Embedded cobalt sulfide and porous carbon nanorod composite electrode material and preparation method and application thereof

A composite electrode and cobalt sulfide technology, which is applied in the field of nanomaterials and electrochemistry, to achieve the effect of improving the rate performance, improving the utilization rate of materials, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 4mmol cobalt nitrate hexahydrate in 60mL DMF, add 4mmol trimesic acid, 2mmol 4,4'-bipyridyl, stir well until completely dissolved, then transfer to high temperature and high pressure reactor, heat at 120°C for 4h, cool After reaching room temperature, a solution containing cobalt metal-organic framework (Co-MOF) was obtained, filtered and washed, and vacuum-dried at 60° C. for 12 h. The sample was ground and mixed with sublimed sulfur at a ratio of 1:0.8, and calcined in a tube furnace at 700 °C for 2 h under a vacuum atmosphere to obtain the target product.

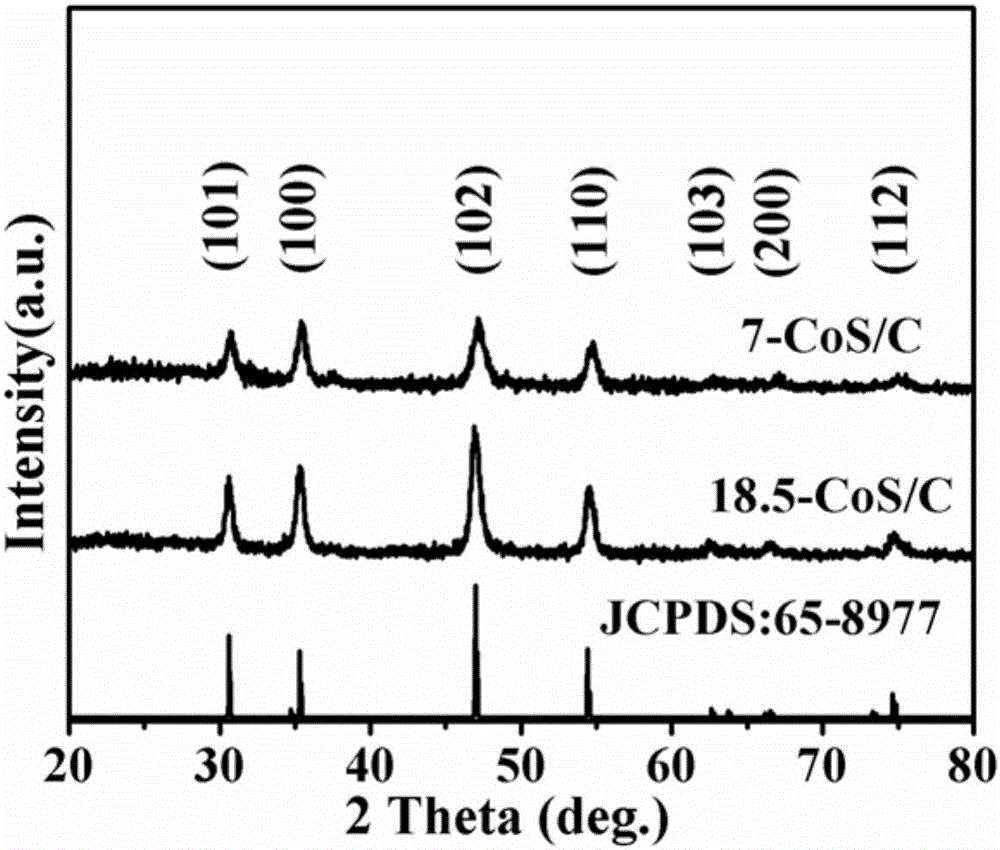

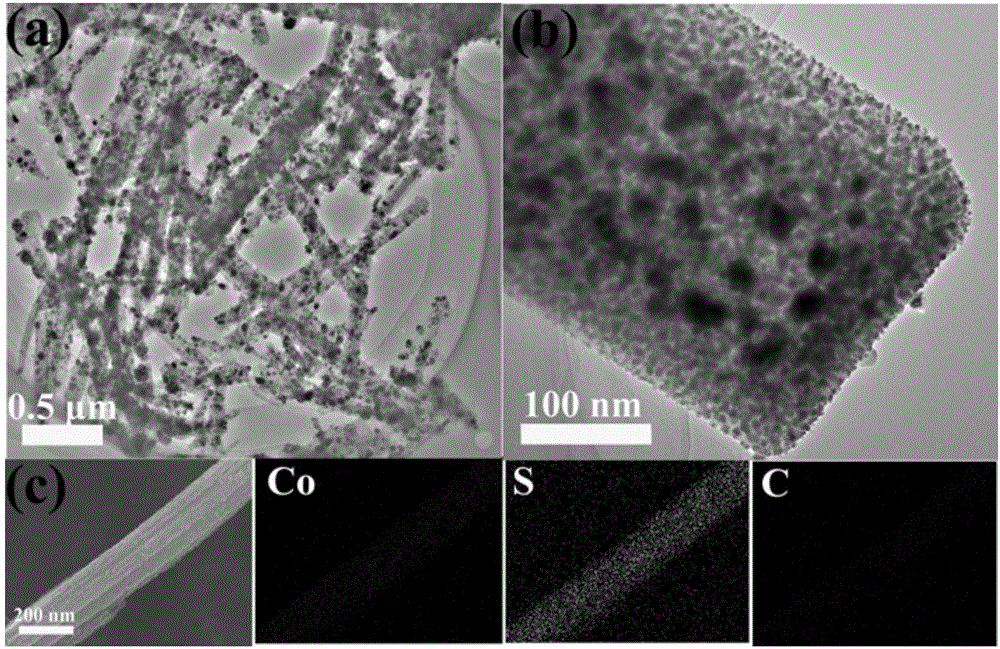

[0030] Taking the embedded cobalt sulfide and porous carbon nanorod composite (7-CoS / C), the product of this example, as an example, its structure is confirmed by X-ray diffraction (XRD) pattern. Such as figure 1 The XRD pattern shows that the embedded cobalt sulfide and porous carbon nanorod composite is pure phase cobalt sulfide (JCPDS card number is 65-8977). Such as figure 2 As shown in the TEM im...

Embodiment 2

