Coal gasification ash water treatment method

A treatment method and technology of coal gasification, which are applied in the fields of gaseous effluent wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The problem of high residual carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

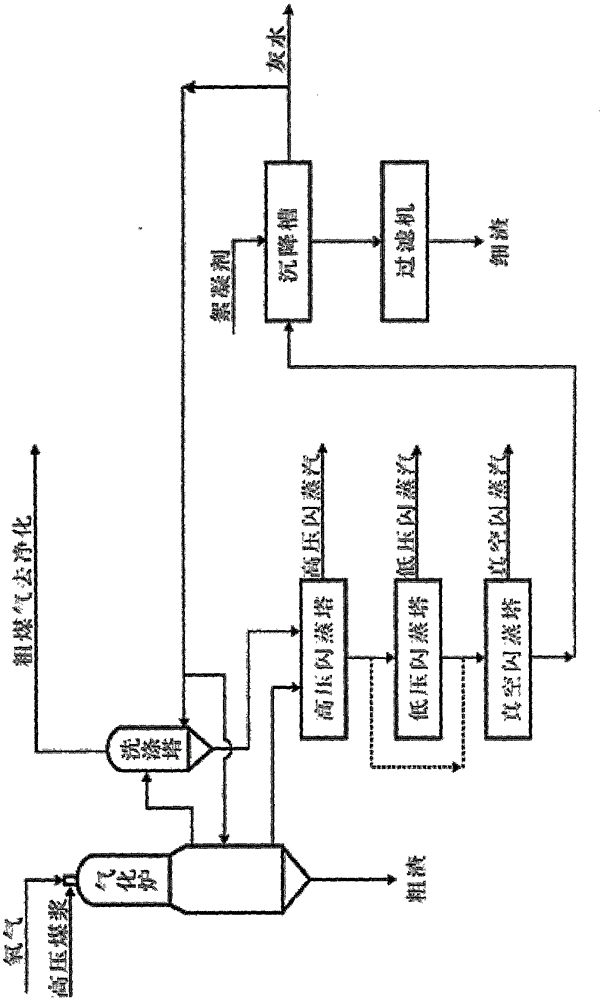

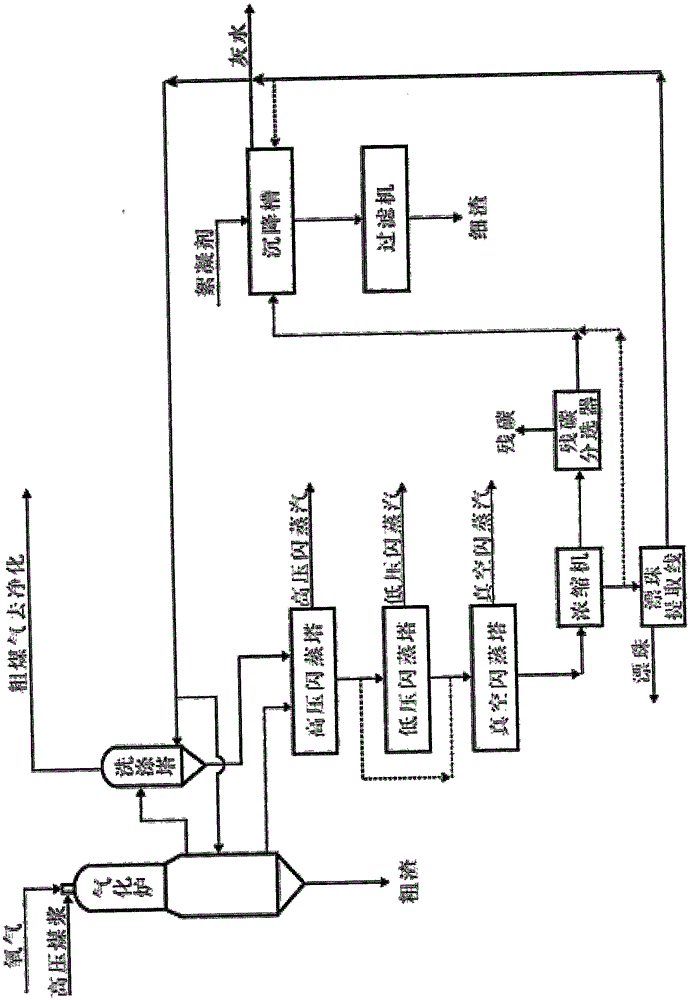

[0033] figure 2 A process flow chart of the treatment method of a kind of coal gasification ash water of the present invention is provided, and it comprises the following steps

