Patents

Literature

460 results about "Settling basin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A settling basin, settling pond or decant pond is an earthen or concrete structure using sedimentation to remove settleable matter and turbidity from wastewater. The basins are used to control water pollution in diverse industries such as agriculture, aquaculture, and mining. Turbidity is an optical property of water caused by scattering of light by material suspended in that water. Although turbidity often varies directly with weight or volumetric measurements of settleable matter, correlation is complicated by variations in size, shape, refractive index, and specific gravity of suspended matter. Settling ponds may be ineffective at reducing turbidity caused by small particles with specific gravity low enough to be suspended by Brownian motion.

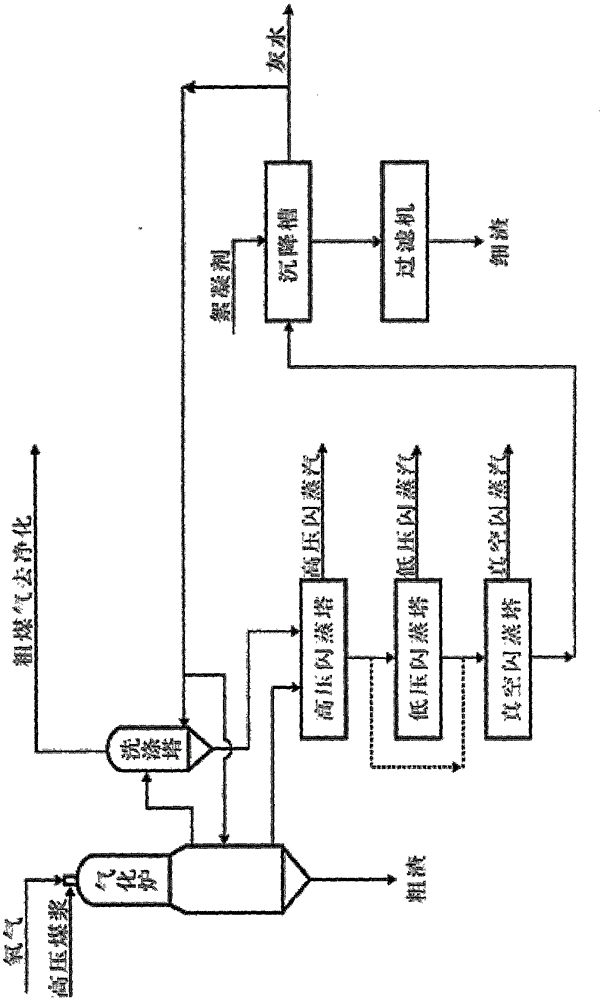

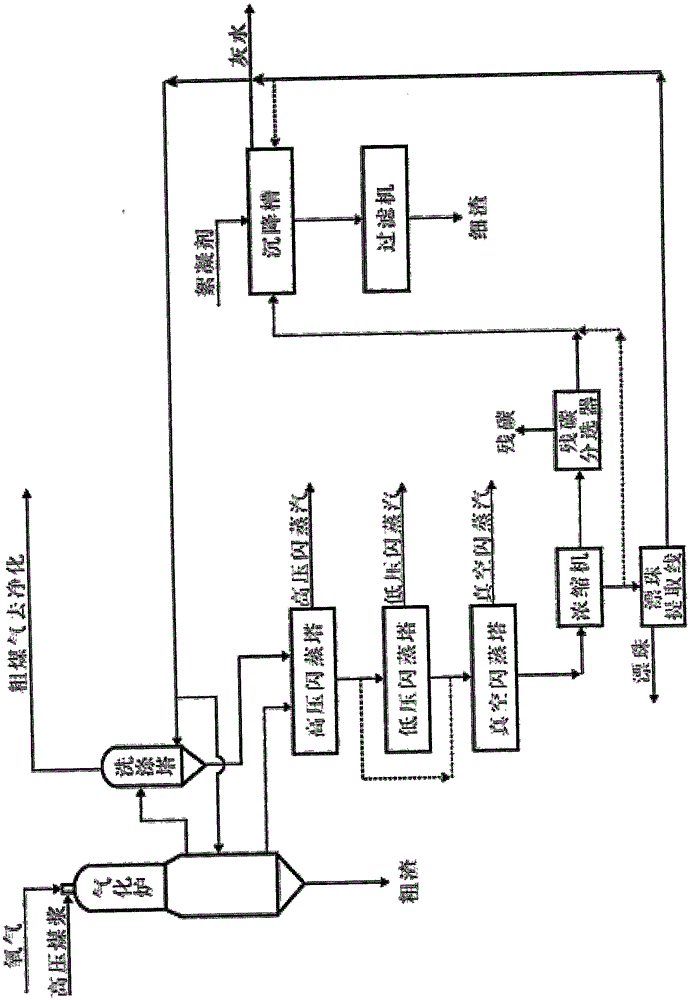

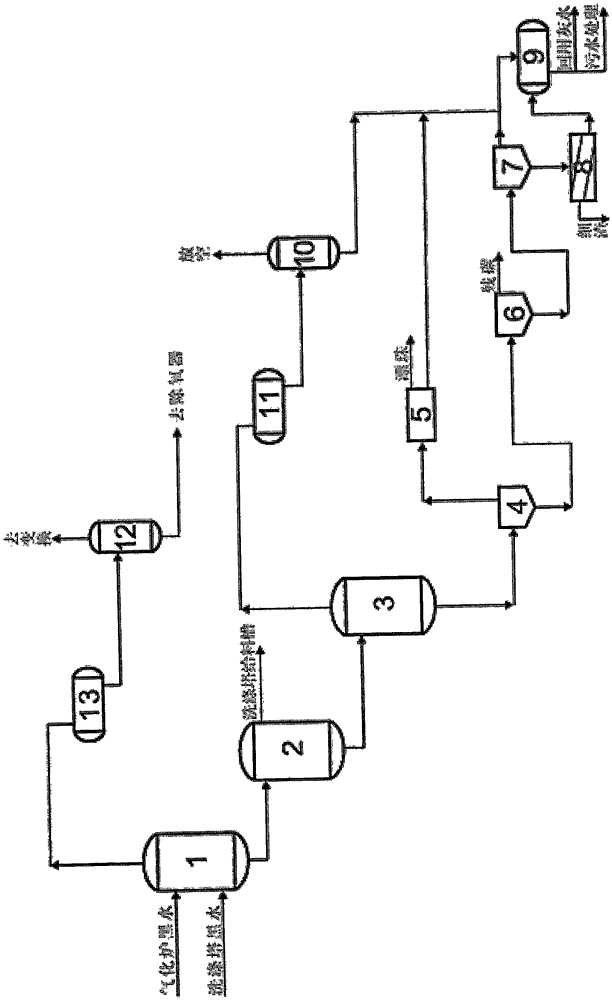

Coal gasification ash water treatment method

InactiveCN105293804AReduce carbon residueReduce suspended particlesWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSuspended particlesThree stage

The invention relates to a coal gasification ash water treatment method. The problem that in the prior art, gasified fine residue is too high in carbon residue and reused ash water contains plenty of suspended particles is solved mainly. The ash water treatment method comprises the steps that black water coming from a gasification furnace and a washing tower undergoes two-stage or three-stage flash evaporation and concentration and then enters a thickener; under the stirring effect, the black water coming from the thickener is divided into two layers, floating bead slurry of the upper layer overflows and enters an ash water circulation system or a sedimentation tank after floating beads are separated; the concentrated black water of the lower layer enters a carbon residue classifier, carbon residue undergoes floatation, tailing slurry of a lower layer of a floatator; supernatant of a settling tank enters the ash water circulation system, and lower layer turbidity solution of the settling tank enters a filter to be dehydrated to obtain filter cake (gasified fine residue). By adopting the ash water treatment method, the carbon residue content of the coal gasified fine residue can be reduced, the utilization of the gasified fine residue is facilitated, and the suspended particles in reused ash water can be reduced.

Owner:张晓峰

Industrial waste water treatment process

InactiveUS7491333B1Easy to reuseFacilitated releaseSolid sorbent liquid separationWater/sewage treatment by neutralisationClean Water ActIndustrial waste water

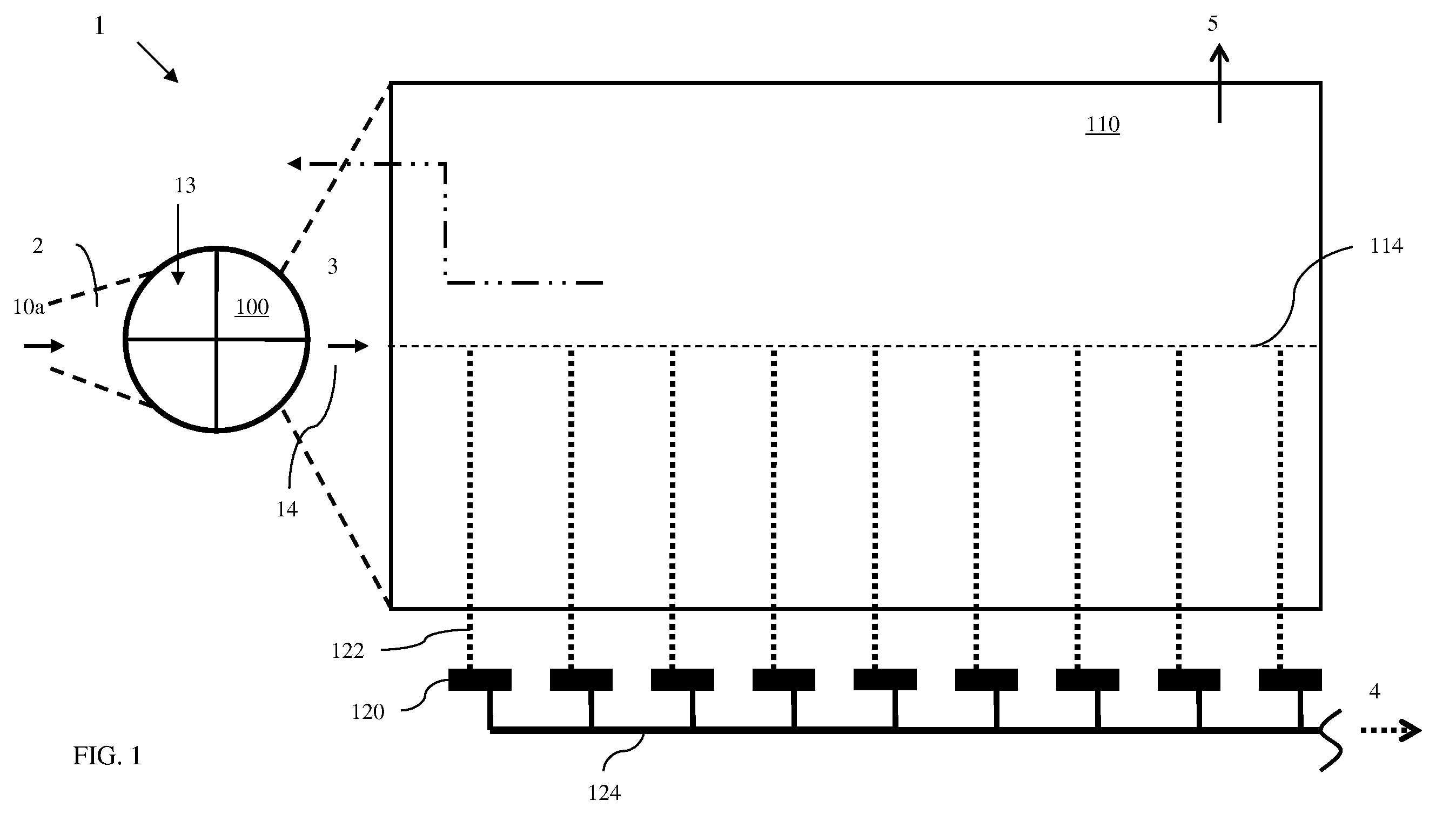

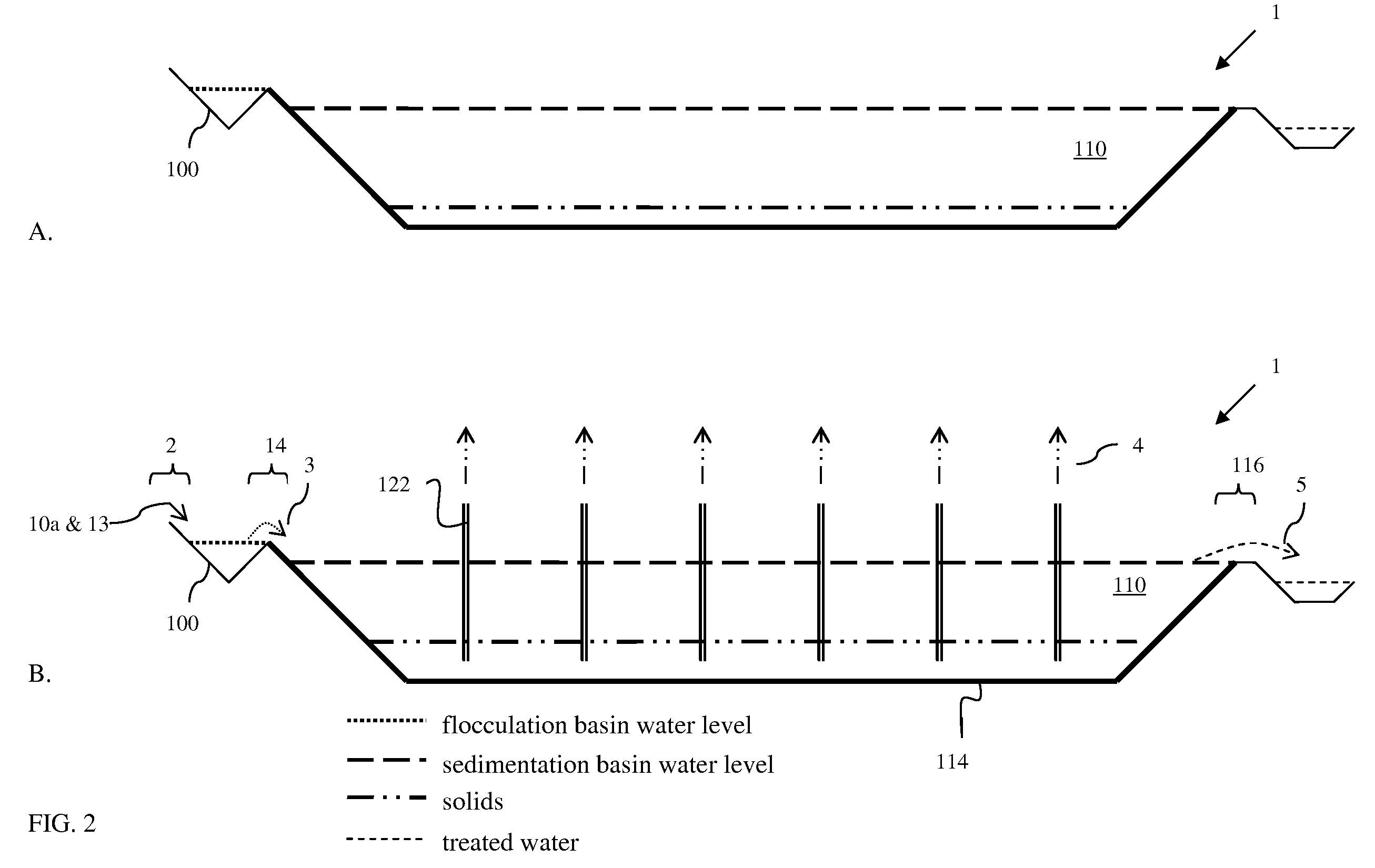

A process for the treatment of industrial waste water. The process includes the steps of admixing partially-treated waste water containing precipitated impurities with a flocculating agent in a flocculation basin, directing the admixed waste water to an elongated sedimentation basin, allowing flocculated solids in the waste water to settle to the bottom of the sedimentation basin, removing the settled solids from the bottom of the sedimentation basin and directing the treated water from the sedimentation basin. The process can further include the step of adjusting the pH of the waste water to precipitate impurities in the waste water prior to the addition of the flocculation agent. The elongated sedimentation basin can include a pair of sloped sides to consolidate the settled solids at the bottom of the basin. The settled solids can then be removed by suction. The basins can be formed from the excavation or impoundment of earth in an area adjacent to a waste water-generating facility. Furthermore, the flow of the streams between basins can be controlled by overflow, with flow rates further controlled by recycle of solids and treated water. The treatment of industrial water according to the present processes allows removal of impurities such that the water is suitable for internal re-use in an operating phosphoric acid facility or release. Additionally, the process is able to treat acidic industrial waste water by the removal of impurities as a preliminary treatment stage leading to discharge of the final treated water to natural water bodies in compliance with the Federal Clean Water Act. Moreover, treated water may be processed by reverse osmosis to remove residual impurities. By employing the processes taught herein reverse osmosis becomes possible and practicable in the context of industrial waste water treatment. Treatment of waste water in accordance with the present invention will require less expensive capital equipment for the separation stages and provide a more concentrated solids stream.

Owner:CLEANWATER TECH

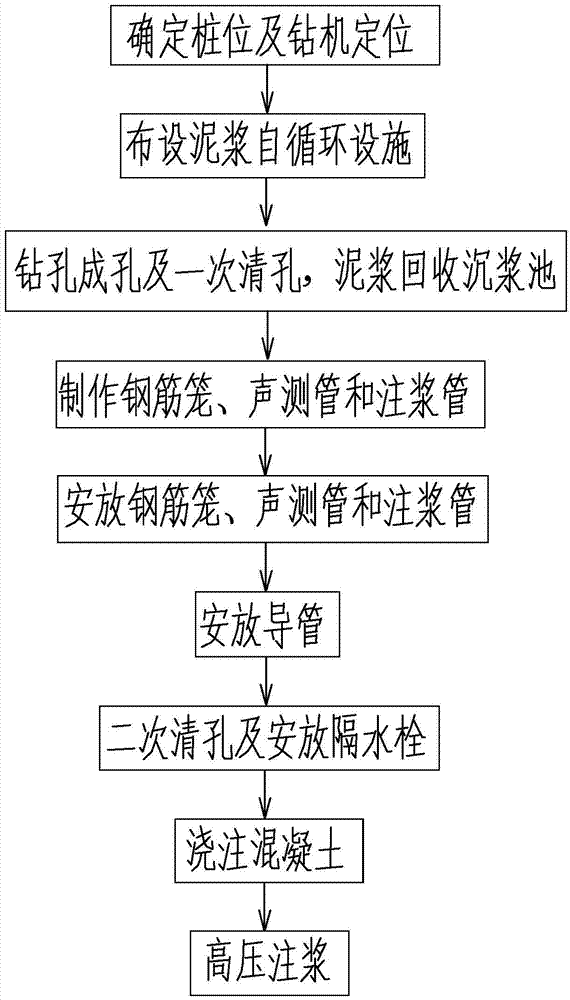

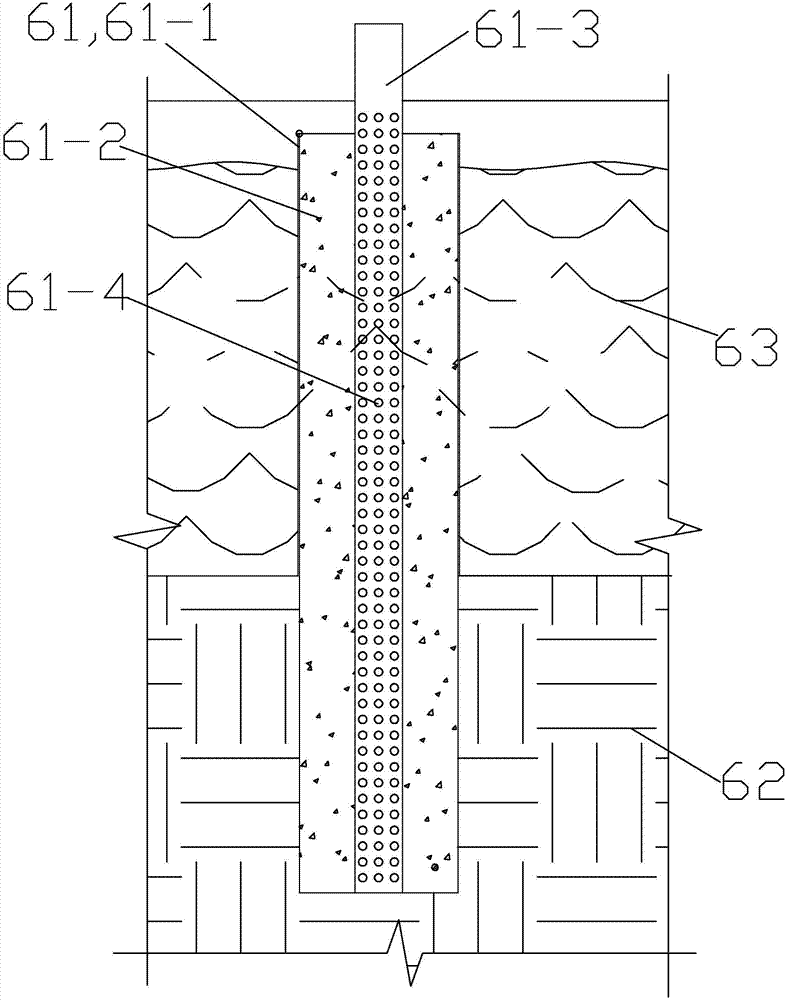

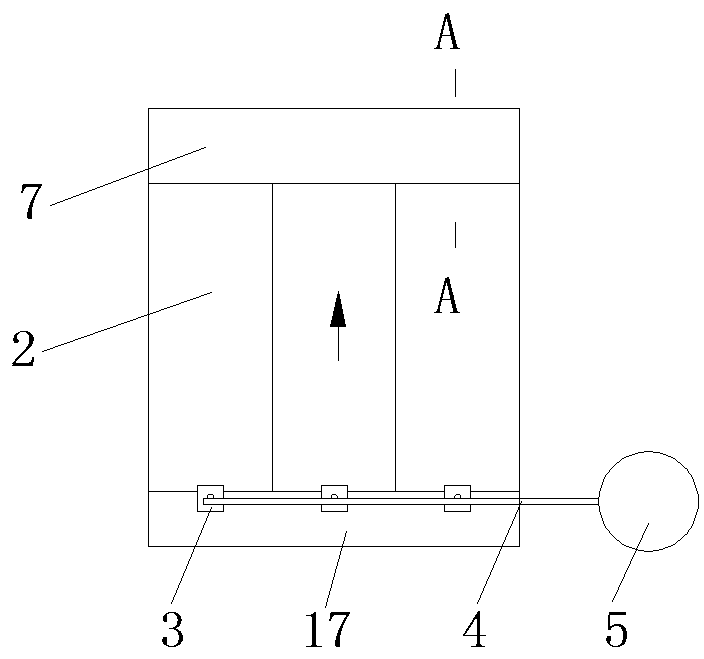

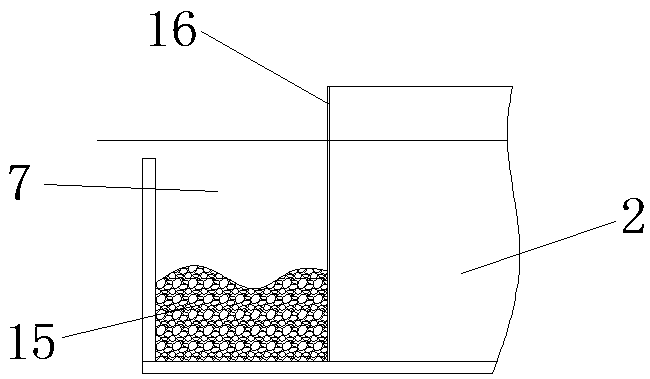

Self-circulating posterior grouting bored pile construction method

ActiveCN104846810AReduced settling timeReduce pollutionBulkheads/pilesLand resourcesEconomic benefits

The invention provides a self-circulating posterior grouting bored pile construction method. The construction method comprises the steps of (1) determining the pile position and locating a drilling machine (5), (2) arranging a mud self-circulation facility, (3) boring and primary bore clearing, (4) fabricating a steel reinforcement cage, a sounding pipe and a grouting pipe, (4) placing the steel reinforcement cage, the sounding pipe and the grouting pipe, (5) mounting a guide pipe, (7) secondary bore clearing and mounting a waterproof hydrant, (8) pouring concrete, and (9) grouting under a high pressure. According to the self-circulating posterior grouting bored pile construction method, the supporting facilities such as a mud settling basin for recovering and recycling mud are arranged in the construction site, so that the land resources and the water resources can be effectively saved, the pollution of the mud to the environment can be greatly reduced, and the environment can be protected; meanwhile, the construction cost is reduced; furthermore, the bearing capacity of the foundation pile can be effectively improved by about 30%, and therefore, under the circumstance of the certain load of the foundation pile, the diameter of the foundation pile can be accordingly reduced, the construction investment can be saved and the economic benefit can be further increased.

