Nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet

A technology of nano-silicon nitride and nano-boron nitride, which is applied in the field of titanium carbonitride)-based cermet materials and its preparation, can solve the problems of unfavorable mixing uniformity, unknown parameters such as strength and hardness of cermet materials, bending strength and The problem of limited wear resistance, etc., to achieve the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

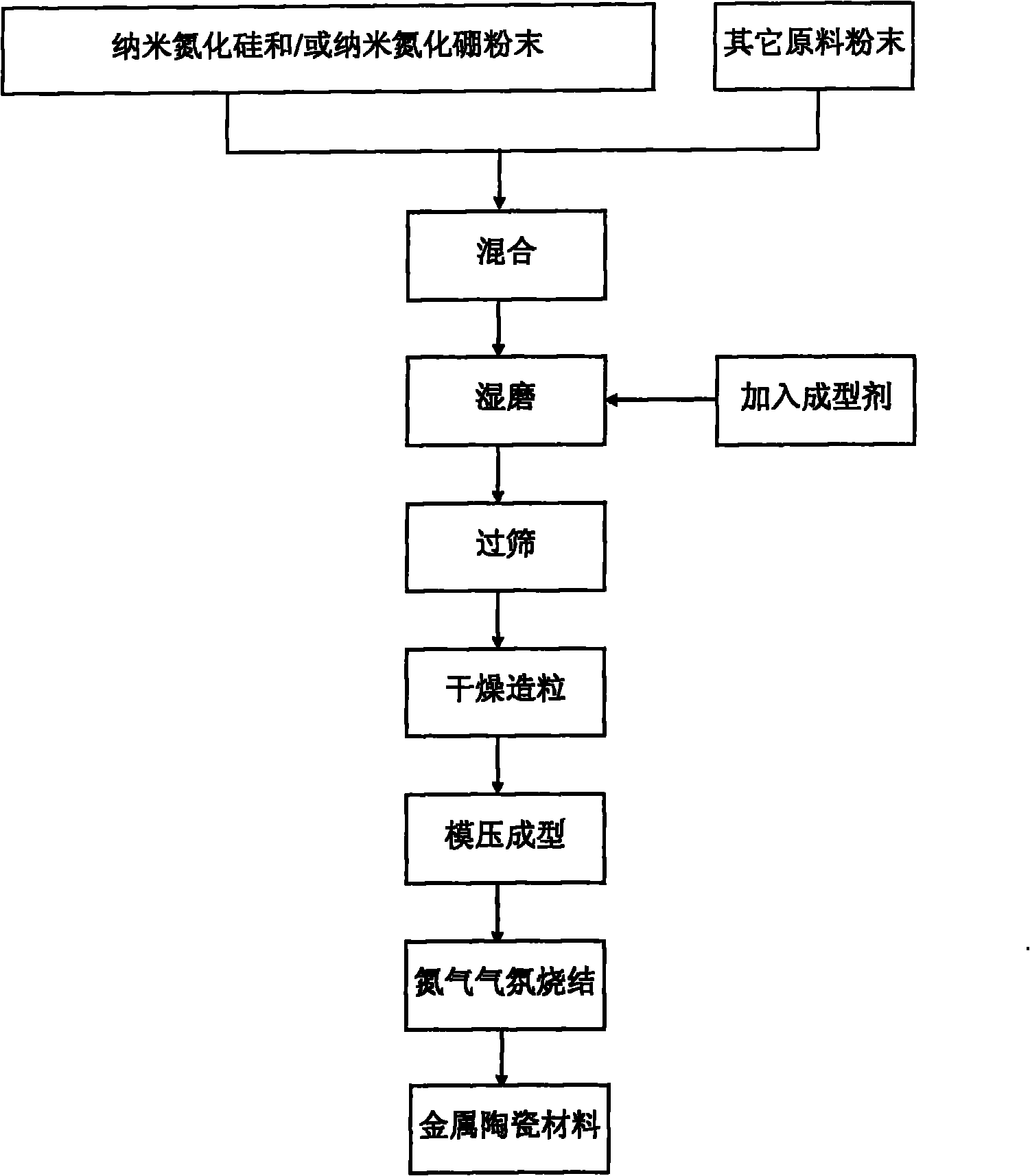

[0063] Preparation process see figure 1 and figure 2 .

