Method for increasing yield of clean fuel oil

A fuel oil, clean technology, used in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the liquid products - coker gasoline, diesel and wax oil poor quality, liquid yield and light fuel oil products The problems of low yield, high investment and operating costs, to achieve the effect of increasing conversion rate, reducing gas and coke yield, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

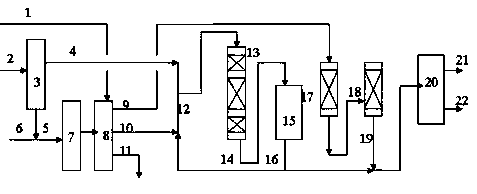

[0045] use figure 1 process. The weight ratio of C9 fraction and ethylene tar in each embodiment is 1.2:1.

Embodiment 1

[0047] Embodiments 1-3 Hydrofinishing treatment The liquid phase product is recycled back to the hydrofinishing reaction zone and mixed with the sum of the coker diesel fraction and the ethylene tar light fraction, and the circulation described in Examples 1 and 2 is recycled to the hydrotreating reaction The weight ratio of the weight of the hydrotreated liquid phase product of the reactor to the sum of the ethylene tar light fraction and coker diesel oil (ie the cycle weight ratio) is 2.0, and the cycle weight ratio in Example 3 is 3.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com