Converter turbid circulating water treatment method utilizing superconductive high-gradient magnetic field

A high-gradient magnetic field and treatment method technology, applied in the fields of magnetic field/electric field water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of affecting the normal operation of production, complicated equipment, and scaling Problems such as clogging, to achieve efficient and rapid removal of suspended solids, simple equipment, and improved chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described below with reference to the accompanying drawings.

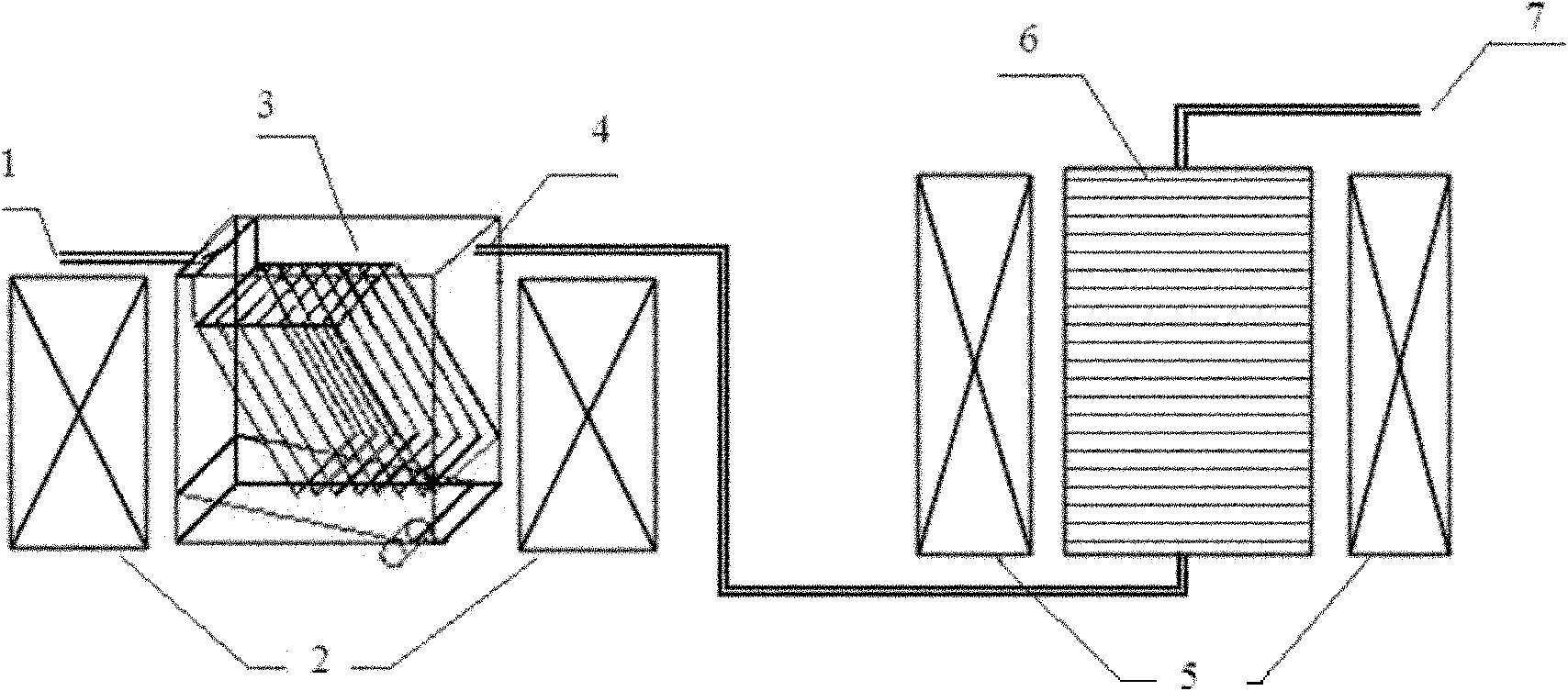

[0030] figure 1It is a schematic diagram of the system for treating the turbid ring water of the converter in the present invention. First, the turbid ring water of the converter flows into the inclined plate sedimentation tank 3 in the high-intensity magnetic field from the first water inlet 1 on the upper part of the inclined plate sedimentation tank. The waste water flow rate is 50L / min. The first superconducting magnet 2 generates a high-intensity magnetic field with a central field strength of 3T. Under the action of a high-intensity magnetic field of 3T, the large ferromagnetic substances and suspended particles in the wastewater are adsorbed and precipitated in the inclined plate sedimentation tank. Since the sedimentation processes between the inclined plates do not interfere with each other, it is equivalent to many small sedimentation tanks. Therefore, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com