[0034] 1) Flash concentration

[0035] The black water discharged from the gasification furnace and scrubber is concentrated by 2-stage or 3-stage flash evaporation to recover heat and separate acid gas;

[0036] 2) Concentration and separation of black water

[0037] The black water after flash evaporation enters the concentrator. The concentrator has two functions, one is to concentrate black water to facilitate flotation; the other is to separate floating beads;

[0038] In the concentrator, the floating beads float up, and the other components sink because the density is greater than water, so that the black water is divided into two layers, the upper layer is the floating bead slurry, and the lower layer is the concentrated black water. Concentrated black water enters the flotation machine f...

Embodiment 2

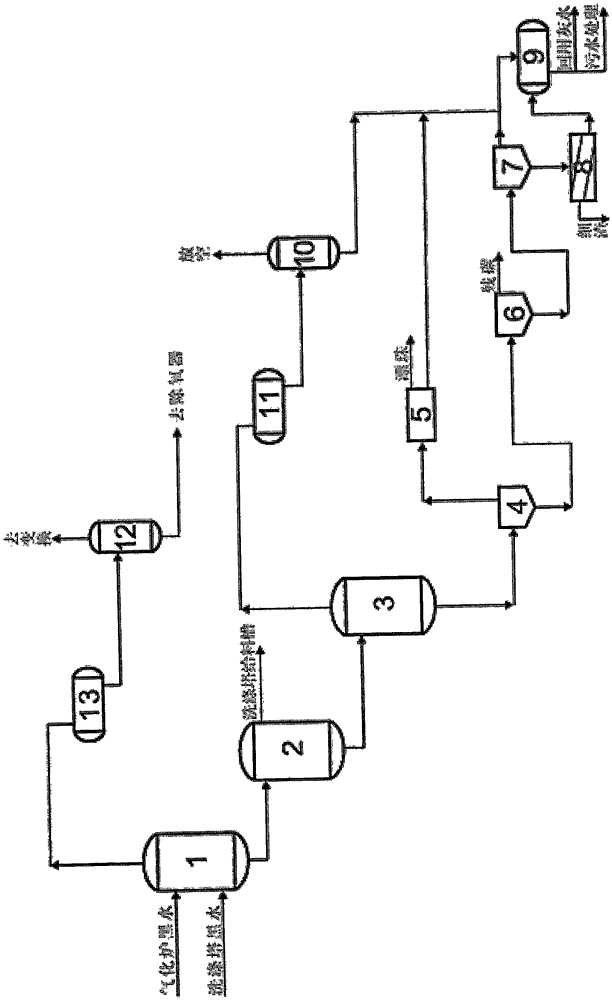

[0048] image 3 Provide the working principle diagram of the specific implementation device of the treatment method of coal gasification ash water of the present invention, comprise the steps:

[0049] 1) Flash concentration

[0050] The black water from the Texaco gasifier and washing tower passes through the high-pressure flash tower 1, the low-pressure flash tower 2 and the vacuum flash tower 3, and then enters the concentrator 4 after being flashed and decompressed to separate the acid gas.

[0051] 2) Concentrate and separate floating beads

[0052] Under the agitation of the concentrator 4, the floating beads float up and overflow, and then enter the floating bead extraction device 5 to extract the floating beads. The black water concentrate in the lower layer of the concentrator enters the flotation device 6 .

[0053] The clear liquid that has extracted floating pearl enters gray water tank 9.

[0054] 3) Flotation residual carbon

[0055] The mechanical stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com