Owner:CHANGZHOU NO 1 CONSTR GRP

Domestic sewage denitrifying-dephosphorizing method and apparatus

InactiveCN1709810AStrong resistance to shock loadsHigh removal rateWaste based fuelMultistage water/sewage treatmentSettling basinNitrobacter

One kind method and equipment for life sewage's denitrogenation and dephosphorization belongs to the water treatment domain. The method is that the sewage through obligate baffle reactor obligate sludge layer, spreads the phosphorus on the iron filings padding layer, remove the organic pollutant microorganism in obligate way, the not transformed organic pollutant is degraded in aerobic sunk-style biofilter biomembrane, the ammonia nitrogen transforms to nitrate nitrogen, then is removed again in obligate region by biomembrane counter- nitrobacter, again passes through the precipitation then discharges. The installment is made up of obligate baffle reactor mutually linking and in turn, the aerobic sunk-style biofilter and settling basin. The obligate baffle reactor compose of 3 - 4 baffle in, the partition board, obligate sludge separate room , 1st traverse has the iron filings padding layer, has counter- tube, in the aerobic sunk-style biofilter has the padding layer.

Owner:HUBEI UNIV

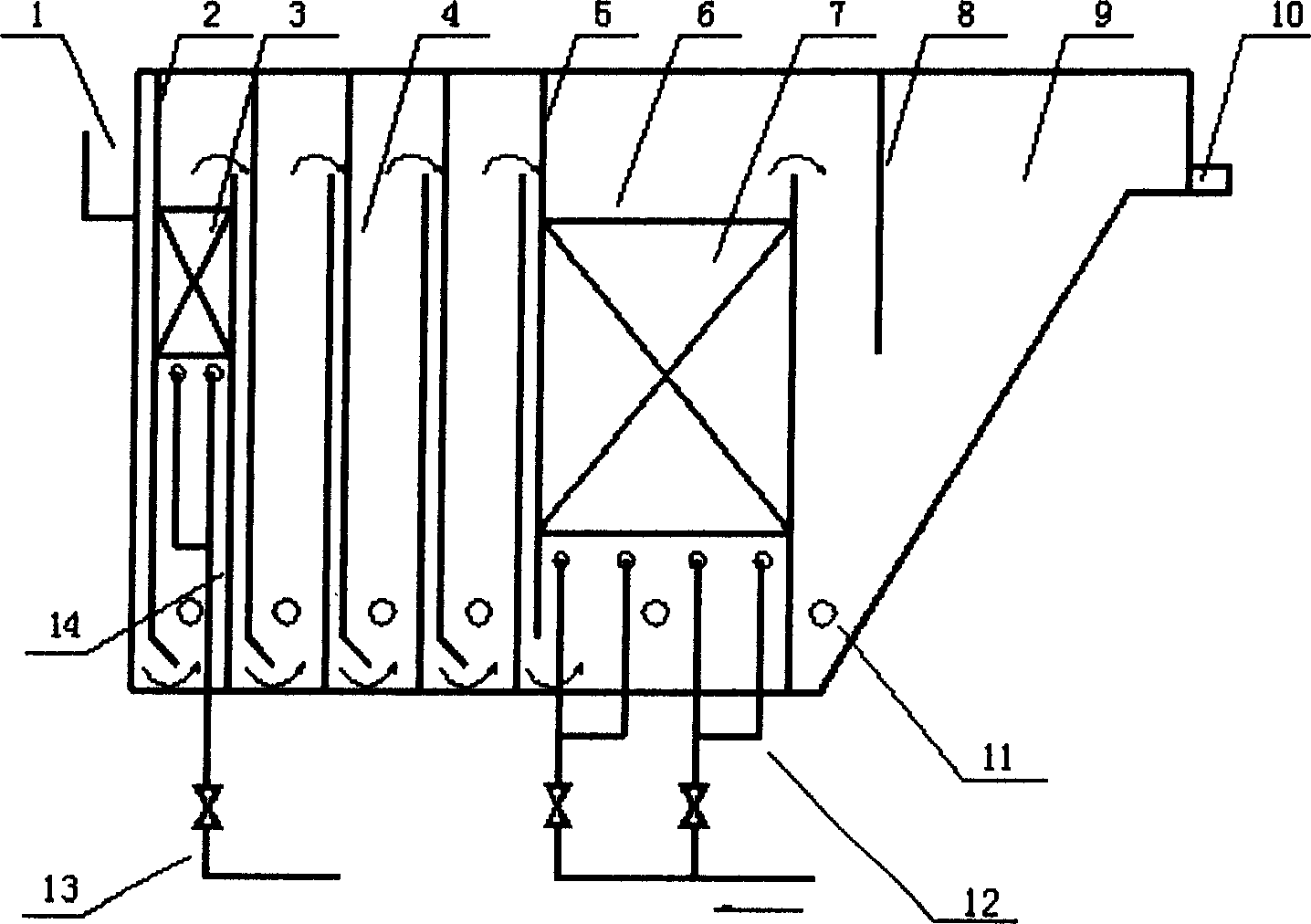

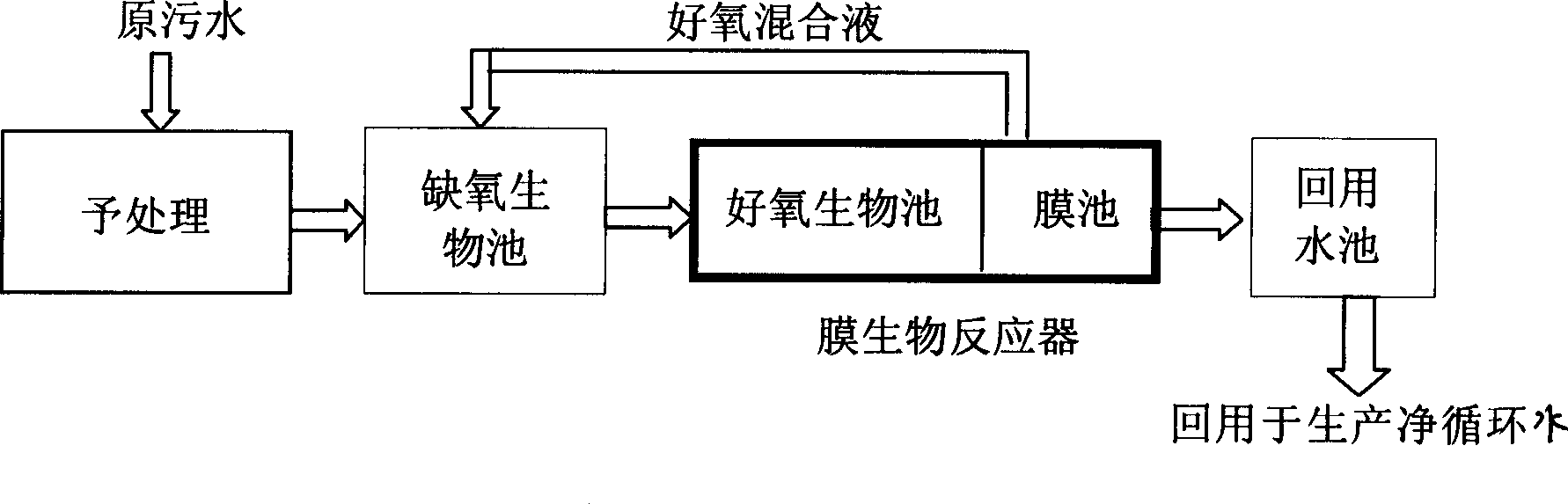

Treatment of biological reactor for coking sewage membrane

ActiveCN1778726AAchieving zero emissionsIncrease concentrationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAfter treatmentWater quality

A treatment of coking sewage membrane biological reactor consists of pretreatment, biochemical treatment, after-treatment water recovery and utilization. Membrane biological reactor is set in anoxic biological pool, the reactor consists of oxygen biological pool and membrane pool. The process is carried out by mud and water separating for curtain micro-filter membrane or super-filter membrane substituting secondary settling basin and removing high-molecular lysate to decrease outfall COD. Its advantages include higher mud concentration and volume load, and floor-area saving. It can be used to recover and utilize production circulating water system and coked sewage zero displacement.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Indigo paste industrial preparation method

ActiveCN102690529ASolve the troublesome problem of manual preparationReduce pollutionNatural dyesWater filterSettling basin

The invention discloses an indigo paste industrial preparation method, comprising a first step of raw material preparation, wherein mature indigo stems and foliages are cut into small parts by using a guillotine or a fiber cutter; a second step of raw material soaking, wherein the small parts are placed in a fermentation tank, fresh water is added for immersion, lime milk or industrial base is further added and thoroughly evenly stirring is carried out; a third step of sealed fermentation, wherein the fermentation tank is covered with a thin film for the sealed fermentation; a fourth step of impurities removal and standing, wherein after fermentation, fermentation broth is continuously turned and stirred, residue of the stems and foliages is then removed by filtering, and an indigo solution in the fermentation tank is discharged into a settlement tank for standing; and a fifth step of water filtering, wherein the indigo paste is obtained after a precipitate in the bottom of the settlement tank undergoes the water filtering. The method utilizes natural plant resources to prepare dye material through an industrial method, and the problem that the indigo dye preparation is troublesome is solved. With the method of the invention, the product has good and stable quality, treatment of three wastes is centralized, environmental pollution is reduced, and product cost is reduced. The method lays a foundation for batik product development.

Owner:GUIZHOU DANZHAI NINGHANG BATIK

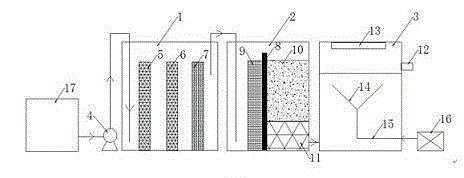

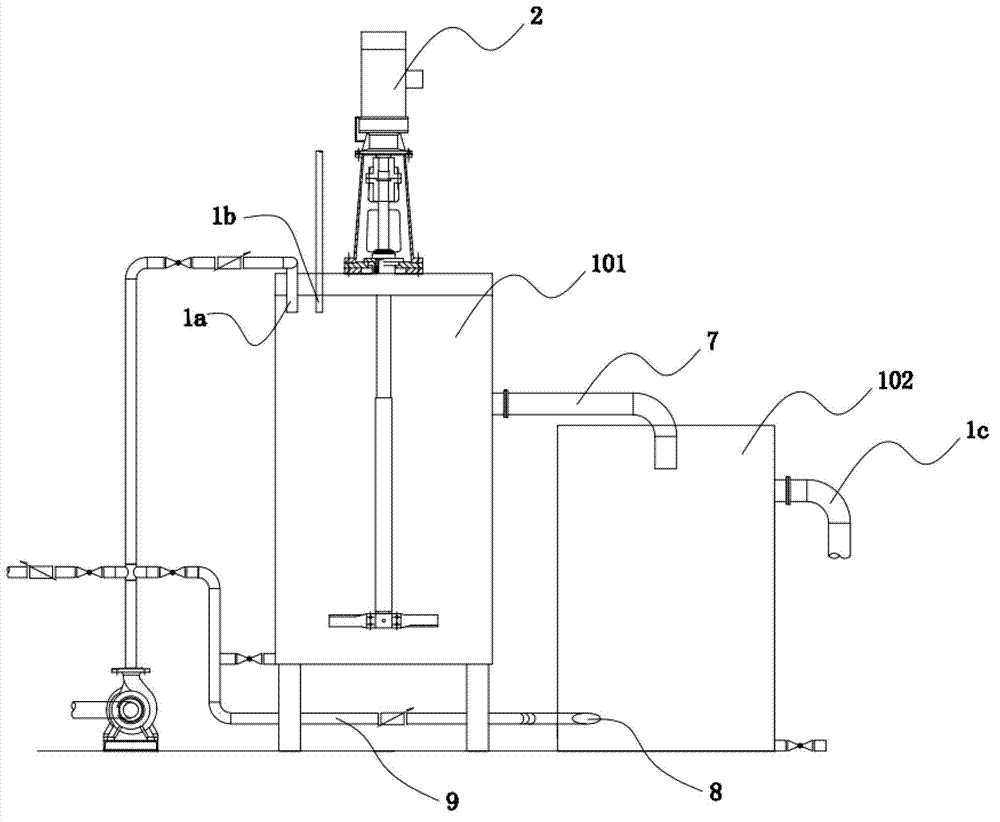

Aquatic product culture waste water processing apparatus

InactiveCN103910453ASimple structureImprove applicabilityMultistage water/sewage treatmentAquaculture industryFiber

The invention discloses an aquatic product culture waste water processing apparatus, which comprises a three-stage settlement filter tank, a water inlet pump is arranged outside the three-stage settlement filter tank, three groups of filter layers are arranged in the three-stage settlement filter tank; culture sewage is introduced in the three-stage settlement filter tank for sedimentation and filtration through the water inlet pump, then is introduced in an oxidation absorption pool, the oxidation absorption pool is divided into a left space and a right space by a separator plate, an ecology carbon fiber filling layer is arranged in the left space, a netted support bracket and a biology active carbon filling layer are arranged at the right side, water through oxidation, absorption and filtration is introduced in a disinfection oxygenation pool through the netted support bracket; an ultraviolet ray sterilization apparatus is arranged at the inner top of the disinfection oxygenation pool, a Y-shaped aeration pipe is arranged in the disinfection oxygenation pool, and is communicated with a blower outside the disinfection oxygenation pool through an air inlet pipe. The aquatic product culture waste water processing apparatus integrates the functions of mechanical filtration, chemical filtration and biofiltration, the culture waste water is purified and processed to recyclable water resource without pollution, pollution on natural water can be effectively avoided, water source is saved, and the aquatic product culture waste water processing apparatus promotes the healthy development for the aquaculture industry.

Owner:SUZHOU YANGCHENGHU MODERN AGRI INDPARK SPECIAL AQUACULTURE

Constant water level sequencing batch active sludge process and system for treating sewage

ActiveCN1986455ASmall footprintEasy maintenanceTreatment with aerobic and anaerobic processesSettling basinSmall footprint

The present invention is constant water level sequencing batch active sludge process for treating sewage, and belongs to the field of sewage treating technology. The process includes pre-treating sewage in grille and settling basin, treating partial sewage in the anoxia pond and the other in the anaerobic pond with sludge, treating in the aerobic pond to degrade organic matter, eliminate ammonia nitrogen and absorb phosphorus from sewage, and final flowing into the sequencing batch pond for exhausting water reaching the drainage standard. The present invention has the advantages of high treating efficiency, stable running, high apparatus utilization rate, low power consumption, etc.

Owner:THUNIP CORP LTD

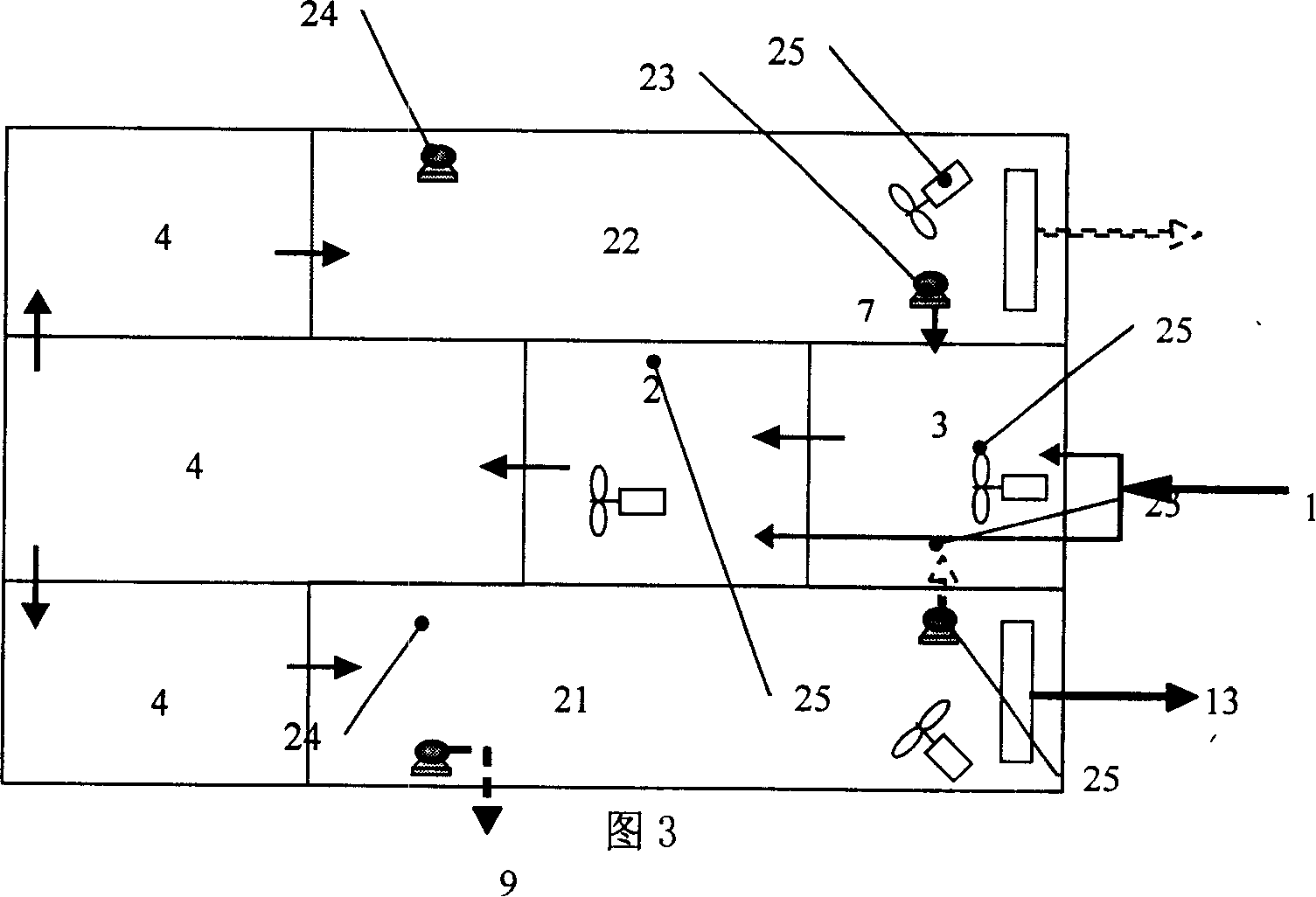

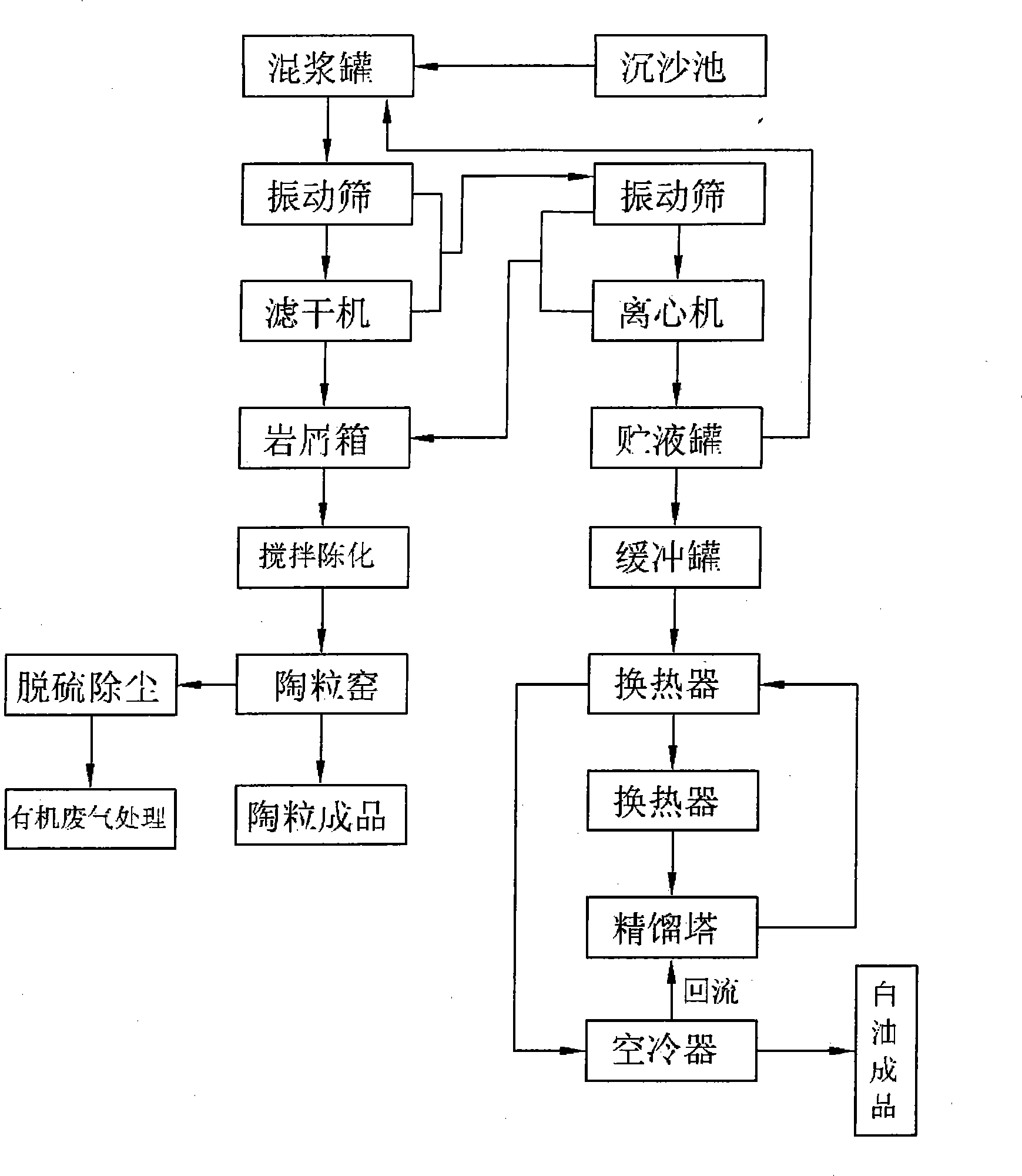

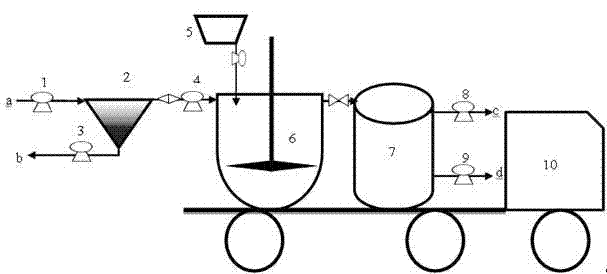

Method for processing and recycling drill cuttings

InactiveCN101172284AAchieve Multiple HarvestsReduce disposal costsSolid waste disposalRecovery methodExpanded clay aggregate

The invention discloses a processing and recovery method of a drill chip. The method comprises the following steps: the drill chip in a settling basin is pumped into a slurry mixing tank; mixed slurry in the slurry mixing tank is pumped into a first vibratory screen to be screened; screenings of the first vibratory screen freely falls into a filtering dryer to perform filtering and drying, solid phase after being filtered and dried is sent to a screw conveyer to be conveyed to a salt chip box; the screenings of the first vibratory screen and the flowing of the filtering dryer are mixed and conveyed into a second vibratory screen; the screenings of the second vibratory screen falls into the screw conveyer to be conveyed to the salt chip box, the screenings is pumped into a centrifugal machine through a pump; solid phase separated by the centrifugal machine enters into the screw conveyer to be conveyed to the salt chip box, liquid phase enters into a liquid storage tank to be produced into a white oil product; the drill chip in a salt chip box and clay are mixed and produced into haydite. The method of the invention is to recovery oil base in the drill chip, building materials manufactured by rock chip slurry reduce the cost expense, compared with the prior art, the running cost is low, the processing rate is large, and the efficiency is high.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Well drilling wastewater flocculation precipitation treatment device and wastewater treating method

