Cobaltous oxide/carbon composite hollow nanostructure material of dodecahedron structure and application thereof in negative electrodes of lithium batteries

A nanostructure and dodecahedron technology is applied to a cobalt oxide/carbon composite hollow nanostructure material with a dodecahedron structure and its application in the negative electrode of lithium batteries, which can solve irreversible capacity loss, limit the development of lithium batteries, problems such as low theoretical capacity, to achieve the effect of good experimental repeatability, low risk and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

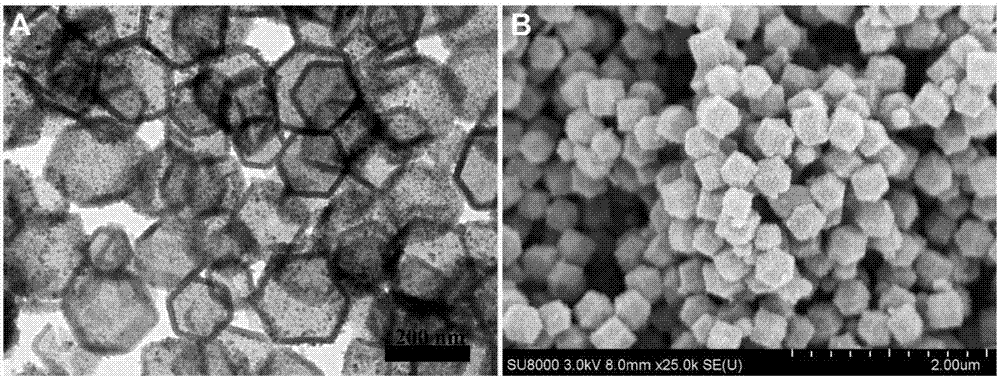

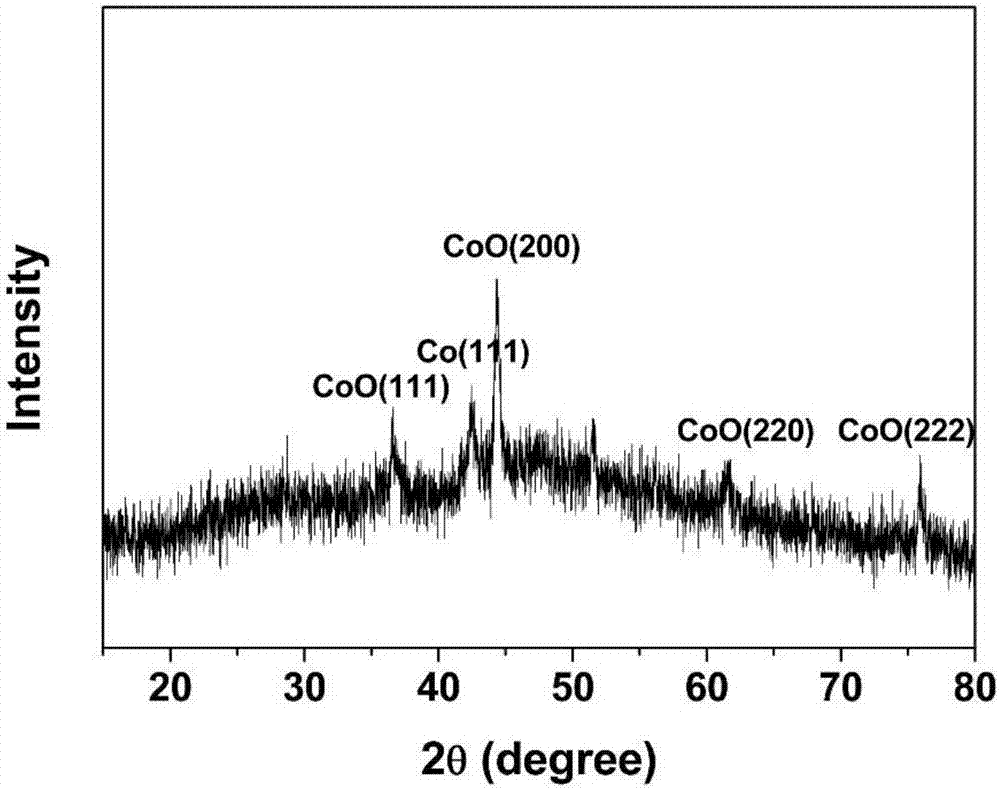

[0017] (1) Preparation of metal organic framework compound ZIF-67 containing cobalt metal: 498mg Co(NO 3 ) 2 ·6H 2 O and 1400mg of 2-methylimidazole were dissolved in 50mL of methanol to form a clear solution, and then the two solutions were mixed and allowed to stand at room temperature for 6h. The obtained product was processed by centrifugation (7000rpm, 10min) and washed three times with methanol to obtain the nanostructure material of metal-organic framework compound ZIF-67 dodecahedron containing cobalt metal.

