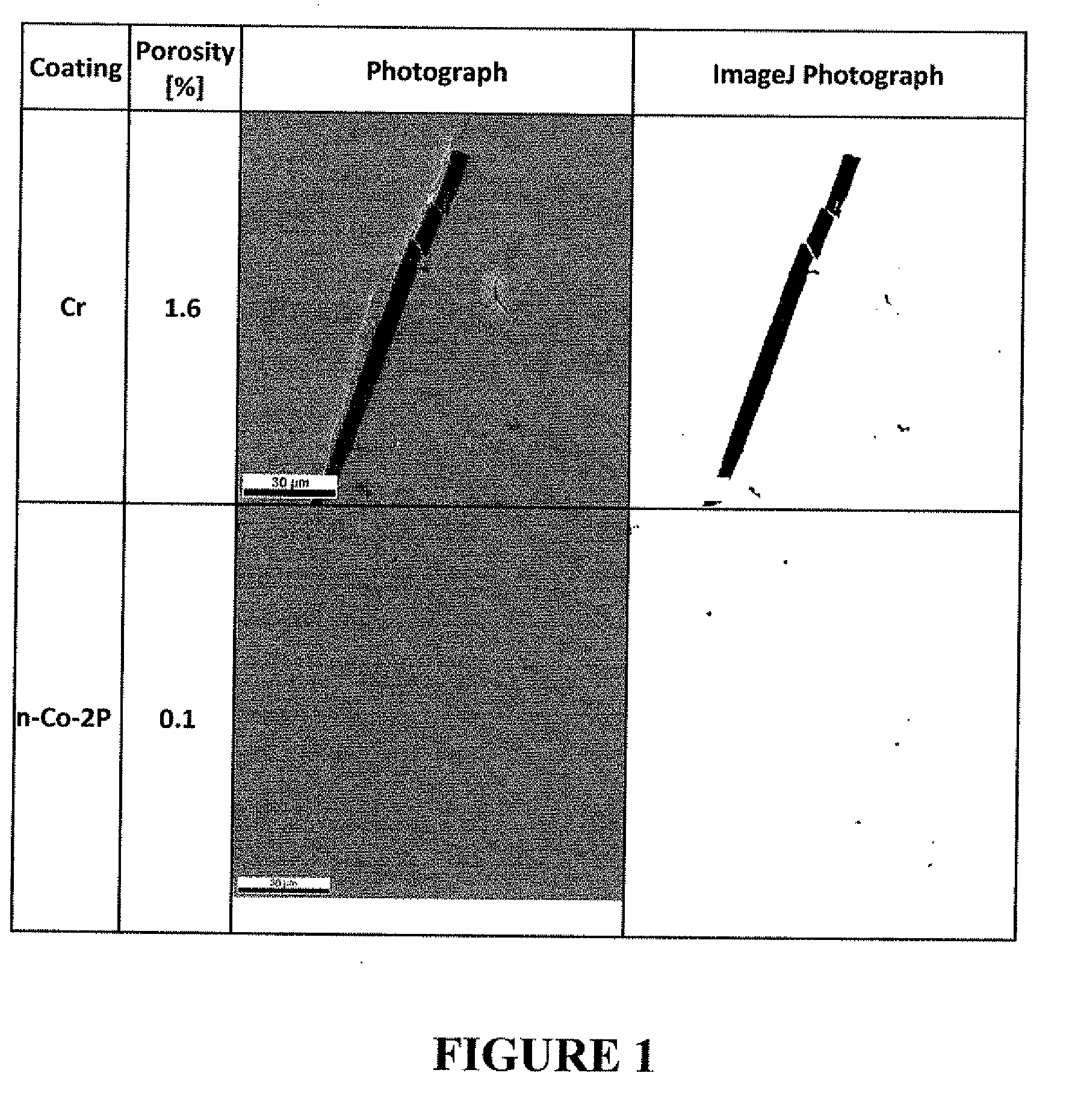

ActiveUS20100304182A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageParticulatesPorosity

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

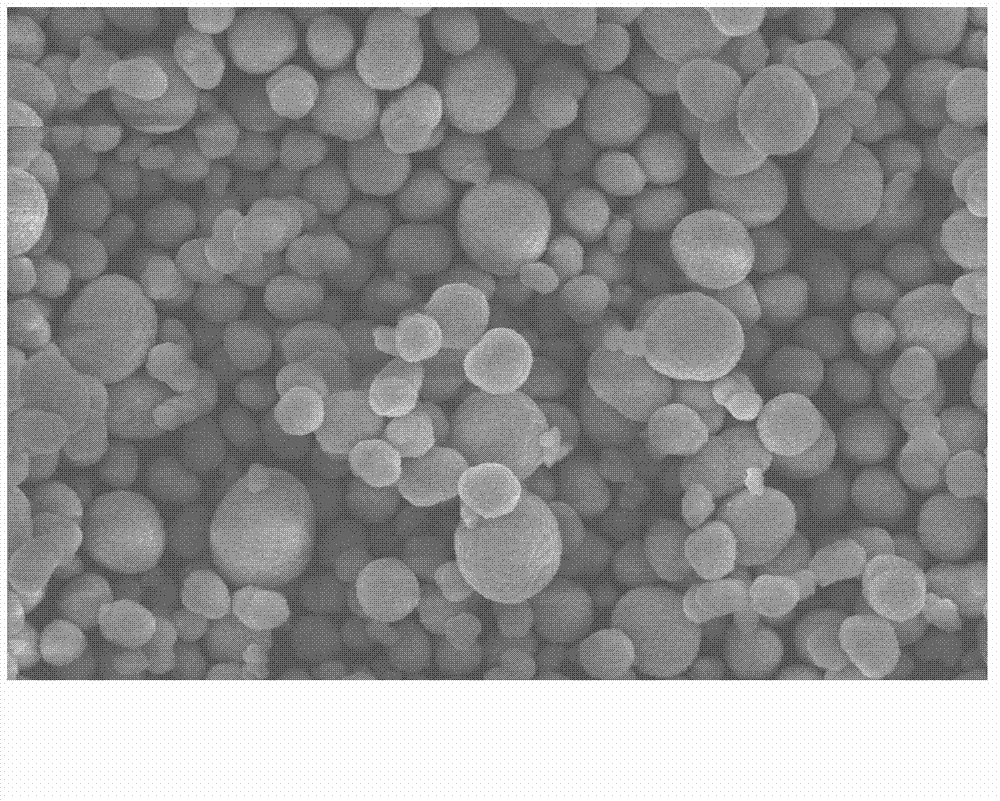

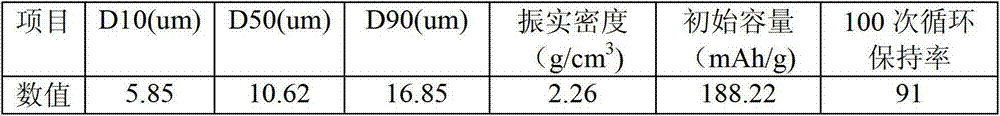

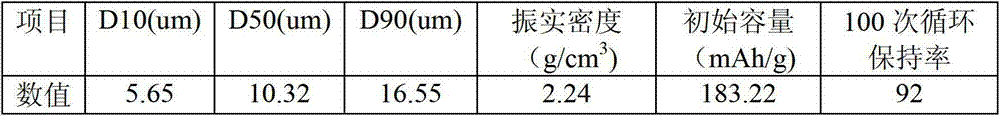

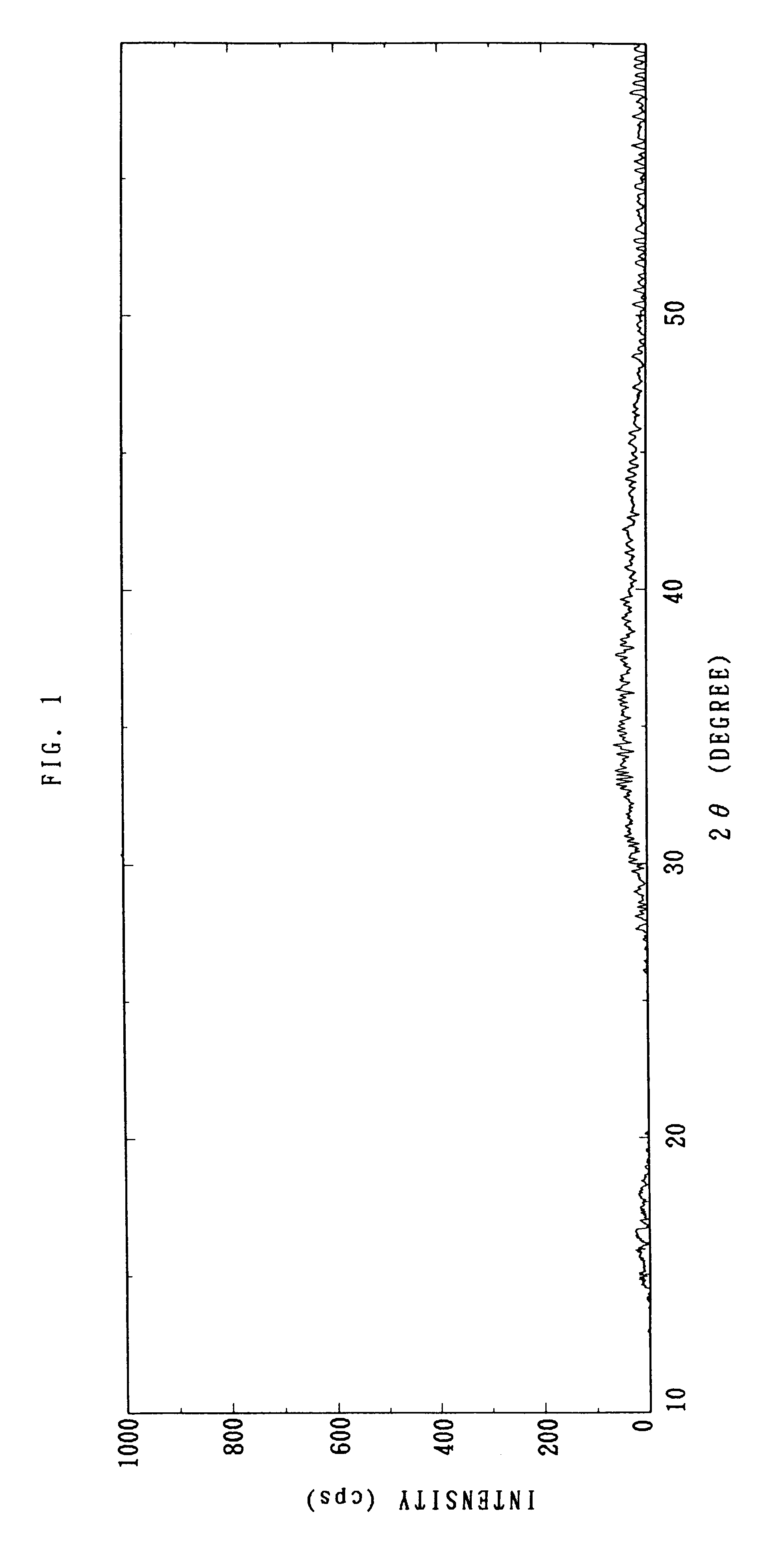

Method for preparing nickel-cobalt lithium aluminate as anode material of lithium ion battery

InactiveCN103094546AImprove electrical performanceImprove cycle performanceCell electrodesLithium aluminateOxygen

The invention discloses a method for preparing nickel-cobalt lithium aluminate as an anode material of a lithium ion battery. The method comprises the following steps: (1) mixing a nickel-cobalt metal salt water solution, a sodium metaaluminate solution, a complexing agent and a precipitant, regulating the pH value of a reaction system to be 9 to 12, and then maintaining a stirring state to carrying out a reaction at the temperature of 30 to 80 DEG C for 20 to 200 hours, thereby obtaining nickel-cobalt aluminum hydroxide precipitates; (2) washing the nickel-cobalt aluminum hydroxide precipitates by using pure water of 50 to 100 DEG C, drying, screening the part of precipitates capable of passing through a sieve being 300 meshes, adding a lithium source to the precipitates, mixing evenly, and sintering at the temperature of 600 to 1000 DEG C, wherein oxygen is filled during the sintering process; and finally sintering for 5 to 50 hours, thereby obtaining the nickel-cobalt lithium aluminate. According to the method, the sodium metaaluminate is adopted as the lithium source, so that the nickel-cobalt aluminum elements can evenly form a coprecipitation, so that the aluminum is evenly distributed in the nickel-cobalt lithium aluminate material. As a result, the electrical performance of the material is improved, and especially the cycling performance of the material is improved.