InactiveCN102757143ASlow down hard to transportReduce uniformityWaste water treatment from quariesMultistage water/sewage treatmentFlocculationWater discharge

Owner:四川省环保科技工程有限责任公司

Method for treating high-concentrated non-degradable wastewater by using wastewater containing hydrogen peroxide

InactiveCN101659483AReduce processing costsSignificant social benefitsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSocial benefitsSettling basin

The invention discloses a method for treating high-concentrated non-degradable wastewater by using wastewater containing hydrogen peroxide, which comprises: (1) uniformly mixing the wastewater containing the hydrogen peroxide and the high-concentrated non-degradable wastewater in an oxidation pond, adding acid to adjust the pH value of the wastewater, and adding a catalyst to perform Fenton oxidation reaction; (2) adding an alkali in wastewater obtained after the completion of the oxidation to adjust the pH value of the wastewater, and performing flocculating setting in a settling basin; and (3) treating supernatant and settled sludge respectively after the completion of the settlement. The method treats the high-concentrated non-degradable wastewater by using the wastewater containing thehydrogen peroxide, thereby saving the treatment cost of both the wastewater containing the hydrogen peroxide and the high-concentrated non-degradable wastewater. The method has obvious social benefits and environment protection benefits while creating excellent economic social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

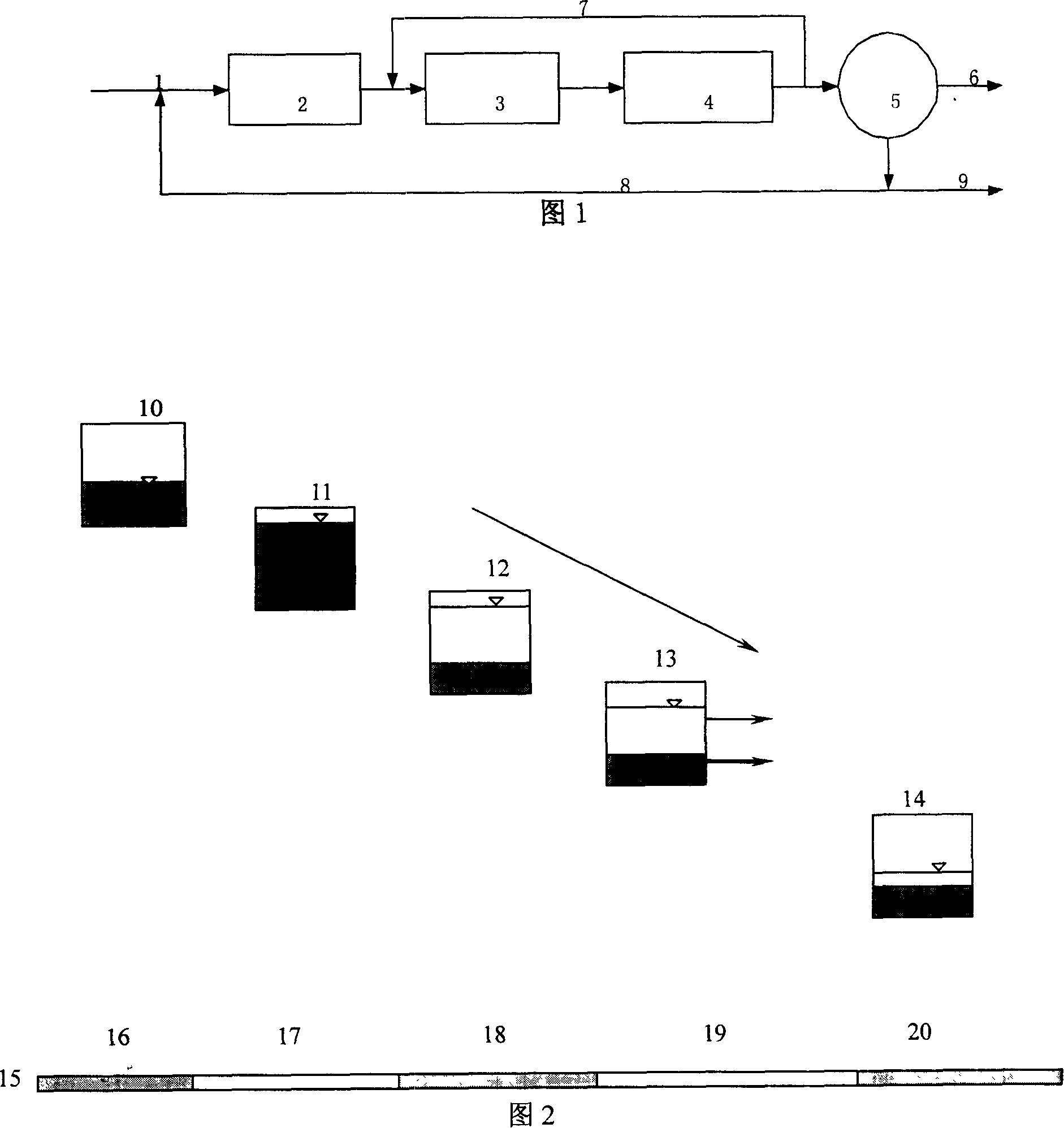

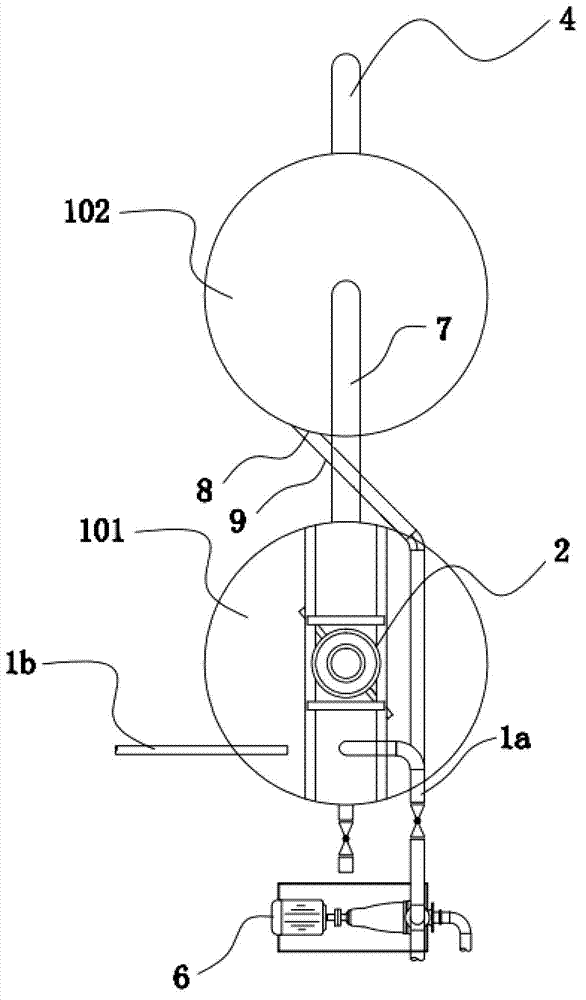

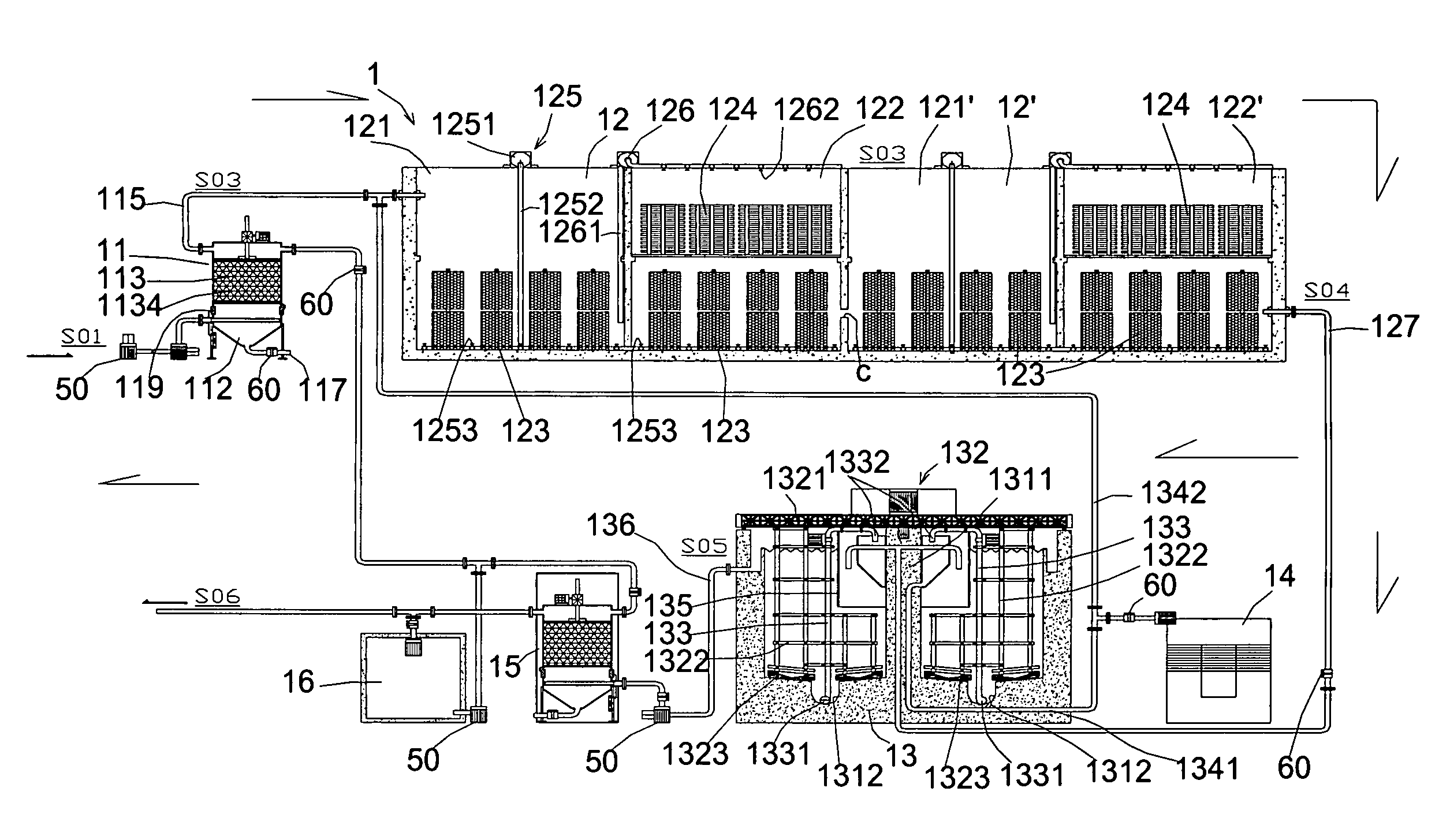

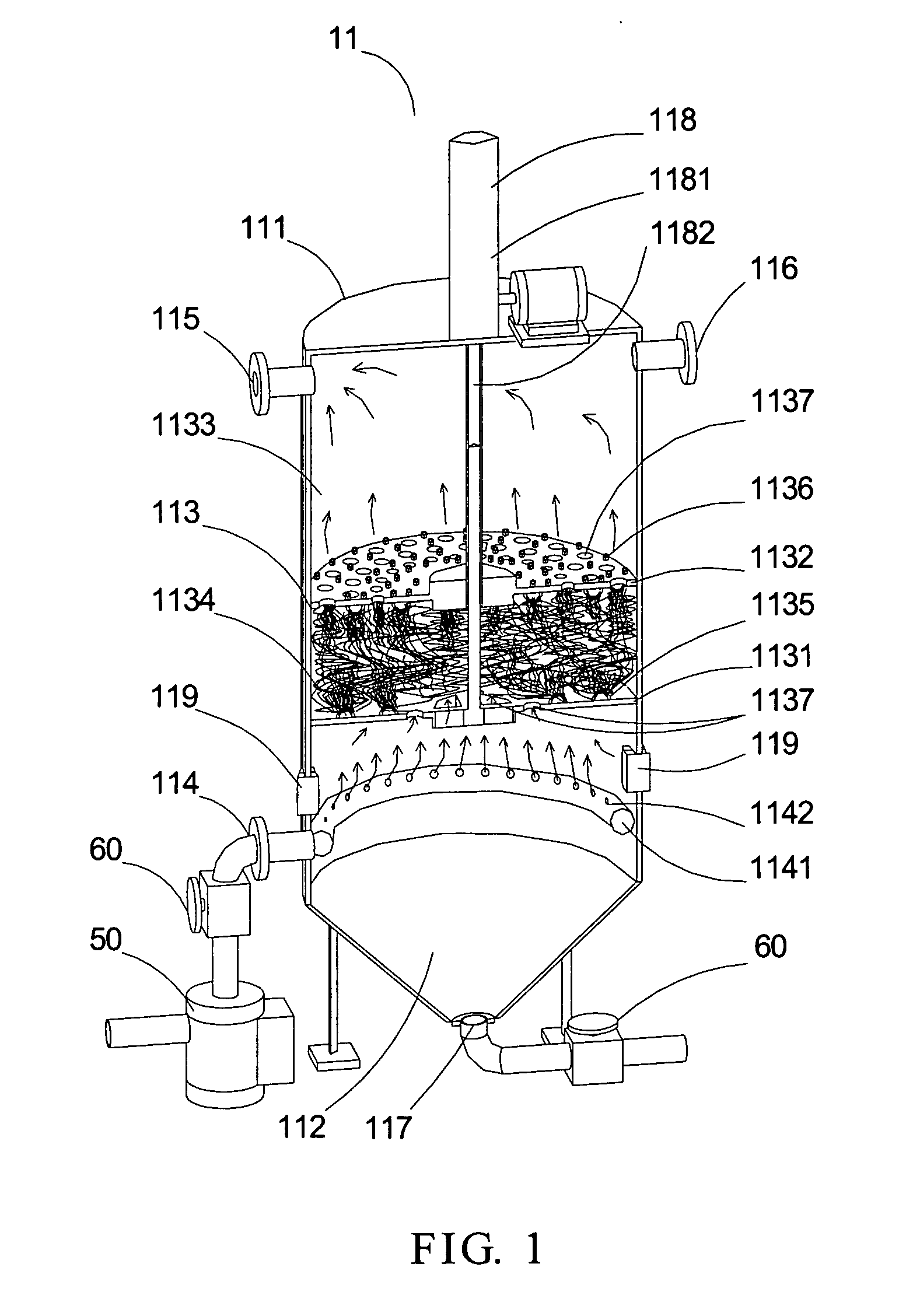

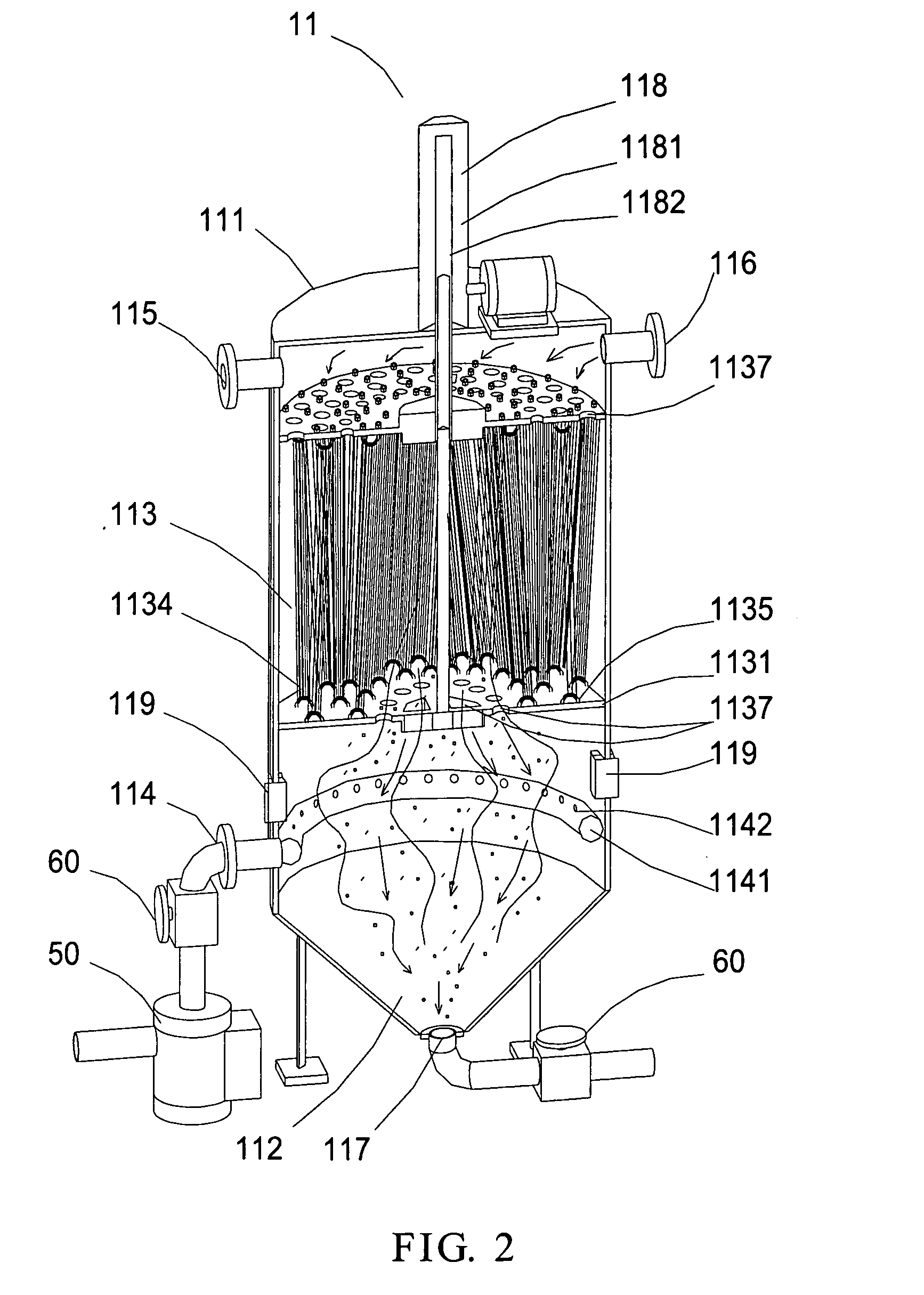

Water purification and treatment apparatus and treatment process using the apparatus

InactiveUS20080011659A1Large amount of processingAddressing slow performanceTreatment using aerobic processesLiquid displacementFiltrationWastewater

The present invention provides a water purification and treatment apparatus using a combination of sedimentation, filtration, and bio-contact aeration processes, which comprises at least one rapid water purification filter having a hopper base for settled sludge and a filtering tank; at least one cylindrical settling basin for sedimentation and filtration; and at least one aeration basin having an under water and an over water bio-film contact parts, for rapidly filtering raw water or wastewater contacted with bio-contact aeration, and performing water purification and treatment.

Owner:CHENG JIAN RUNG +1

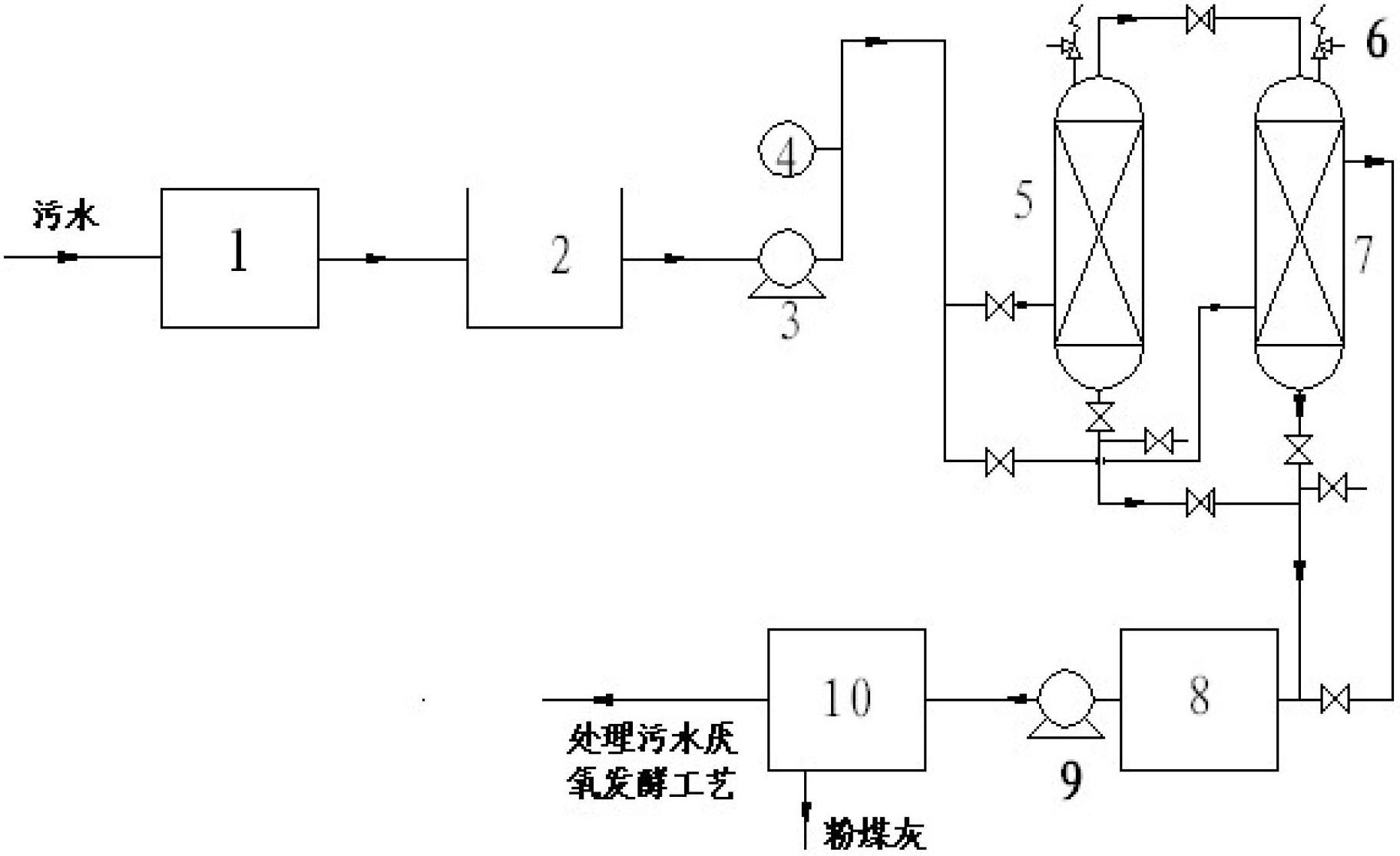

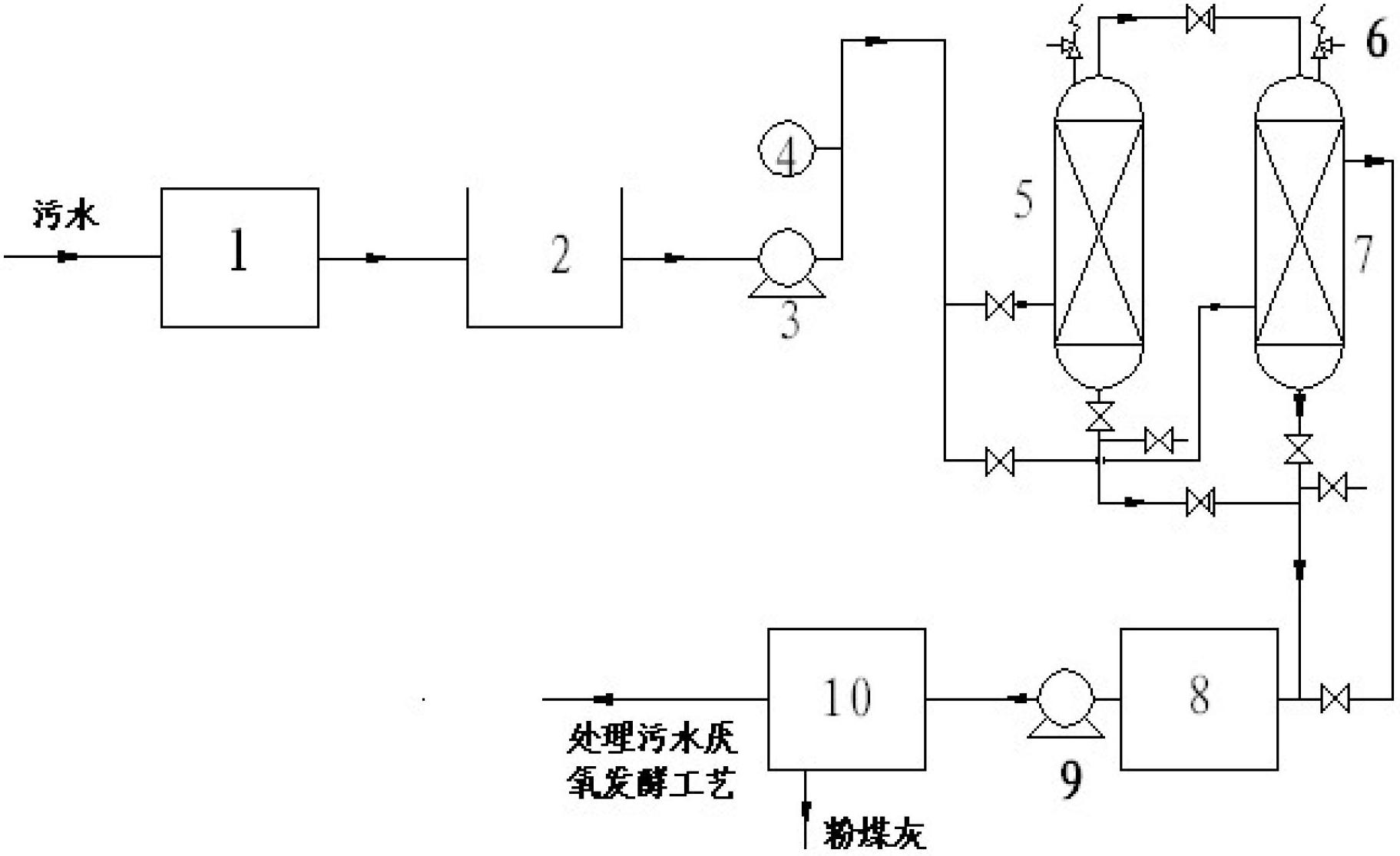

Method for treating sewage with high ammonia, nitrogen and phosphorus contents in livestock and poultry farms by chemical precipitation

ActiveCN102690001AHigh removal rateWide variety of sourcesWaste water treatment from animal husbandryMultistage water/sewage treatmentFixed bedSettling basin

The invention discloses a method for treating sewage with high ammonia, nitrogen and phosphorus contents in livestock and poultry farms by chemical precipitation. The method comprises the following steps of: performing solid-liquid separation on the sewage by using a solid-liquid separator, wherein liquid is discharged into a sedimentation tank for further separation; pumping the sewage which is obtained after separation and deposition into a fixed bed reaction tower in which calcium, magnesium and phosphate fertilizers serve as main reactants, wherein substances which contain the ammonia, the nitrogen or the phosphorus are removed from the sewage in the reaction tower simultaneously; importing sediment and the sewage into a crystallizing pond, and crystallizing to generate struvite; separating the struvite by using the solid-liquid separator; and performing a sewage anaerobic fermentation process on the liquid for further treatment. According to the method, the removal rate of the phosphorous can reach 80 to 90 percent, the removal rate of the ammonia and the nitrogen can reach 70 to 80 percent, and the discharged water can meet the requirement of anaerobic fermentation. The method is high in reaction speed, not influenced by temperatures and low in cost, raw materials are readily available, and the generated sediment, namely the struvite is an efficient sustained-release fertilizer.

