Well drilling wastewater flocculation precipitation treatment device and wastewater treating method

A technology for drilling wastewater and sedimentation treatment, applied in flocculation/sedimentation water/sewage treatment, mining wastewater treatment, water/sewage multi-stage treatment, etc. Achieve the effect of reducing land occupation area, improving water purification efficiency and reducing land cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

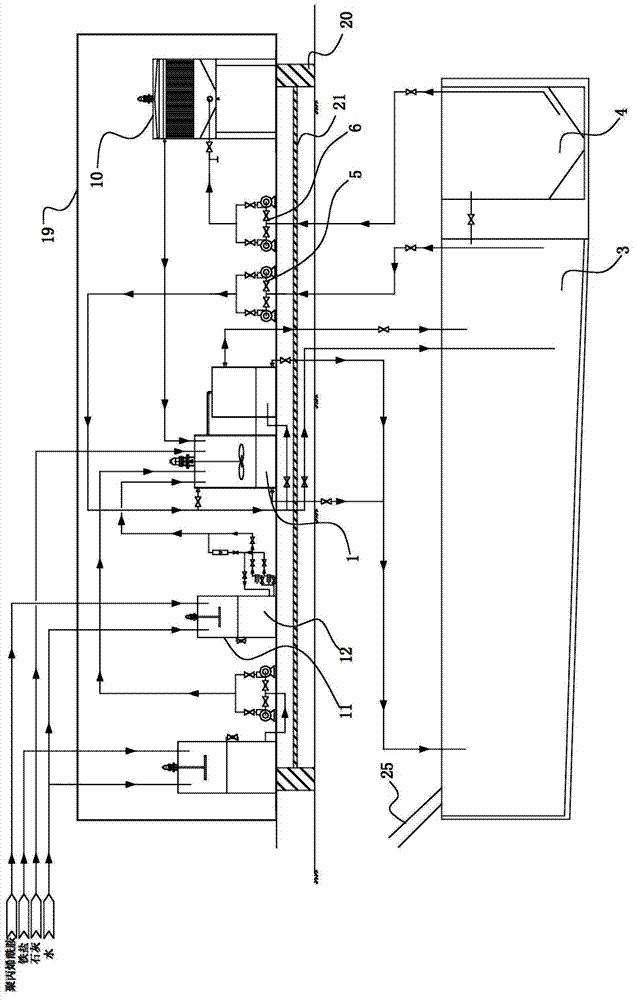

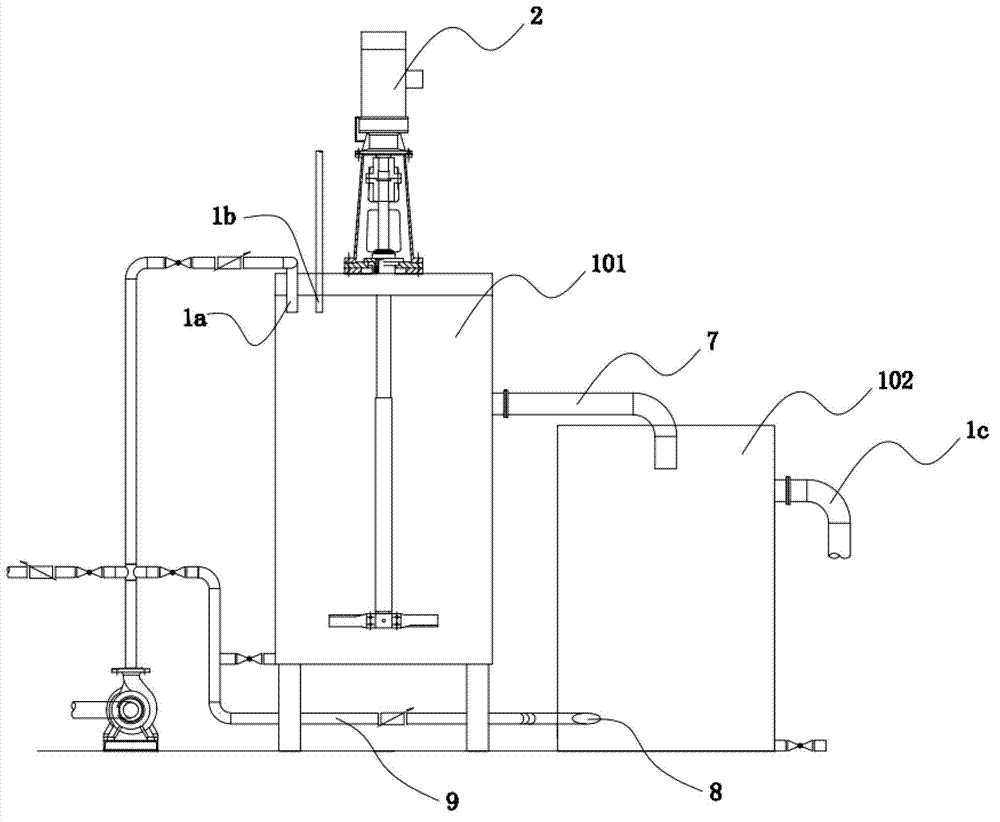

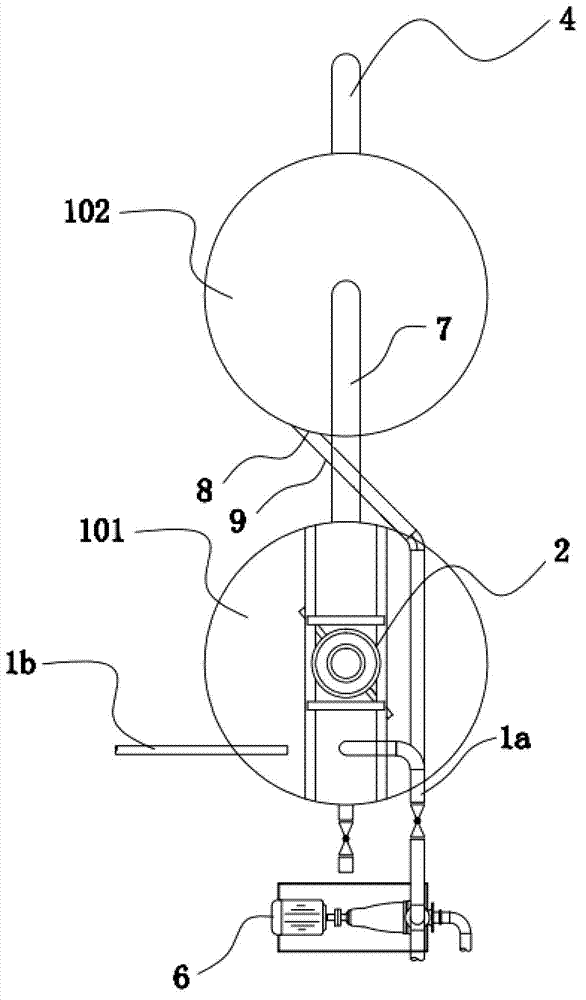

[0046] Such as Figure 1 to Figure 6 As shown, the drilling wastewater flocculation and sedimentation treatment device in this embodiment is provided with a flocculation reaction tank 1 with a stirring device 2, and a flocculation settlement tank 3 and an intermediate tank 4 arranged at the well site, and the flocculation reaction tank 1 is provided with a water supply port connected to the outside 1a, dosing port 1b and drain port 1c, a communication valve is arranged between the flocculation sedimentation tank and the intermediate tank 4, and the two ends of the communication valve connect the upper water body of the flocculation sedimentation tank with the intermediate tank 4, when the liquid in the flocculation sedimentation tank After the position is higher and the connecting valve is opened, the liquid in the flocculation sedimentation tank flows into the middle tank 4 . A first water pump 5 is arranged between the flocculation settling tank 3 and the flocculation reacti...

Embodiment 2