Owner:HUNAN BRUNP RECYCLING TECH +1

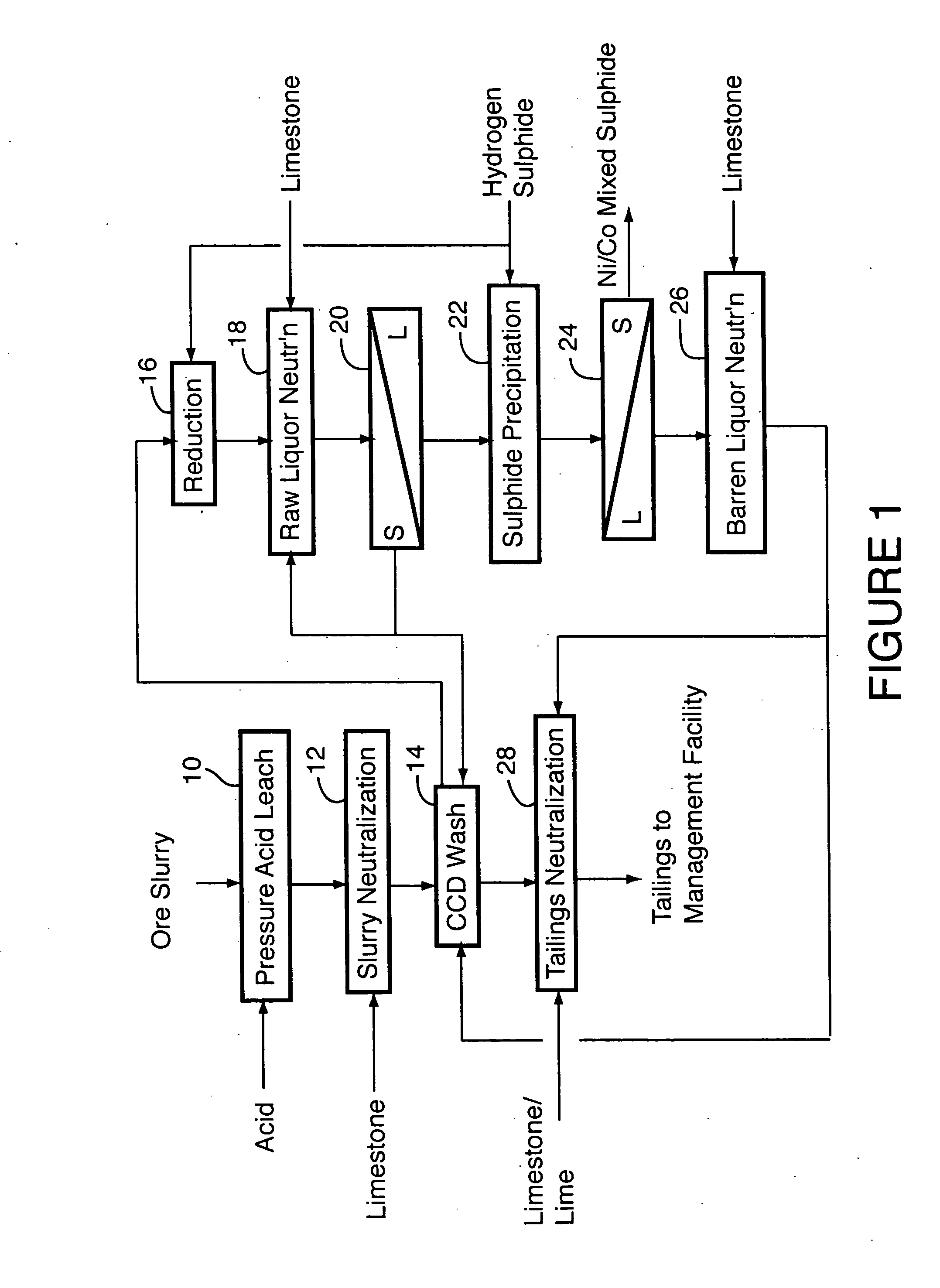

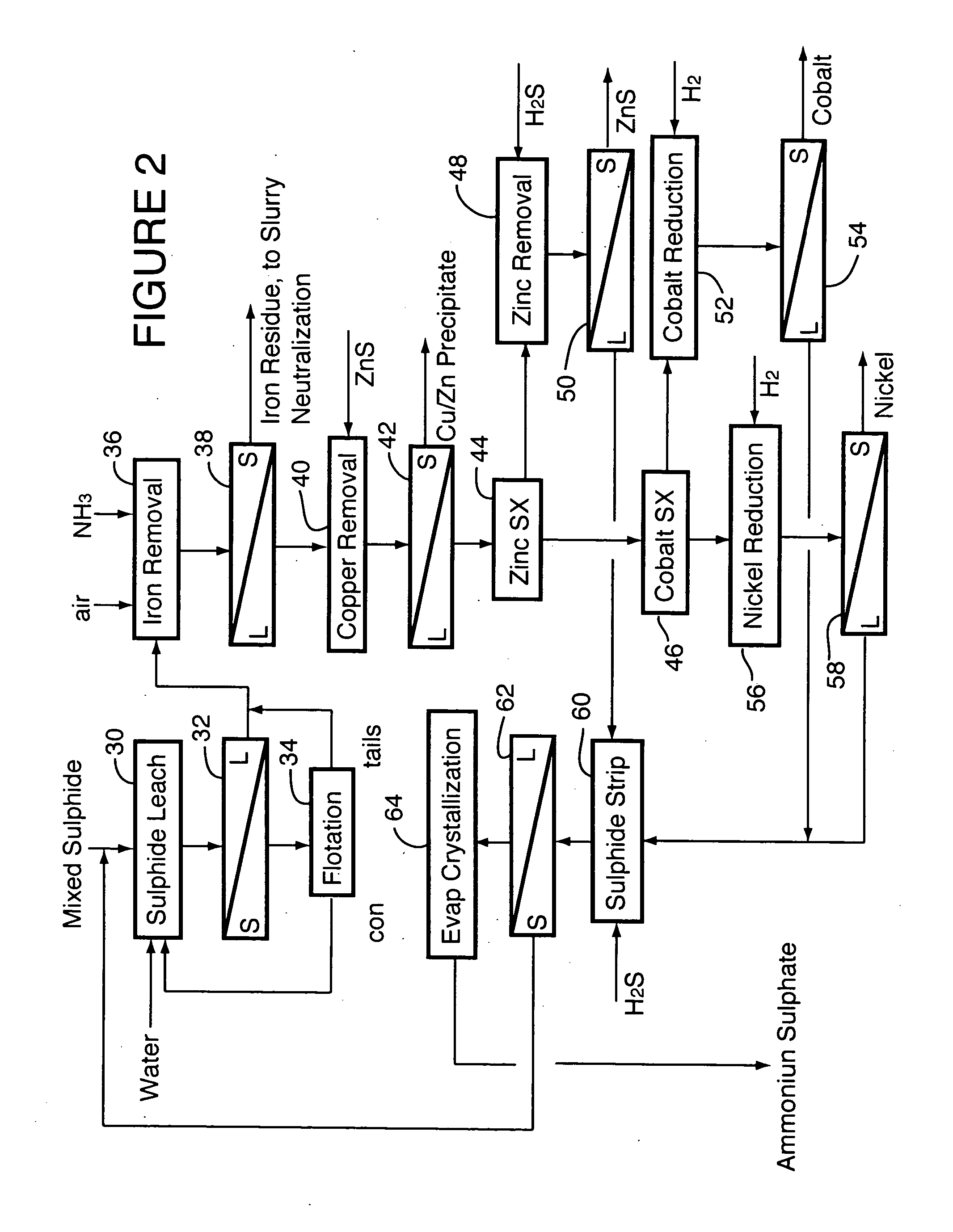

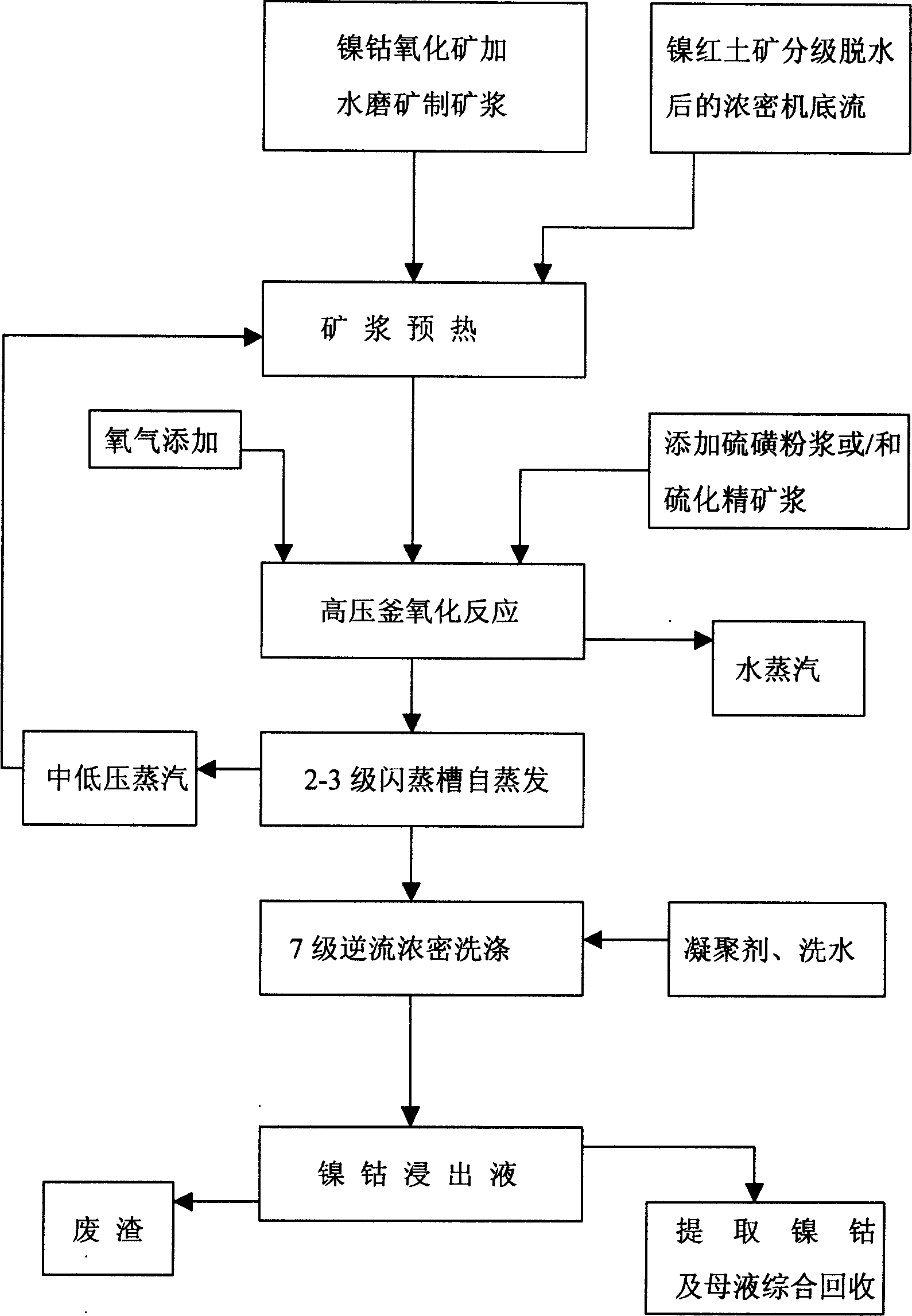

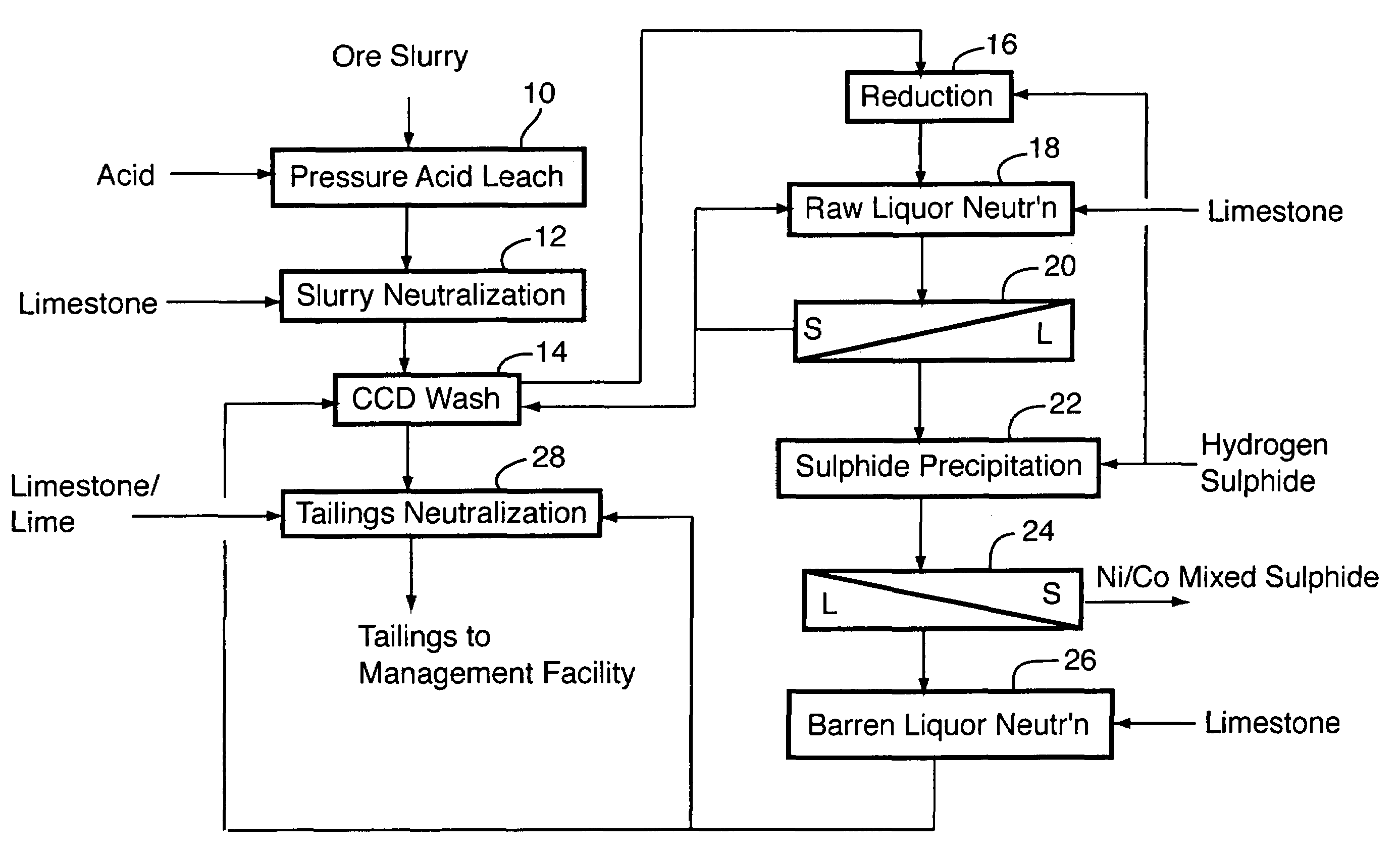

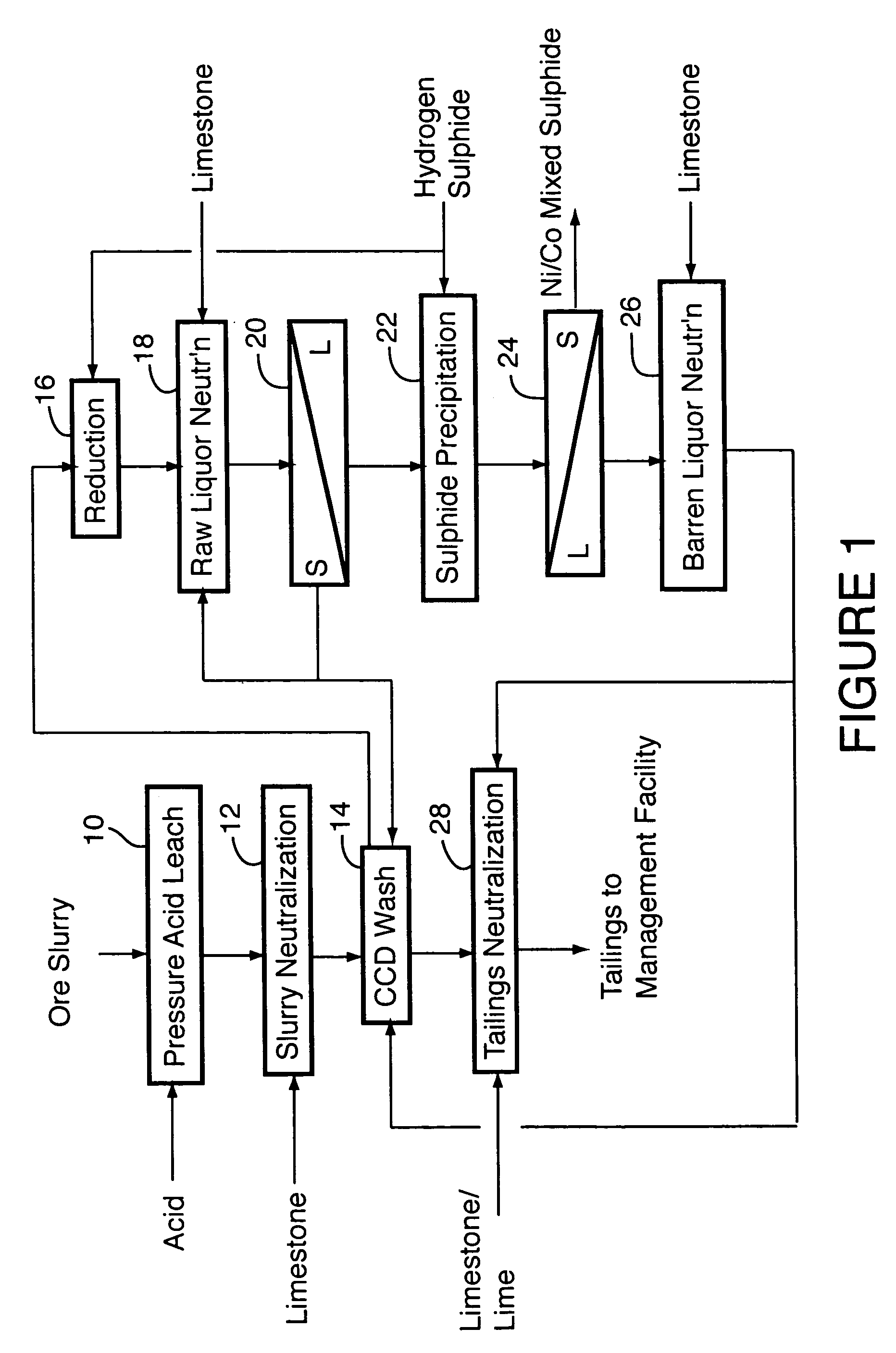

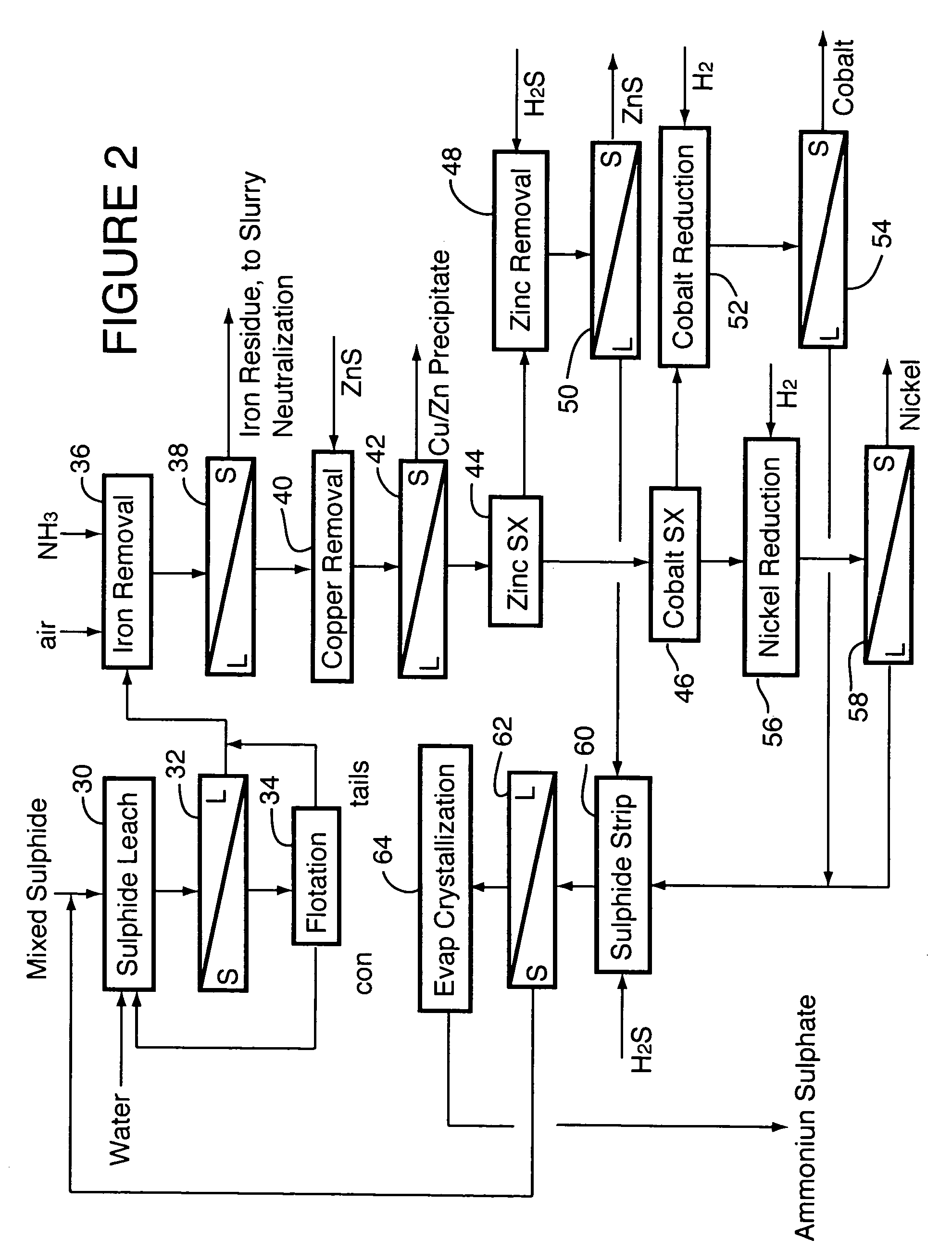

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

Nucleation method for atomic layer deposition of cobalt on bare silicon during the formation of a semiconductor device

ActiveUS20060157863A1Semiconductor/solid-state device detailsSolid-state devicesCobalt metalHydrogen

A method used to form a cobalt metal layer on a silicon surface using an atomic layer deposition (ALD) process comprises a treatment of the silicon surface prior to cobalt formation. Treatment includes serial exposure to one or more cycles comprising a titanium nitride precursor or a tantalum nitride precursor, followed by an optional exposure to ammonia. After this treatment, the silicon surface is exposed to a metal organic cobalt such as cyclopentadienylcobalt dicarbonyl to form a cobalt precursor on the silicon surface, which is then exposed to hydrogen or ammonia to reduce the precursor to an ALD cobalt metal layer. Once this initial metal layer is formed, additional cobalt ALD layers may be completed to form a cobalt metal layer of a desired thickness.

Owner:MICRON TECH INC

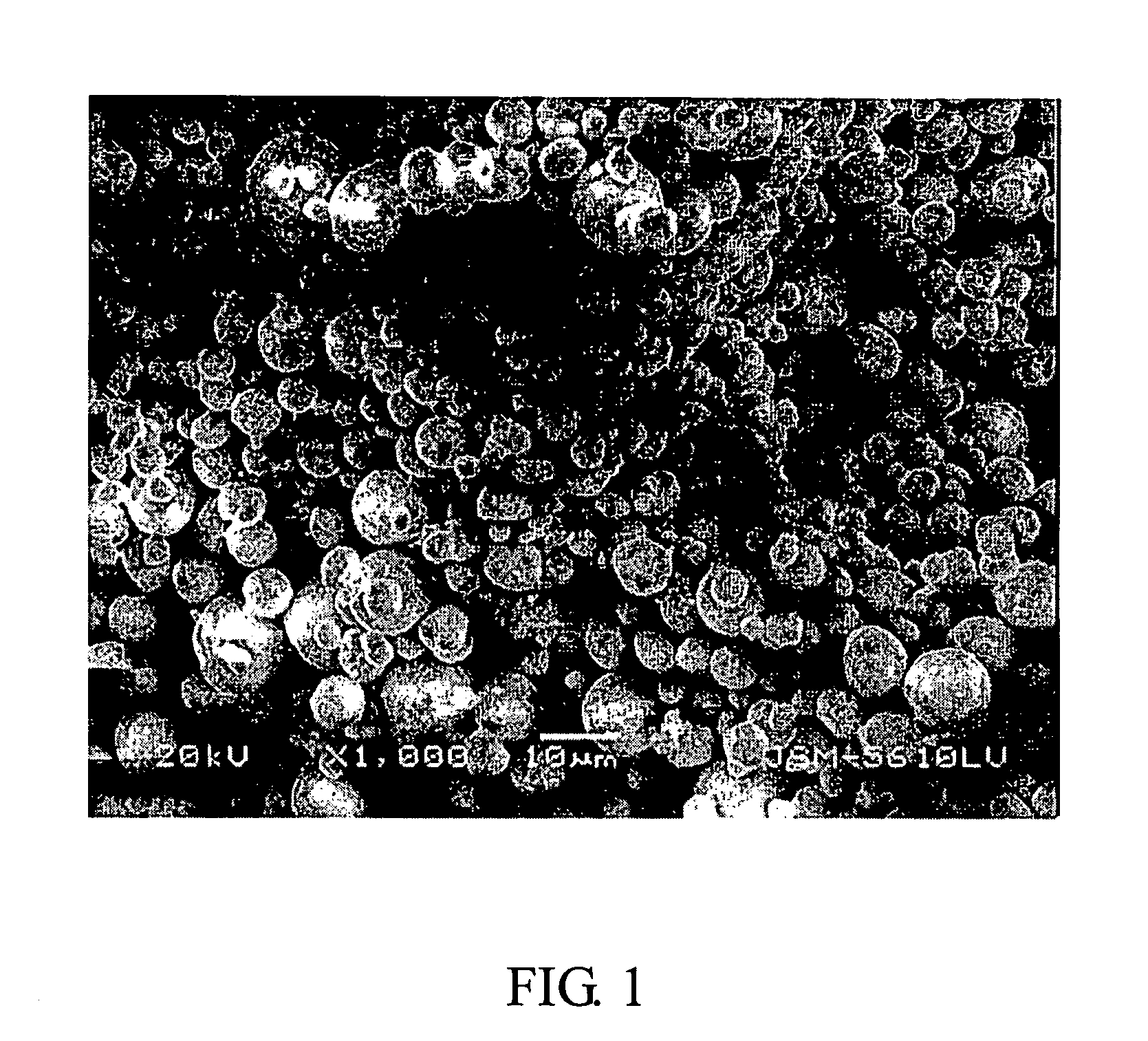

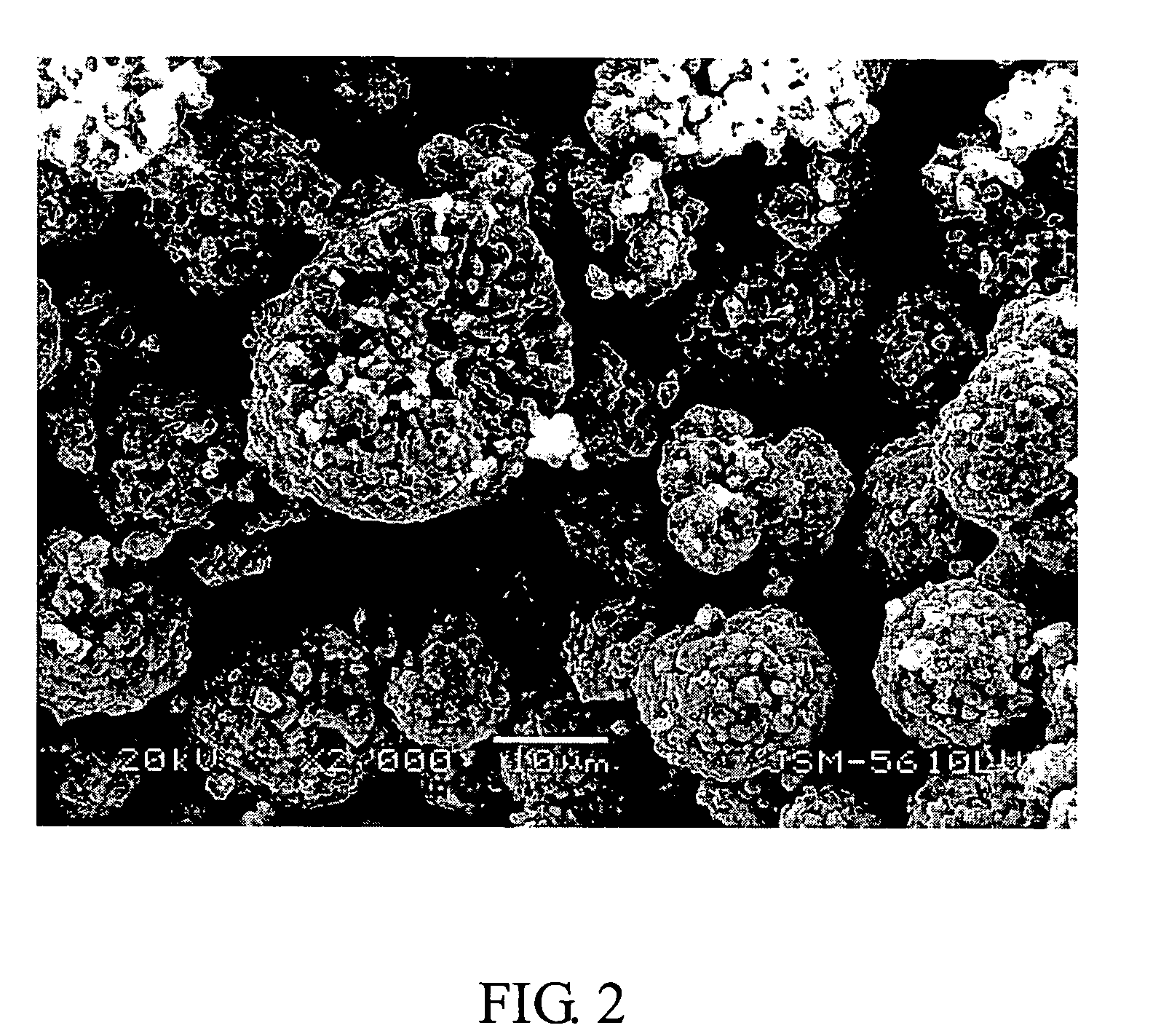

Method for producing fine spherical particles of carbonate or hydroxide of nickel, cobalt or copper

InactiveUS6197273B1Amino compound purification/separationOxide/hydroxide preparationSal ammoniacCobalt metal

The invention provides a process for production of fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper which comprises: dissolving a carbonate or a hydroxide of nickel, cobalt or copper having the general formula (I)wherein M represents Ni, Co or Cu, and x and y are numerals satisfying the followings: 0<=x<=2, 0<=y<=2 and x+y=2, in aqueous ammonia, converting the resulting solution to a W / O emulsion containing droplets of the solution in a non-aqueous medium, and then removing volatile components including ammonia from within the droplets, thereby precipitating a basic carbonate or a hydroxide of a metal selected from nickel, cobalt and copperin the droplets.The fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper obtained according to the process of the invention are especially useful as a precursor for the manufacture of uniform, fine spherical particles of nickel, copper or cobalt metal, as well as useful as themselves as a catalyst for use in organic synthesis, a carrier, a pigment, a filler or a glaze.

