A waste oil-based drilling fluid solid residue treating method

The technology of an oil-based drilling fluid and a treatment method is applied in the field of drilling mud waste liquid treatment, which can solve the problems of soil pollution, medium oil, inorganic salts and metal ions exceeding the standard, and achieve the effect of effectively utilizing resources and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

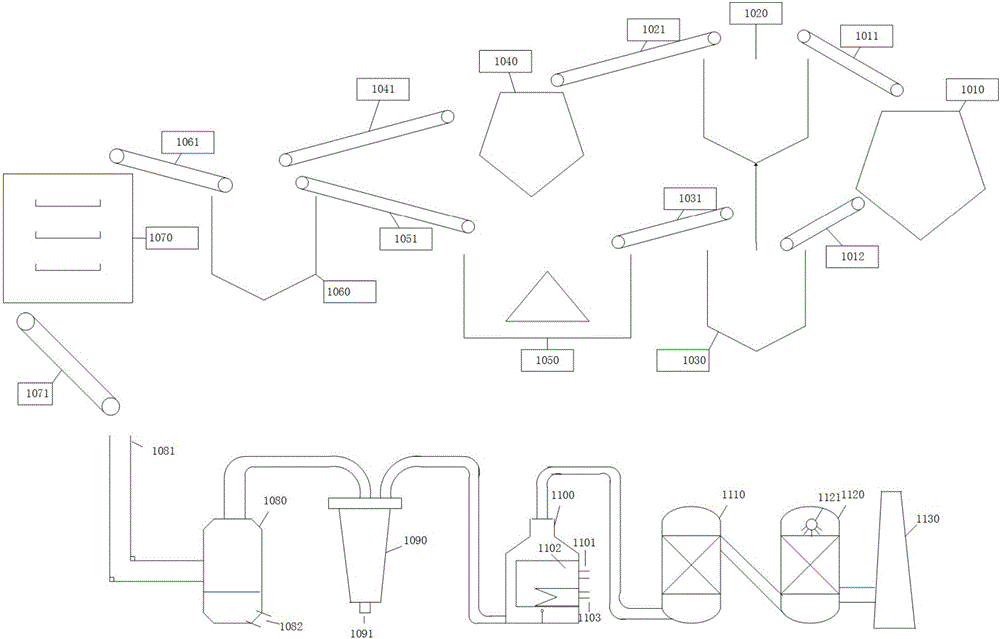

[0017] The present invention will be further described below in conjunction with accompanying drawing:

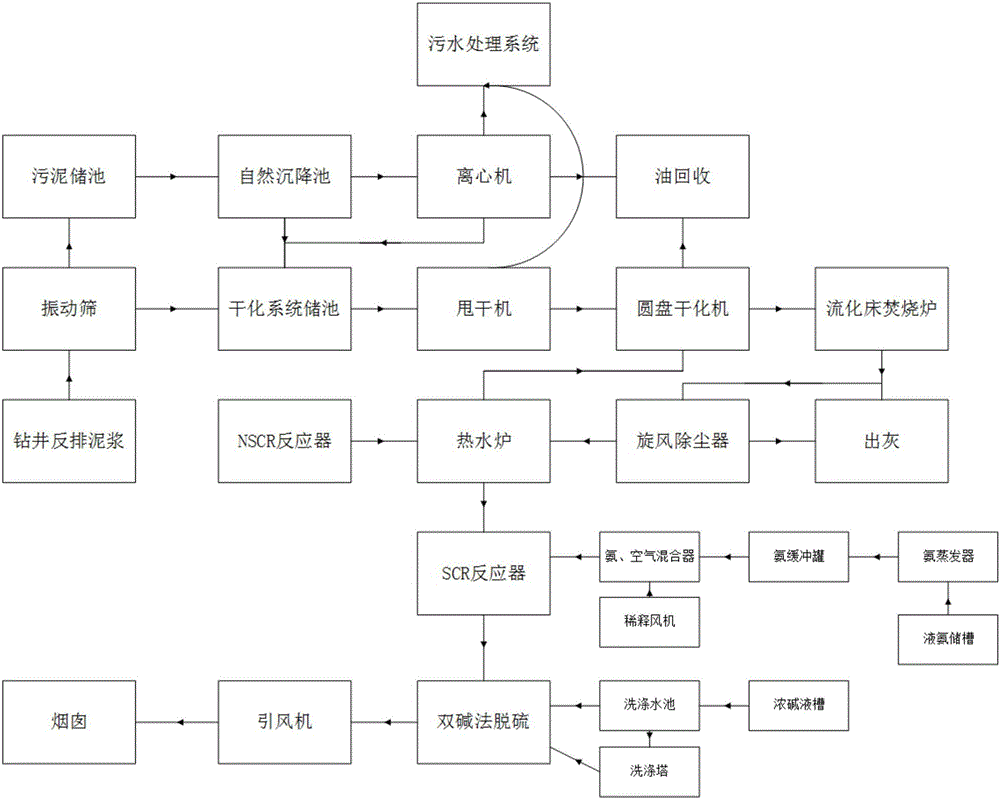

[0018] Depend on figure 1 As shown, the treatment method of this kind of waste oil-based drilling fluid solid residue is carried out according to the following process:

[0019] The oil-based drilling fluid mud waste liquid with solid residues produced by drilling is processed by a vibrating screen without falling to the ground, and is divided into two parts: drilling debris and mud, which are collected separately. The drilling debris enters the storage tank of the drying system, and the mud enters the sludge storage tank. pool;

[0020] After entering the sludge storage tank, the mud enters the natural sedimentation tank for natural sedimentation and separation. The upper filtrate and mixed liquid generated after natural sedimentation are sucked through the pump, and flocculant is added to the upper filtrate and mixed liquid to enter the centrifuge for further processing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com