[0049] Such as Figure 1 to Figure 6 As shown, the flocculation reaction tank 1 in this embodiment includes a first tank body 101 and a second tank body 102, the water supply port 1a is arranged on the top of the first tank body 101, and the stirring device 2 is arranged on the first tank body 101, between the first tank body 101 and the second tank body 102 is provided with a through-pipe 7, and one end of the through-pipe 7 communicates with the inside of the first tank body 101 from the side of the first tank body 101 , the other end of the through pipe 7 is connected to the inside of the second tank body 102 from the top of the second tank body 102, the drain port 1c is arranged on the side of the second tank body 102, and the second tank body 102 A secondary reaction water inlet 8 is arranged on the top, and the secondary reaction water inlet 8 is arranged on the side of the second tank body 102 and connected to the inside of the second tank body 102 along the tangential ...

Embodiment 3

[0062] Such as Figure 1 to Figure 6 As shown, the flocculation and sedimentation tank 3 in the drilling wastewater flocculation and sedimentation treatment device of this embodiment includes an adjacent debris pool 22 and a turbid water pool 23, and the side of the debris pool 22 adjacent to the turbid water pool 23 is provided with three Connecting port 24, in other embodiments, the quantity of communicating port 24 also can be one, two or several, and described debris pool 22 is provided with water inlet ramp 25 away from the side of turbid water pool 23, described The bottom surface of the debris pool 22 slopes downward along the direction from the water inlet ramp 25 to the connecting port 24 , the bottom of the turbid water pool 23 is conical, and the water inlet end of the first water pump 5 is connected to the inside of the turbid water pool 23 . After the drilling waste water is introduced into the cuttings pool 22, the silt with a relatively large proportion will set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com