[0064] (1) Containing Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x The components and weight percentages in the batch

[0065] The content is:

[0066] WC 15wt% TaC 10wt% Mo 2 C 8wt% Co 10wt%

[0067] Ni 5wt% ZrC 1.0wt% VC 0.5wt% (nm) Si 3 N 4 8wt%

[0068] The balance is Ti(C 0.5 N 0.5 ). The particle size of the remaining powders is ≤2 μm.

[0069] (2) Mixing: Fully mix the raw material powders in a mixer for 24 hours.

[0070] (3) Wet milling: put the above mixed powder into a stainless steel ball milling tank, add hexane at 350ml / l, select Φ5 hard alloy balls, the ball-to-material ratio is 5:1, the rotating speed is 200rpm, and ball mill for 72 hours.

[0071] (4) Add molding agent: weigh paraffin wax at 5wt%, dissolve it in hexane, add it into a ball mill jar, and continue ball milling for 2 hours.

[0072] (5) Screening: pass the milled slurry through a 60-mesh sieve, and settle for 2 hours.

[0073]...

Embodiment 2

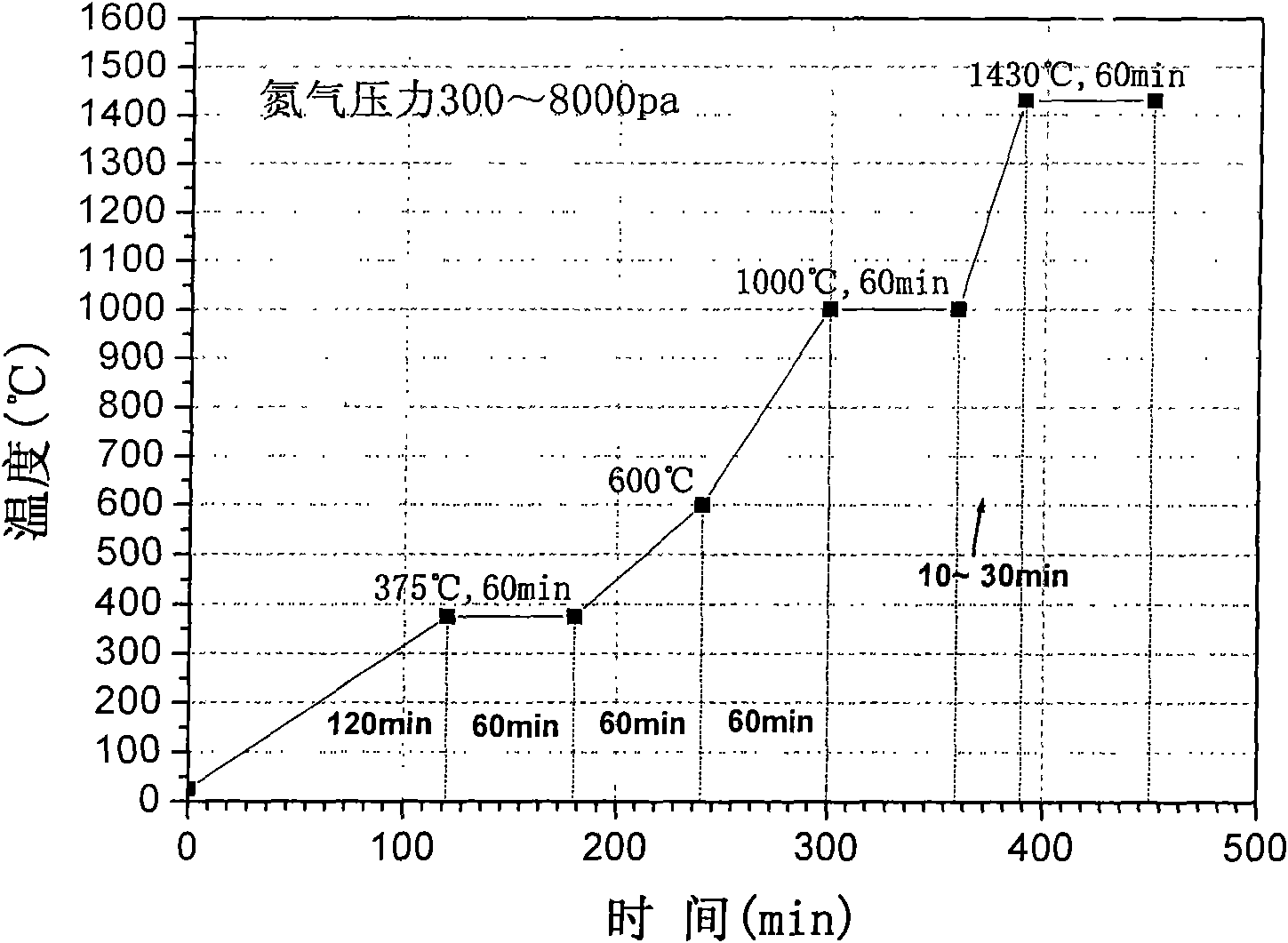

[0078] Preparation process see figure 1 and figure 2 .

[0079] (1) Containing Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x The components and weight percentages in the batch are:

[0080] WC 17wt% TaC 7wt% Mo 8wt% C 0.6wt%

[0081] Co 8wt% Ni 7wt% ZrC 0.5wt% Cr 3 C 2 0.5wt%

[0082] VC 0.5wt% (nm) BN 3.0wt% balance (TiC) 0.6 +(TiN) 0.4 . The particle size of the remaining powders is ≤2 μm.

[0083] (2) mixing: with embodiment 1.

[0084] (3) wet milling: with embodiment 1.

[0085] (4) Add forming agent: with embodiment 1.

[0086] (5) sieving: with embodiment 1.

[0087] (6) dry granulation: with embodiment 1.

[0088] (7) compression molding: same as embodiment 1.

[0089] (8) Sintering: press attached figure 2 Process sintering, the nitrogen pressure is 2000Pa.

[0090] The hardness of the obtained cermet material is HRA93.4, the bending strength is 1810MPa, and the fracture toughness is 14.2MPa m 1 / 2 .