Owner:SAKAI CHEM IND CO LTD

Distillate oil hydrorefining catalyst

ActiveCN101733151AImprove hydrodesulfurization activityImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsCobalt metalCarboxylic acid

The invention relates to a distillate oil hydrorefining catalyst which contains carbon-containing molded heat-resisting oxide carrier, molybdenum and / or tungsten metal component that are / is loaded on the carrier and selected from VIB cluster and nickel and / or cobalt metal component selected from VIII cluster; the method is based on the oxide and takes catalyst as reference; and the content of molybdenum and / or tungsten is 5-40wt%, and the content of nickel and / or cobalt is 1-8wt%. The carbon-containing carrier is prepared by the method comprising the steps of: (1) adopting water solution containing one or more in organic carboxylic acid and organic carboxylic acid salt for dipping the molded heat-resisting oxide carrier; (2) drying the product obtained in the step (1), and activating under the condition that inert gas exists; and in the steps (1) and (2), due to the dosage of the components and the operation condition, the weight ratio between carbon and the heat-resisting oxide in the carrier is 0.1:99.9-10:90. Compared with the existing catalyst, the catalyst has high hydrodesulphurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

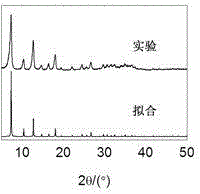

Magnetic Co3O4-C nano material and preparation method thereof as well as application of magnetic Co3O4-C nano material as catalyst for activating peroxymonosulfate to wastewater treatment

InactiveCN105854882AEfficient enrichmentImprove degradation efficiencyWater treatment compoundsCatalyst activation/preparationPorous carbonUsability

The invention discloses a magnetic Co3O4-C nano material and a preparation method thereof as well as application of the magnetic Co3O4-C nano material as a catalyst for activating peroxymonosulfate to wastewater treatment and belongs to the technical field of water pollution control. The method takes a cobalt metal-organic framework compound as a precursor, and the precursor is calcined at a high temperature in a certain atmosphere to finally obtain the magnetic Co3O4-C nano material. A porous carbon component in the material can be used as a carrier of metal oxide so that catalytic sites are uniformly distributed, and pollutants in a water body can be effectively enriched so that the system degradation efficiency is improved; and a magnetic Co3O4 component in the material can be used as a heterogeneous catalyst for efficiently activating peroxymonosulfate to generate free radicals for degrading the pollutants in the water body. The method has the characteristics of high efficiency and convenience, wide pH applicable range, capability of recycling the catalyst through an external magnetic field, good circulating usability and environmental friendliness, and has an extremely great potential to actual treatment application of organic wastewater.

Owner:SOUTH CHINA UNIV OF TECH

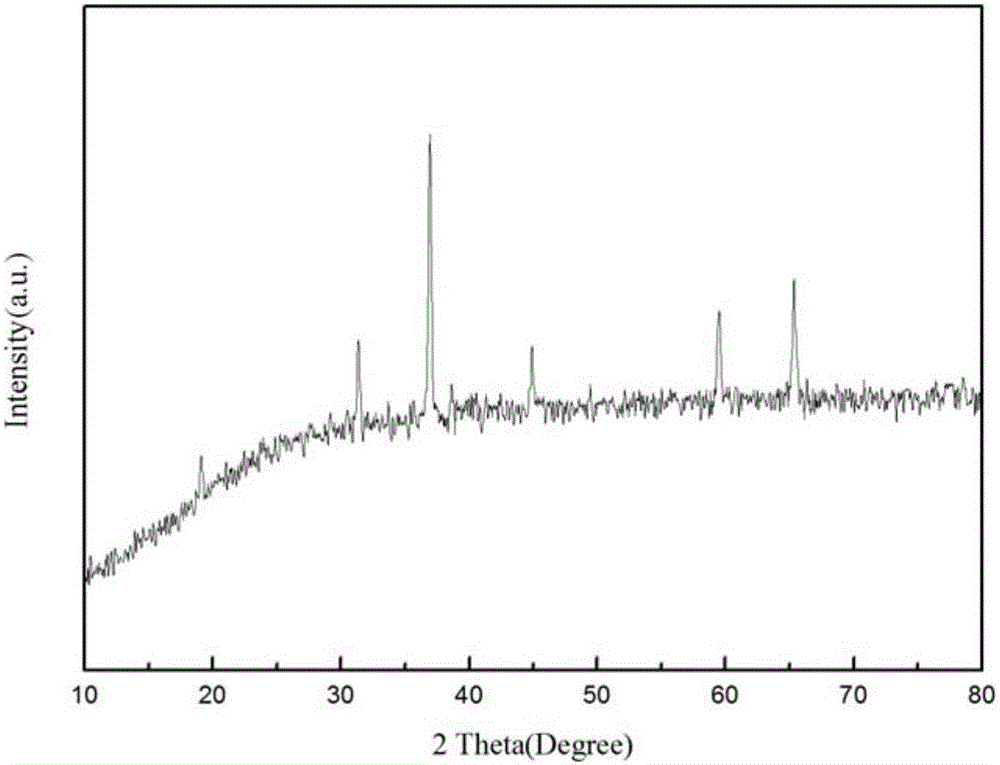

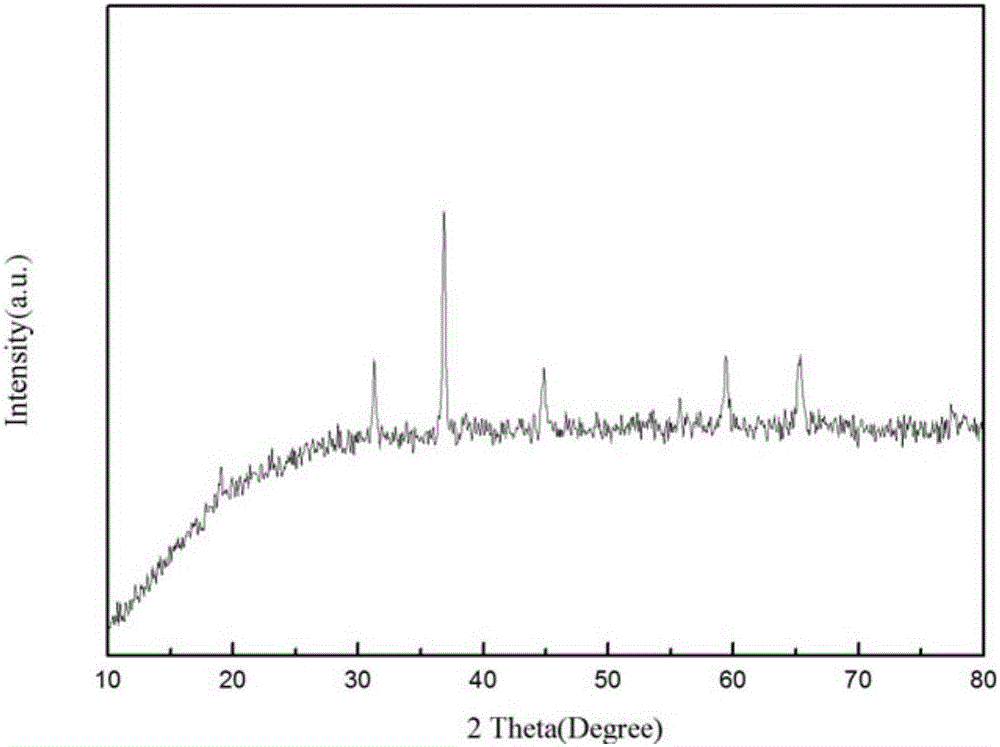

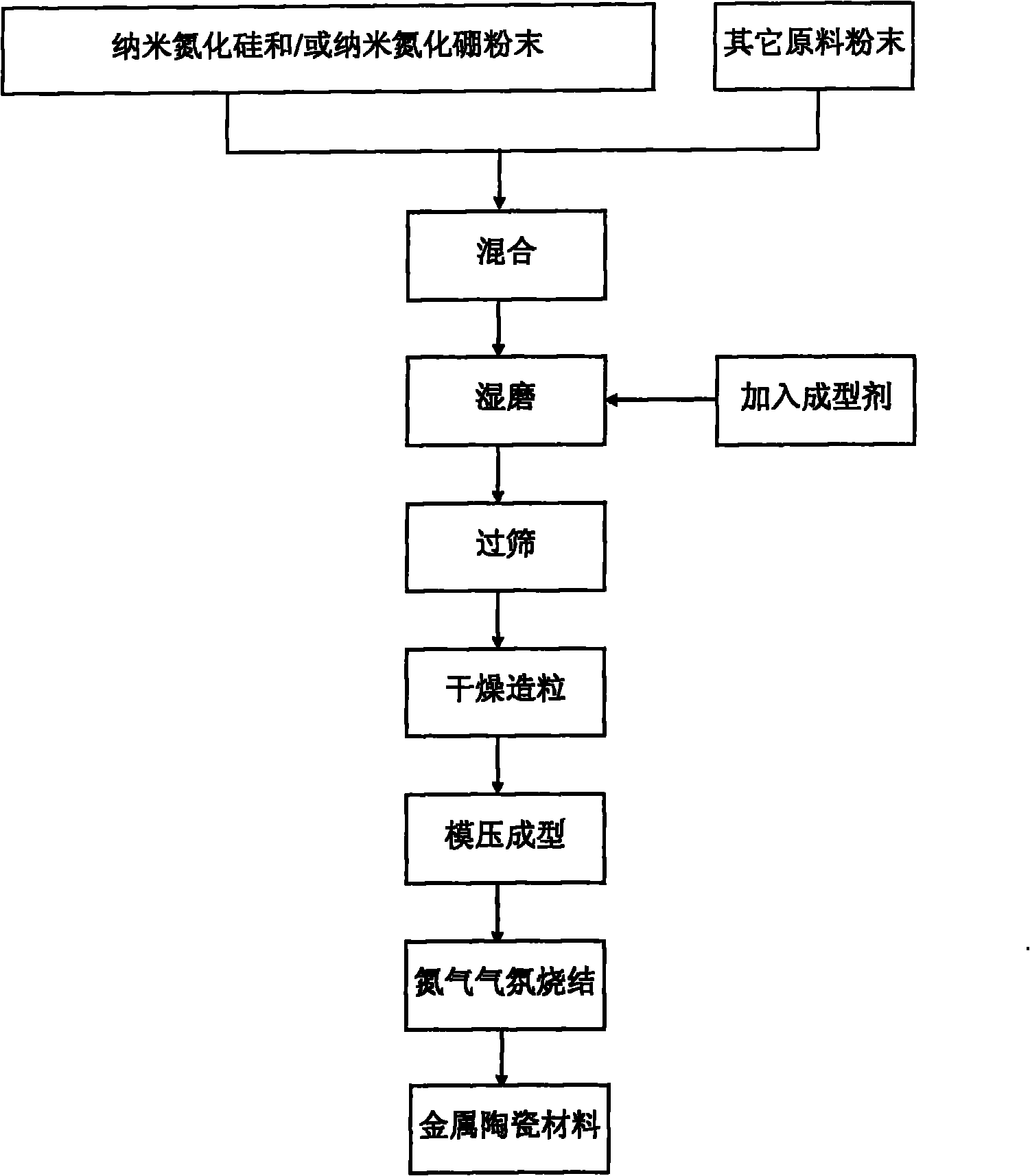

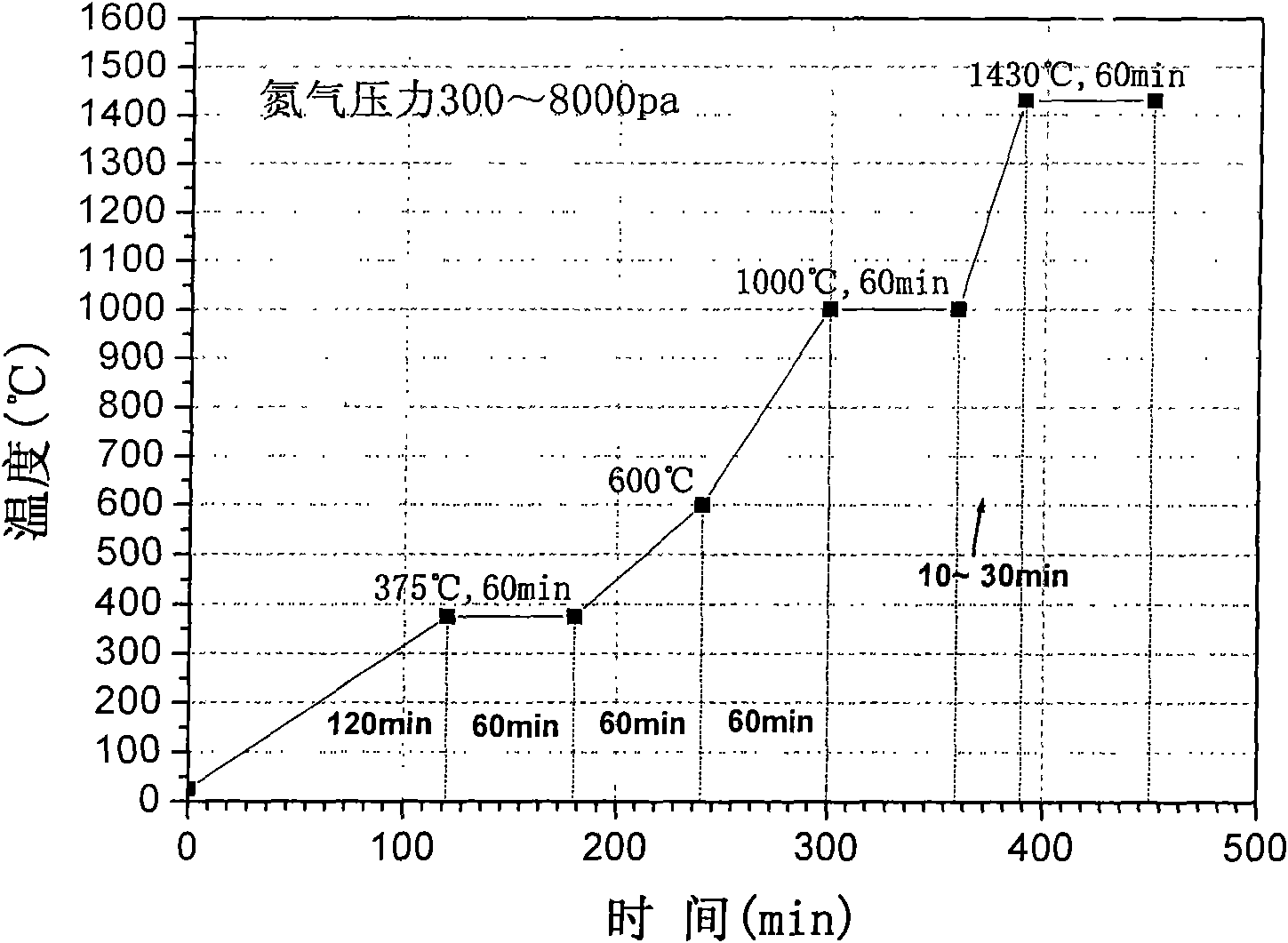

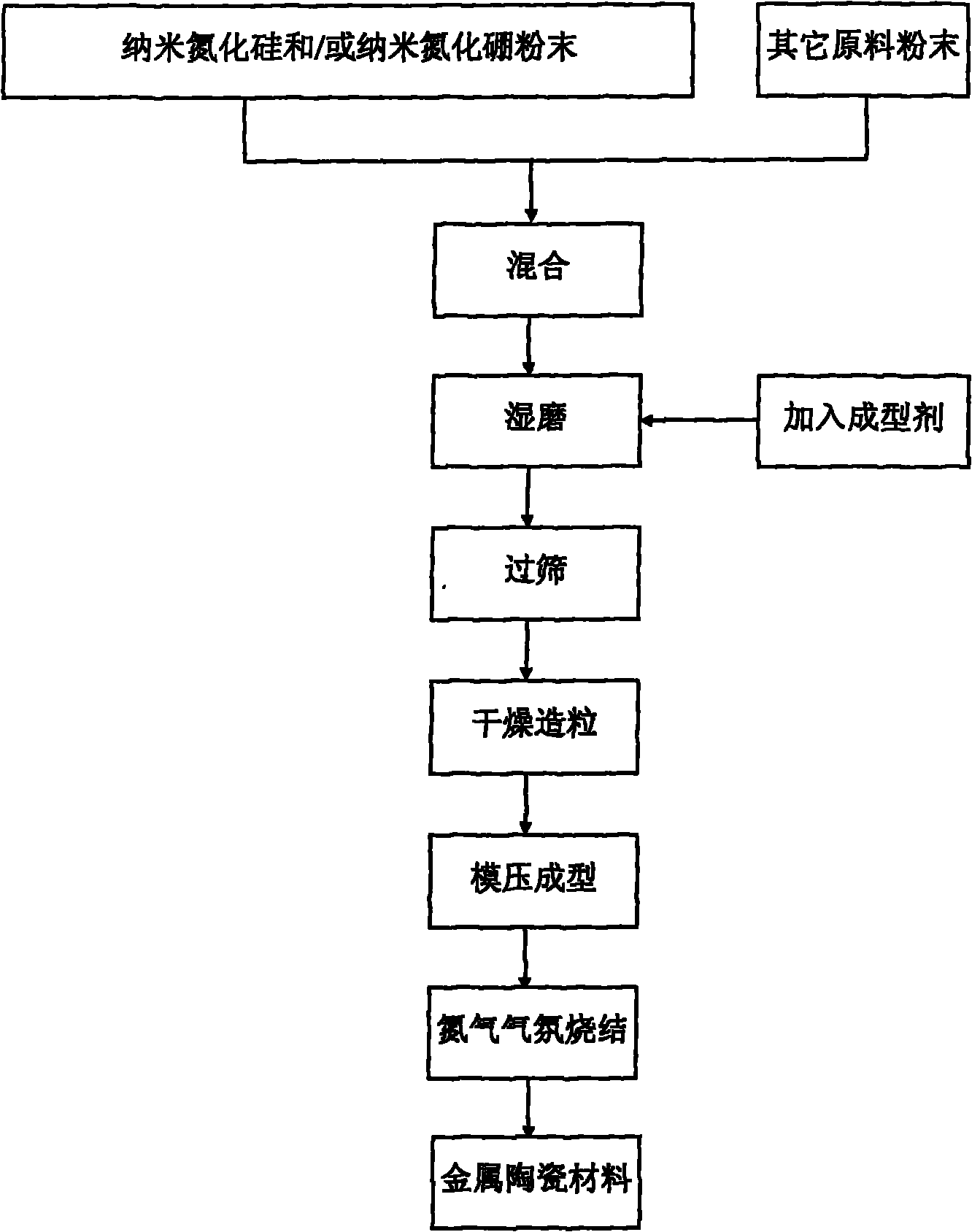

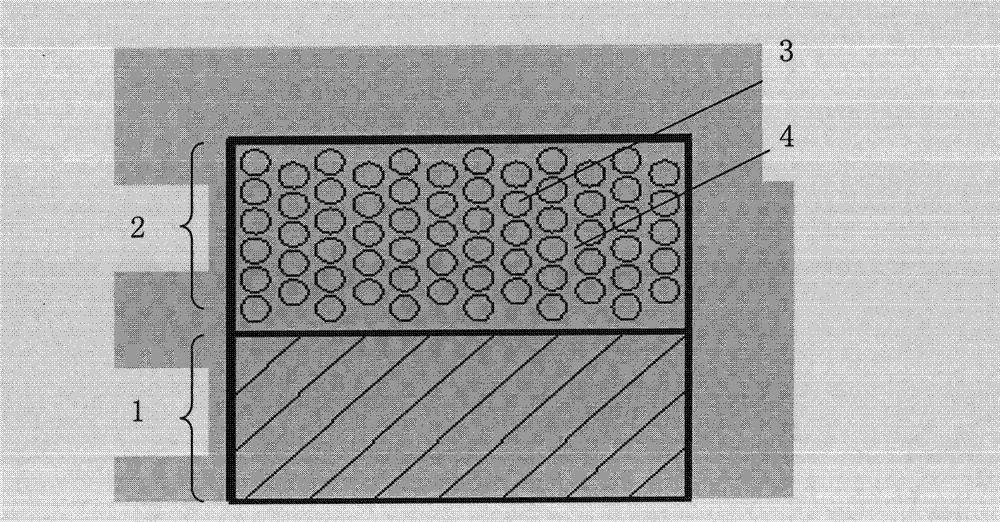

Nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet

The invention discloses a nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet. A reinforced phase is added into a base material having a main phase of titanium carbonitride Ti(C, N) and a binder phase of nickel and cobalt metals, is at least one of nano silicon nitride and nano boron nitride, and is 0.5 to 2.5 volume percent of the base material. The preparation method comprises the following process flows: preparing raw material powder containing the nano silicon nitride and / or nano boron nitride; mixing; adding a forming agent; performing wet grinding; sieving; drying and granulating; performing compression molding; sintering in nitrogen; and obtaining the cermet. The cermet has the advantages of high hardness, high strength and high toughness, and can be widely applied to middle and low carbon steel and low alloy steel high-speed cutting tool materials; and the preparation process is easy to control and is suitable for large-scale industrial production.

