Detoxification and cement kiln cooperated resource-converting treatment system for beryllium slag and process

A treatment process and treatment system technology, which is applied in the field of beryllium slag detoxification and cement kiln collaborative resource treatment system and process, can solve the problems of inability to achieve harmless treatment, threats to the environment and human health, and high disposal costs, and achieve disposal The process is environmentally friendly, eliminates leaching hazards, and saves energy consumption for disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

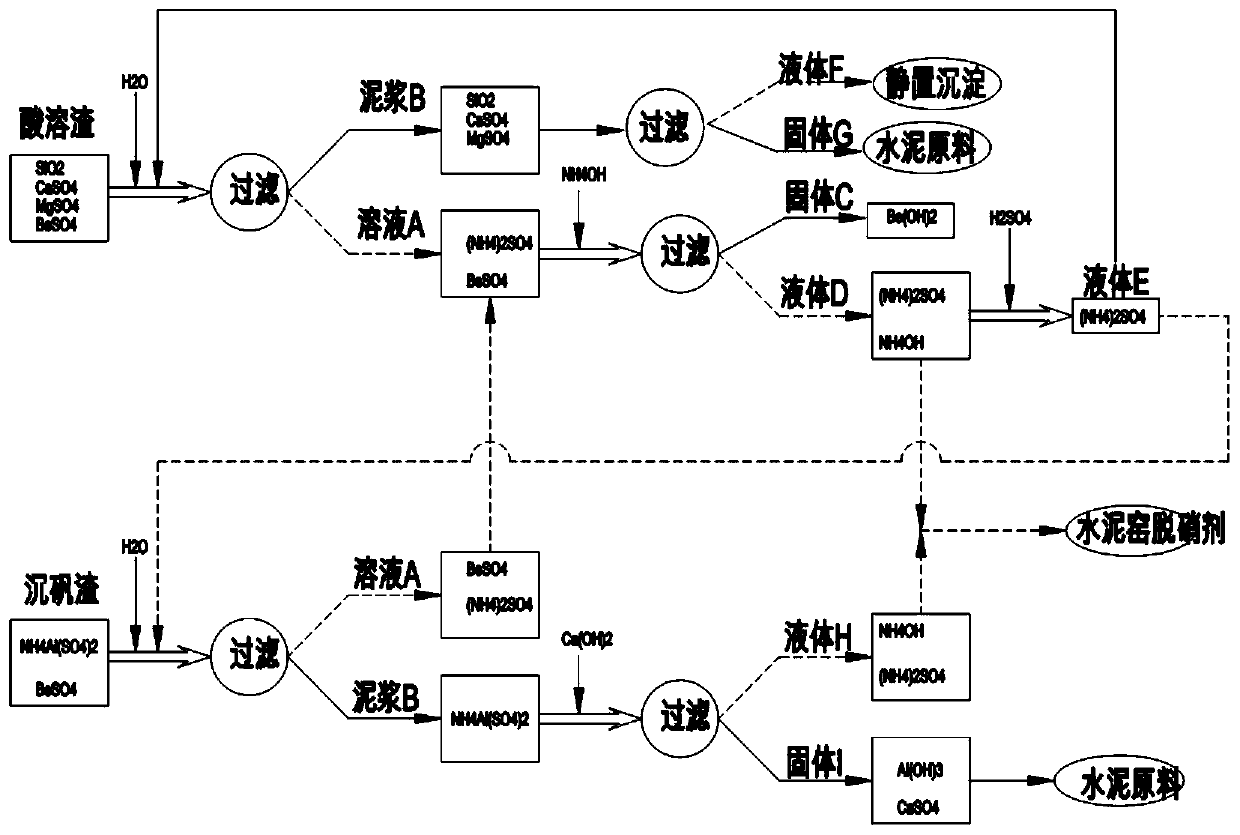

Method used

Image

Examples

Embodiment 1

[0072] Treatment of Acid Dissolved Slag (Beryllium Slag)