Owner:GUANGXI UNIV

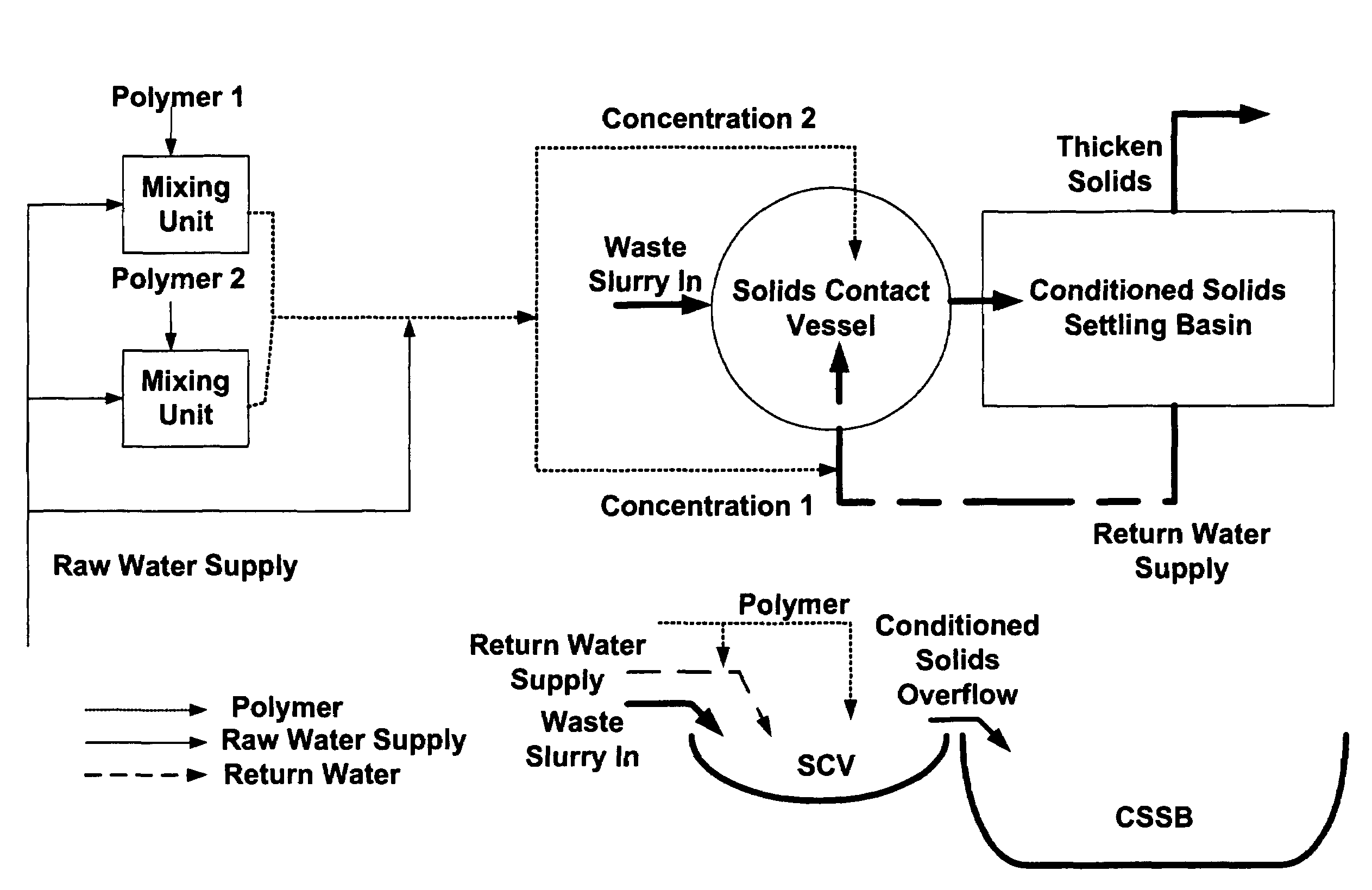

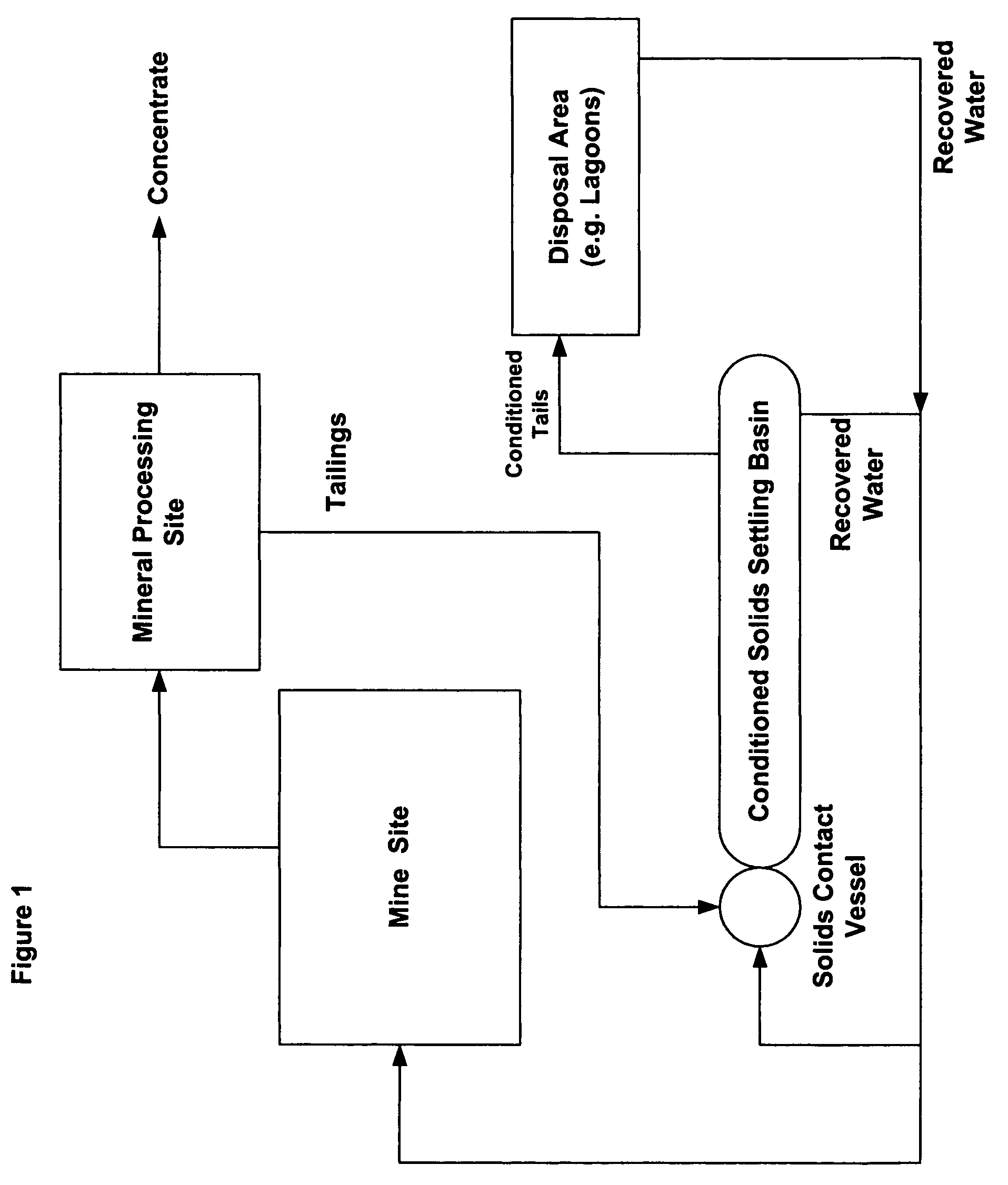

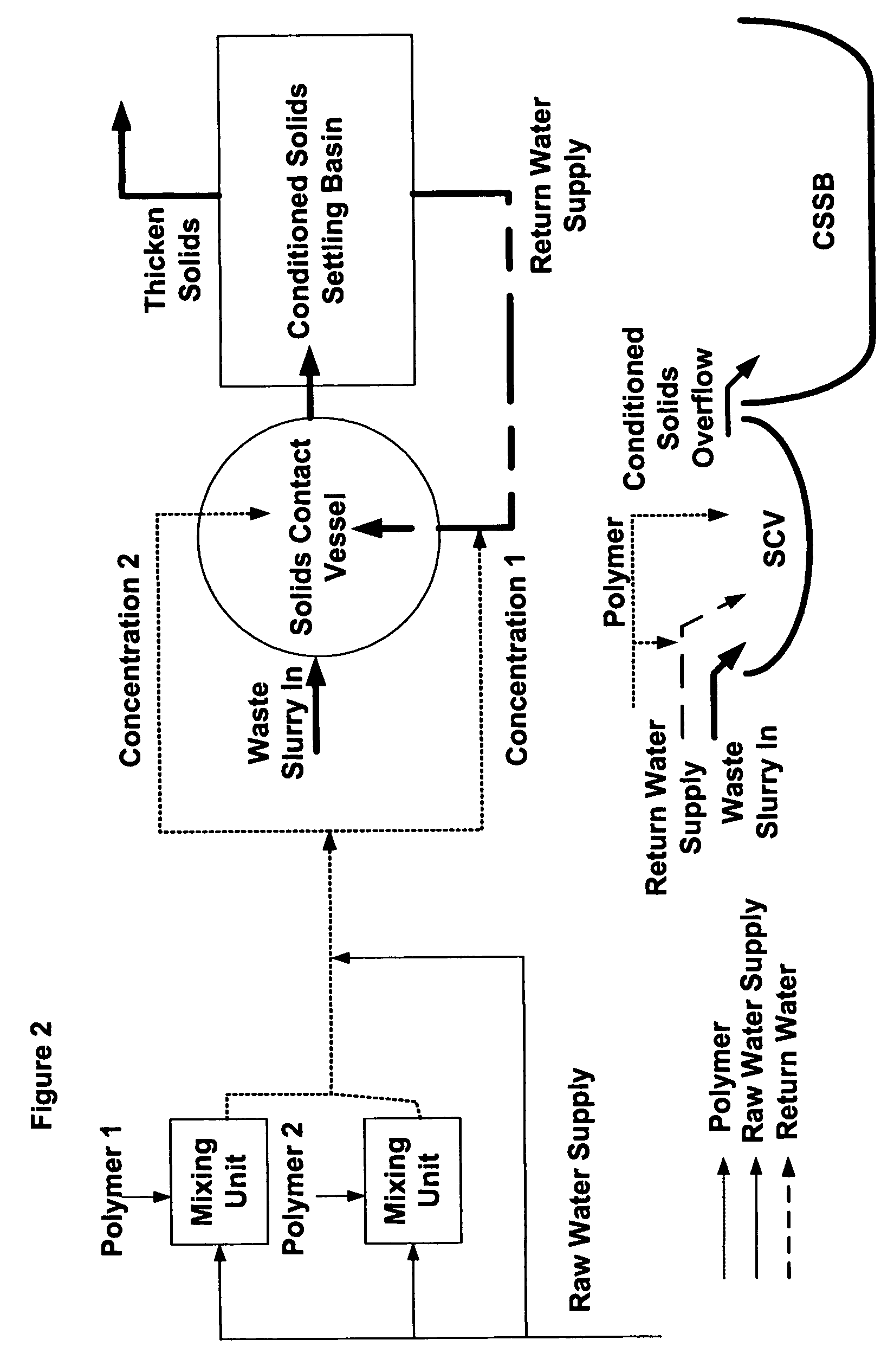

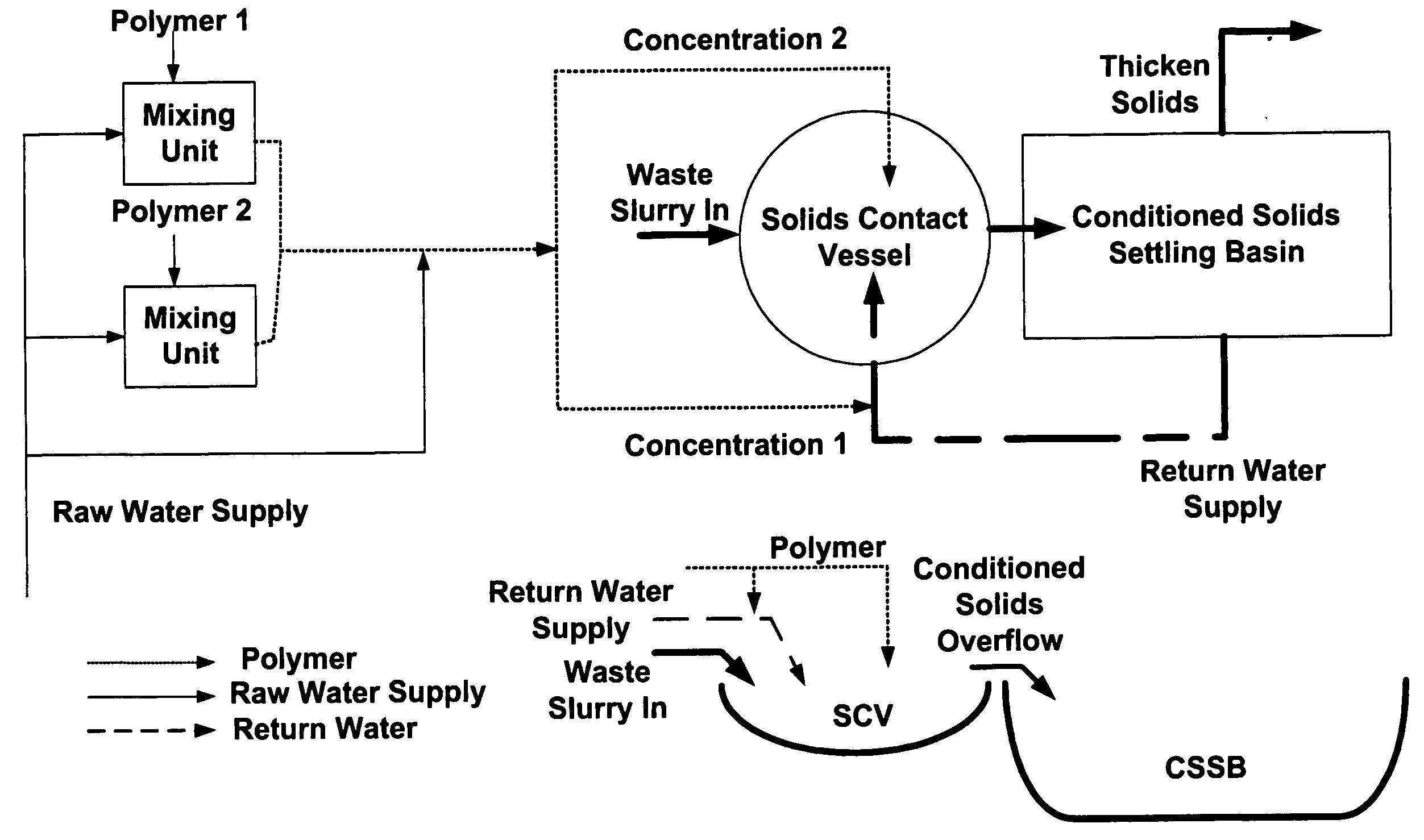

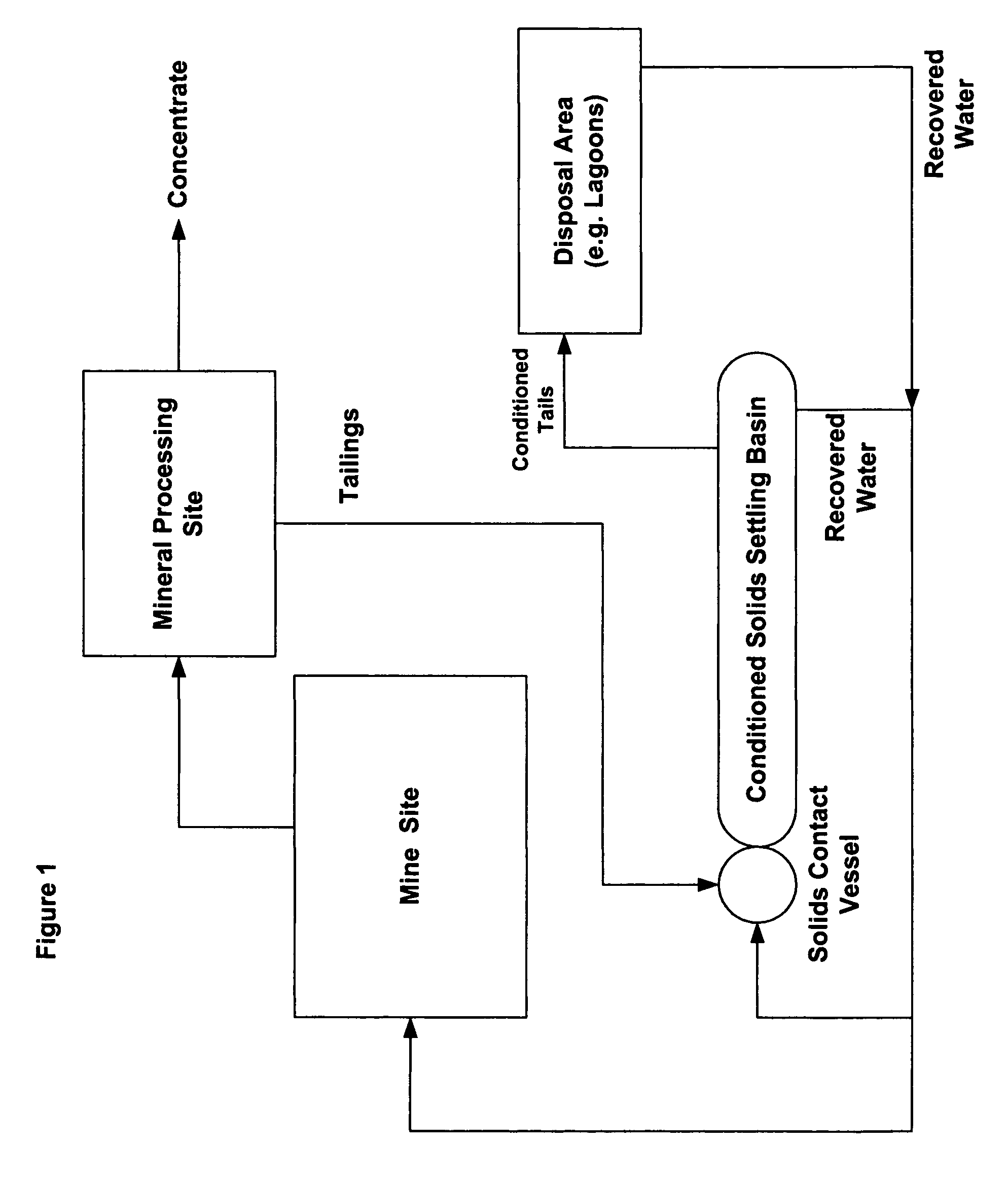

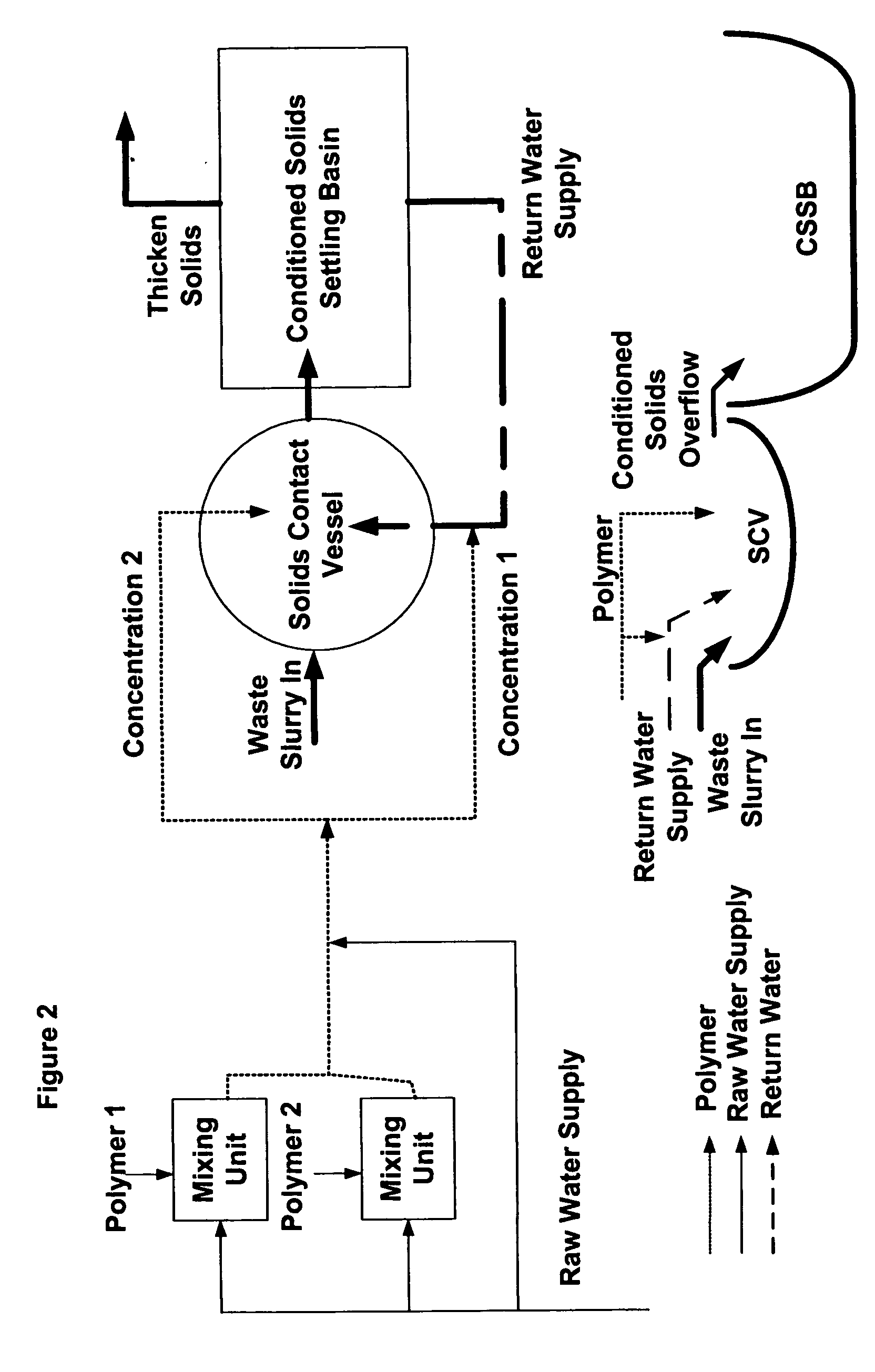

Metals/minerals recovery and waste treatment process

InactiveUS7244361B2Reduce the amount requiredReduce flow rateWaste water treatment from quariesWater contaminantsLiquid layerSettling basin

A metals / minerals recovery and waste treatment process comprising a main separation stage in which a metal / mineral-bearing ore is slurried with water and separated into an enriched fraction and an aqueous metal / mineral waste fraction, and a waste sedimentation stage in which the aqueous metal / mineral waste fraction is sedimented in one or more settling lagoons to provide a thickened sediment layer and supernatant; and the waste sedimentation stage comprises feeding the aqueous metal / mineral waste into a solids contact vessel or other flocculating chamber, wherein the aqueous metal / mineral waste is diluted with water containing one or more flocculant(s) at more than one concentration, one of which concentrations is at least 10 times higher than the other, within the SCV, flocculating the diluted aqueous waste, and sedimenting the diluted and flocculated aqueous waste to provide a liquid supernatant layer and a pumpable thickened sediment layer in a settling basin.