Owner:XIAMEN UNIV OF TECH

Electrodeposited metallic-materials comprising cobalt

InactiveUS20100304172A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryElectrolytic coatingsMetal coatingCobalt metal

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

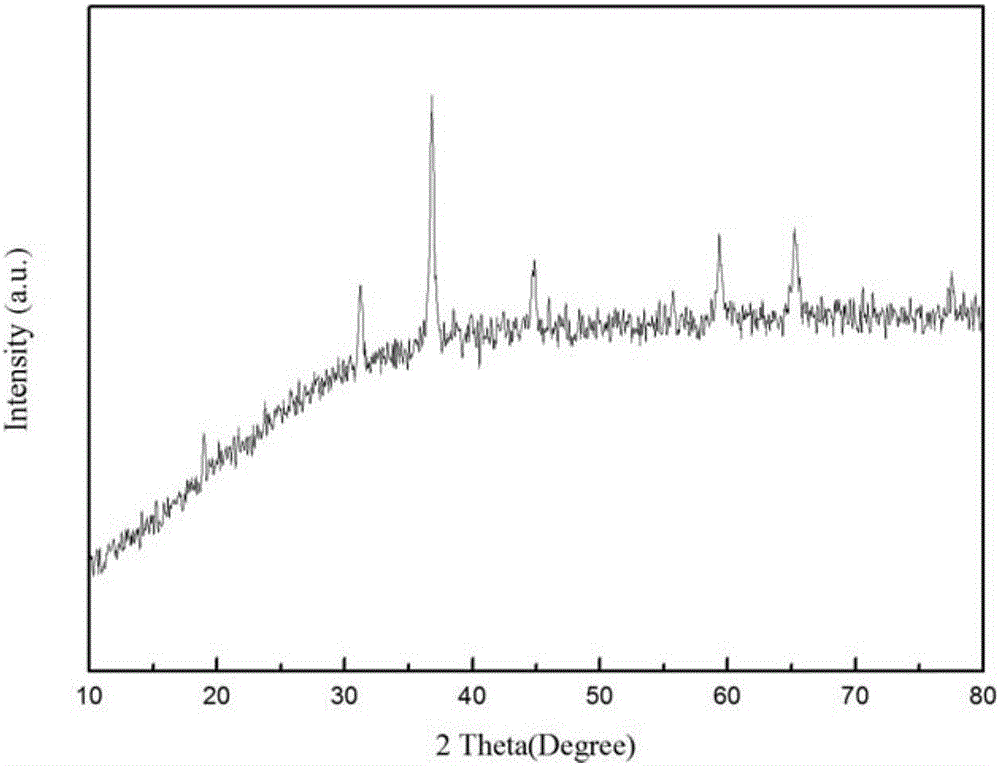

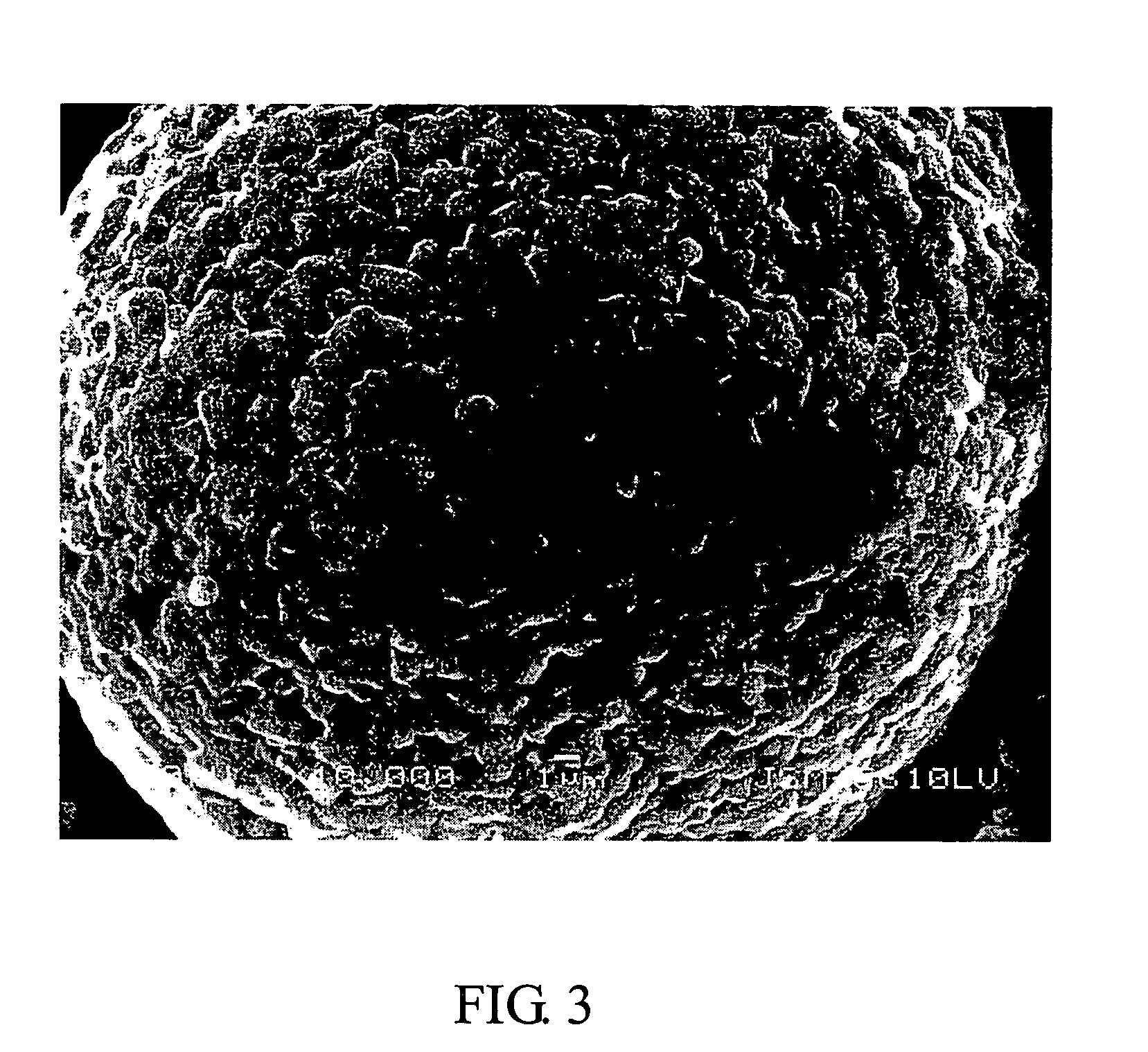

Compounds of lithium nickel cobalt metal oxide and the methods of their fabrication

InactiveUS20040191161A1High tap densityImprove electrochemical performanceCell electrodesAlkali metal oxidesManganeseLithium compound

This invention discloses compounds of lithium nickel cobalt metal oxide and the methods of their fabrication. The formula for said compounds of lithium nickel metal of oxide is LiaNi1-b-cCobMcO2 where 0.97<=a<=1.05 , 0.01<=b<=0.30 , 0<=c<=0.10, and M is one or more or the following: manganese, aluminum, titanium, chromium, magnesium, calcium, vanadium, iron, and zirconium. The method for the fabrication of said compounds of lithium nickel cobalt metal oxide includes: (a) fabricating a cobalt nickel hydroxy compound; (b) ballgrinding to evenly mix said cobalt nickel hydroxy compound; a lithium compound and compound of said metal M; (c) calcining said mixture in oxygen at between 600° C. and 720° C. for 1 hour to 10 hours; (d) calcining a second time in oxygen at between 750° C. and 900° C. for 8 hours to 10 hours; (e) cooling the twice calcined compound rapidly; (f) ballgrinding and then sifting the cooled compound to obtain said compound of lithium nickel cobalt metal oxide. The fabrication method of this invention produces said compound containing a high percentage of secondary granules that are formed by the aggregation of crystalline granules. These granules are spherically or elliptically shaped with no halite magnetic domains resulting in a material that has excellent electrochemical properties. Using these materials in the positive electrodes of rechargeable batteries produce batteries with high capacity and good cycle characteristics.

Owner:BYD AMERICA CORP

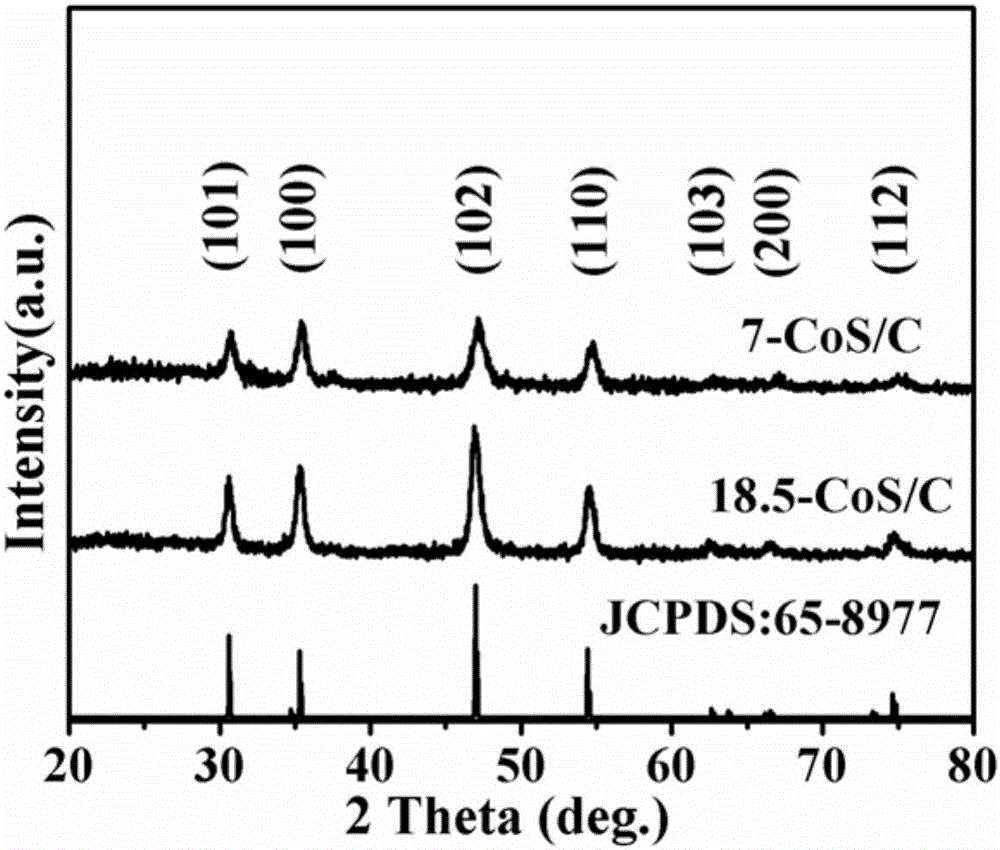

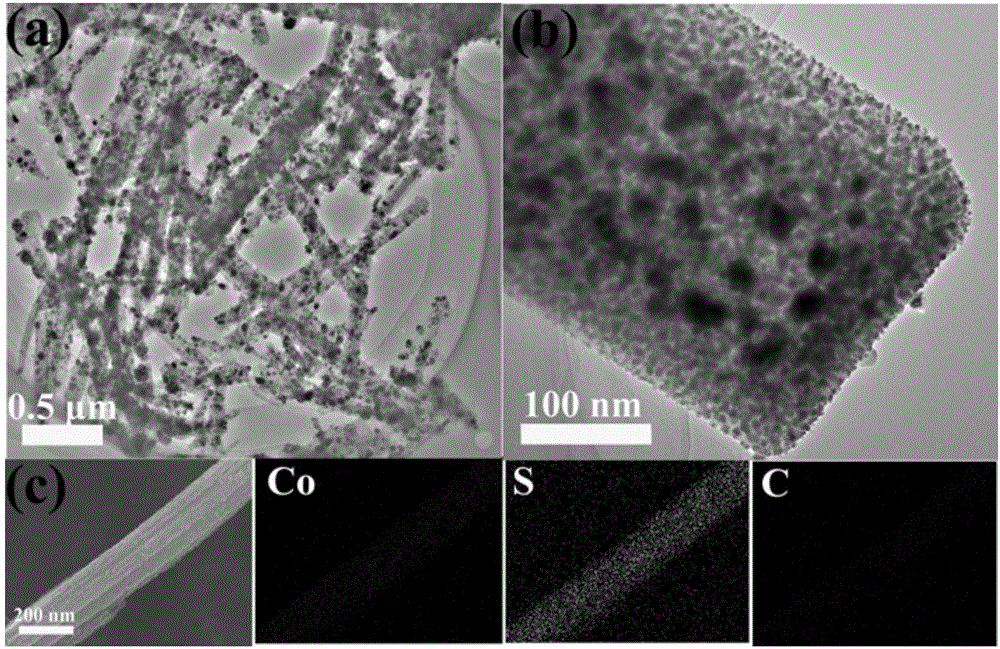

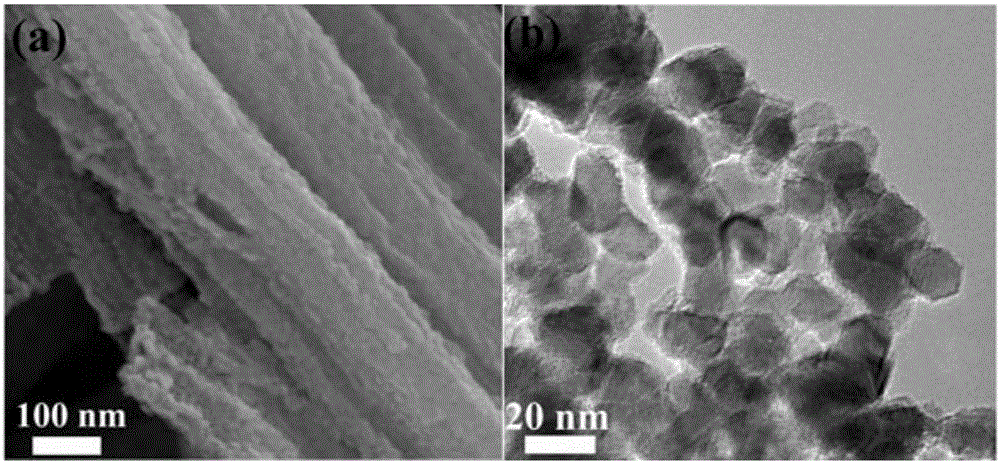

Embedded cobalt sulfide and porous carbon nanorod composite electrode material and preparation method and application thereof

InactiveCN106531999AImproved magnification performanceIncrease profitCell electrodesSecondary cellsPorous carbonHigh pressure

The invention relates to an embedded cobalt sulfide and porous carbon nanorod compound and a preparation method thereof. Cobalt sulfide nanoparticles are embedded in a porous carbon nanorod, the porous carbon nanorod is of a one-dimensional porous rod-like structure, the sizes of the cobalt sulfide nanoparticles are 5 to 10 nm, the length of the porous carbon nanorod is 2 microns, and the diameter of the porous carbon nanorod is 200 nm. The preparation method comprises the following steps: 1) dissolving a cobalt salt soluble in organic solvents into an organic solvent, adding a ligand, and stirring to form a transparent solution; 2) transferring into a high-temperature high-pressure reaction still, heating for reacting, and cooling to obtain a solution containing a cobalt metal organic skeleton compound; 3) carrying out filtering, washing and vacuum drying treatment on the solution in sequence so as to obtain Co-MOF powder; and 4) carrying out grinding and mixing on the powder and sublimed sulfur in a certain proportion, and calcining to obtain a target product. The compound has the advantages that the rate capability of the material is improved, and the compound still can show relatively high specific capacity and good cycle performance under large current density.

Owner:WUHAN UNIV OF TECH

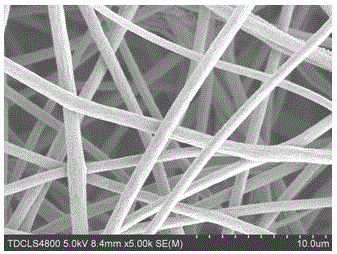

Preparation for anode material of tin-cobalt alloy/carbon nanofiber film lithium ion battery

InactiveCN102751475AImprove conductivitySmall volume changeMaterial nanotechnologyCell electrodesFiberComposite film

The invention discloses a preparation method for anode material of tin-cobalt alloy / carbon nanofiber film lithium ion battery. The method process comprises a first step of preparing a polymer nanofiber film via electrostatic spinning with proper electrostatic spinning parameters by a uniform electrostatic spinning solution which is formed by employing stannous octoate as a tin precursor, cobalt acetate as a cobalt precursor, polyacrylonitrile as a carbon nanofiber precursor and an organic solvent; and a second step of preparing the tin-cobalt alloy / carbon nanofiber film by using a pre-oxidation treatment and a carbonization treatment. The tin-cobalt alloy / carbon nanofiber composite film prepared by the method effectively improves specific capacity and cycle performance of the anode material of the lithium ion battery, because tin-cobalt alloy particles are uniformly dispersed in the carbon nanofibers with uniform diameters; cobalt metal component increases conductivity of the material and can buffer volume change to a certain degree when the tin metal is charged and discharged; and simultaneously the carbon fibers can further play a role for buffering the volume change of the materials.

Owner:TIANJIN UNIV

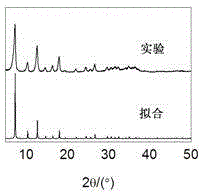

Method for preparing zeolite imidazate framework material

ActiveCN105985362AHigh yieldHigh yield for high purityCobalt organic compoundsZinc organic compoundsCobalt metalPhysical chemistry

The invention provides a method for preparing a zeolite imidazate framework material. The method prepares the zeolite imidazate framework material (ZIFs) from an imidazole compound and zinc and cobalt metal ions at normal temperature and normal pressure with inorganic base or organic amine as a deprotonation agent. The method is fast and highly efficient; and the prepared framework material is high in purity, free of impurities like zinc oxide and high in a specific area, and has a nanometer particle size and yield of 85% or above. The method is short in procedures, easy in product separation, simple to operate and suitable for large-scale industrial production. The prepared zeolite imidazate framework material is extensively applied to fields of isolated storage of gas, sustained release of drugs, membrane sensors and heterocatalysis.

Owner:李亚丰

Polycrystalline diamond compact and preparation method thereof

ActiveCN103072332AImprove wear resistanceAvoid chippingDrill bitsMetal layered productsCobalt metalPolycrystalline diamond

The invention provides a polycrystalline diamond compact and a preparation method thereof, and aims to improve abrasive resistance and impact resistant endurance of the polycrystalline diamond compact, and then the service life of the polycrystalline diamond compact and the continuous work efficiency are improved. In order to achieve the purpose, the technical scheme adopted by the invention is that the polycrystalline diamond compact comprises a hard alloy matrix layer and a polycrystalline diamond layer, wherein the polycrystalline diamond layer comprises an abrasive resistant region and an impact resistant region, the abrasive resistant region comprises cobalt-less polycrystalline diamond particles, the impact resistant region comprises cobalt-enriched polycrystalline diamond particles, and the cobalt-less polycrystalline diamond particles are distributed in the impact resistant region. According to the polycrystalline diamond compact provided by the invention, the abrasive resistant region which comprises the cobalt-less polycrystalline diamond particles is formed by fully sintering fine-grained diamond particles, so that the extremely high abrasive resistance of the polycrystalline diamond compact is guaranteed; and moreover, the cobalt-enriched polycrystalline diamond region has extremely good impact toughness due to the high cobalt metal content.

Owner:SHENZHEN HAIMINGRUN SUPERHARD MATERIALS

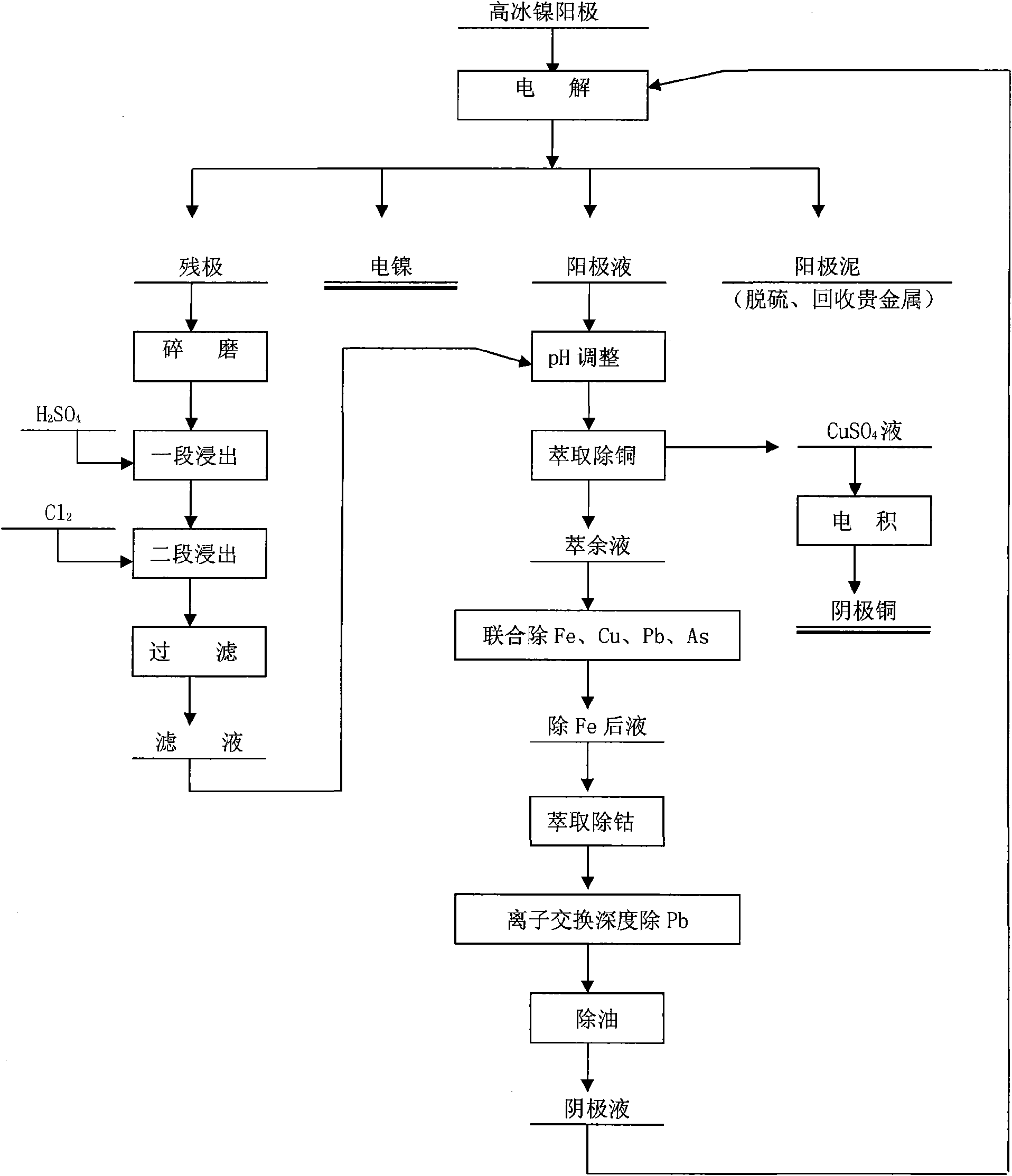

Method for refining high nickel matte

InactiveCN101560670AAdaptableAchieve synchronous deep removalPhotography auxillary processesProcess efficiency improvementCobalt metalElectrolysis

The invention provides a method for refining high nickel matte, and in particular relates to a method for refining the high nickel matte for producing cathode nickel by adopting a hydrometallurgical method and using the high nickel matte as a raw material. The method is characterized in that the refining process comprises the following steps: directly casting the high nickel matte into a high nickel matte anode, electrolyzing the high nickel matte anode to obtain the cathode nickel; purifying an anolyte after the electrolysis and using the anolyte for back electrolysis of a catholyte; electrolyzing an anode scrap, performing grinding, leaching and filtering processes, and mixing the filtrate into the anolyte to perform purification; and performing conventional desulfurization on anode mud, and recovering noble metal. The method has the advantages of simple and short flow, thorough separation of copper, nickel and cobalt metals, high metal yield, less quantity of slag and good operating environment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for producing nickel-cobalt metal powder

The invention discloses a preparation method for nickel cobalt metal powders, which belongs to the technical field for preparation of non-ferrous metal metallurgy, powder metallurgy and material preparation. The preparation method is characterized in that nanometer or ultrafine nickel and cobalt metal powders is adopted as a seed crystal, which is mixed with ammoniacal water solution with nickel sulfate, cobalt sulfate, ammonia and ammonium sulfate, the preparation method adopts a hydrometallurgical hydrothermal hydrogen reducing technology and a device thereof, and the nanometer, ultrafine or tenuous nickel powder, cobalt powder and nickel cobalt alloy powder are prepared through the procedures such as ingredient, high-pressure hydrothermal hydrogen reduction, filtration, washing, drying and the like. The preparation method can be used for the field such as hydrogen storage alloy, galvanization, catalyst, sintering activating agent, magnetic materials, electric conduction slurry, battery materials, wave-absorbing materials, hard alloy, multi-layer porcelain capacitor, powder metallurgy and the like. The preparation method has the advantages of simple raw materials, simple process, short technological process, low manufacturing cost, controllable manufacturing process, high production efficiency, even graininess of metal powders, controllable size and composition and good quality of products.