[0018] (2) Preparation of cobalt ion-coordinated polymer hollow nanostructures: the cobalt-containing metal-organic framework compound ZIF-67 nanostructures prepared in step (1) were dispersed in methanol to form a concentration of 2 mg / mL Dispersions. Take 1 mL of the dispersion, add 1.5 mL of methanol and 0.5 mL of a 20 mM dopamine solution in methanol, and place the reaction system at 60° C. under reflux and stir for 12 h. The obtained product was centrifu...

Embodiment 2

[0022] (1) Preparation of metal organic framework compound ZIF-67 containing cobalt metal: 600mg Co(NO 3 ) 2 ·6H 2 O and 790mg of 2-methylimidazole were dissolved in 50mL of methanol to form a clear solution, and then the two solutions were mixed and allowed to stand at room temperature for 24h. The obtained product was centrifuged (7000rpm, 10min) and washed three times with methanol to obtain a cobalt metal-containing metal-organic framework compound ZIF-67 nanostructure material.

[0023] (2) Preparation of polymer hollow nanostructures coordinated by cobalt ions: the cobalt-containing metal-organic framework compound ZIF-67 nanostructure material prepared in step (1) was dispersed in methanol to form a concentration of 2 mg / mL Dispersions. 1 mL of the dispersion was taken, 1.5 mL of methanol and 0.5 mL of a 20 mM dopamine solution in methanol were added thereto, and the reaction system was refluxed and stirred at 60° C. for 12 h. The obtained product was centrifuged (7...

Embodiment 3

[0026](1) Preparation of the working electrode of lithium ion battery: the cobalt oxide / carbon composite hollow nanostructure material prepared in Example 1, acetylene black and polyvinylidene fluoride (PVDF) are 80:10:10 according to the weight ratio Mix in the electrolyte (the electrolyte is a mixture of dimethyl carbonate and ethylene carbonate at a volume ratio of 1:1). The mixture solution was uniformly coated on the copper sheet, and dried under vacuum at 100° C. for 10 h.

[0027] (2) Lithium-ion charge-discharge cycle test of the electrode: The charge-discharge test is performed with a Land CT2001A battery test system under the conditions of a voltage range of 0.01-3V and different current densities.

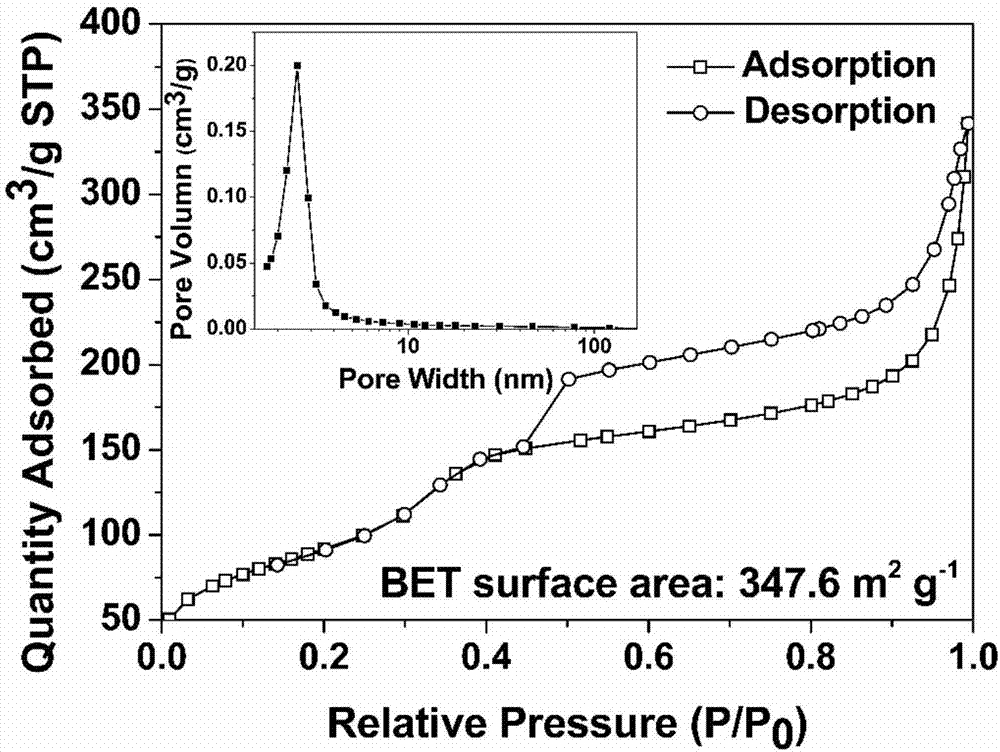

[0028] Lithium-ion battery performance results of electrode materials such as Figure 4 As shown, the first discharge specific capacity of the cobalt oxide / carbon composite hollow nanostructure material can reach 1301mAh g -1 , and the specific capacity can be stabiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bet surface area | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

| First cycle discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com