Preparation forming method of nano tungsten-copper alloy cooling fin

A technology of copper alloy and heat sink, which is applied in the field of preparation and forming of nano-tungsten copper alloy heat sink, can solve the problems of restricting the development of tungsten-copper alloy materials and difficult production of tungsten-copper alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

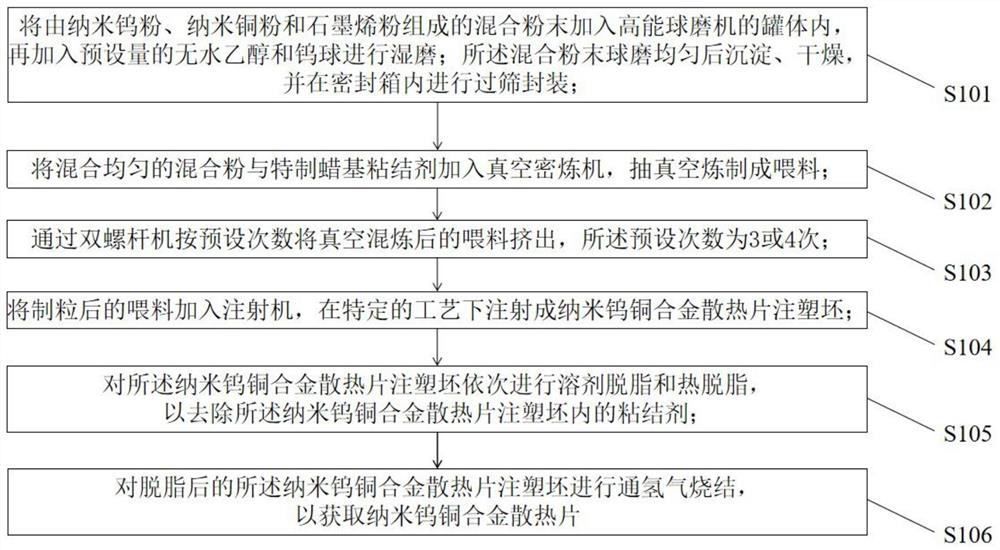

[0025] The embodiment of the invention discloses a method for preparing and forming a nano-tungsten-copper alloy heat sink, such as figure 1 shown, including:

[0026] Step S101, high-energy ball milling: Add the mixed powder composed of nano-tungsten powder, nano-copper powder and graphene powder into the tank of the high-energy ball mill, and then add a preset amount of absolute ethanol and tungsten balls for wet milling; after the mixed powder is ball-milled evenly Precipitation, drying, and sieving and packaging in a sealed box; in this embodiment, the weight ratio of absolute ethanol to metal mixed powder is (0.1-0.5):1, and the weight ratio of the grinding tungsten balls of the high-energy ball mill to the mixed powder is The ratio is (1-5): 1; the particle size of nano-tungsten powder is 10-100nm, the particle size of nano-copper powder is 100-500nm, the diameter of the grinding ball is 3-8mm, the speed of the high-energy ball mill is 100-500r / min, the milling time For...

Embodiment 2

[0035] The embodiment of the invention discloses a method for preparing and forming a nano-tungsten-copper alloy heat sink, such as figure 1 shown, including:

[0036] Step S101, high-energy ball milling: Add the mixed powder composed of nano-tungsten powder, nano-copper powder and graphene powder into the tank of the high-energy ball mill, and then add a preset amount of absolute ethanol and tungsten balls for wet milling; after the mixed powder is ball-milled evenly Precipitate, dry, and sieve and pack in the airtight box; In the present embodiment, wherein graphene powder accounts for the mass ratio of metal mixed powder is 1%, and the weight ratio of dehydrated alcohol and metal mixed powder is (0.1~0.5 ): 1. The weight ratio of grinding tungsten balls and mixed powder of high energy ball mill is (1~5):1. The particle size of the nano-tungsten powder is 10-100nm, the particle size of the nano-copper powder is 100-500nm, the diameter of the ball is 3-8mm, the speed of the ...

Embodiment 3

[0045] The embodiment of the invention discloses a method for preparing and forming a nano-tungsten-copper alloy heat sink, such as figure 1 shown, including:

[0046] Step S101, high-energy ball milling: Add the mixed powder composed of nano-tungsten powder, nano-copper powder and graphene powder into the tank of the high-energy ball mill, and then add a preset amount of absolute ethanol and tungsten balls for wet milling; after the mixed powder is ball-milled evenly Precipitate, dry, and sieve and package in a sealed box; in this embodiment, the mass ratio of graphene to metal mixed powder is 3%. The weight ratio of the absolute ethanol to the metal mixed powder is (0.1-0.5):1, and the weight ratio of the grinding balls of the high-energy ball mill to the metal powder is (1-5):1. The particle size of the nano-tungsten powder is 10-100nm, the particle size of the nano-copper powder is 100-500nm, the diameter of the ball is 3-8mm, the speed of the high-energy ball mill is 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com