Owner:张建玲

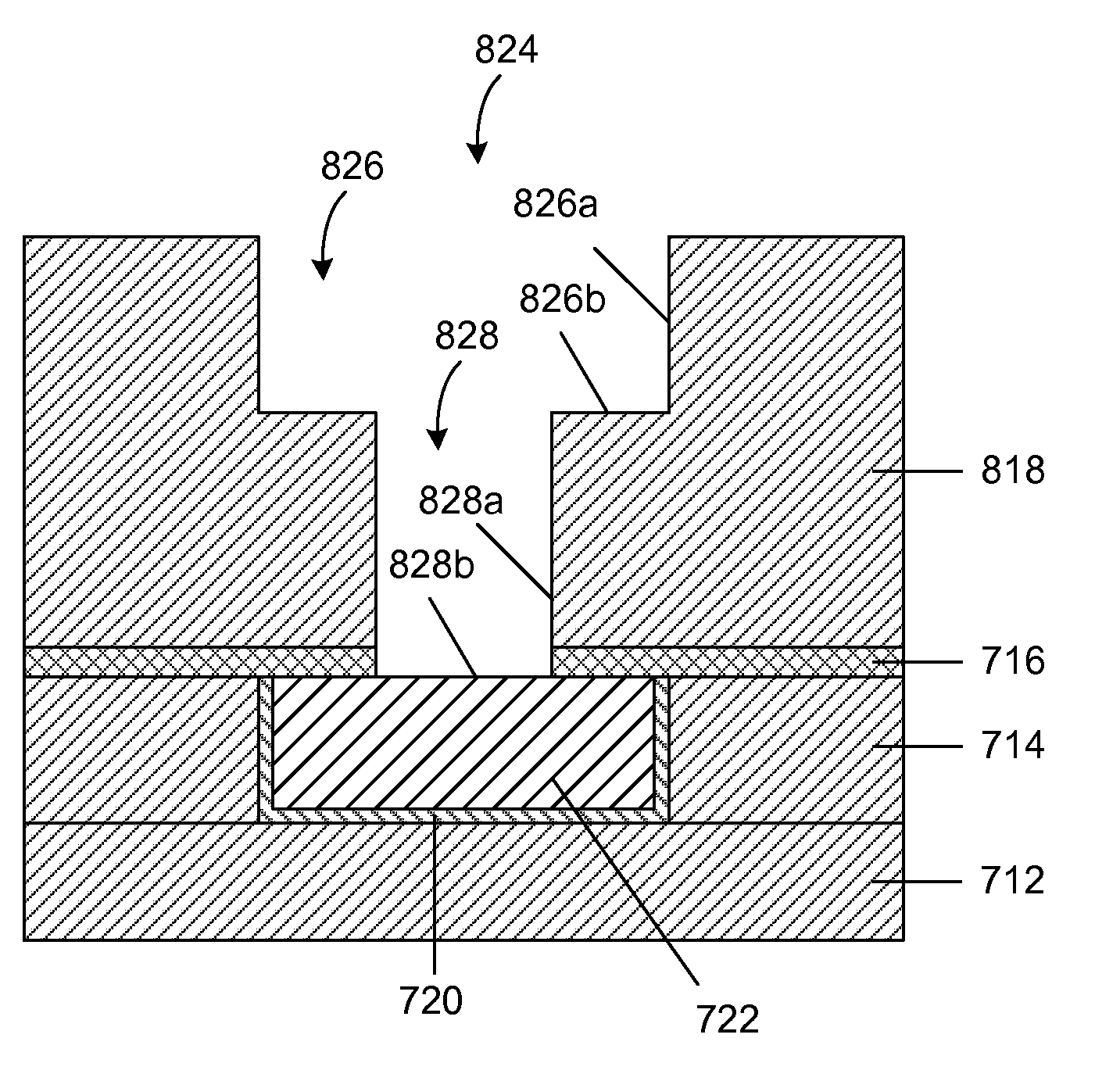

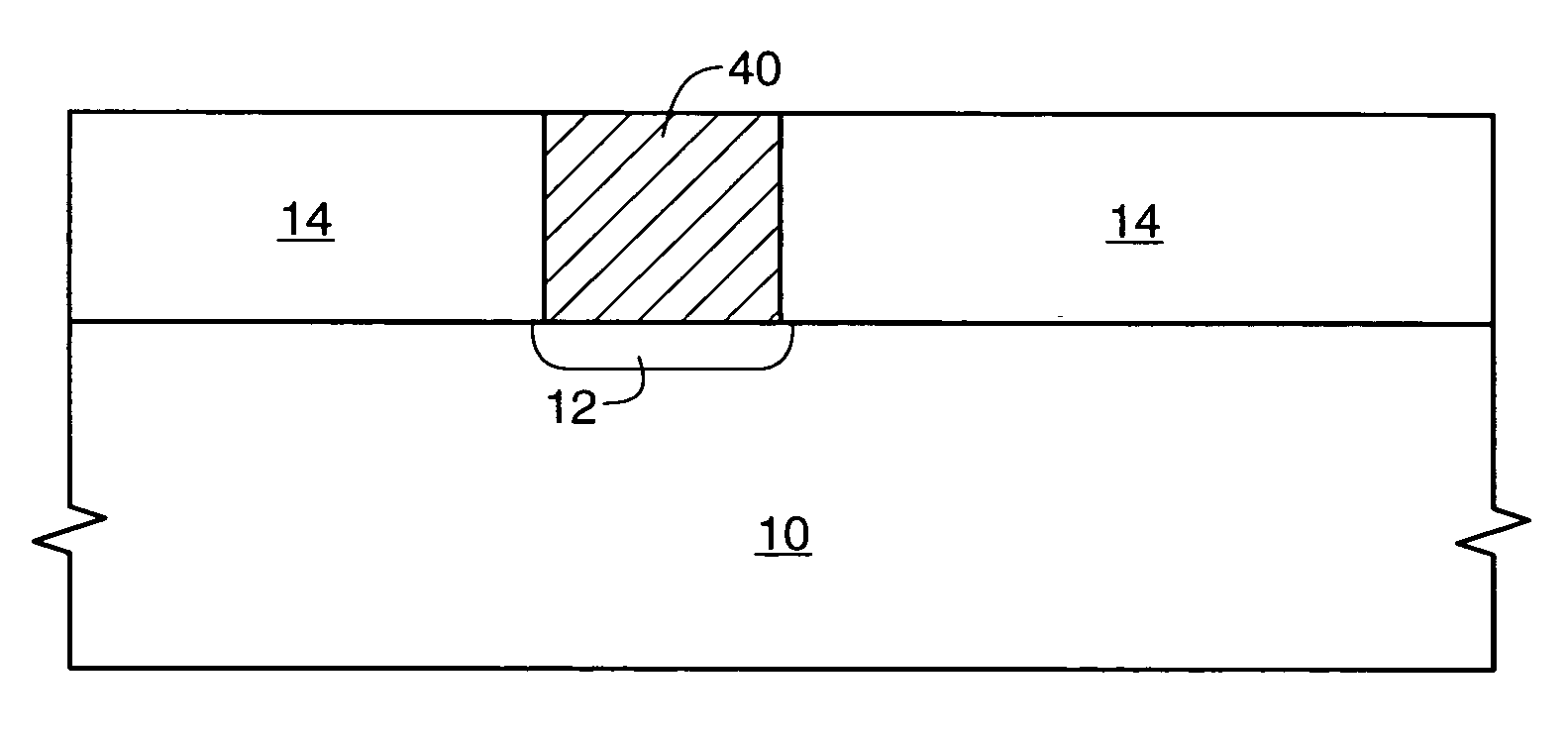

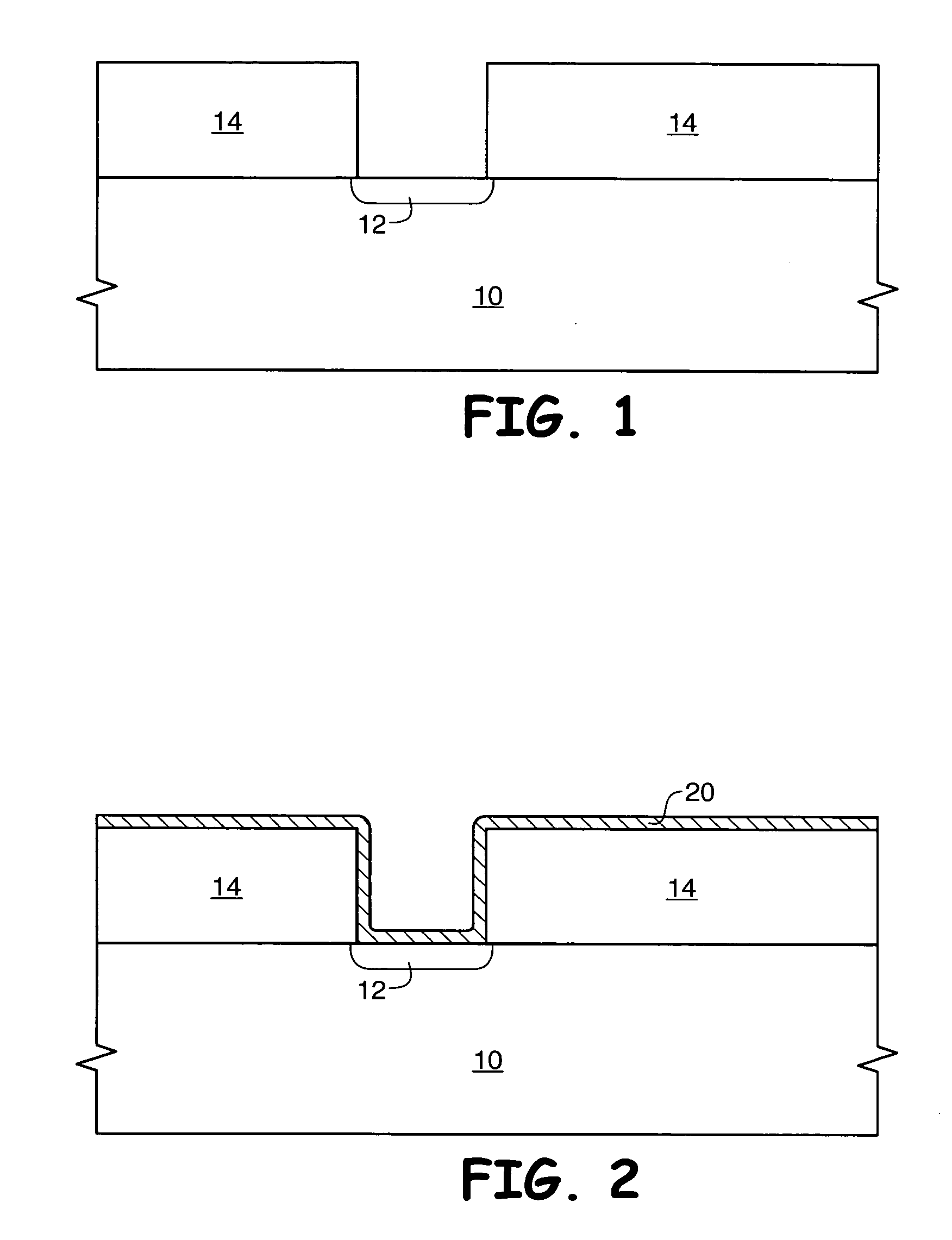

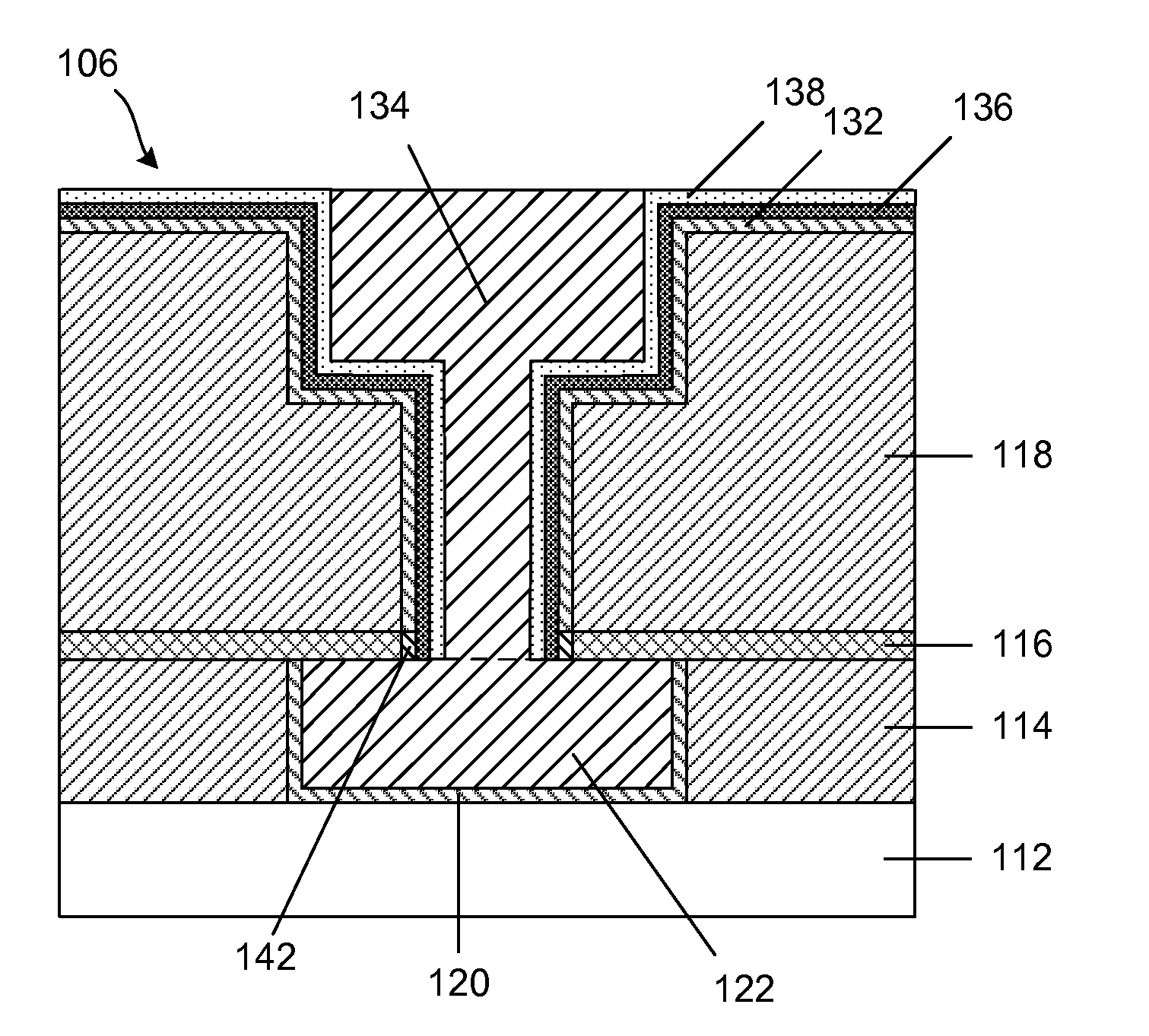

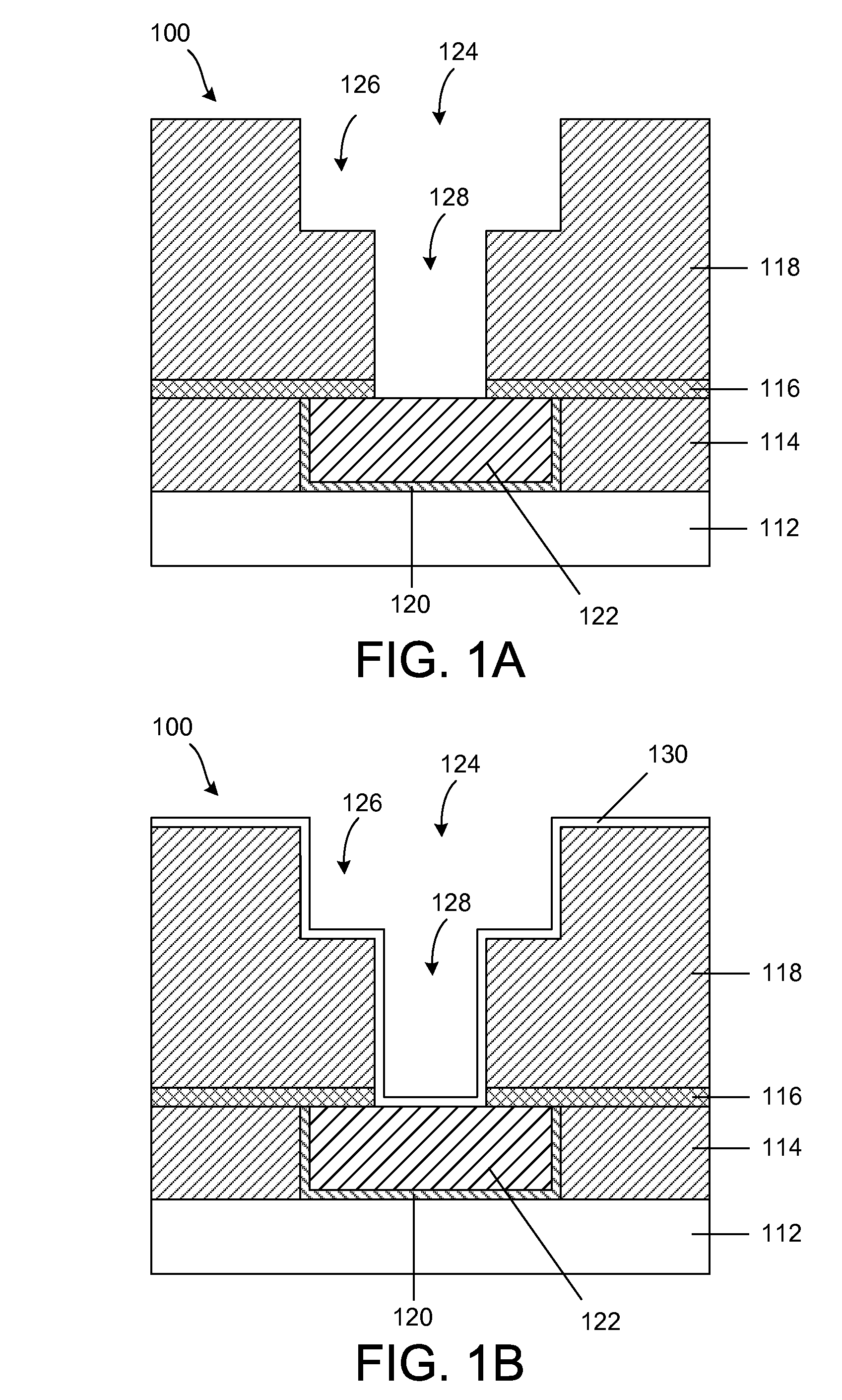

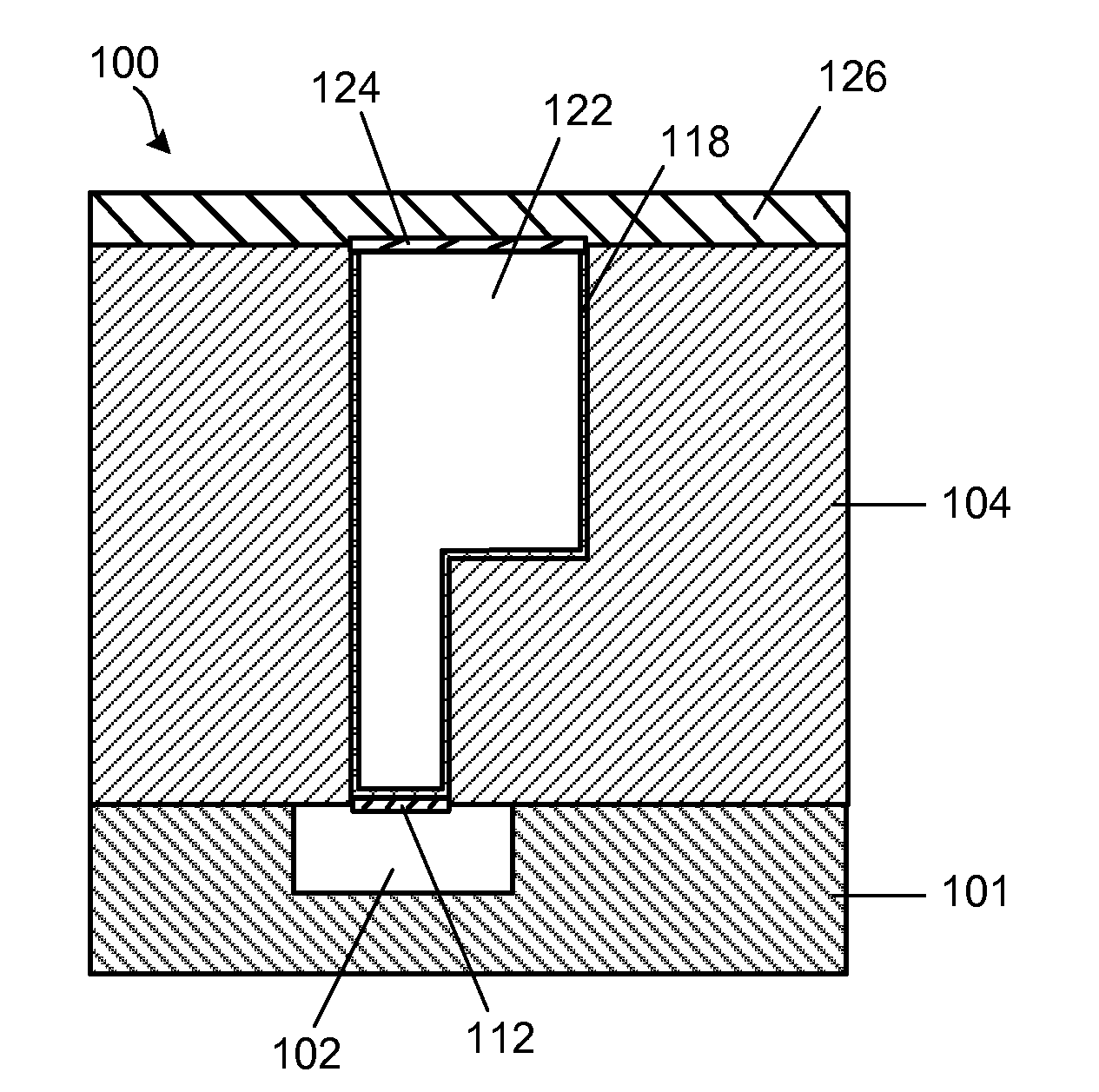

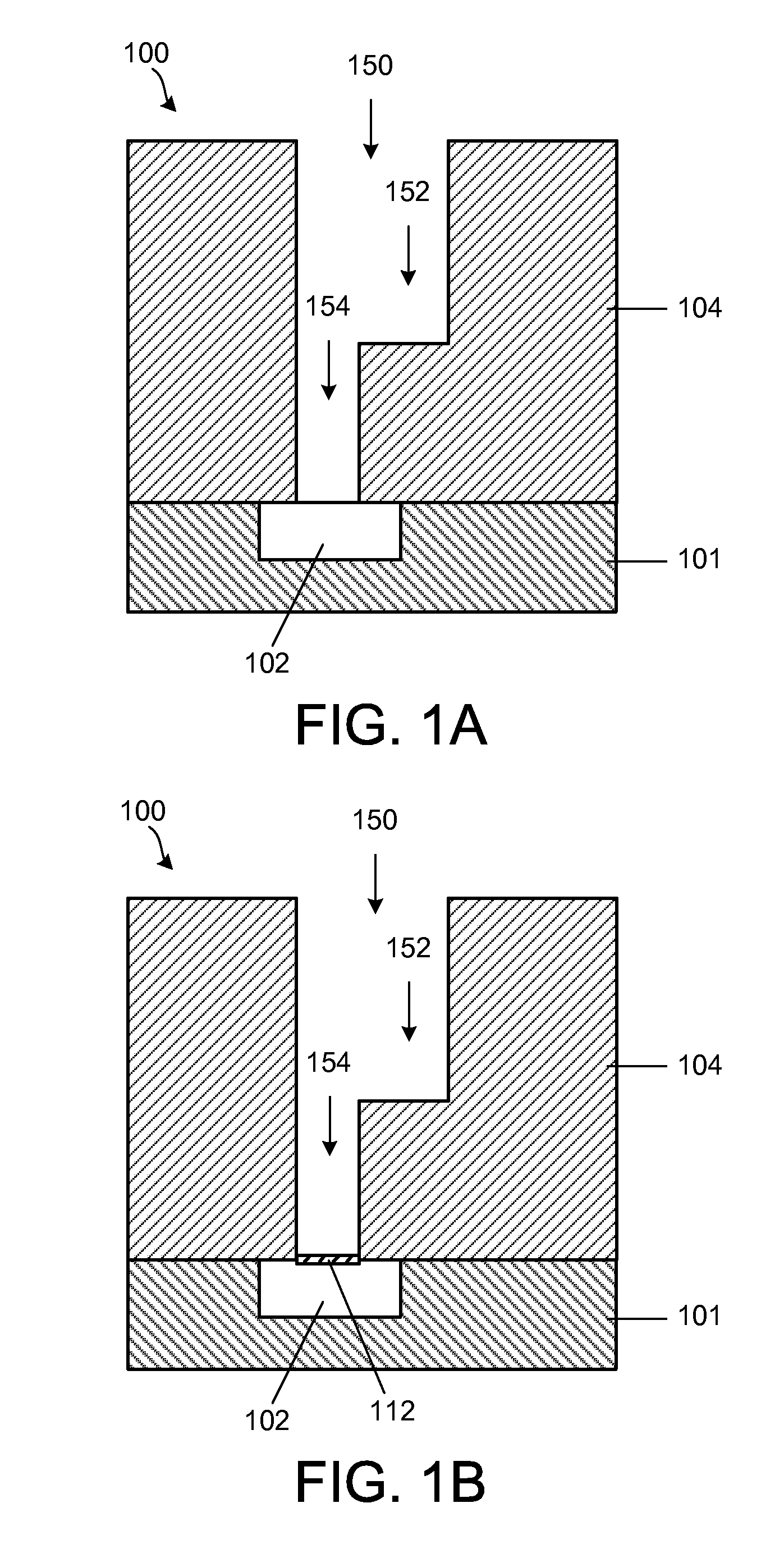

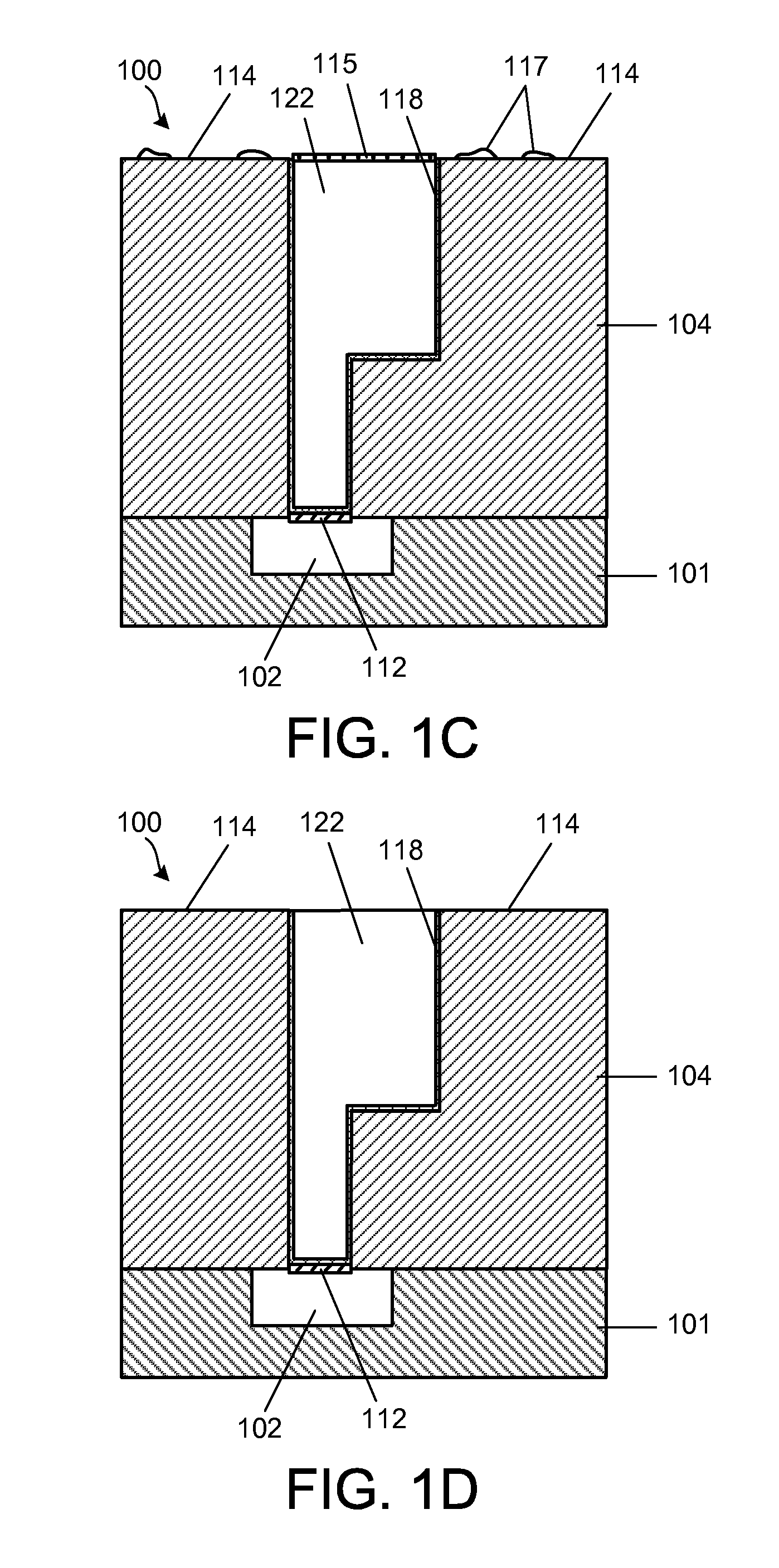

Cobalt metal barrier layers

InactiveUS20120161320A1Semiconductor/solid-state device detailsSolid-state devicesCobalt metalDopant

Electrical interconnects for integrated circuits and methods of fabrication of interconnects are provided. Devices are provided comprising copper interconnects having metal liner layers comprising cobalt and a metal selected from the group consisting of Ru, Pt, Ir, Pd, Re, or Rh. Devices having barrier layers comprising ruthenium and cobalt are provided. Methods include providing a substrate having a trench or via formed therein, forming a metal layer, the metal being selected from the group consisting of Ru, Pt, Ir, Pd, Re, and Rh, onto surfaces of the feature, depositing a copper seed layer comprising a cobalt dopant, and depositing copper into the feature.

Owner:INTEL CORP

Pressure oxidation leaching-out method for nickel-cobalt oxide ore

InactiveCN1676634AReduce pollutionImprove protectionProcess efficiency improvementCobalt metalPresent method

This invention discloses a nickel cobalt oxide ore pressure ore oxygenation leaching method, which includes the technique flow of milling the nickel cobalt oxide paste, adding sulfur powder paste or sulfuration refining paste, high-pressure still oxidization, automatic steaming of flash