Method for growing large-area graphene on insulating substrate

A technology on an insulating substrate and an insulating substrate, which is applied in the field of growing large-area graphene, can solve the problems of graphene size limitation, cumbersome process, and graphene performance degradation, so as to reduce production cost, high preparation repeatability, and external less disturbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

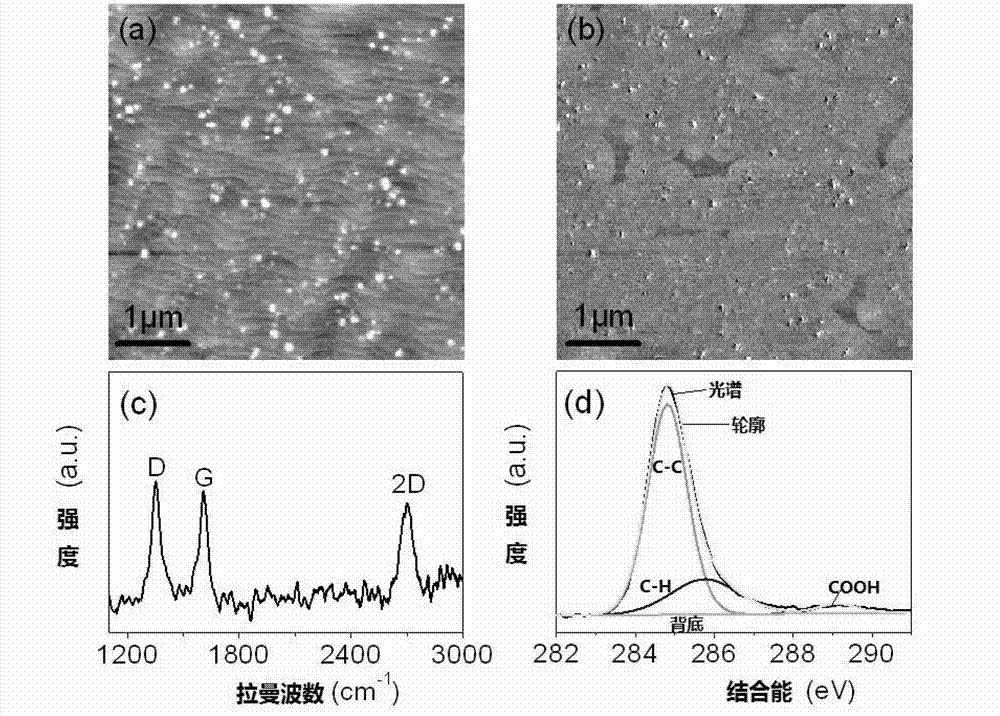

[0029] Example 1. Growth of large-scale single-layer graphene on (0001) sapphire substrate

[0030] 1) Use acetone to ultrasonically clean the sapphire (Kyocera, Japan) and copper foil (Alfa Aesar, UK) to remove organic residues, then use deionized water to ultrasonically remove metal ions and other impurities, and then quickly dry them with a nitrogen gun sample.

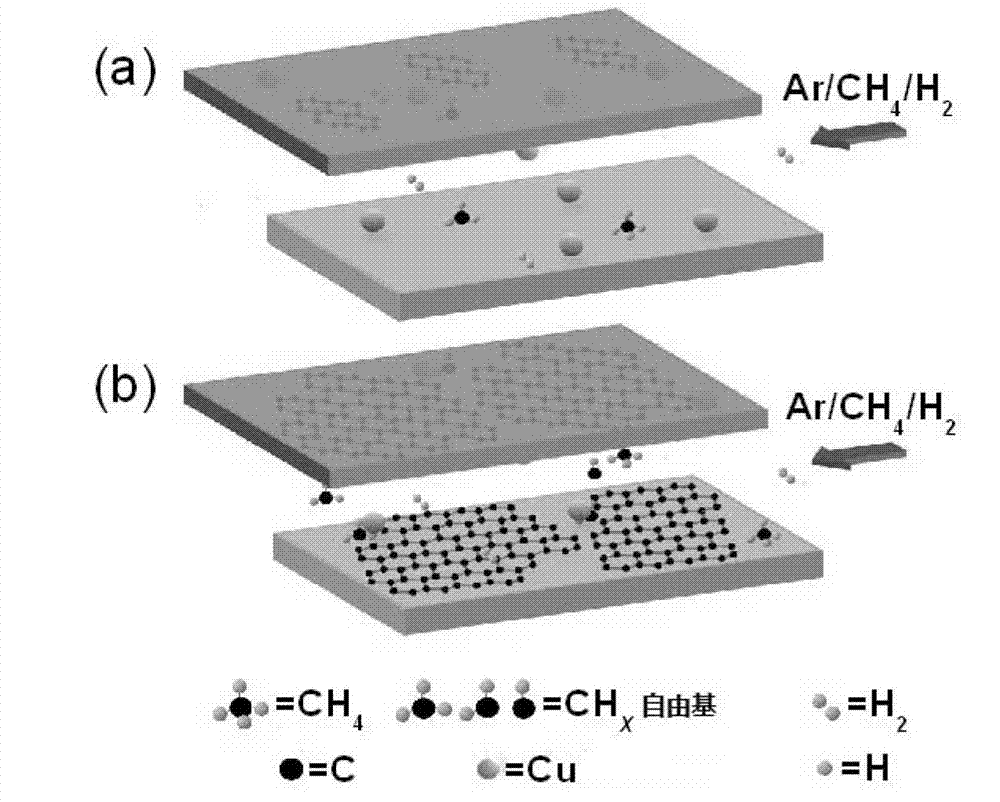

[0031] 2) Cover the (0001) sapphire on the copper foil and bring the two in close contact. Then push the entire sample into the central area of the horizontal quartz tube furnace.

[0032] 3) The entire quartz tube of the tube furnace is cleaned three times with argon to remove the remaining impurity gas in the quartz tube.

[0033] 4) Before the temperature rise starts, argon gas of 100 sccm and hydrogen gas of 20 sccm are introduced, and the pressure is stabilized at 400 Pa by controlling the valve of the mechanical pump. Then raise the tube furnace to 1020°C within 50 minutes, and stabilize the growth temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com