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

Integrated treatment process and equipment for river sediment dredging and residual water

InactiveCN102295371AEfficient killingReduce pollutionWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentRapid processingWater flow

Owner:TONGJI UNIV

Cane sugar manufacture production system

InactiveCN103981291ALow investment costReduce manufacturing costSucrose extractionSugar juice boiling/evaporationIndustrial equipmentSettling basin

The invention discloses a cane sugar manufacture production system. The production system is characterized by comprising a cleaning system, a discoloring system, an evaporation system, a sugar boiling system and a purging and drying system; the system device comprises a pipeline filter, a mixed juice tank, a mixed juice pump, a static mixer, a heater, a rapid settling basin, a dosing storage tank, a filter press, a falling film evaporator, a condenser, a discoloring column, a bag filter, a sugar boiling crystallizing tank, a syrup tank, a help-crystallization box, a purging box, a conveyor, a drying machine, a gas-liquid separator, a honey jar, a clear juice pump, a syrup pump, a circulating pump and a vacuum pump. According to the cane sugar manufacture production system, a stove drying system and a carbonation system in the original sugar refining design are canceled, a novel process is adopted, novel industrial equipment is introduced, and the system can serve as a scientific research platform for performing a novel cane sugar manufacture process or an industrial production line for producing raw sugar, primary white granulated sugar, high-grade sugar and refined sugar.

Owner:GUANGXI UNIV +1

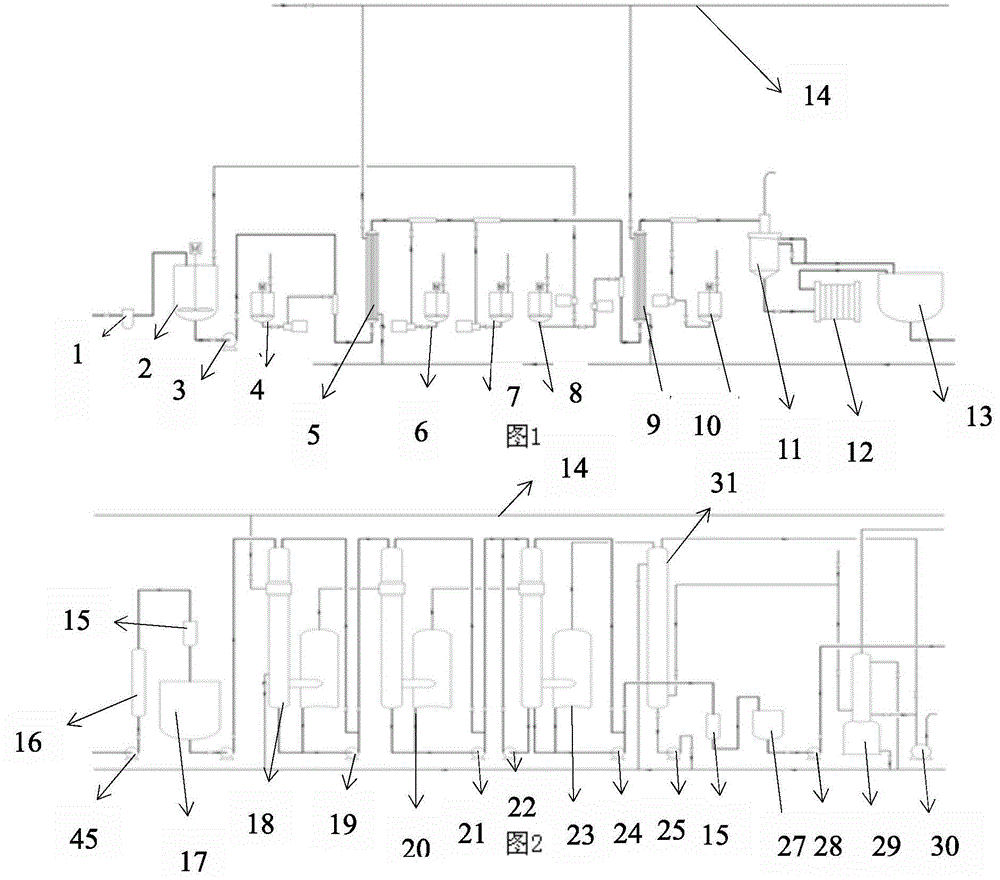

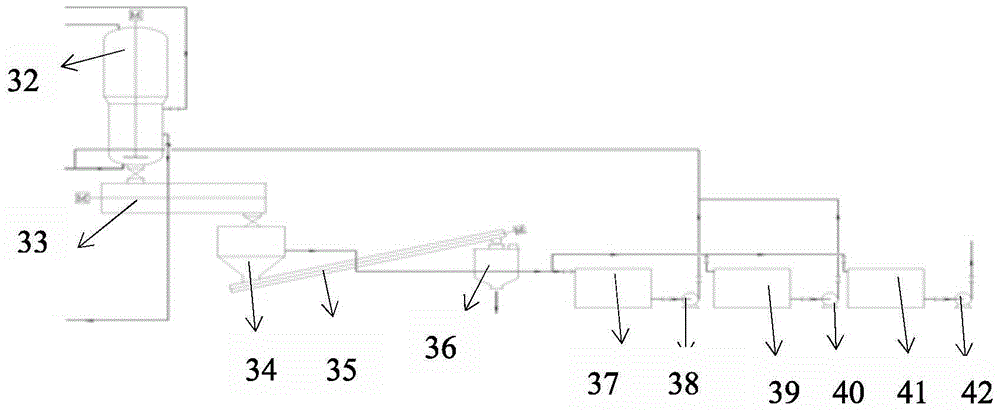

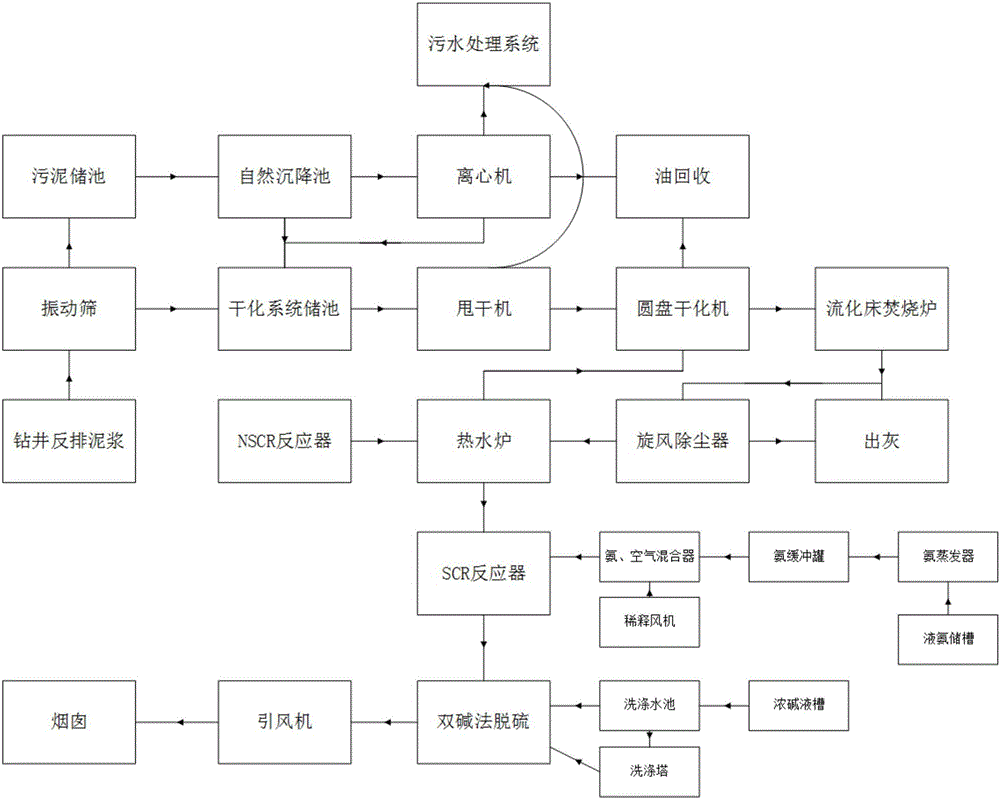

A waste oil-based drilling fluid solid residue treating method

ActiveCN106630504AClean up thoroughlyAchieve efflux indicatorsWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningLiquid wasteAbsorption column

A waste oil-based drilling fluid solid residue treating method is disclosed. The main objective is to overcome the problem that oil, inorganic salts and metal ions in discharged drilling fluid solid waste exceed standards. The method is characterized in that mud waste liquid is treated through a vibrating screen, drilling scraps are fed into a drying system storage tank, mud is fed into a settling tank and separated, then dehydration separation is performed, materials in the drying system storage tank are fed into a system spin dryer, subjected to spin drying, fed into a disc type dryer after dehydration, and dried, residues after drying are fed into a fluidized bed incinerator, the incineration temperature is controlled, gas after incineration is dedusted by a deduster and then fed into a water heater, nitrate in exhaust gas that is finally generated is treated through an SCR+NSCR process, then desulphurization is performed by a two-alkali process, the exhaust gas is fed into an absorption column and brought into reverse contact with a cyclic liquid that is mist formed by injection through an atomizing nozzle, and dust in the exhaust gas is adsorbed by the cyclic liquid to achieve thorough dust removing. The treating method can achieve thorough harmless treatment for waste oil-based drilling fluid solid residues.

Owner:NORTHEAST GASOLINEEUM UNIV

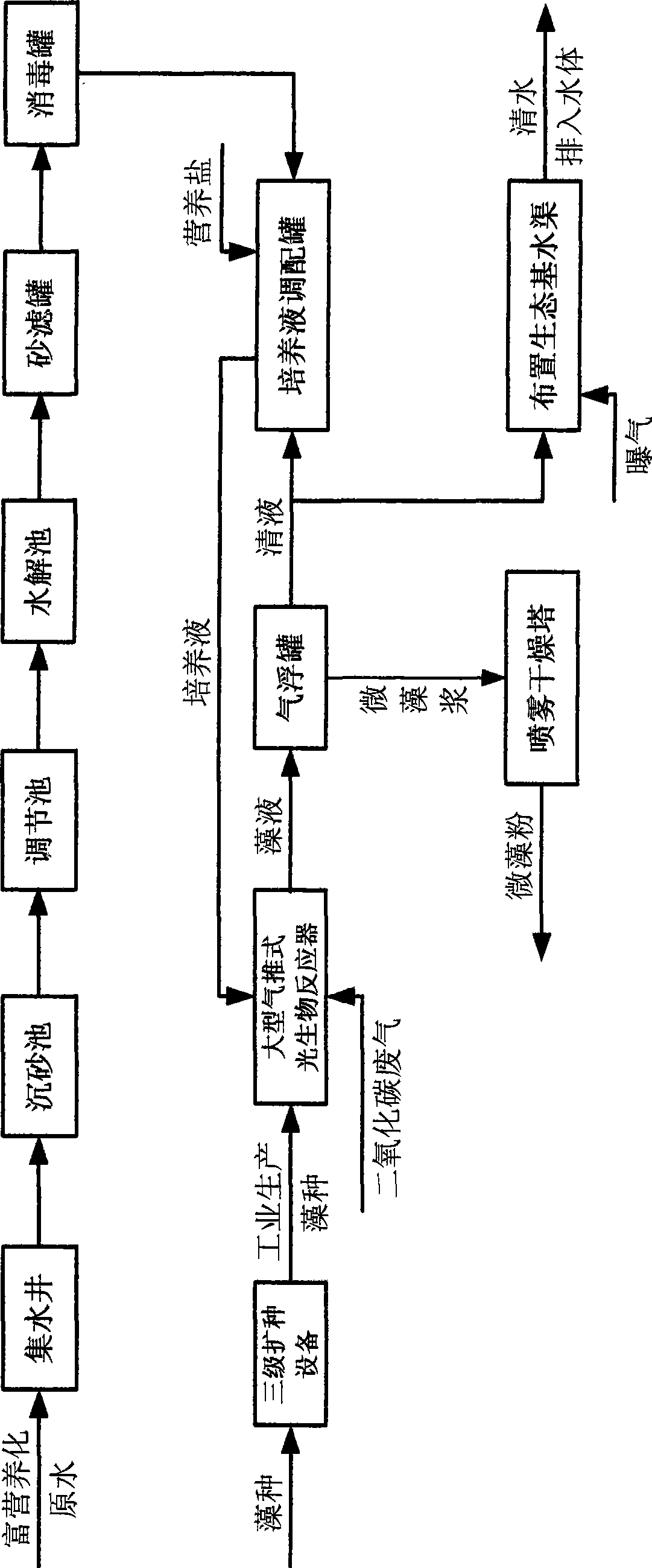

Method for ectopically and ecologically repairing eutrophication water

InactiveCN101503264AWater/sewage treatment by irradiationMultistage water/sewage treatmentEutrophicationCulture fluid

The invention relates to the environmental protection field and the microalga culturing engineering filed, and particularly relates to a method for repairing an eutrophication water body by ectopic ecology. A collecting well, a sand settling basin, an adjusting tank, a hydrolytic tank, a sterilizing tank, a culture fluid preparing tank, a large-scale air push type photo bioreactor and an air floating tank production device are adopted; the method is characterized in that the method comprises the following steps: preparing microalga culturing liquid by using eutrophication raw water; then culturing and collecting microalga by utilizing the eutrophication water body and carbon dioxide exhaust gas; and finally treating clear liquid collected by utilizing an ecological base after air float is collected, so that the water quality achieves above surface water type-V water standard. In the invention, the microalga is cultured by utilizing the eutrophication water body, the carbon dioxide exhaust gas and the like; nitrogen, phosphorous and other nutrient salts in the eutrophication water body can be largely absorbed during the growth process of the microalga, so as to achieve the purpose of repairing the eutrophication water body by the ectopic ecology.

Owner:上海大祺环保工程有限公司

Closed cyclic utilization method for production water of monoammonium phosphate

ActiveCN103213961ASolve the amount of sewage waterEasy to handlePhosphatesPhosphate productEvaporation

A closed cyclic utilization method for production water of monoammonium phosphate, is suitable for a dihydrate pulp wet-process phosphoric acid technology and an ammonia neutralization fluidized drying phosphate fertilizer production system. A production water cyclic system mainly comprises a clear water recovery pond, a sewage settling basin, a settlement and overflow groove, a water flushing and distribution tank, a thick slurry groove, a round plate filter, an extraction tail gas washing tower, a dried tail gas washing tower. Multi stage closed cyclic utilization is preformed on sewage, and primary water consumed by per ton product is 2.5-2.8t, in order to supplement water entering into the product or phosphogypsum and lost by evaporation. The method provided by the invention resolves problems of a lot of sewage and difficult treatment, which puzzles a monoammonium phosphate production enterprise for a long time. The method has advantages of simple technology process, good sewage treating effect, small technology equipment and investment, low personnel labor intensity and high water utilization rate. The method can effectively save water resource, the water consumption of monoammonium phosphate product is reduced to 2.5-2.8t per ton product from 20t per ton product. The method implements closed cyclic utilization for production water of monoammonium phosphate, and zero discharge of sewage.

Owner:襄阳泽东化工集团股份有限公司

Metals/minerals recovery and waste treatment process

InactiveUS20050109702A1Great water dilution ratioEffective sedimentationWaste water treatment from quariesWater contaminantsSettling basinEnvironmental engineering

A metals / minerals recovery and waste treatment process comprising a main separation stage in which a metal / mineral-bearing ore is slurried with water and separated into an enriched fraction and an aqueous metal / mineral waste fraction, and a waste sedimentation stage in which the aqueous metal / mineral waste fraction is sedimented in one or more settling lagoons to provide a thickened sediment layer and supernatant; and the waste sedimentation stage comprises feeding the aqueous metal / mineral waste into a solids contact vessel or other flocculating chamber, wherein the aqueous metal / mineral waste is diluted with water containing one or more flocculant(s) at more than one concentration, one of which concentrations is at least 10 times higher than the other, within the SCV, flocculating the diluted aqueous waste, and sedimenting the diluted and flocculated aqueous waste to provide a liquid supernatant layer and a pumpable thickened sediment layer in a settling basin.