[0034]Dissolve 4mmol cobalt nitrate hexahydrate in 60mL DMF, add 4mmol trimesic acid, 2mmol 4,4'-bipyridyl, stir well until completely dissolved, then transfer to high temperature and high pressure reactor, heat at 120°C for 4h, cool After reaching room temperature, a solution containing cobalt metal-organic framework (Co-MOF) was obtained, filtered and washed, and vacuum-dried at 60° C. for 12 h. The sample was ground and mixed with sublimed sulfur at a ratio of 1:0.8, and calcined in a tube furnace at 800 °C for 2 h under a vacuum atmosphere to obtain the target product.

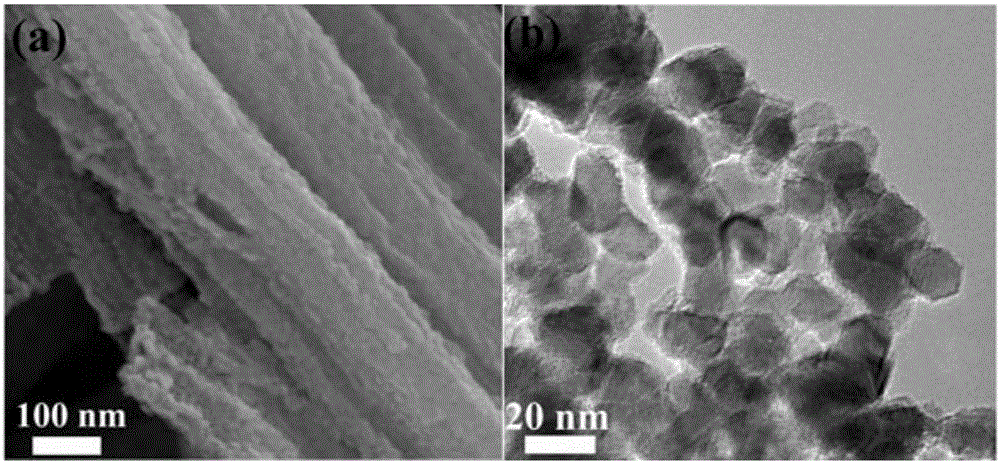

[0035] Taking the embedded cobalt sulfide and porous carbon nanorod composite (18.5-CoS / C), which is the product of this example, as an example, its structure is determined by X-ray diffraction (XRD) patterns. Such as figure 1 The XRD pattern shows that the embedded cobalt sulfide and porous carbon nanorod composite is pure phase cobalt sulfide (JCPDS card number is 65-8977). However, its half peak width...

Embodiment 3

[0038] Dissolve 4mmol cobalt perchlorate in 60mL DMF, add 4mmol trimesic acid, 2mmol 4,4'-bipyridyl, stir well until completely dissolved, then transfer to high temperature and high pressure reactor, heat at 120°C for 4h, cool After reaching room temperature, a solution containing cobalt metal-organic framework (Co-MOF) was obtained, filtered and washed, and vacuum-dried at 60° C. for 12 h. The sample was ground and mixed with sublimed sulfur at a ratio of 1:1.2, and calcined in a tube furnace at 700 °C for 2 h under a vacuum atmosphere to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com