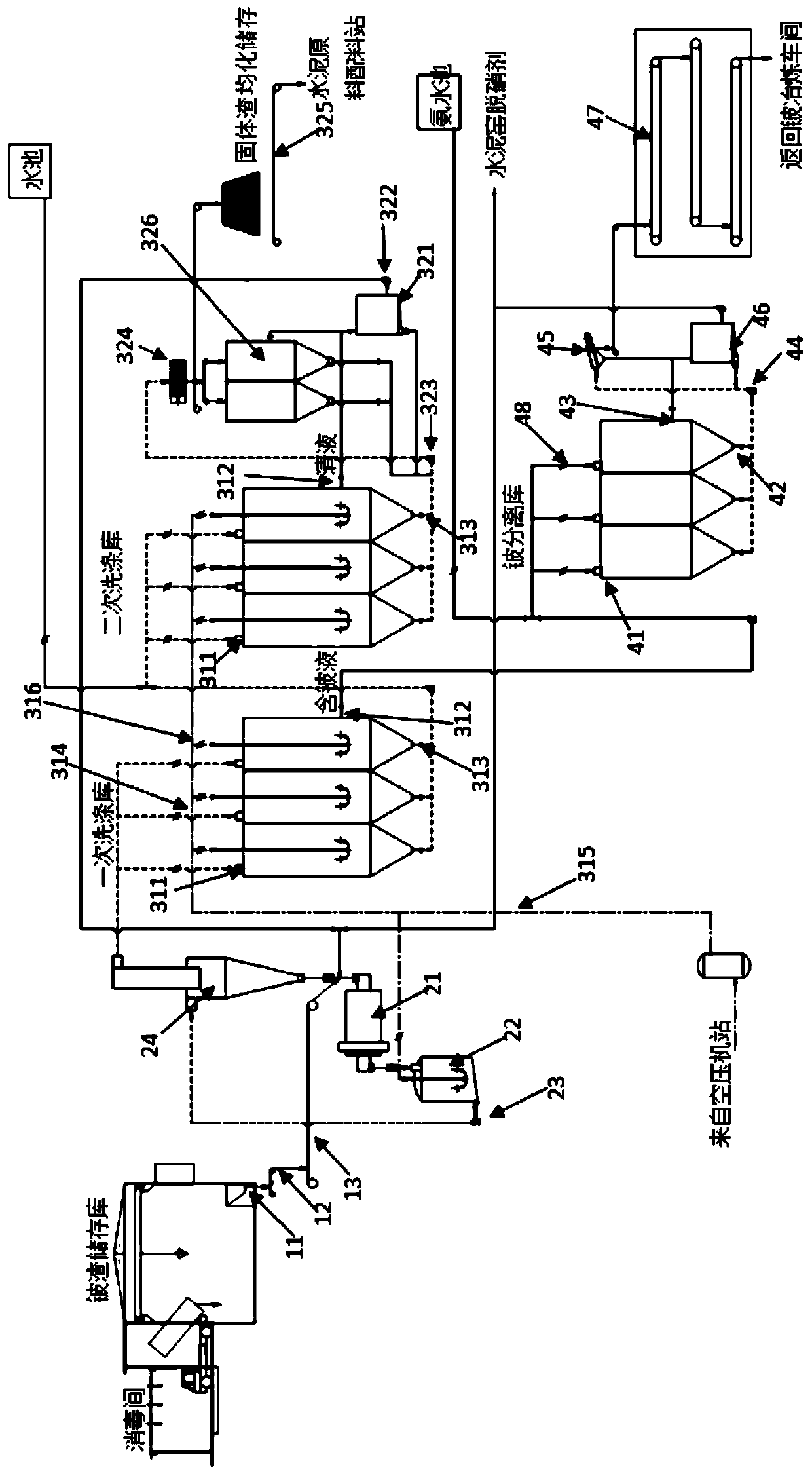

[0073] Step 1: Transportation and storage of acid-dissolved slag

[0074] After the acid-soluble slag transported by the special transportation vehicle for hazardous waste is transported into the factory, it is directly unloaded into the storage warehouse for storage. The storage warehouse is a sealed shunting garage with an intelligent grab crane, and the warehouse is designed according to the requirements of the temporary storage warehouse for dangerous goods. , adopt the centralized ventilation method, and send the gas sucked in the warehouse into the cement kiln system as the wind for the high temperature section of the grate cooler.

[0075] Step 2: Acid-dissolved slag washing and detoxification

[0076] The acid-soluble slag is hoisted to the steady flow bin in the storage warehouse with a grab bucket. The bottom of the steady flow bin is connected to the apron feeder, and the apron feeder is connected to the me...

Embodiment 2

[0085] Treatment of alum residue (ammonium alum residue)

[0086] Step 1: Transportation and storage of alum residue

[0087] The alum slag transported by the special transportation vehicle for hazardous waste is transported into the factory, and is directly unloaded into the storage warehouse for storage. The storage warehouse is a sealed dispatching garage with an intelligent grab crane, and the warehouse is designed according to the requirements of the temporary storage warehouse for dangerous goods. , adopt the centralized ventilation method, and send the gas sucked in the warehouse into the cement kiln system as the wind for the high temperature section of the grate cooler.

[0088] Step 2: Acid-dissolved slag washing and detoxification

[0089] Since the main component of the ammonium alum slag is aluminum ammonium sulfate, it is usually packed in fiber bags. Therefore, a bag breaker is added before entering the mill to separate the glass fiber bags, and the glass fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com