groove, flocculating agent adding, 7-grade reflux thick cleaning, distilling nickel cobalt and comprehensively recycling bitter salt. It has high leaching ratio of leaching nickel cobalt metals and the relative components. This invention greatly improves the present method that adds pressure and acid dips nickel cobalt oxide ores and lowers the investment, reduces the operation workers, saves the energy and improve the environment, lowers the cost and expands the utilization range of this leaching method and can comprehensively uses the other components.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

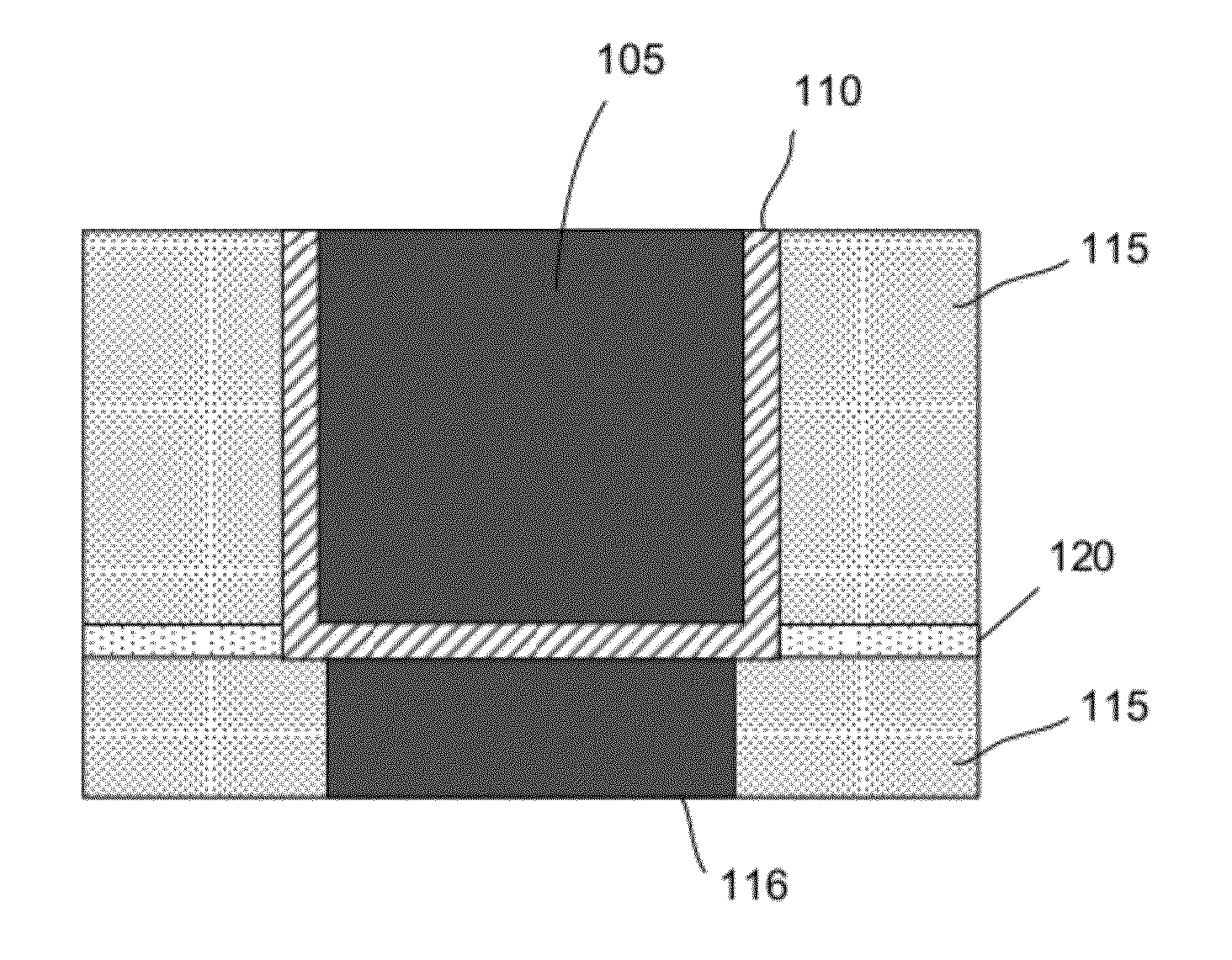

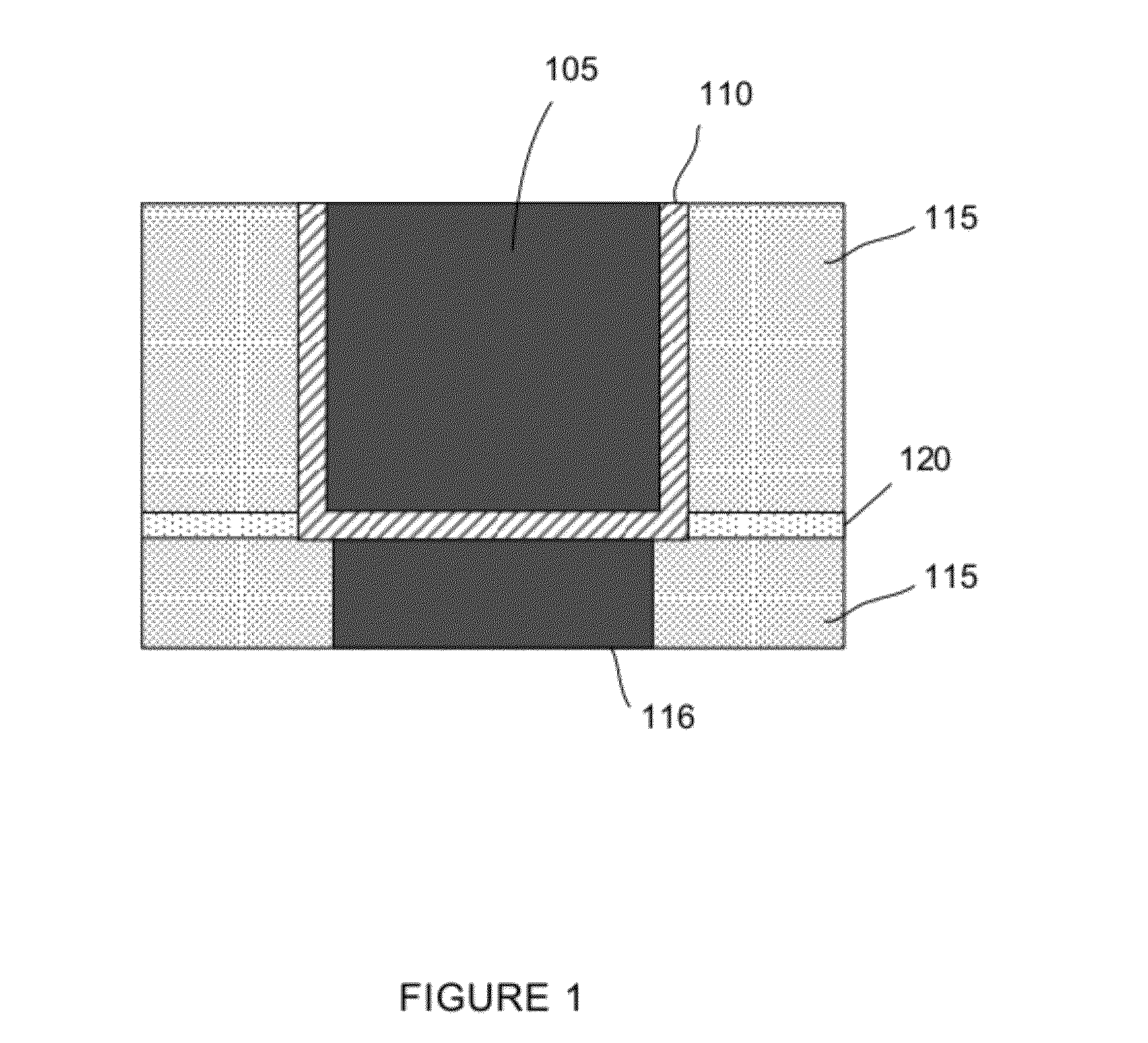

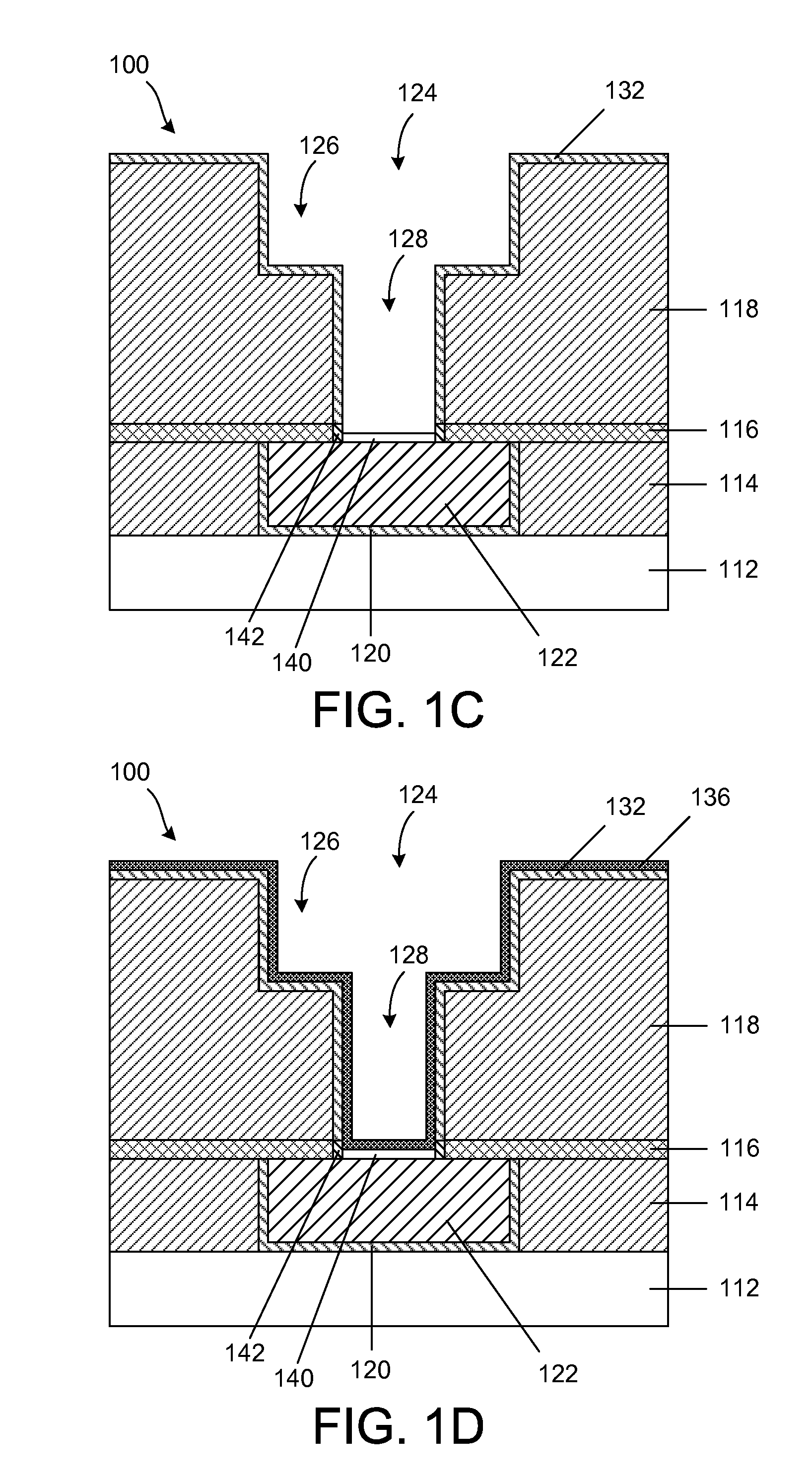

Diffusion barrier and adhesion layer for an interconnect structure

InactiveUS20100078818A1Semiconductor/solid-state device detailsSolid-state devicesCobalt metalCompound (substance)

An interconnect structure is provided. The interconnect structure includes an interconnect opening formed within a dielectric material, a diffusion barrier on the dielectric material, where the diffusion barrier contains a compound from a thermal reaction between cobalt (Co) metal from at least a portion of a cobalt metal layer formed on the dielectric material and a dielectric reactant element from the dielectric material. The interconnect structure further includes a cobalt nitride adhesion layer in the interconnect opening, and a Cu metal fill in the interconnect opening, wherein the diffusion barrier and the cobalt nitride adhesion layer surround the Cu metal fill within the interconnect opening.

