Co-processing technology of organic hazardous wastes in cement kiln

A hazardous waste and co-processing technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of increasing greenhouse gas emissions, large ash and slag production, secondary pollution, etc., and achieve reduction and treatment capacity. The effect of large and saving coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

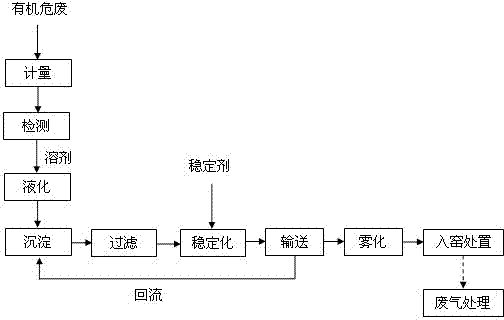

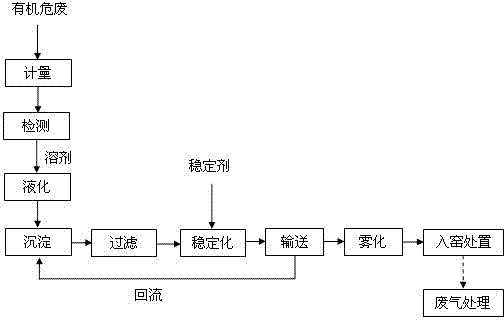

Method used

Image

Examples

Embodiment 1

[0029] In the distillation residue produced by a tannery, the content of C element is 41.51%, and the content of H, N, S, Cl and O are 6.45%, 3.31%, 1.30%, 0.17% and 29.43%, respectively, accounting for 40% of the total 82.17%.

[0030] Add water to each batch of rectification residue for liquefaction, the addition amount is 15%, so that the rectification residue changes from a viscous semi-solid state to a less viscous flow state. The liquefied distillation residue was precipitated for 2 hours and then filtered. Add a flash point enhancer to the filtered rectification raffinate for stabilization, and the addition amount is 0.03%. The rectification raffinate produced after pretreatment is sprayed into the cement kiln at a rate of 1.8 tons per hour through the kiln inlet system to replace part of the fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com