Ethylene glycol rectification device system and rectification technique in industry of producing ethylene glycol by synthesis gas

A technology of ethylene glycol and synthesis gas, which is applied in the preparation of hydroxyl compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of high energy consumption and low output of high-grade products, and achieve improved purity and high-quality products The effect of product output and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

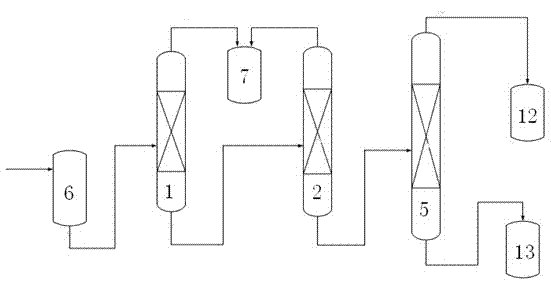

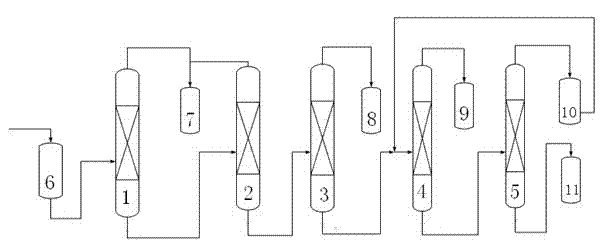

[0030] The ethylene glycol rectification process in the synthesis gas system ethylene glycol industry of the present invention is:

[0031] (1) Ethylene glycol mixture (49.2% methanol, 0.14% ethanol, 45.2% ethylene glycol, 1.0% butanediol, 2.0% water, 2.46% methyl glycolate) produced by hydrogenation reactor , enter the rectification work number, first enter the primary dealcoholization tower 1, open 3kg of steam, atmospheric rectification extracts light component methanol at 72°C from the top of the tower, enters the methanol tank 7, and contains ethylene glycol at the bottom of the tower The alcohol mixture (methanol 16.24%, ethanol 2.9%, ethylene glycol 75.71%, butanediol 1.7%, water 3.45%) enters the secondary dealcoholization tower 2;

[0032] (2) Open 3kg of steam to extract methanol at 45°C from the top of the secondary dealcoholization tower 2 at a vacuum degree of -0.045MPa, and also enter the methanol tank 7, and the ethylene glycol mixture (methanol 0.3%, ethanol 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com