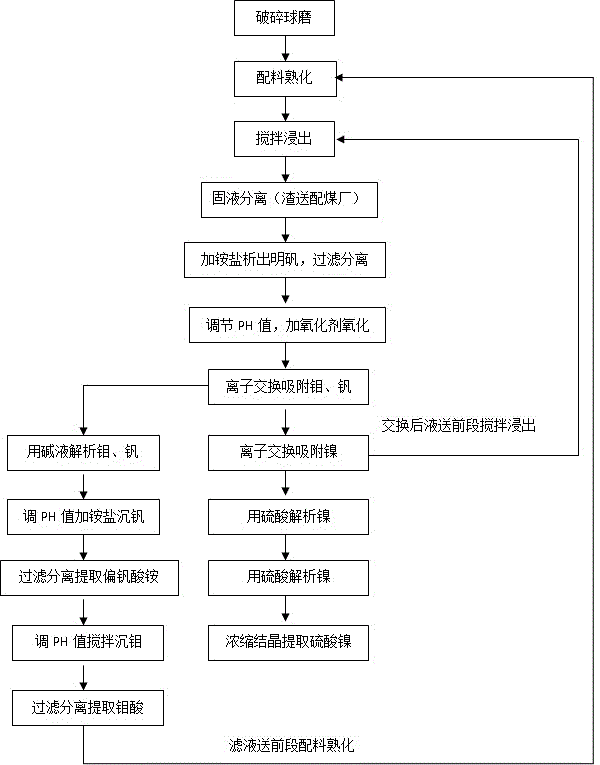

Production process for extracting elements such as aluminum, vanadium, molybdenum and nickel from black shale

A black shale and production process technology, applied in the direction of improving process efficiency, can solve the problems of high equipment cost, large acid consumption, high extraction cost, etc., and achieve the effect of reducing production cost and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The black shale molybdenum-nickel-vanadium symbiotic ore in a certain place in Zhangjiajie, Hunan Province is mainly composed of 4.65% aluminum, 0.53% vanadium, 3.36% molybdenum, 1.65% nickel, 13.2% iron, 17.1% sulfur, and 13% carbon. Crushed and finely ground to 100 mesh, according to the mass ratio of additives: water: sulfuric acid: ore = 1.5: 10: 18: 100, mix evenly, put it in the aging tank for natural aging for 5 days, and stir with 1: 1 water for 1 hour to leach , separated by filtration. Add ammonium sulfate to the filtrate to form ammonium alum crystals, filter and separate, adjust the pH value with calcium carbonate, add hydrogen peroxide to oxidize, then pass through the acrylic anion resin, analyze with sodium hydroxide, adjust the solution to a pH value of 7~10, and add ammonium sulfate Precipitation, resulting in ammonium metavanadate precipitation. Filter and separate, adjust the pH value to 1~2 with sulfuric acid, heat and stir to form molybdic acid pre...

Embodiment 2

[0068] Black shale rock coal vanadium mine in a certain place in Jishou, Hunan Province, the main components are: aluminum 5.25%, vanadium 1.50%, molybdenum 0.16%, iron 9.5%, sulfur 3.1%, carbon 11%. Crushed and finely ground to 100 mesh, according to the mass ratio of additive: water: sulfuric acid: ore = 2:8:20:100, mix evenly, put it into the aging tank for natural aging for 6 days, and stir with 1:1 water for 1 hour to leach , separated by filtration. Add ammonium sulfate to the filtrate to form ammonium alum crystals, filter and separate, adjust the pH value with calcium carbonate, add ammonium persulfate to oxidize, and then pass through acrylic anion resin, after ion exchange, the liquid is sent to step (2) for stirring and leaching, and is analyzed with sodium hydroxide. Adjust the analytical solution to a pH value of 7~10, add ammonium sulfate to precipitate, and generate ammonium metavanadate precipitate. Filter and separate, adjust the pH value to 1~2 with sulfuric...

Embodiment 3

[0070]The black shale molybdenum-nickel ore in Zunyi, Guizhou Province is mainly composed of 7.1% aluminum, 6.1% molybdenum, 3.85% nickel, 13.5% iron, 18.1% sulfur and 16% carbon. Crushed and finely ground to 100 mesh, according to the mass ratio of additives: water: sulfuric acid: ore = 0.5: 11: 25: 100, mix evenly, put it in the aging tank for natural aging for 7 days, and stir with 1: 1 water for 1 hour to leach , filtered and separated, and the filter residue is sent to the cement plant. Add ammonium sulfate to the filtrate to generate ammonium alum crystals, filter and separate, adjust the pH value with calcium carbonate, add potassium permanganate to oxidize, and then pass through the acrylic anion resin to absorb molybdenum. Analyze with sodium hydroxide, adjust the solution to a pH value of 1~2, heat and stir to form a molybdic acid precipitate, filter and separate, and send the filtrate to step (1), and mature it with the raw material ratio, and solidify the potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com