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

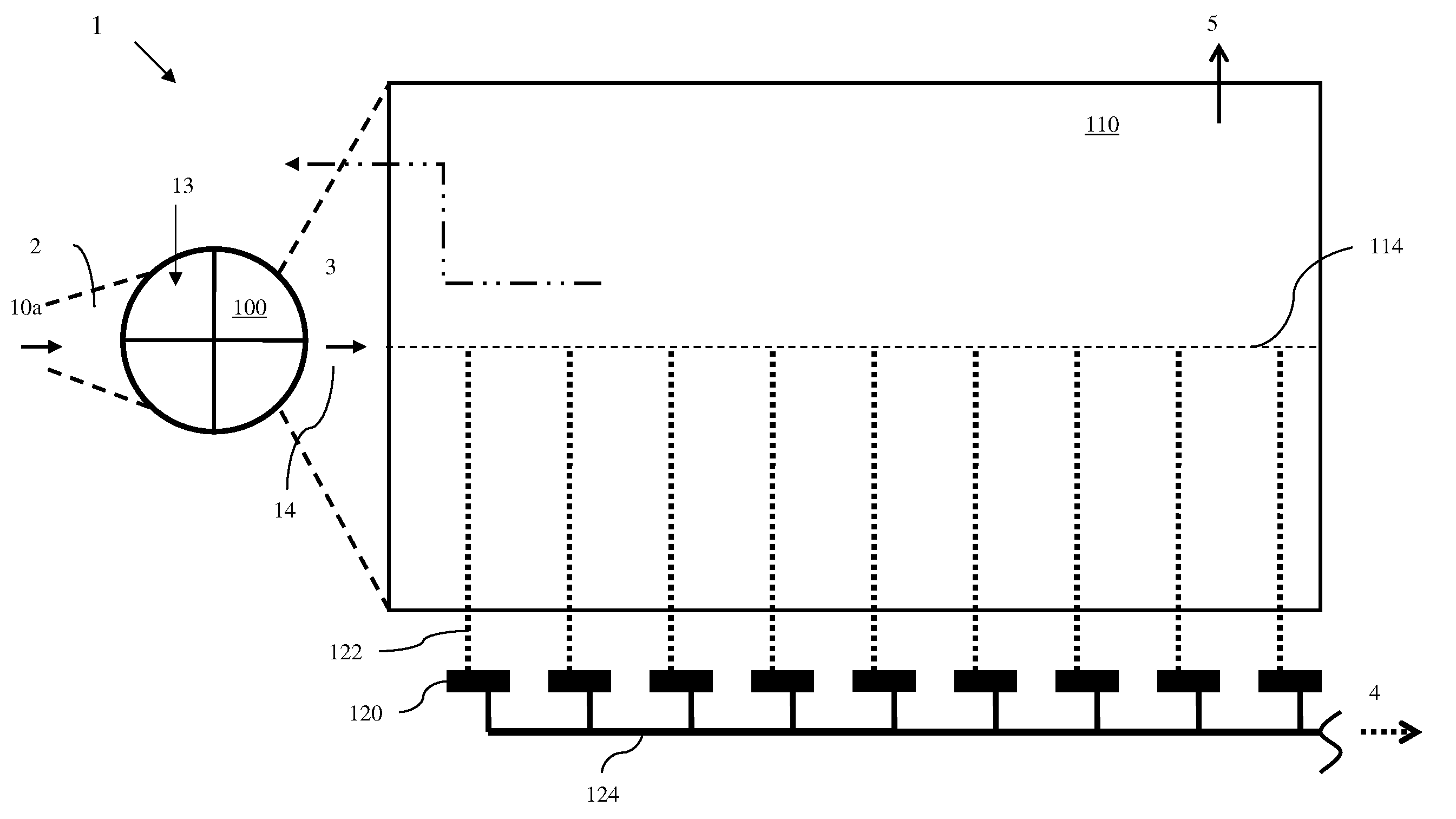

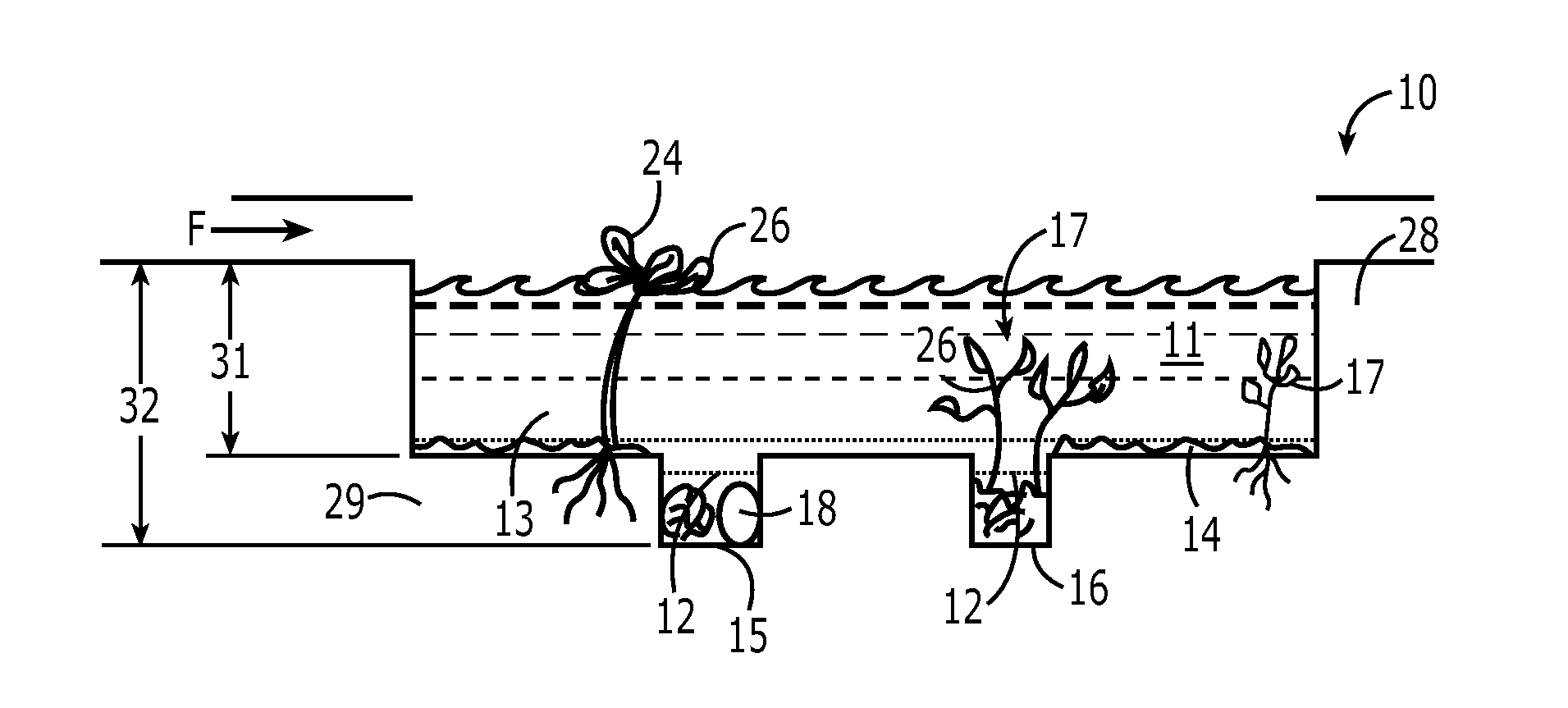

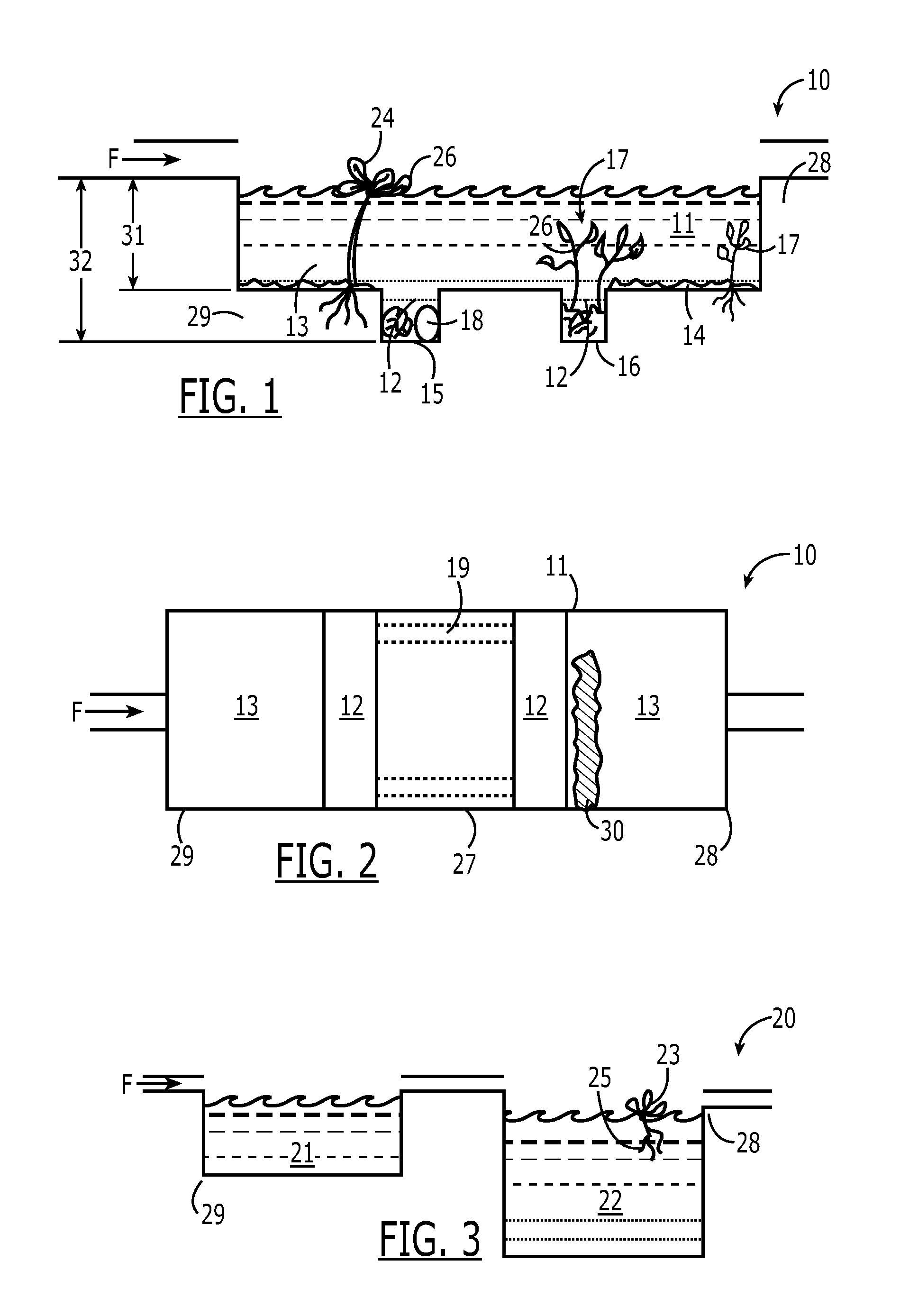

Surface water treatment using flocculation and associated methods

A method and system for removing pollutants from water are provided. The system includes at least one settling basin having shallow and deep areas. Coagulants can be added to bring pollutants down to the bottom surface of the basin. During dry periods, the deep areas retain a level of water therein, and the flocs that have settled on the bottom of the shallow areas will dry out, and can be tilled into the soil until re-flooding.

Owner:DEBUSK THOMAS A

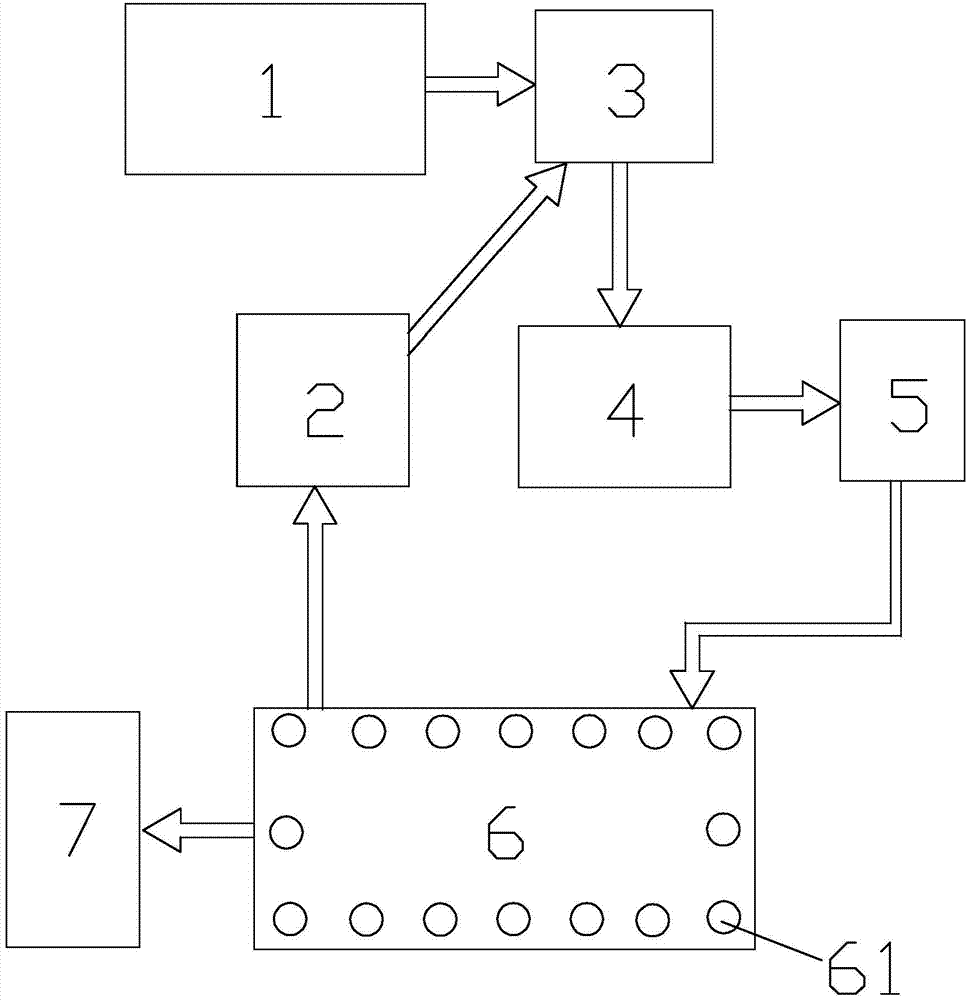

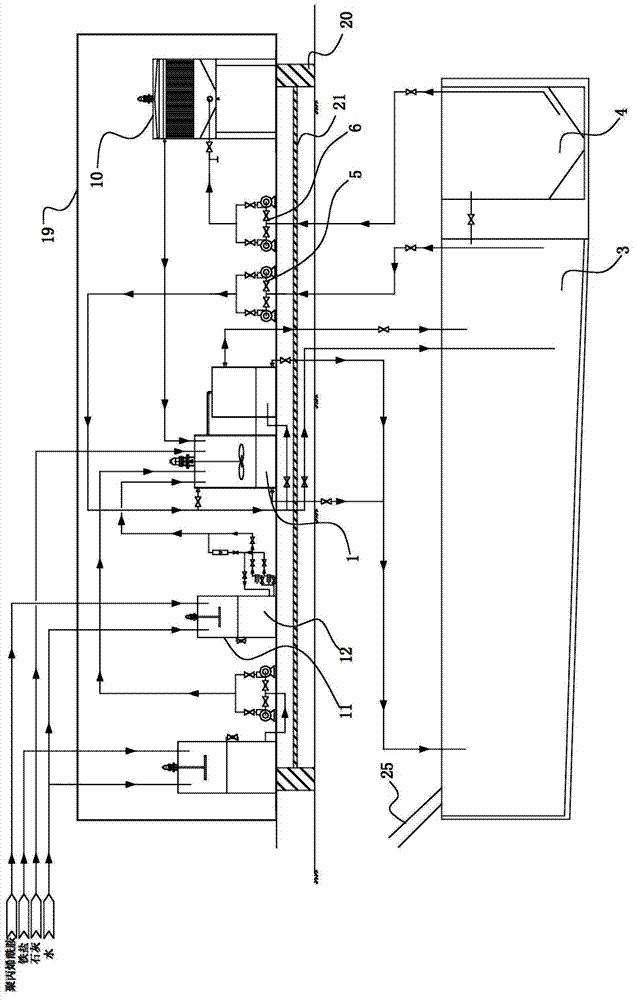

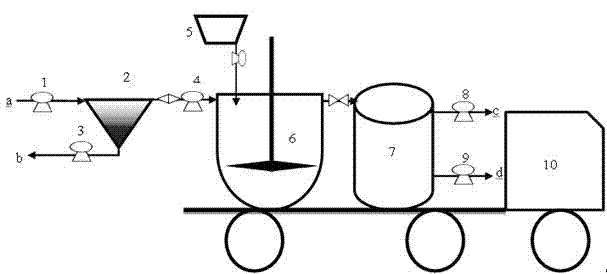

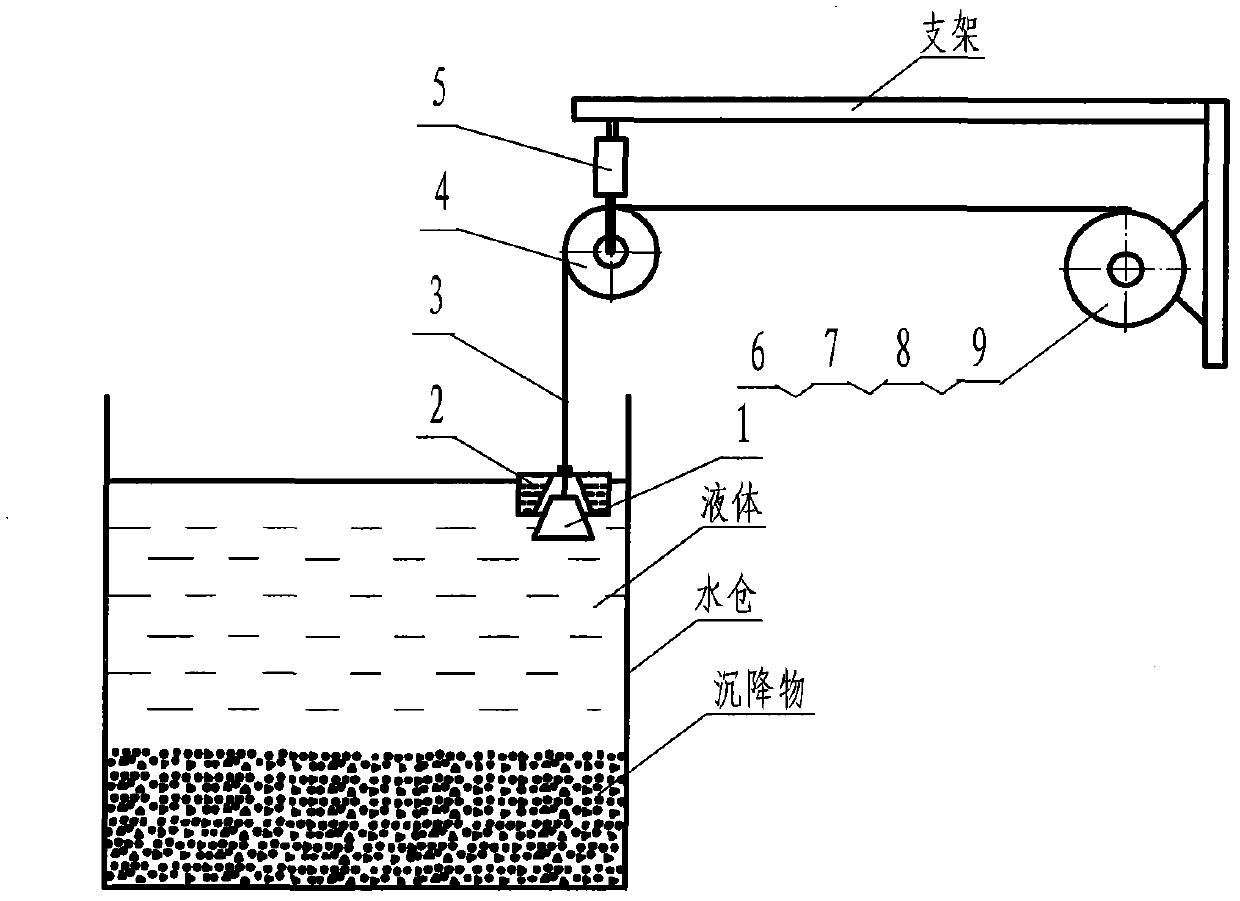

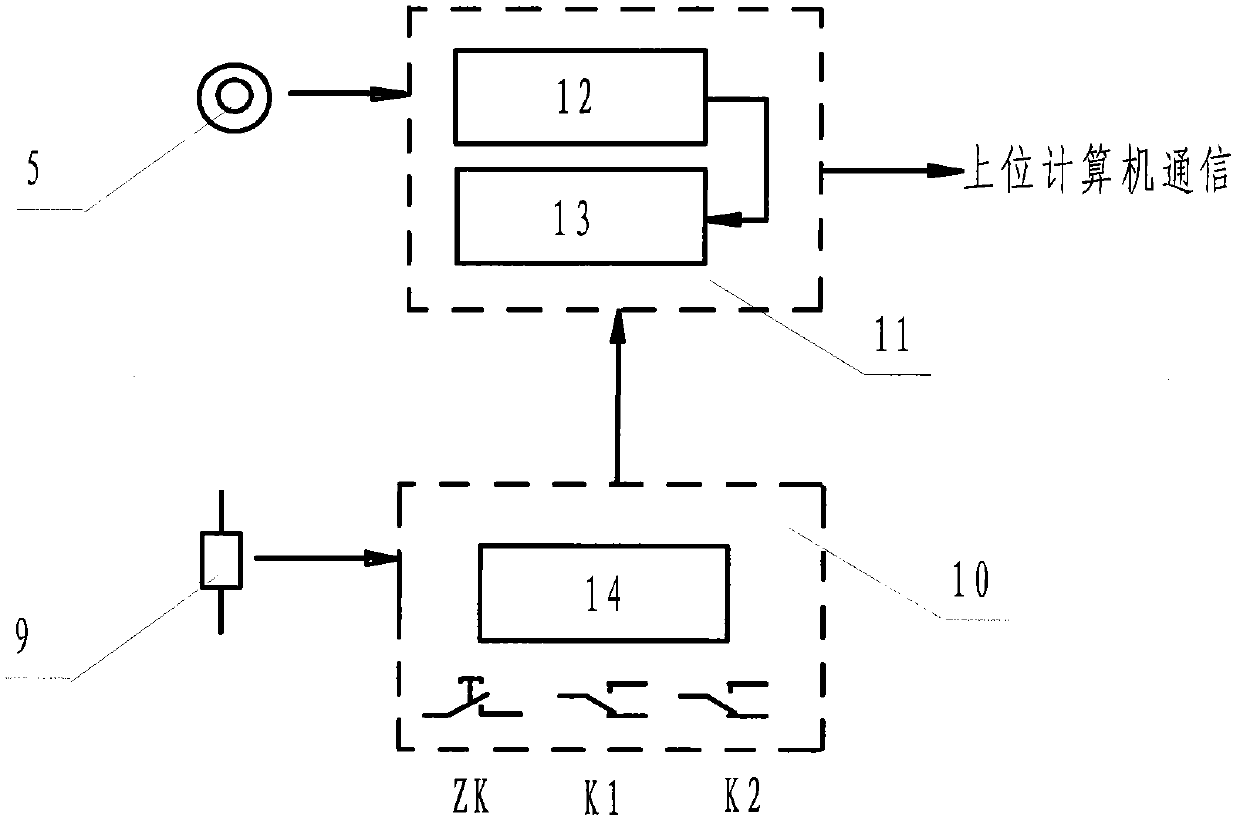

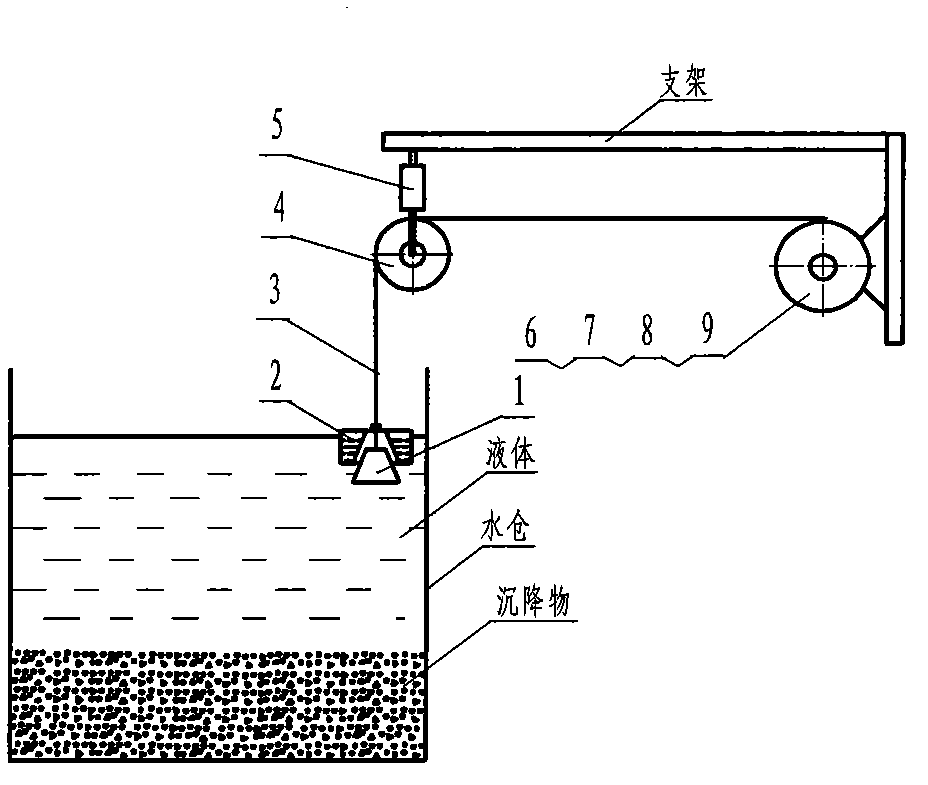

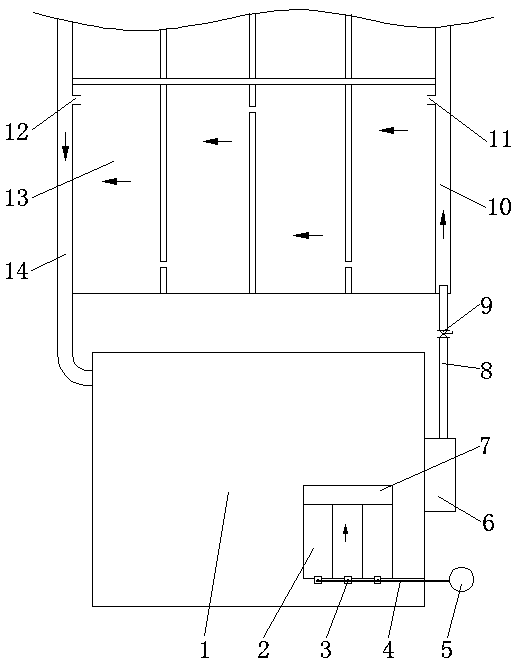

Integrated measuring apparatus of liquid level and material level

InactiveCN102589650AExtended service lifeLow failure rateLevel indicators by floatsLevel indicators by weight measurementMeasuring instrumentEngineering

The invention discloses an integrated measuring apparatus of a liquid level and a material level, which belongs to the technical field of measurement, wherein the integrated measuring apparatus is characterized in that: the integrated measuring apparatus has dual functions of measuring the liquid level and the material level at the same time. The measuring apparatus comprises a heavy hammer 1, a buoy 2, a steel wire rope 3, a pulley 4, a weighing sensor 5, a motor 6, a speed reducer 7, a wire rope roller 8, an encoding sensor 9, an intelligent weighing meter 10 and an intelligent water level and material level meter 11. The integrated measuring apparatus of the liquid level and the material level has the advantages of long service life, low fault rate and convenience in maintenance. The integrated measuring apparatus of the liquid level and the material level is suitable for use of the industries such as a large sewage treatment plant, a coal cleaning plant, coal mine and the like, used for measuring the liquid levels and the material levels of a settling basin and a water sump, and can replace two suits of traditional measuring instruments of the liquid level and the material level.