Owner:TOKYO ELECTRON LTD

Method for forming cobalt tungsten cap layers

InactiveUS20100081276A1Improve electromigrationImprove stress migrationSemiconductor/solid-state device detailsSolid-state devicesCobalt metalDevice material

A method is provided for integrating cobalt tungsten cap layers into manufacturing of semiconductor devices to improve electromigration and stress migration in copper (Cu) metal. One embodiment includes providing a patterned substrate containing a recessed feature formed in a low-k material and a first metallization layer at the bottom of the feature, forming a cobalt tungsten cap layer on the first metallization layer, depositing a barrier layer in the recessed feature, including on the low-k dielectric material and on the first cobalt metal cap layer, and filling the recessed feature with Cu metal. Another embodiment includes providing a patterned substrate having a substantially planar surface with Cu paths and low-k regions, and forming a cobalt tungsten cap layer on the Cu paths.

Owner:TOKYO ELECTRON LTD

Recovery of nickel, cobalt, iron, silica, zinc and copper from laterite ore by sulfuric acid leaching

ActiveUS7387767B2Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INC

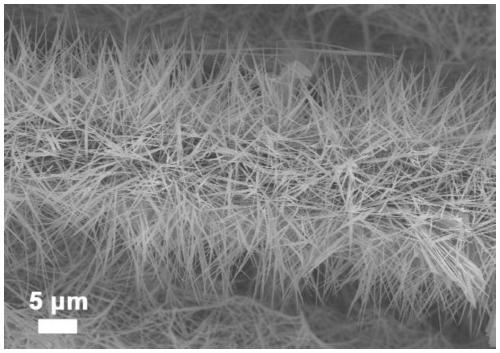

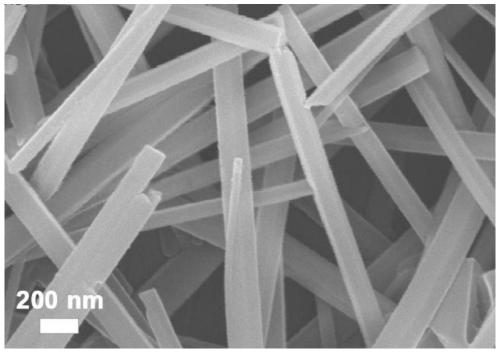

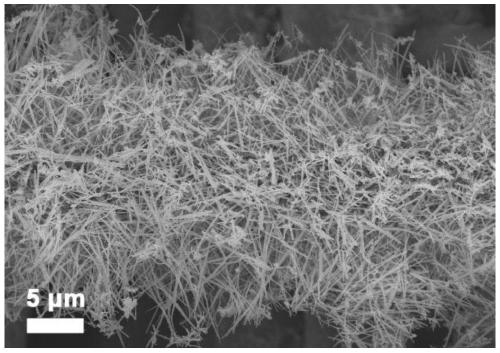

Phosphorus-doped cobalt nitride nanowire electrocatalyst as well as preparation method and application thereof

InactiveCN110433846AImprove conductivityIncrease surface areaPhysical/chemical process catalystsElectrodesNanowireSolvent

The invention relates to a phosphorus-doped cobalt nitride nanowire electrocatalyst as well as a preparation method and application thereof, and belongs to the technical field of electrocatalysis. Thepreparation method comprises the following steps: a cobalt metal salt and urea are used as raw materials, water is used as a solvent, a carbon cloth is used as a substrate, and a cobalt hydroxide nanowire precursor array is grown in situ on the surface of the carbon cloth substrate by a hydrothermal process; and the precursor array is placed in an ammonia gas atmosphere, high-temperature calcination is performed, the calcination product is placed in a tube furnace with a phosphorus source, calcination is performed for doping phosphorus, and finally the phosphorus-doped cobalt nitride nanowirecatalyst is obtained. According to the method provided by the invention, the catalyst obtained by the method has a material with nanowire morphology grown in situ, the nanowire structure has a largersurface area, the carbon cloth as a substrate has good electrical conductivity, so that the catalyst has superior performance in an electrocatalytic oxygen evolution reaction and an electrocatalytichydrogen evolution reaction; and at the same time, the process is simple to operate, and the catalyst is a non-precious metal, has low preparation costs and high stability, and has good application prospects in the oxygen evolution reaction and the hydrogen evolution reaction.

Owner:ZHEJIANG UNIV OF TECH

Co-based fischer-tropsch synthesis catalyst and method for preparing the same

ActiveCN101134164AHigh activityHigh selectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCobalt metalChemistry

The present invention is cobalt-base catalyst for Fischer-Tropsch process and its preparation process. The catalyst containing cobalt metal component in an effective amount and carrier is prepared through one dipping carrier in solution containing cobalt metal component with the ratio between the immersion liquid volume VL and the carrier pore volume VC meeting the relationship of VL / VC=0.01-0.99. The catalyst of the present invention has high reaction activity and high C5+ selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for increasing cobalt catalyst hydrogenation activity via aqueous low temperature oxidation

InactiveUS6465529B1Improve catalytic performanceImprove performanceLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesCobalt metalHydrogenation reaction

An aqueous low temperature oxidation (ALTO) process wherein a catalyst or catalyst precursor constituted of a solids support, or powder component, and a metal, or metals component, inclusive of cobalt, is oxidized, reduced and rendered catalytically active for conducting carbon monoxide hydrogenation reactions. The cobalt catalyst or cobalt catalyst precursor is thus contacted at low temperature with an oxidant in the presence of water (e.g., water to which an oxidant is added), sufficient to oxidize the cobalt metal, or metals component of the catalyst or catalyst precursor. On reduction, the hydrogenation activity of the cobalt catalyst is increased. All or a portion of the cobalt metal of the catalyst precursor is oxidized to form a Co2+ cationic or oxo-anionic species at least during the initial phase of the reaction. On reduction, as may be produced by contact and treatment of the oxidized catalyst or catalyst precursor with hydrogen, or a hydrogen-containing gas, the catalytic metal, or metals component of the catalyst, is reduced to metallic metal, e.g., Co, and the catalyst thereby activated, and / or the catalytic activity increased.

Owner:EXXON RES & ENG CO

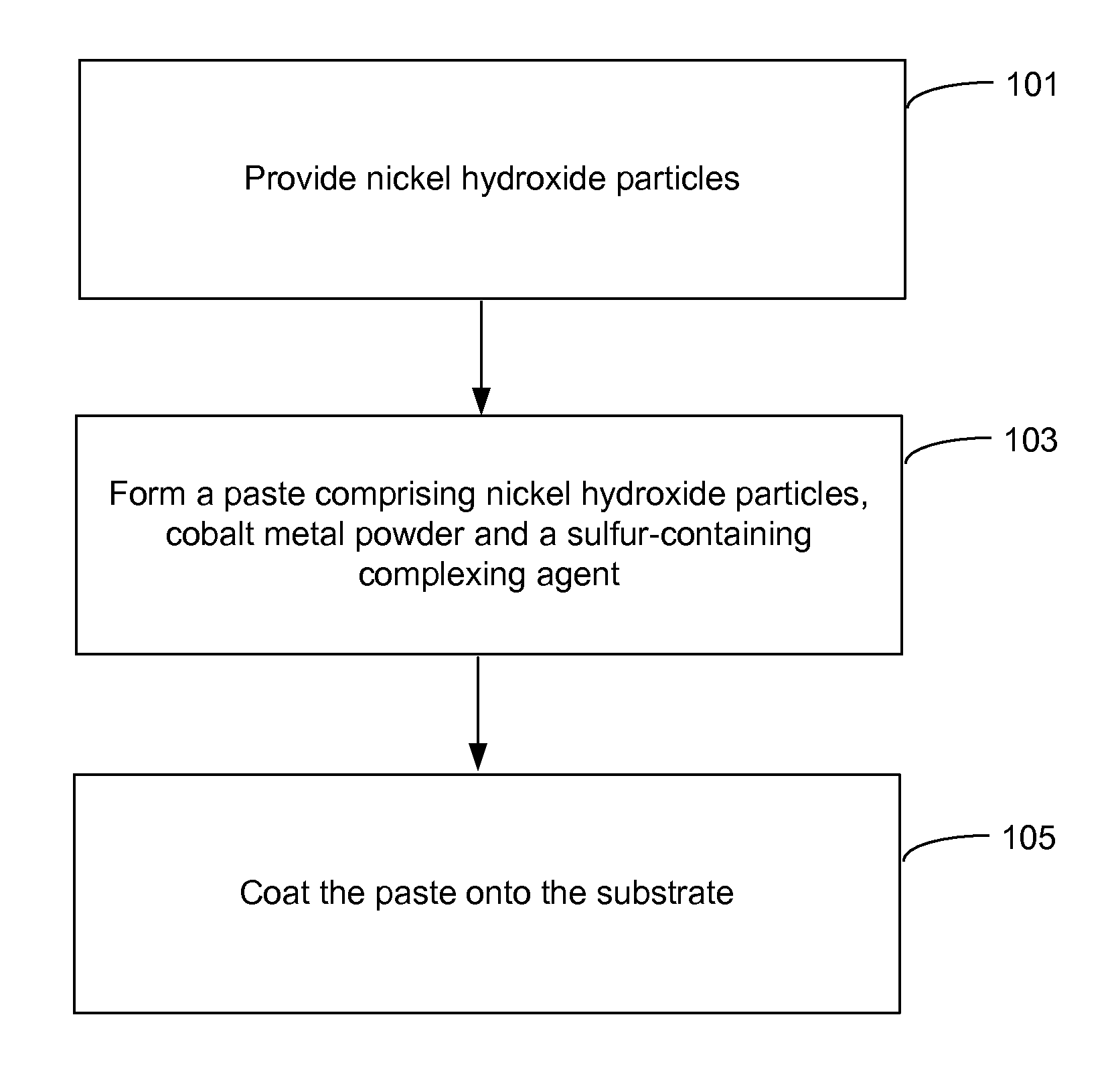

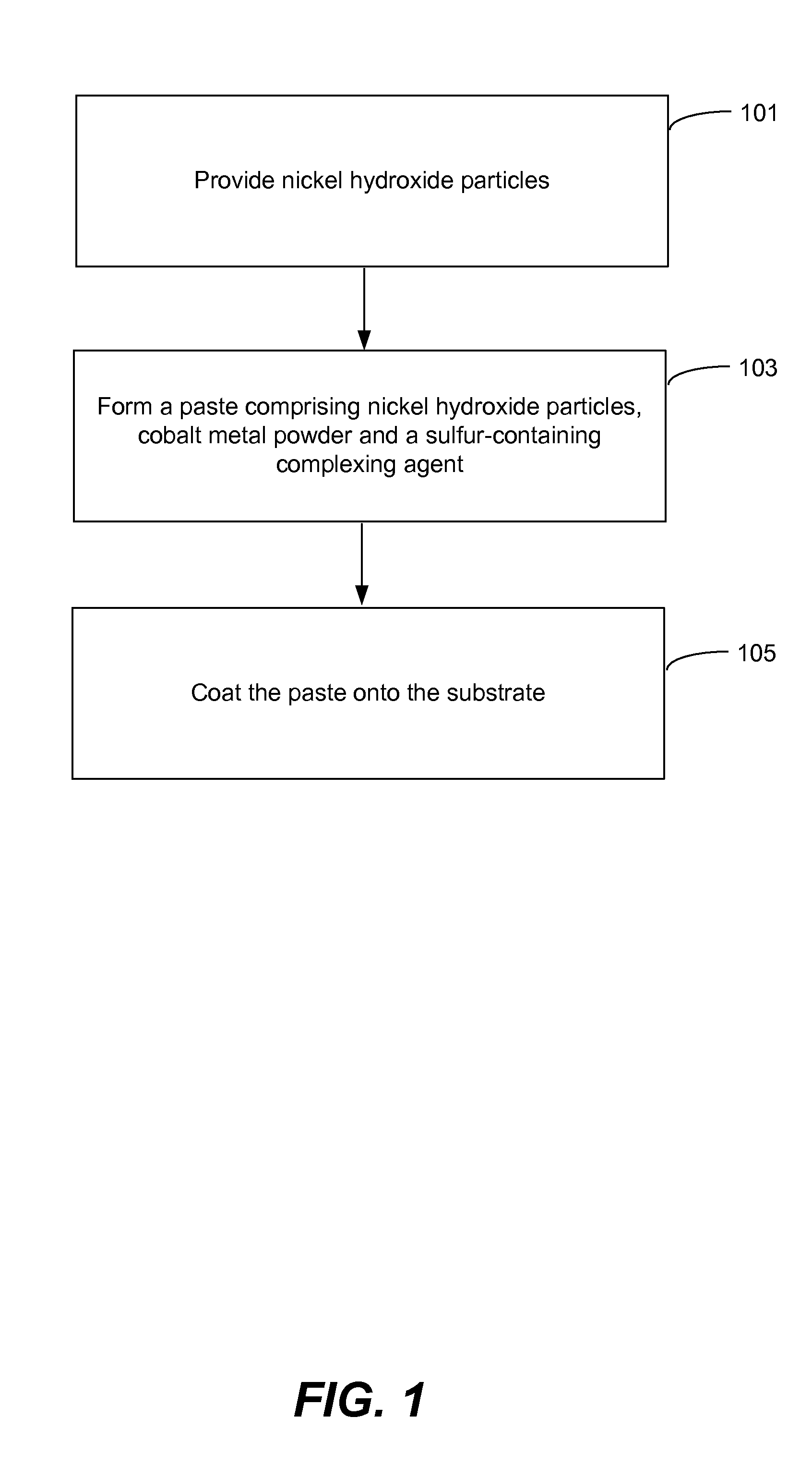

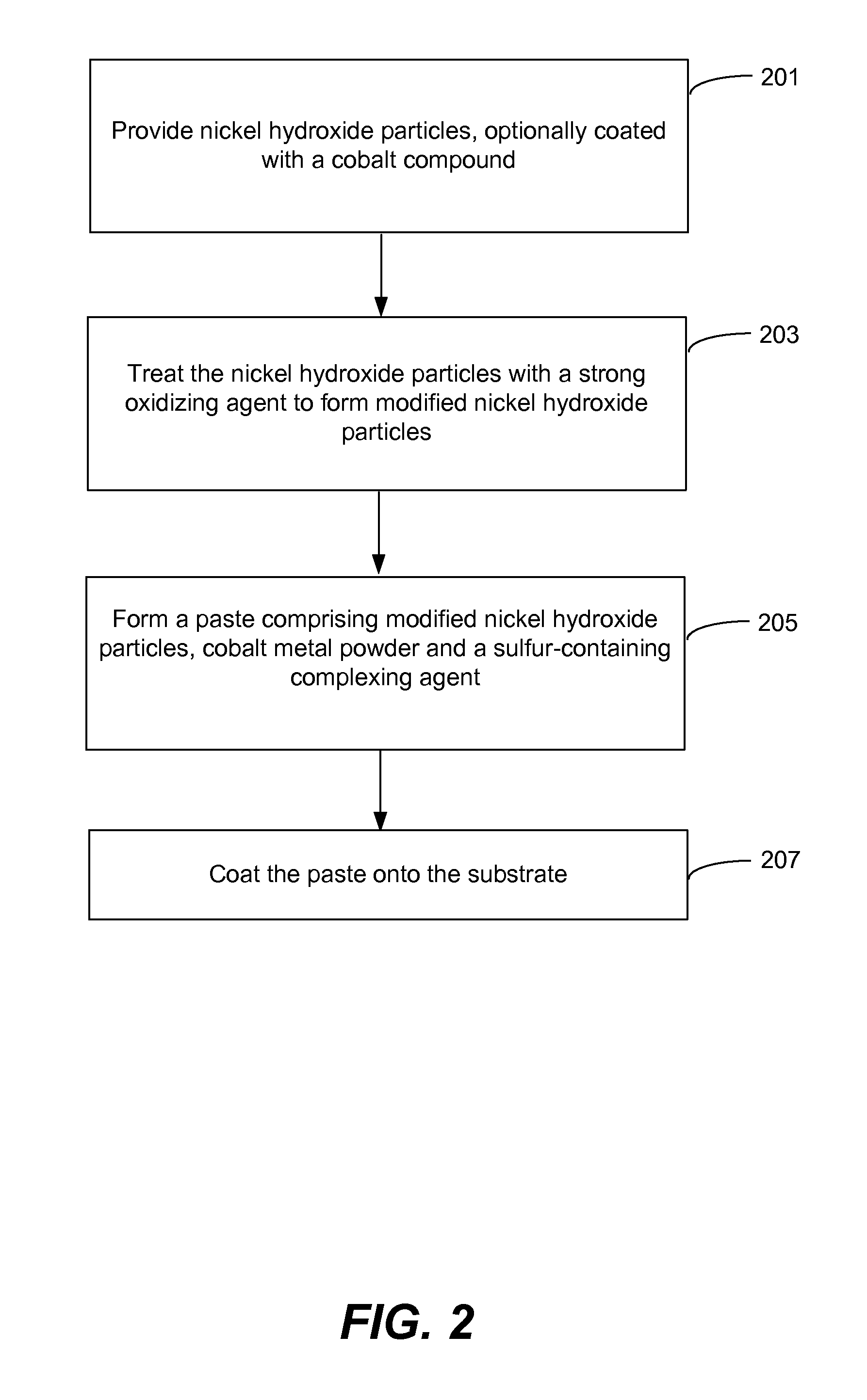

Pasted nickel hydroxide electrode and additives for rechargeable alkaline batteries

ActiveUS20140199591A1Prevent peelingMinimize migrationFinal product manufactureConductive materialNickel electrodeNickel zinc

A pasted positive nickel hydroxide electrode for use in battery cells (e.g., in nickel zinc cells, and nickel metal hydride cells) includes nickel hydroxide particles, a cobalt metal and / or cobalt compound and a sulfur-containing complexing agent capable of forming a complex with cobalt. The presence of the sulfur-containing complexing agent, such as dialkyldithiocarbamate (e.g., sodium diethyldithiocarbamate) improves lifetime and capacity utilization of the nickel electrode. The resulting pasted nickel hydroxide electrode includes a CoOOH conductive matrix after formation. The surface of the nickel hydroxide particles in the electrode is modified in some embodiments by providing a cobalt-containing coating onto the surface of the nickel hydroxide particles, followed by oxidation with a strong oxidizing agent. The complexing agent can be added before, after, or during the oxidation.

Owner:ZINCFIVE POWER INC

Preparation method of proton exchange film fuel cell film electrode

The invention provides a preparation method of a proton exchange film fuel cell film electrode. Pt / C catalyst layers are coated on two sides of a proton exchange film respectively to obtain a CCM filmsemi-finished product, and anti-reverse pole slurry layers are coated on peripheral edges of anode surfaces of the CCM film semi-finished product; the preparation process of the anti-reverse pole slurry specifically comprises steps of adding an antipole substance into deionized water, uniformly mixing the mixture to form mixed solution, adding mixed solution of organic solvent and proton exchangefilm resin solution into the mixed solution, and uniformly mixing the mixture to obtain anti-reverse pole slurry; the solid content of the anti-reverse pole slurry is controlled to be 1-4%, the anti-reverse pole substance is one or more of iridium, rubidium, tin, cobalt metal and metal oxide thereof, and the organic solvent is one or more of ethanol, isopropanol, tert-butyl alcohol and n-propyl alcohol. The method is simple in process, can reduce the probability of occurrence of a reverse pole phenomenon of a fuel cell in the operation process, and reduces a perforation phenomenon.

