Magnetic Co3O4-C nano material and preparation method thereof as well as application of magnetic Co3O4-C nano material as catalyst for activating peroxymonosulfate to wastewater treatment

A nano-material, co3o4-c technology, applied in the field of wastewater treatment, can solve the problems of difficult recycling of catalysts and environmental hazards, achieve broad practical application prospects, use less catalysts, and improve degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Experiments compared the use of magnetic Co 3 o 4 -C nanomaterial activated potassium hydrogen persulfate, adding magnetic Co alone 3 o 4 -C nanomaterials and the removal rate of RhB in three ways of adding potassium monopersulfate alone.

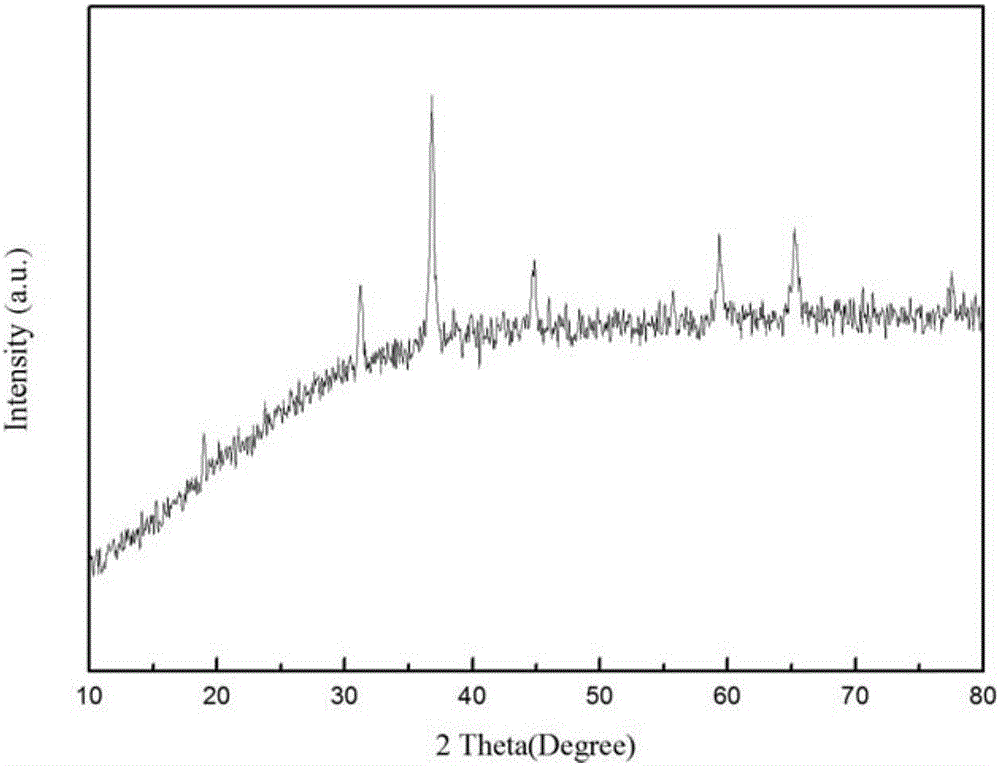

[0041] (1) Dissolve 10mmol fumaric acid and 20mmol NaOH in 50mL deionized water, stir until clear and transparent, then place in an oven and dry overnight at 110°C, the resulting white powder is disodium fumarate; then add 10mmol Co(NO 3 ) 2 ·6H 2 O and 10 mL of disodium fumarate were dissolved in 20 mL of deionized water, and stirred at room temperature for 2 h. The resulting precipitate was vacuum filtered, washed with deionized water three times, and dried at 100 ° C for 12 h to obtain a cobalt-based metal organic framework. compound; then the cobalt-based metal-organic framework compound was calcined at 500°C for 4h under the protection of nitrogen, and then calcined at 450°C for 1h in air to obtain magnetic Co 3...

Embodiment 2

[0048] Example 2: The experiment compares the magnetic Co synthesized by different organic ligands 3 o 4 -C nanomaterials activated potassium hydrogen persulfate on the degradation of RhB.