Owner:TAIYUAN UNIV OF TECH

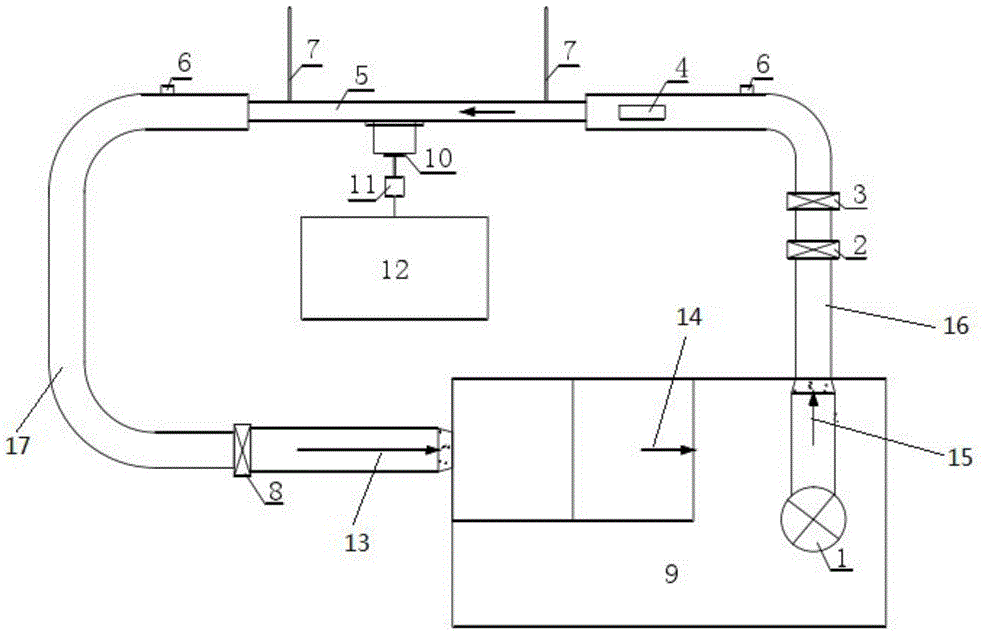

Undisturbed soil scouring test system

InactiveCN105021485APrevent disturbing the soil sampleImprove test accuracyInvestigating abrasion/wear resistanceInlet valveWater flow

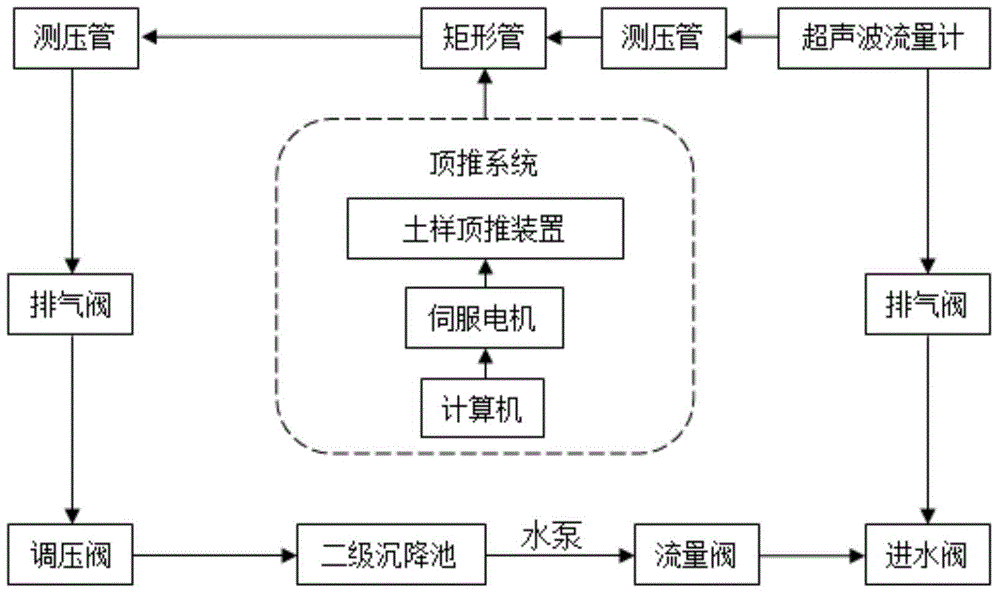

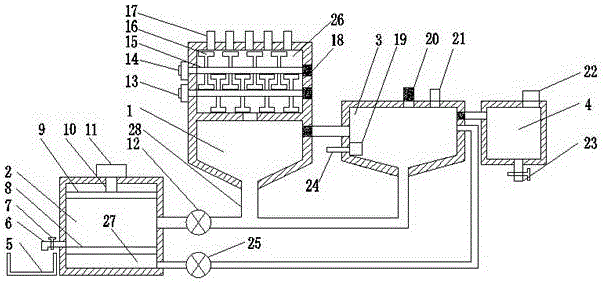

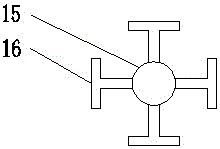

A disclosed undisturbed soil scouring test system comprises a water pump, a water inlet pipe, a flow valve, a water inlet valve, a rectangular pipe, a water outlet pipe, two piezometric pipes, a pushing system, a pressure-regulating valve and a secondary settling basin; the water inlet of the water inlet pipe is connected with the water pump, the water outlet of the water inlet pipe is connected with the water inlet of the rectangular pipe, the water outlet of the rectangular pipe is connected with the water inlet of the water outlet pipe, and the water outlet of the water outlet pipe is connected with the secondary settling basin; the flow valve is disposed at the water inlet end of the water inlet pipe, and the water inlet valve is disposed on the water inlet pipe and at the downstream of the flow valve; the pushing system is communicated with the bottom of the rectangular pipe; the two piezometric pipes are disposed on the rectangular pipe and respectively at two sides of the pushing system; and the pressure-regulating valve is disposed at the water outlet end of the water outlet pipe. The undisturbed soil scouring test system is capable of generating a high-speed water flow for scouring undisturbed soil, and is applicable to research on incipient velocity of sediment in different particle sizes from sand grain to clay particle and undisturbed soil scouring rate tests.

Owner:HOHAI UNIV

Sewage purification treatment device of municipal sewage pipeline net

InactiveCN106746187AImprove processing efficiencyIncrease profitSludge treatmentSpecific water treatment objectivesSettling basinMunicipal sewage

The invention discloses a sewage purification treatment device of a municipal sewage pipeline net. The sewage purification treatment device comprises a settling basin and a crushing tank, wherein blow down branches are arranged at the top of the crushing tank; a first motor and a second motor are arranged on the left side wall of the crushing tank; rotating rods which penetrate through the crushing tank are arranged on the right sides of the first motor and the second motor; the rotating rods are both provided with crushing hammers; a sludge collecting tank is arranged at the bottom of the outlet of a sludge collecting tube; an air inlet tube is connected with the left side of an aerator; an air outlet tube is arranged at the top of a biodegradation tank; a first feeding hole is formed in the right side of the air outlet tube; the bottom of the biodegradation tank is connected with a sludge tube; a sewage pump is arranged on the right side of a sewage backflow tank; the sewage pump is communicated with the biodegradation tank; a sterilization tank is connected with the right side of the biodegradation tank through a connecting pipeline; a second feeding hole is formed in the top of the sterilization tank; a clean water tube is arranged at the bottom of the sterilization tank. The sewage purification treatment device is simple in structure, high in working efficiency, short in construction period and low in sewage treatment cost.

Owner:JIANGSU FUSHENG ENVIRONMENTAL PROTECTION GROUP

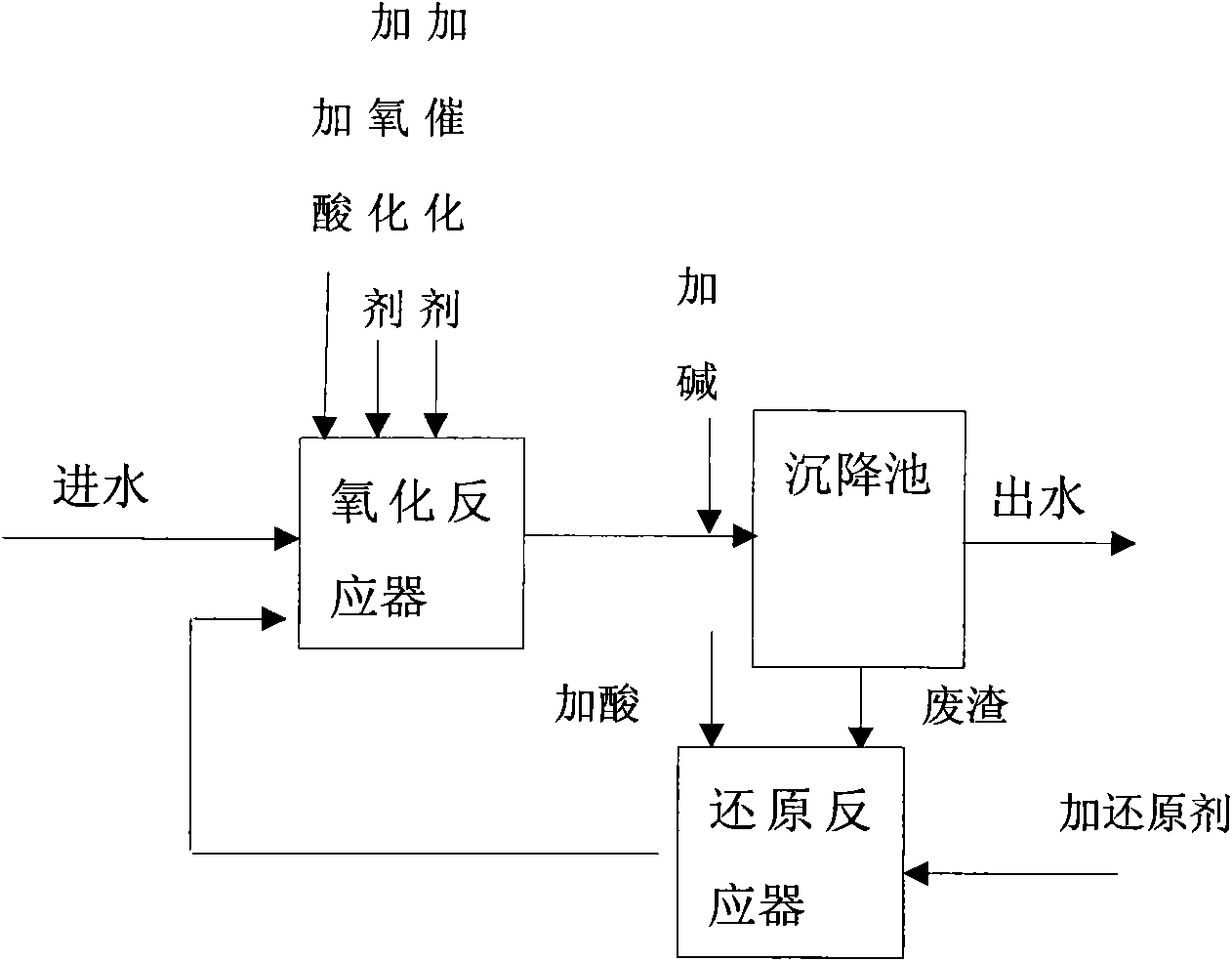

Catalytic oxidation method capable of recycling waste residues

ActiveCN101659484AReduce the amount of waste residueEmission reductionMultistage water/sewage treatmentWater/sewage treatment by neutralisationWastewaterCatalytic oxidation

The invention discloses a catalytic oxidation method capable of recycling waste residues, which comprises (1) delivering wastewater to be treated into an oxidation reactor, adding an acid to adjust the pH value of the wastewater and adding an oxidizer and ferrous iron ions (Fe<2+>) serving as a catalyst to perform catalytic oxidation reaction; (2) adding an alkali into the wastewater obtained after the completion of the reaction to adjust the pH value of the wastewater, and delivering the wastewater to a settling basin for flocculating setting; (3) after the completion of the settling, discharging supernatant, delivering the settled waste residues into a reduction reactor, adding an acid into the waste residues to adjust the pH value of the waste residues, dissolving the waste residues toform solution containing ferric ion (Fe<3+>), and adding a reducer to reduce the Fe<3+> into Fe<2+> at the same time; and (4) circulating the reduced solution containing the Fe<2+> to an oxidation reactor to use the solution as a catalyst to perform the catalytic oxidation reaction. Compared with the conventional catalytic oxidation, the method reduces the discharge of waste iron residues, reducesthe waste iron residue treatment cost, protects environment, reduces the usage amount of the catalyst in a catalytic oxidation process and saves resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

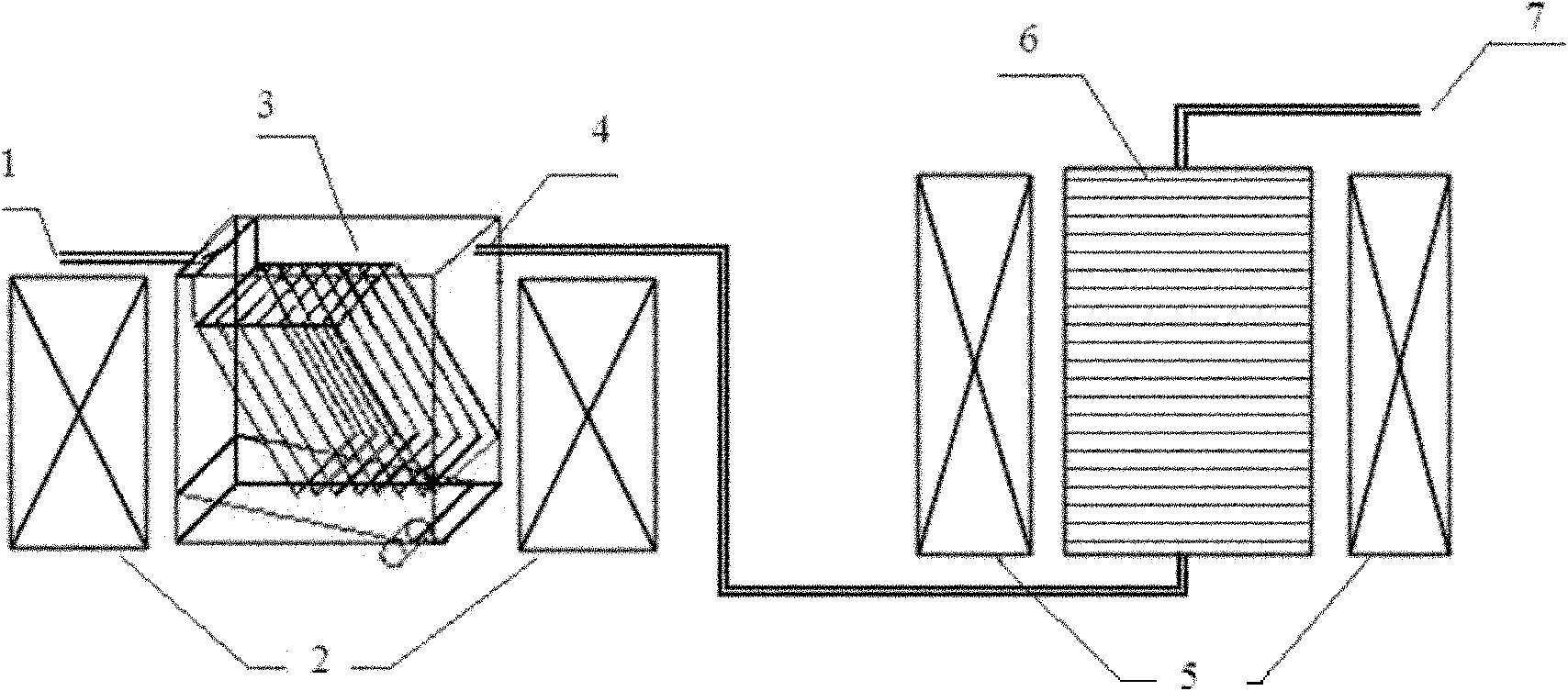

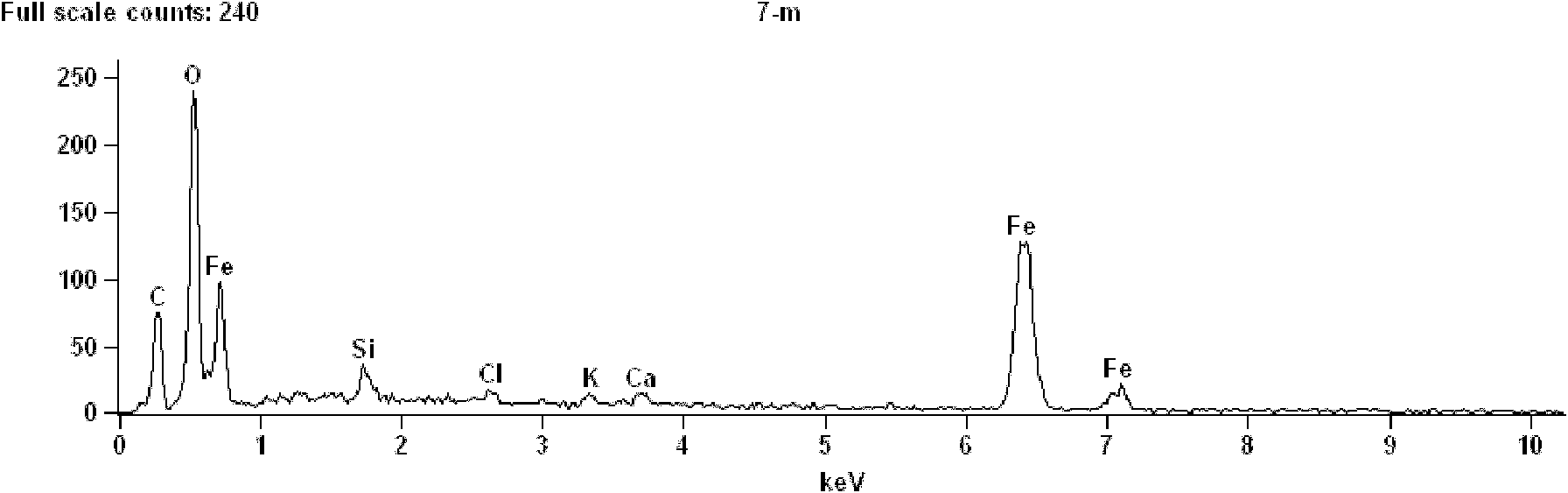

Converter turbid circulating water treatment method utilizing superconductive high-gradient magnetic field

InactiveCN101935129AGood removal effectEfficient removalWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSuspended particlesParticulates

The invention relates to a converter turbid circulating water treatment method utilizing a superconductive high-gradient magnetic field, belonging to the fields of environmental protection and treatment of industrial waste water difficult to treat. The method is characterized in that under a superconductive high-gradient magnetic field, converter turbid circulating water is treated by using an inclined board settling basin and a high-gradient treater; the strong magnetization and strong adsorption effects of the superconductive high-gradient magnetic field can be used for adsorbing strongly magnetic ferric oxide substances in waste water and also can be used for adsorbing weakly magnetic substances and even nonmagnetic substances, such as calcium oxide, silicon dioxide, magnesium oxide, and the like; the suspended particle density of the treated waste water is reduced to 5mg / L from 1,216mg / L, the turbidity is reduced to 22.25 NTU from 2873.5 NTU, and the two indexes both reach the national emission standard; meanwhile, the superconductive high-gradient magnetic field can be used for adsorbing small particulate substances with the particle diameters below 100nm; and the average particle diameter of particles in the waste water is reduced to 1.272 mu m from 6.431 mu m. The invention has the advantages of low running cost, easy realization of automatic control, energy saving and consumption reduction.