Embodiment 3

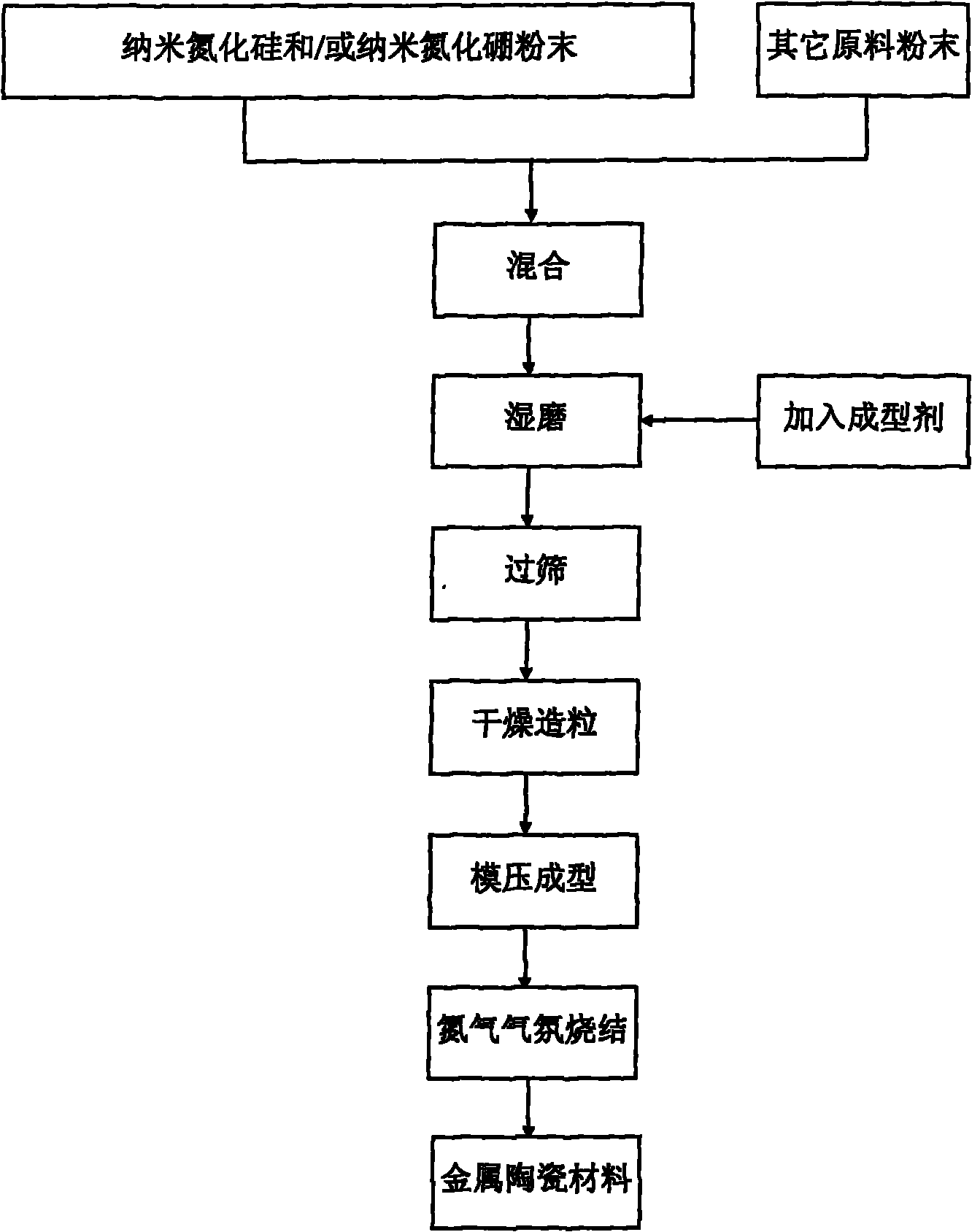

[0092] Preparation process see figure 1 and Figure 3.

[0093] (1) Containing Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x The components and weight percentages in the batch are:

[0094] WC 16wt% TaC 9wt% Mo 2 C 12wt% Co

[0095] 10wt%

[0096] Ni 5wt% ZrC 1.0wt% VC 0.5wt%

[0097] (nm) (Si 3 N 4 ) 0.3 +(BN) 0.7 2.0wt%

[0098] The balance is Ti(C 0.7 N 0.3 ). The particle size of the remaining powders is ≤2 μm.

[0099] (2) mixing: with embodiment 1.

[0100](3) Wet milling: put the above mixed powder into a stainless steel ball milling tank, add ethanol at 400ml / l, select Φ5 cemented carbide balls, the ball-to-material ratio is 10:1, the rotating speed is 200rpm, and ball mill for 48 hours.

[0101] (4) Add molding agent: weigh 1.5wt% rubber, dissolve it in gasoline, add it into a ball mill jar, and continue ball milling for 2 hours.

[0102] (5) sieving: with embodiment 1.

[0103] (6) dry granulation: with embodiment 1

[0104] (7) compression molding: sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com