Owner:先进储能材料国家工程研究中心有限责任公司

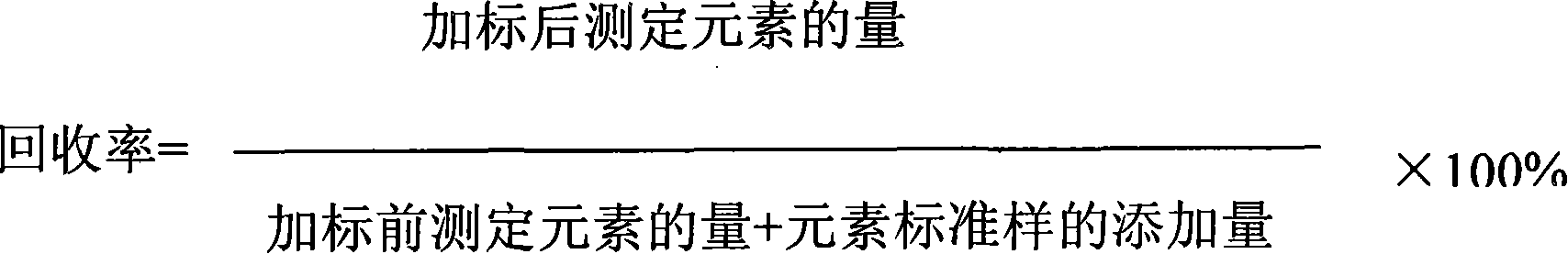

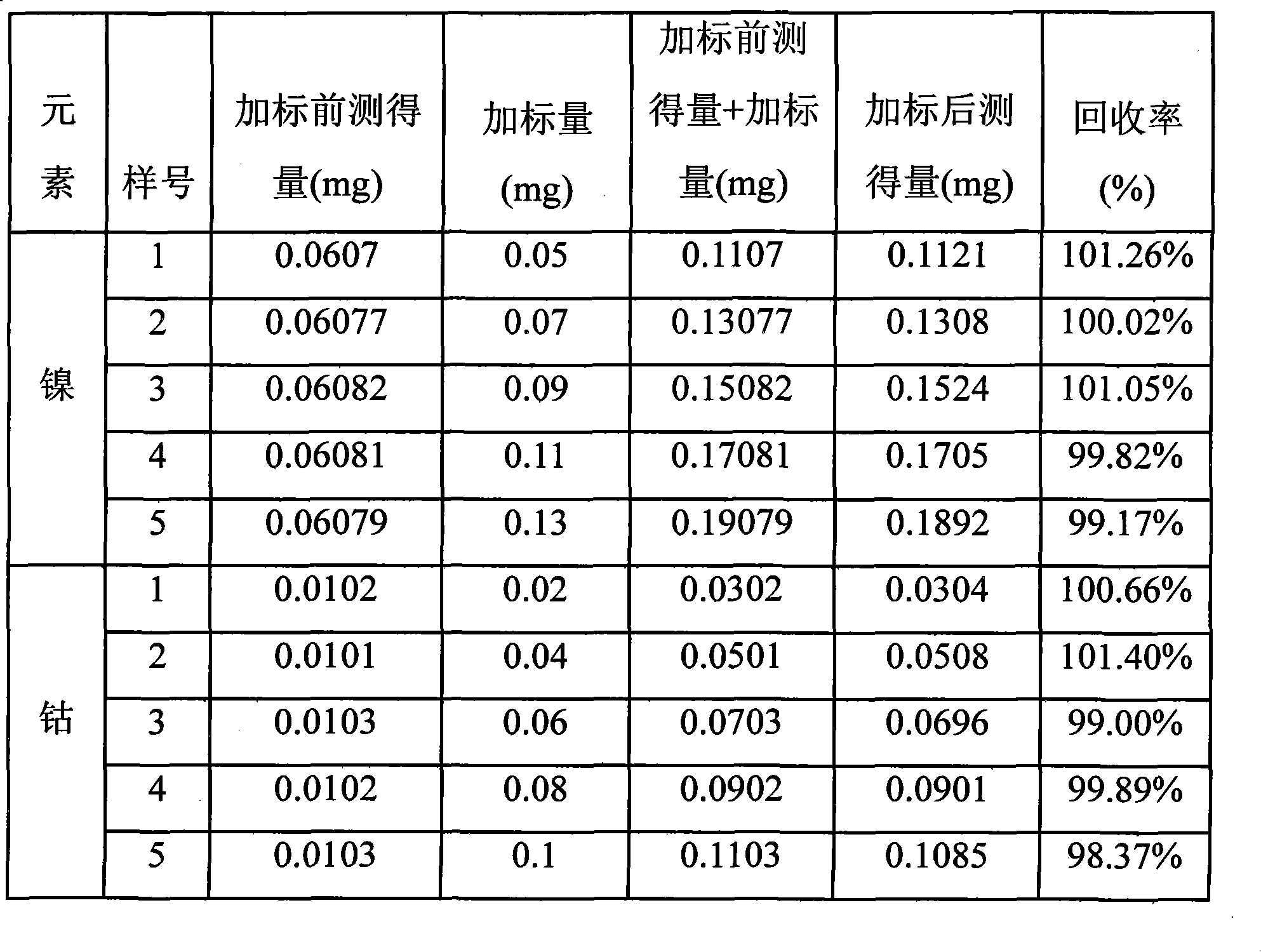

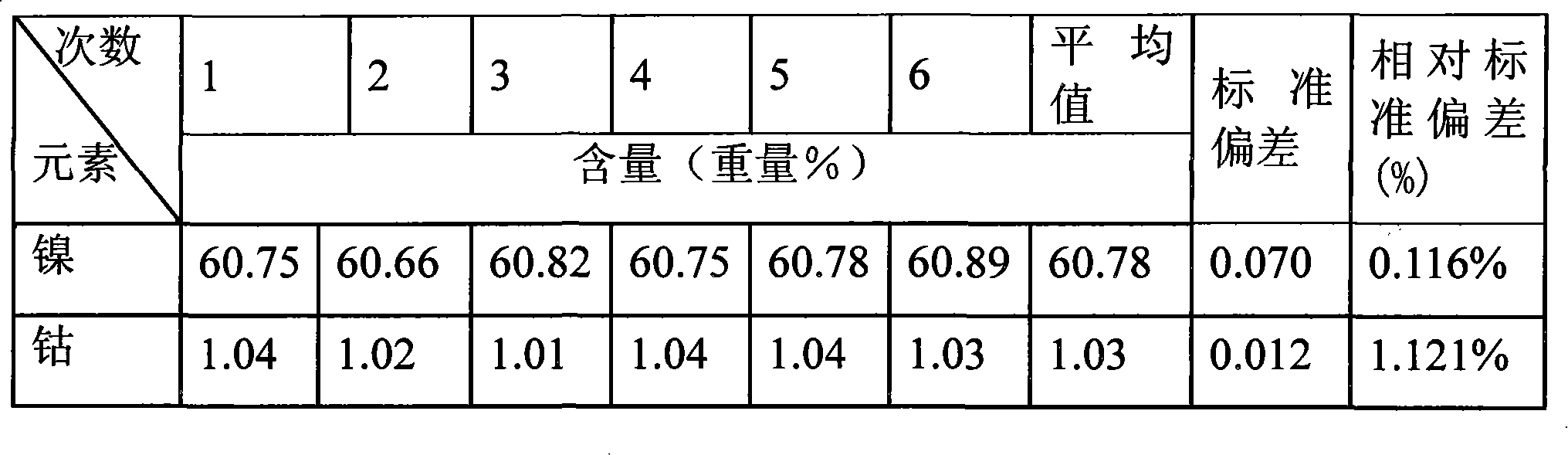

Method for testing nickel and cobalt contents in nickel compound by titration

InactiveCN101609049ALower requirementImprove accuracyMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationCobalt metalNickel compounds

The invention relates to a method for testing nickel and cobalt contents in a nickel compound by a titration, which comprises the following steps of: 1) dissolving the nickel compound to obtain nickel solution; 2) taking the partial nickel solution obtained in step 1), and carrying out complexometric titration on the nickel solution to test the nickel and cobalt metal total content; 3) taking the partial nickel solution obtained in step 1), adding ammonium persulfate, and testing the nickel metal content by using the complexometric titration again; and 4) subtracting the nickel metal content in step 3) from the nickel and cobalt metal total content tested in step 2), and obtaining the cobalt metal content. The nickel and cobalt contents in samples tested by the testing method have the advantages of small relative error and high accuracy. The testing method has the advantages of good repeatability and lower requirements of test conditions at the same time, and is suitable for work and production.

Owner:BYD CO LTD

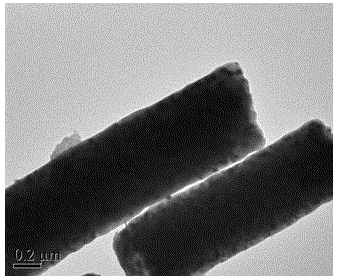

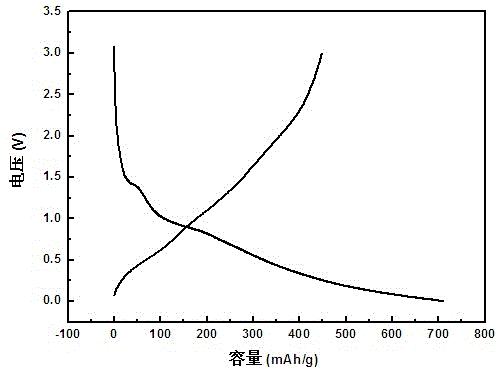

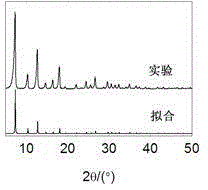

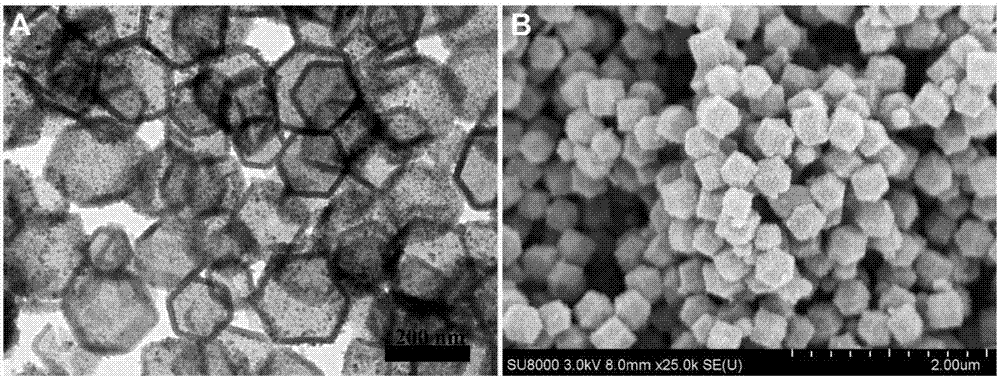

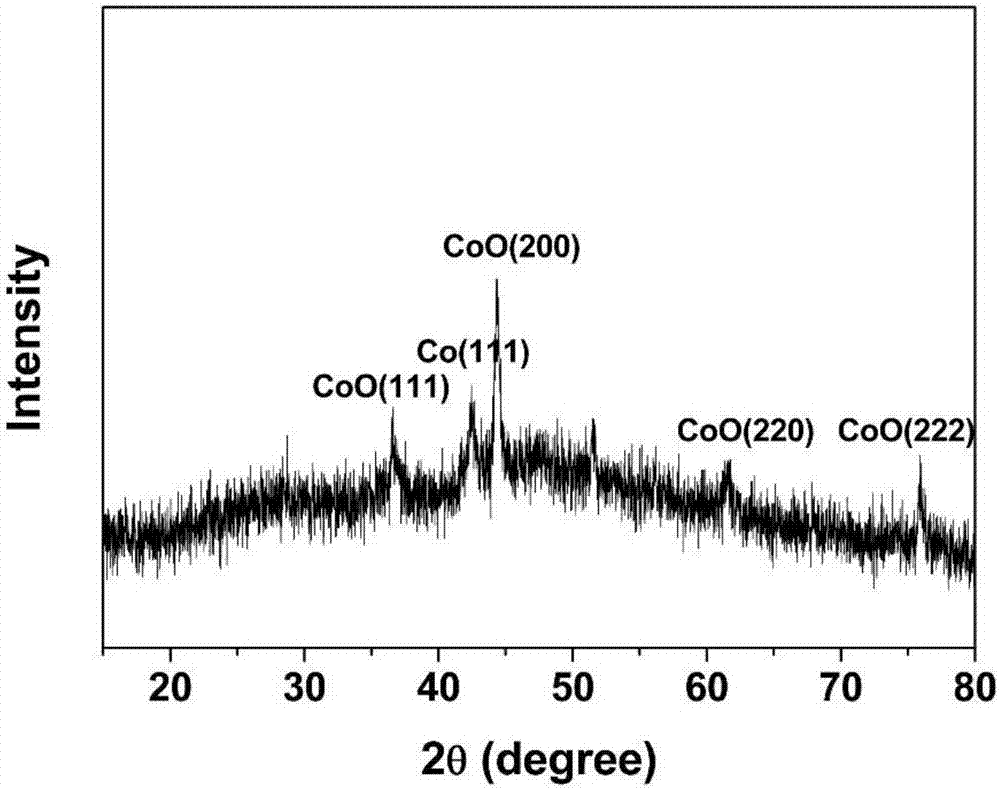

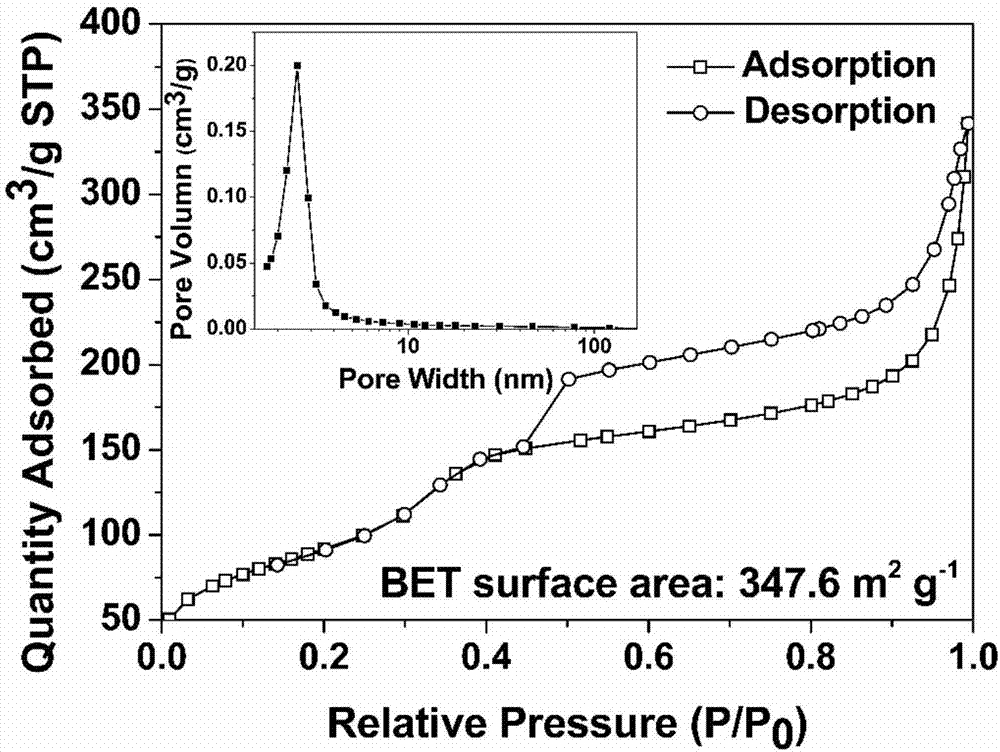

Cobaltous oxide/carbon composite hollow nanostructure material of dodecahedron structure and application thereof in negative electrodes of lithium batteries

ActiveCN107359338AImprove responseExperiment operation is simpleMaterial nanotechnologyCell electrodesCarbon compositesDodecahedron

The invention disclose a cobaltous oxide / carbon composite hollow nanostructure material of dodecahedron structure and application of the cobaltous oxide / carbon composite hollow nanostructure material in negative electrodes of lithium batteries, and belongs to the technical field of preparation of negative electrode materials for lithium batteries. The method comprises the following specific steps: (1) preparing and purifying an organic frame compound ZIF-67 containing cobalt metal; (2) reacting a dopamine monomer with the organic frame compound ZIF-67 containing cobalt metal to generate a cobalt ion coordinated hollow polymer nanostructure; and (3) under the condition of nitrogen production, carbonizing the hollow polymer nanostructure at the temperature of 500 to 600 DEG C to obtain the hollow nanostructure material. The dimensions of the hollow nanostructure material can be adjusted according to the dimensions of the template metal organic frame compound ZIF-67 nanostructure; in the performance testing process of lithium ion batteries, the hollow nanostructure material, as a negative electrode active material, has preferable cycle performance, rate capacity and stability. Therefore, the cobaltous oxide / carbon composite hollow nanostructure material, as the negative electrode active material, can be of preferable application values and prospects in the field of lithium ion batteries.

Owner:JILIN UNIV

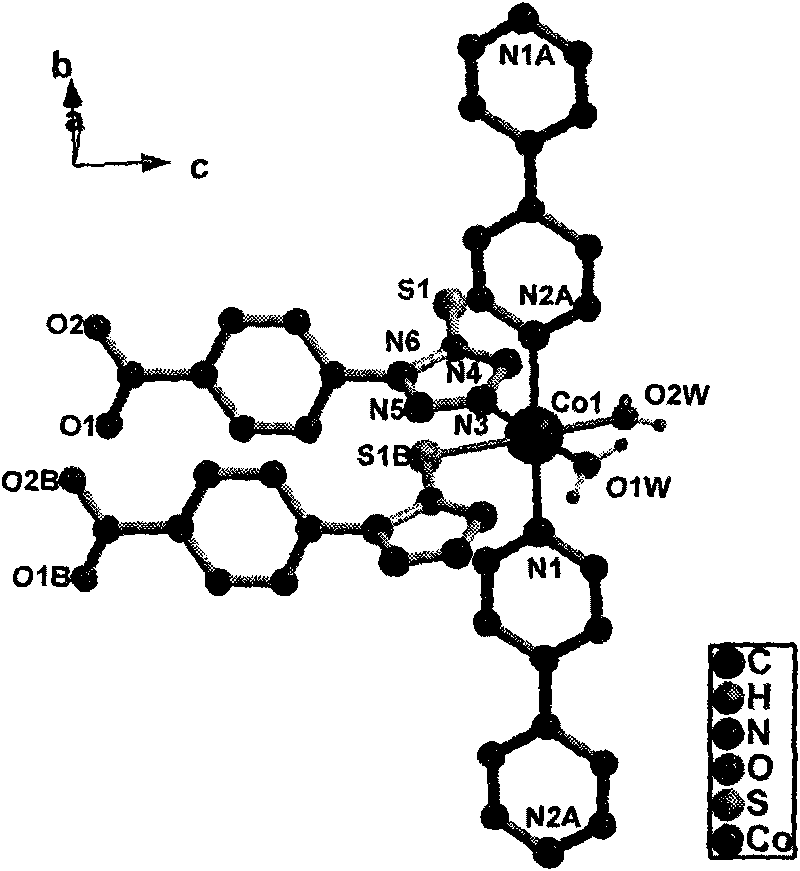

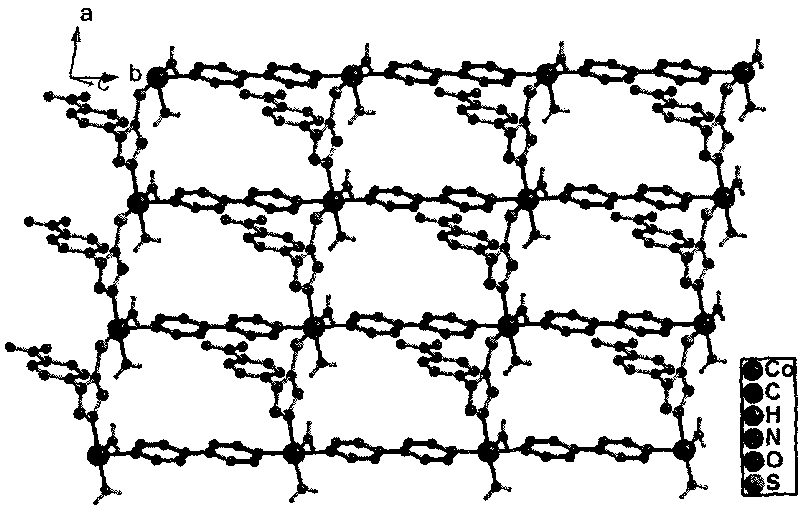

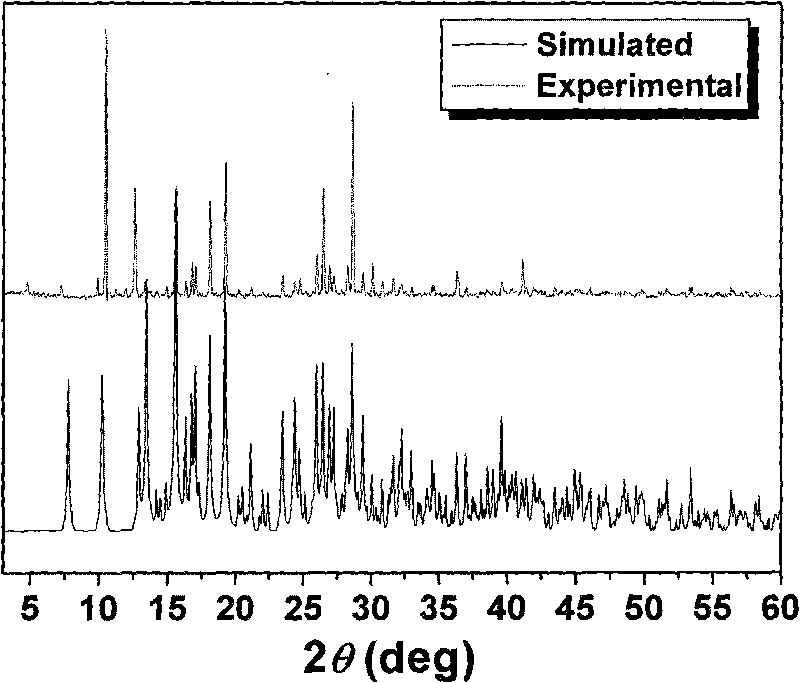

1-(4-carboxy phenyl)-5-sulfydryl-1H-tetrazole and 4, 4'-bipyridyl blending cobalt composition and preparation method thereof

InactiveCN101759723AOvercome high temperature and pressureOvercoming dangerCobalt organic compoundsOrganic/organic-metallic materials magnetismDiffusion methodsTetrazole

The invention relates to a 1-(4-carboxy phenyl)-5-sulfydryl-1H-tetrazole and 4, 4'-bipyridyl blending cobalt composition and a preparation method thereof. The composition has a chemical formula as follows: {[Co(L)(4, 4'-bipy)(H2O)2](H2O)2}, wherein L=1-(4-carboxy phenyl)-5-sulfydryl-1H-tetrazole anion ligand; and 4, 4'-bipy=4, 4'-bipyridyl. The composition is prepared by adopting a diffusion method which is different from synthesizing methods, i.e. a hydrothemal method and the like, of a conventional cobalt metal carboxylic ligand blending composition reported in the traditional literature and overcomes the technical defects of high temperature, pressure and danger, low productivity, difficult purification and separation and poor repeatability; the synthesizing method showed by the invention has moderate condition, high productivity and good repeatability at normal temperature and pressure; and in addition, a magnetism test result of a crystal sample of the composition lays the theoretical foundation for further developing a novel magnetic-function molecular material.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com