Owner:UNIV OF SCI & TECH BEIJING +2

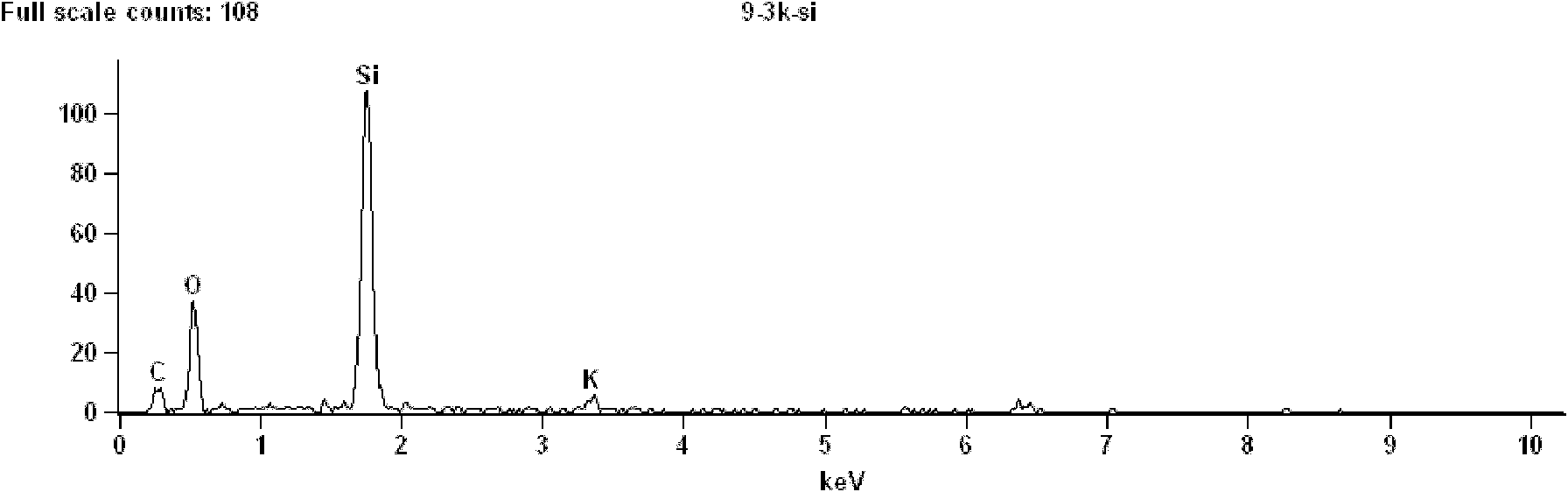

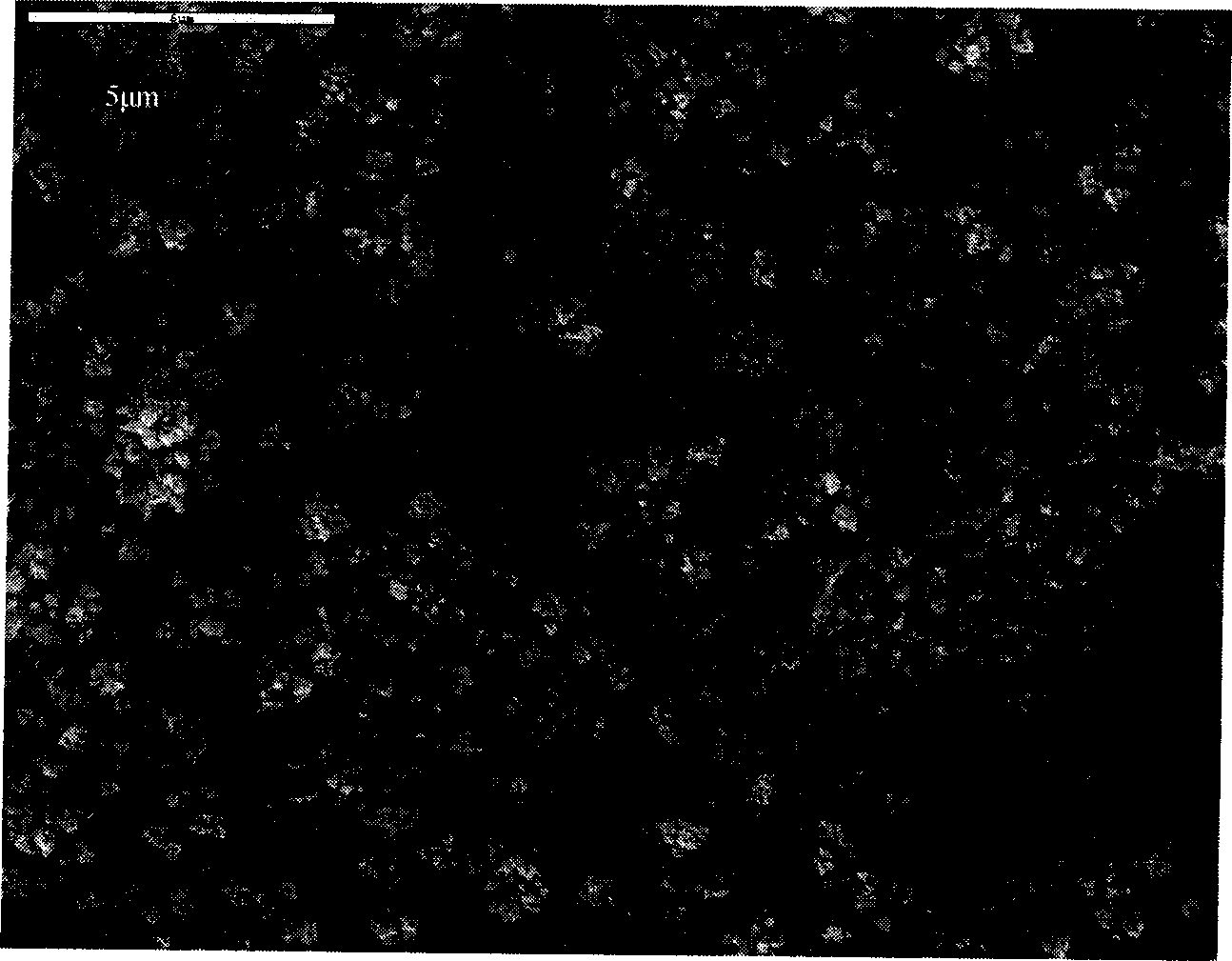

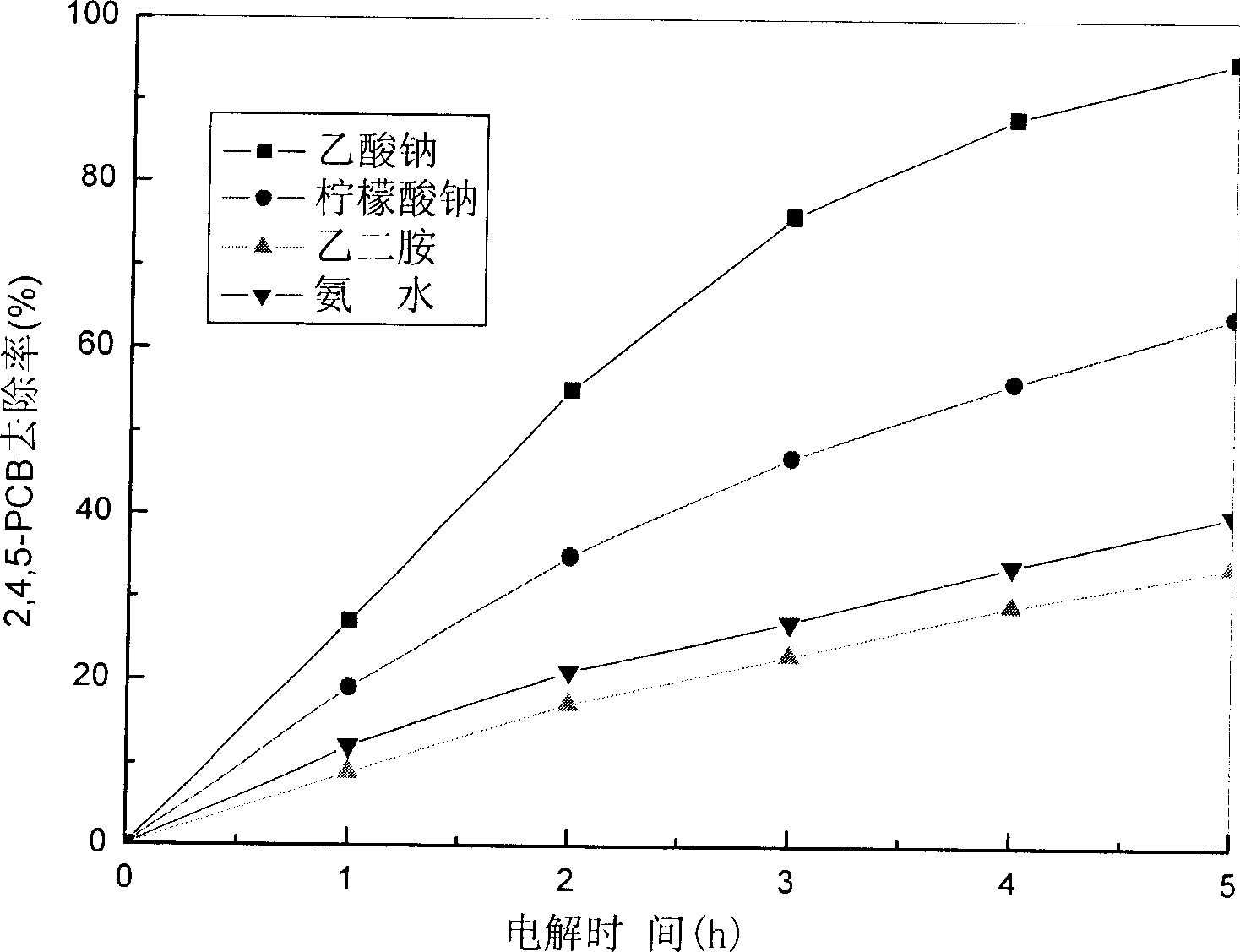

Method for preparing palladium carried metal-based electrode used for electro-catalysis of chlore-aromatics for dechlorination

InactiveCN1831197AHigh catalytic activityImprove dechlorination effectElectrodesSodium acetateElectricity

The invention discloses a manufacture method for Pb load metal base electrode using for dechloridizing in chloroaryl hydrocarbons electrocatalysis. It includes electric sediment liquid mixing process and sediment process. Pouring palladium chloride and sodium acetate into pure water to make mixing sediment liquid of 5mM palladium solution and 50mM-100mM sodium acetate solution, taking heating super sound dissolving to make the color turning to nigger-brown from yellow, adding the liquid and metal base into tri-electrode system single room electric settling basin to take heating and whisking, taking low current sediment for several times and each changing the surface, the electrode loading Pb would be formed and could be taken out to use. The invention has simple technology process, and high controllability.

Owner:TSINGHUA UNIV

Pond engineering culture effluent and ricefield recycling system

PendingCN109430147AAchieve symbiosisPurify waterExcrement fertilisersBioloigcal waste fertilisersWater qualityEngineering

The invention relates to the technical field of integrated utilization of agricultural ecological aquaculture, in particular to a pond engineering culture effluent and ricefield recycling system, comprising a fish pond, a ricefield and an inflow ditch and outflow ditch arranged around the ricefield. The pond engineering culture effluent and ricefield recycling system is characterized n that one end or two sides or the periphery of the fishpond is provided with the ricefield, the inflow ditch and the outflow ditch are arranged on the two sides of the ricefield, the inflow ditch and the outflowditch are communicated with the ricefield through an inflow port and an outflow port; the outflow ditch is communicated with the fish pond; a cyclic running water culture channel is arranged in the fish pond; the outflow end of the cyclic running water culture channel i is provided with a settling basin; a fermenting pond is arranged the side of the fish pond close to the settling basin, the settling basin is communicated with the fermenting pond through a water pump, a drain pipe is arranged between the fermenting pond and the inflow ditch, and the drain pipe is provided with a gate. The pondengineering culture effluent and ricefield recycling system helps effectively purify pond water, fish waste and residual feed to provide high-quality organic fertilizers for the ricefield, and a newscheme is provided for the improvement of western saline-alkaline soil.

Owner:YINCHUAN KEHAI BIOTECH CO LTD

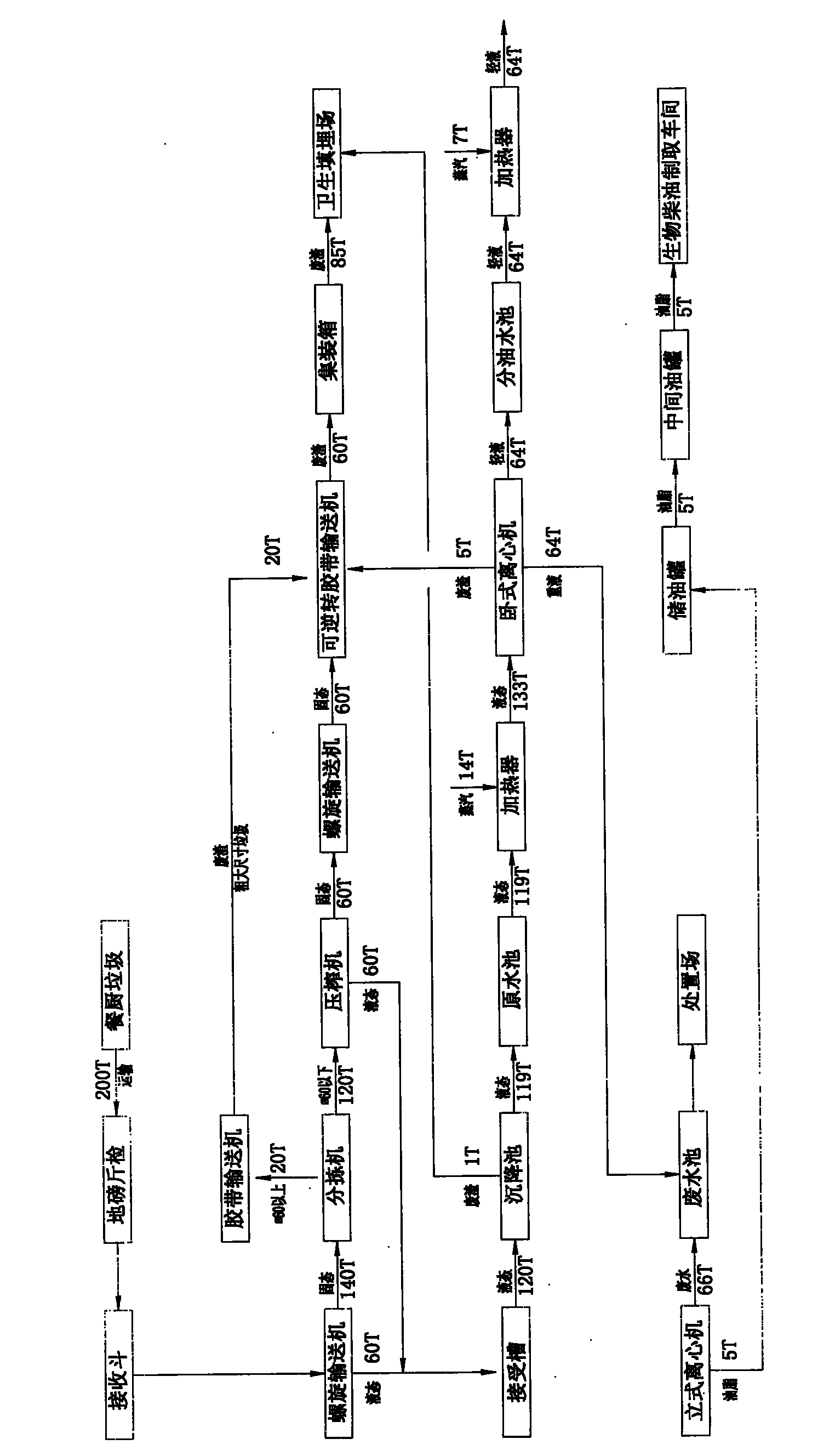

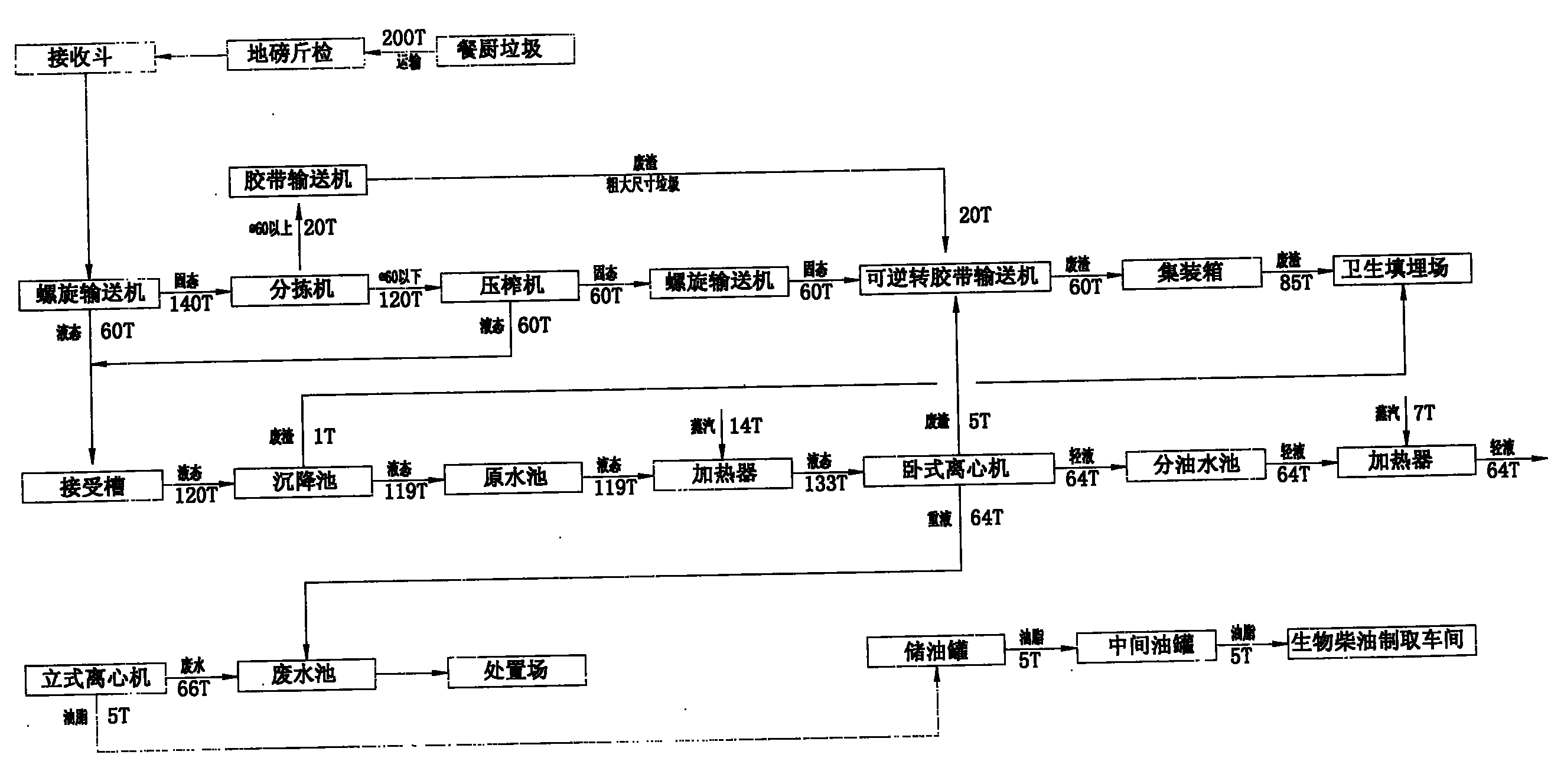

Emergency treatment method for kitchen waste

InactiveCN101954369AEasy to handleGood emergency responseFatty oils/acids recovery from wasteSolid waste disposalOil and greaseSettling basin

The invention discloses an emergency treatment method for kitchen waste, which comprises the following steps of: accommodating the collected kitchen waste by using a receiving bucket, and dividing into two paths by using a first conveyor; sequentially conveying one path of solid materials to a sorting machine, a presser and a second conveyor to reach a container, and conveying to a landfill site for landfill; and collecting the other path of liquid materials by using a receiving groove, sequentially conveying to a first heater for heating through a sedimentation tank and an original basin, and conveying into a three-phase horizontal centrifuge, conveying the separated light liquid to an oil-separating basin, heating by using a second heater, and conveying to a vertical centrifuge for oil-water separation, conveying waste water to a waste water basin, and conveying oil to an oil storage tank. The emergency treatment method can perform emergency and rapid treatment on the kitchen waste through a simple and short treatment process, avoids the influence on municipal waste treatment when a normal treatment device is under the repair or maintenance condition, and has a rational and practical process.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

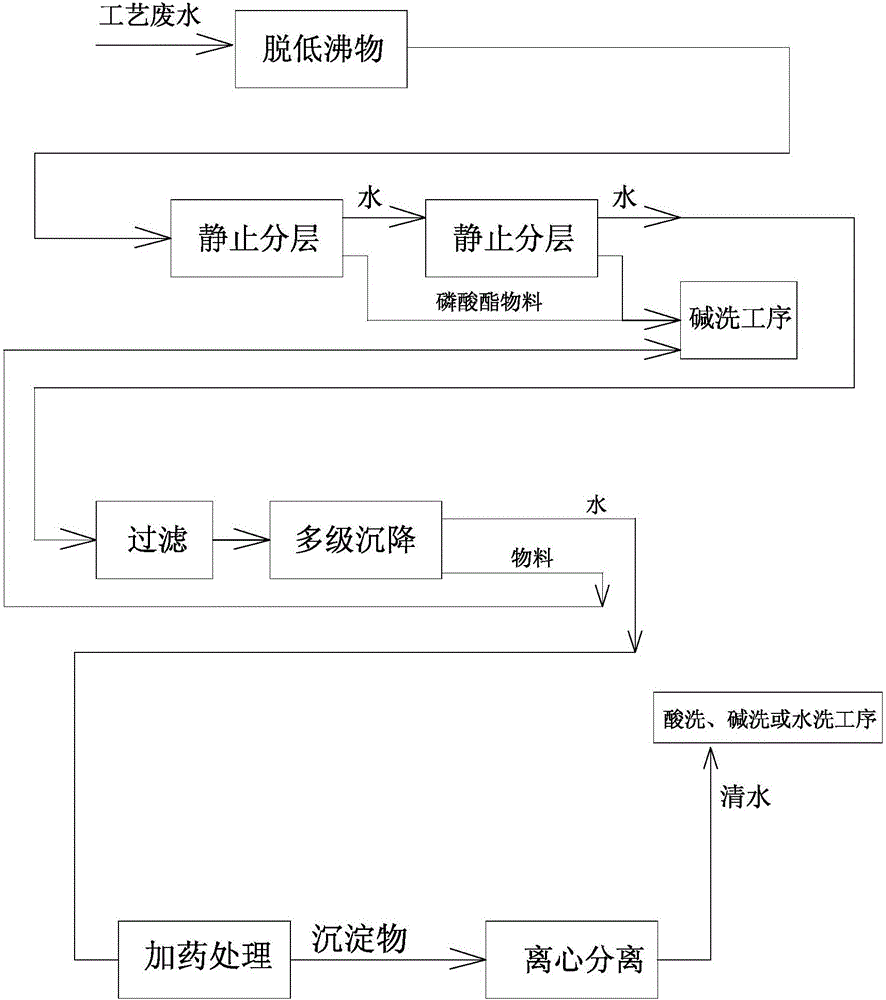

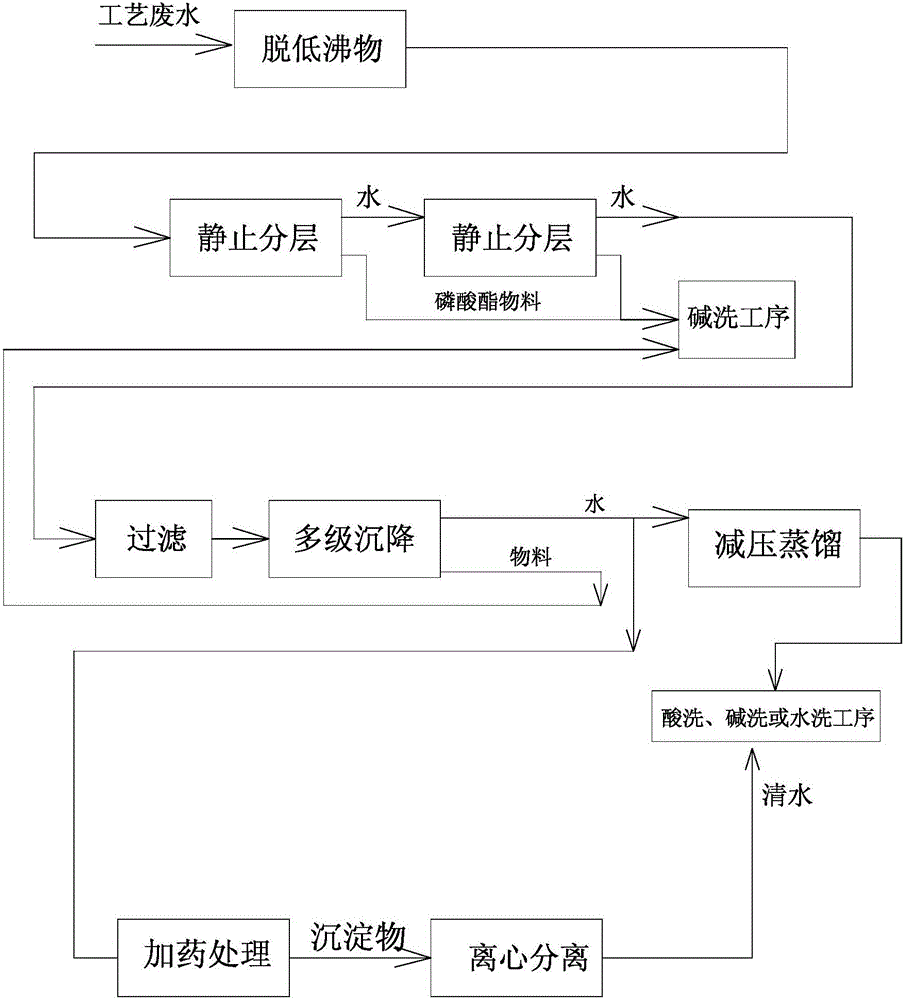

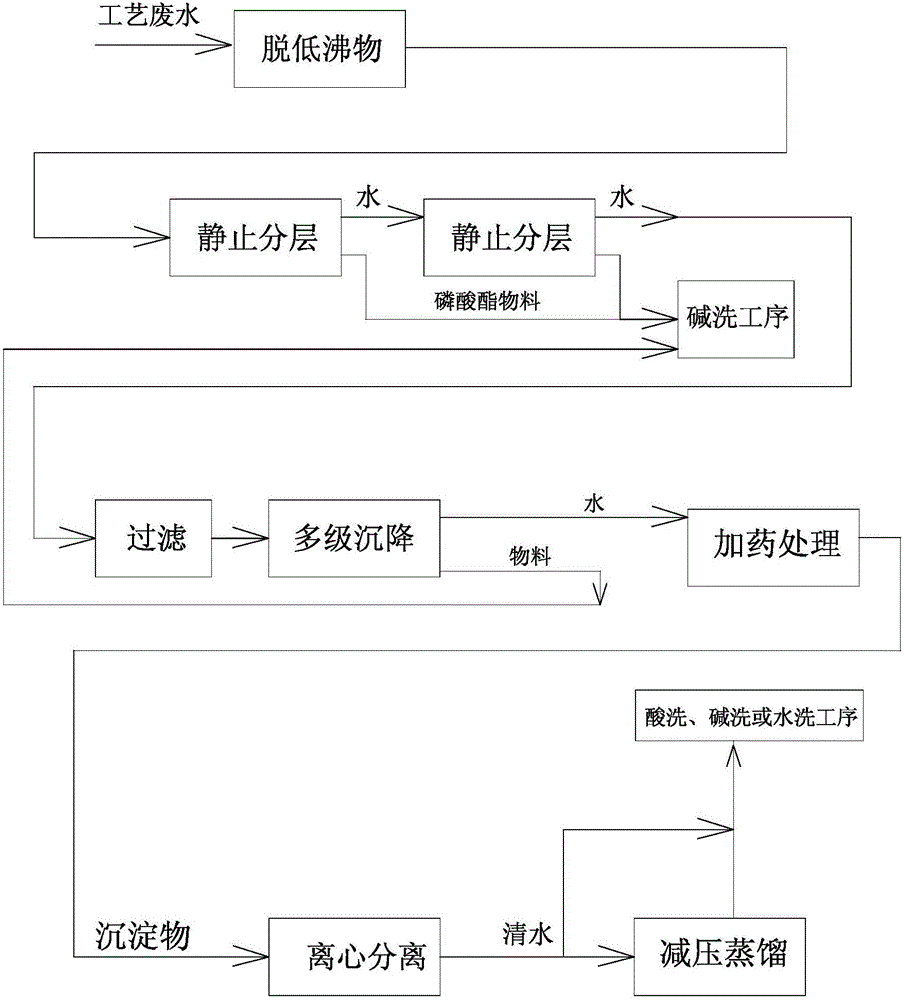

Method for treating wastewater of phosphate fire retardant production process

ActiveCN106336059AReduce contentHigh yieldWater/sewage treatment by centrifugal separationTreatment involving filtrationHigh concentrationEnvironmental resistance

The invention discloses a method for treating wastewater of a phosphate fire retardant production process. The wastewater of the phosphate fire retardant production process is high-concentration salt-containing organic phosphorus wastewater, wastewater treatment is always a difficult problem in the industry, and at present there is no feasible method. The method includes the following steps that 1, process wastewater produced in the phosphate fire retardant preparation process is subjected to low-boiling-point substance removal treatment; 2, the wastewater is fed into a wastewater layering box for static layering; 3, the wastewater is fed into a multistage sedimentation pool for sedimentation, the lower-layer material of the multistage sedimentation pool is recycled, and the upper-portion wastewater is subjected to subsequent treatment; 4, dosing treatment is performed, and organic phosphorus and inorganic phosphorus in the wastewater precipitate in the form of solid; 5, centrifugal separation or filtering is performed. The various impurities in the wastewater of the phosphate fire retardant production process are effectively removed through low-boiling-point substance removal, static layering, multistage sedimentation and dosing treatment, process wastewater reuse is achieved, and the method is economic and environmentally friendly.

Owner:福建新安科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com