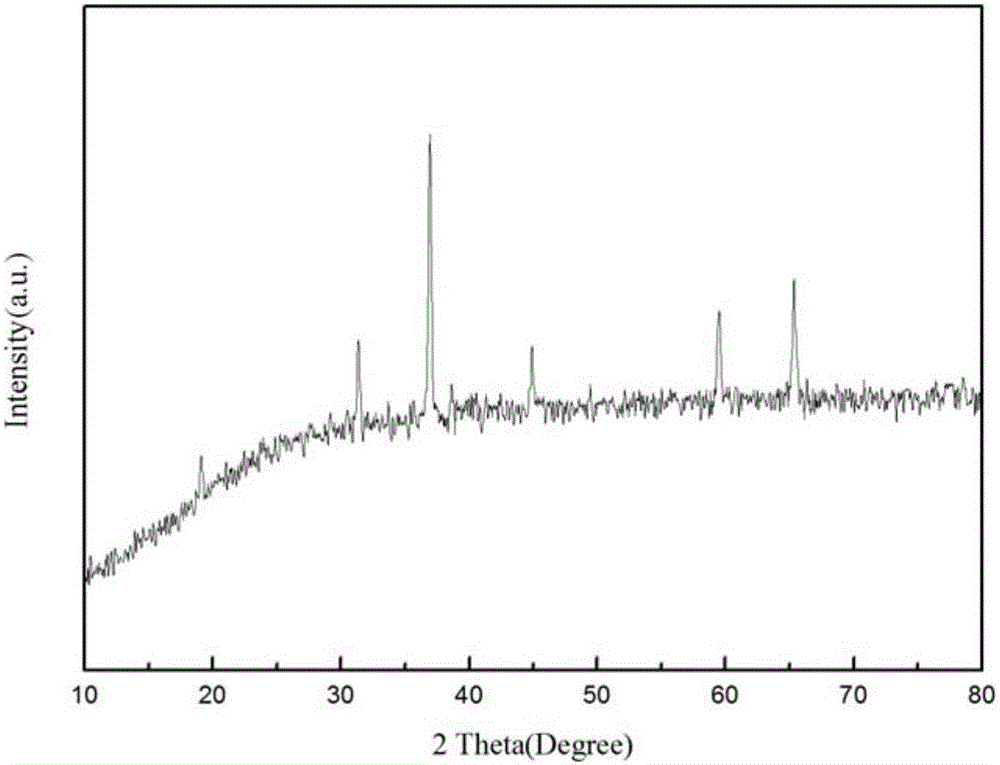

[0049] (1) Dissolve 10mmol fumaric acid and 20mmol NaOH in 50mL deionized water, stir until clear and transparent, then place in an oven and dry overnight at 110°C, the resulting white powder is disodium fumarate; then add 10mmol Co(NO 3 ) 2 ·6H 2 O and 10 mL of disodium fumarate were dissolved in 20 mL of deionized water, and stirred at room temperature for 2 h. The resulting precipitate was vacuum filtered, washed with deionized water three times, and dried at 100 ° C for 12 h to obtain a cobalt-based metal organic framework. compound; then the cobalt-based metal-organic framework compound was calcined at 500°C for 4h under the protection of argon, and then calcined at 450°C for 1h in air to obtain magnetic Co 3 o 4 -C nanomaterials. The prepared magnetic Co 3 o 4 -C nanomaterial...

Embodiment 3

[0056] Example 3: Experiments compared the use of different cobalt metal organic framework materials as precursors to prepare magnetic Co 3 o 4 The removal rate of RhB activated by C nanomaterials under acidic, neutral and alkaline conditions.

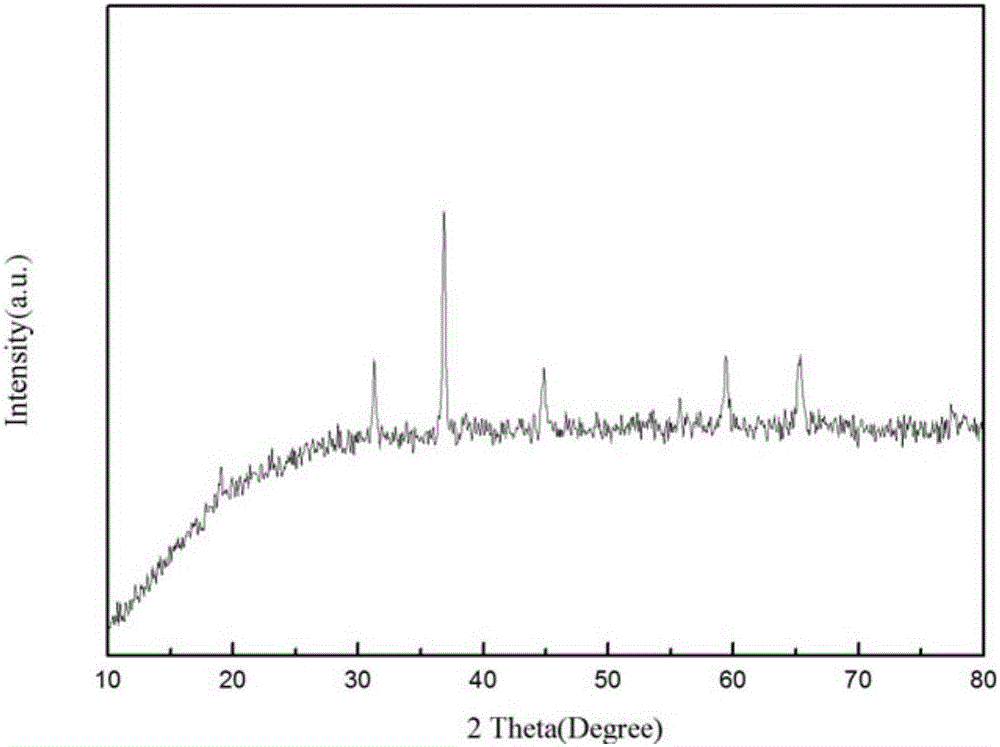

[0057] (1) Dissolve 10mmol fumaric acid and 20mmol NaOH in 50mL deionized water, stir until clear and transparent, then place in an oven and dry overnight at 110°C, the resulting white powder is disodium fumarate; then add 10mmol Co(NO 3 ) 2 ·6H 2 O and 10 mL of disodium fumarate were dissolved in 20 mL of deionized water, and stirred at room temperature for 3 h. The resulting precipitate was vacuum filtered, washed with deionized water for 4 times, and dried at 90°C for 18 h to obtain a cobalt-based metal-organic framework. compound; then the cobalt-based metal-organic framework compound was calcined at 650°C for 5h under the protection of nitrogen, and then calcined at 450°C for 3h in air to obtain magnetic Co 3 o 4 -C nanomater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com