Patents

Literature

277results about How to "Ensure mixing uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

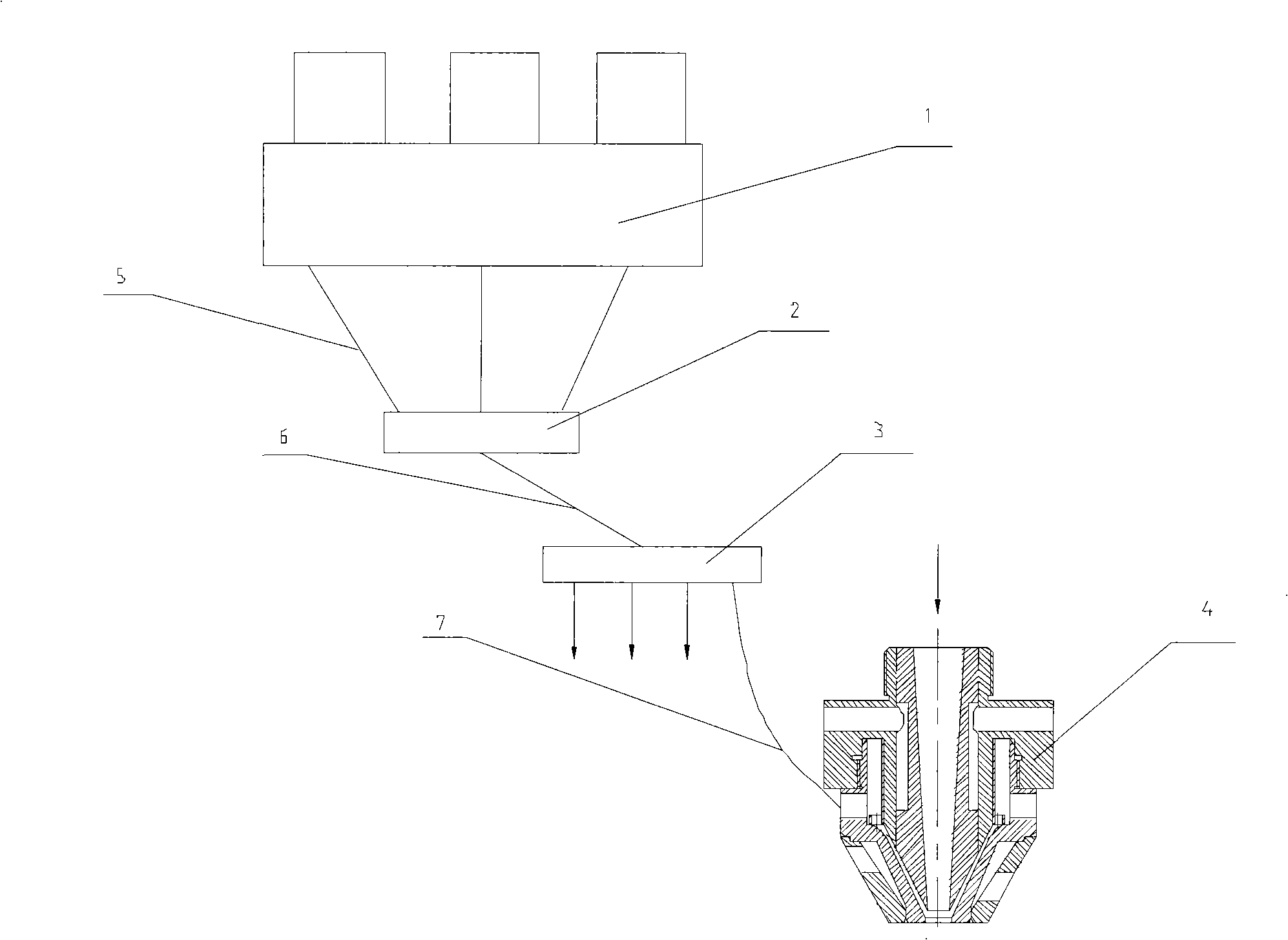

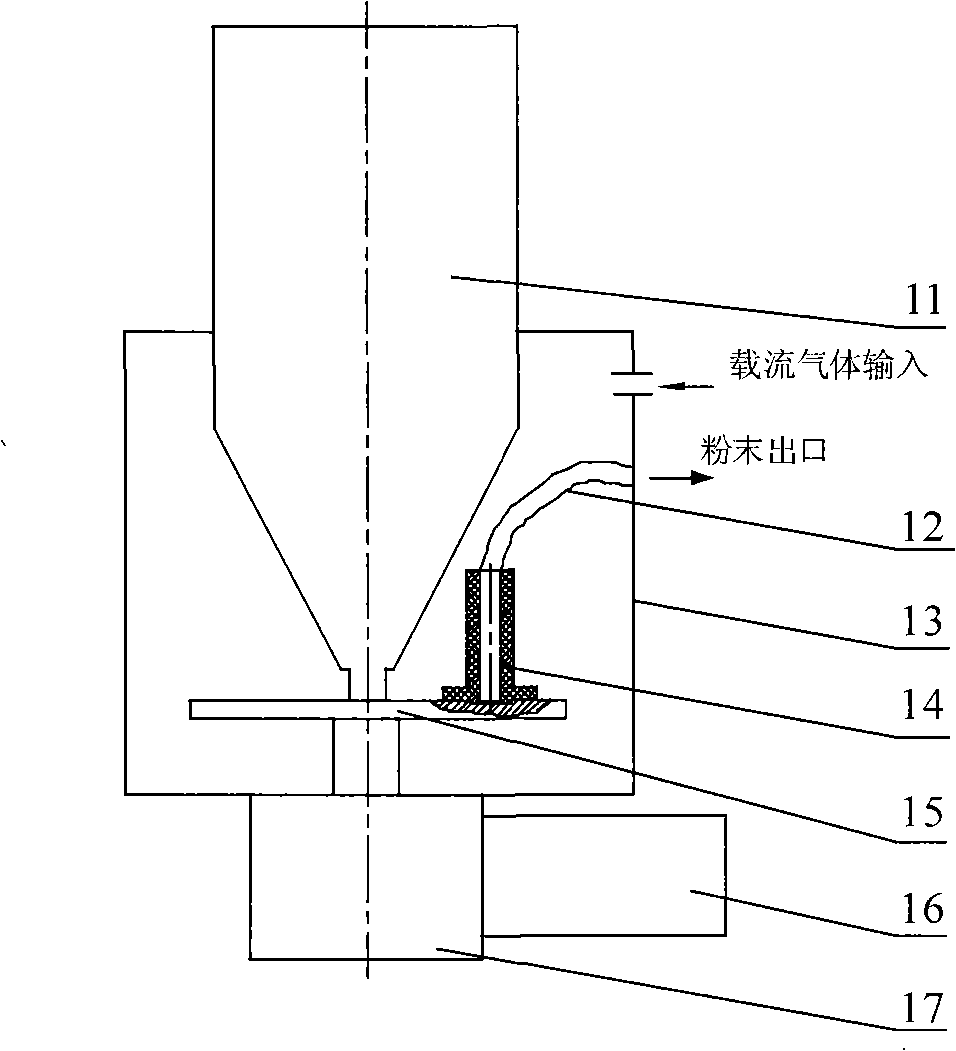

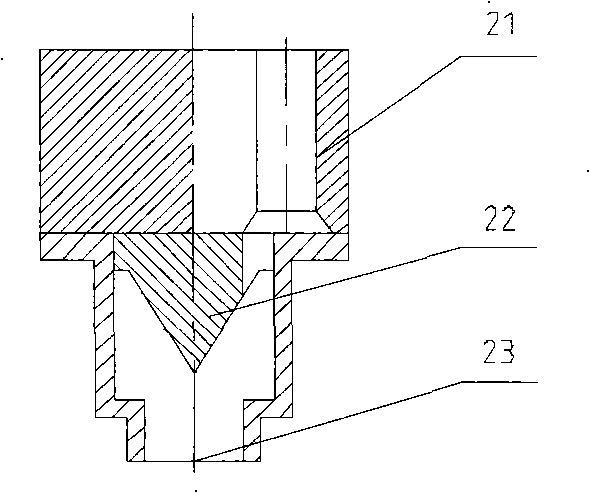

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

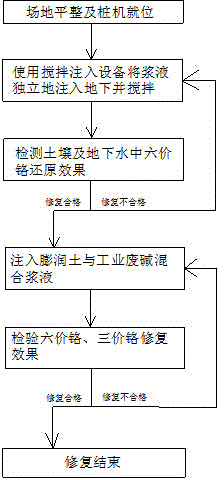

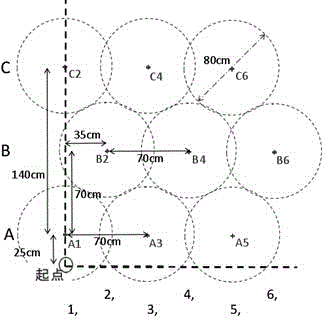

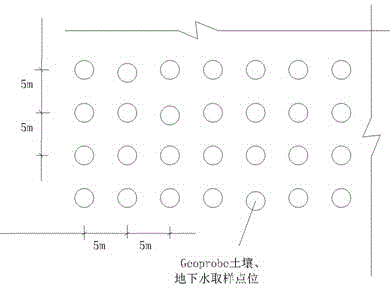

Remediation method for hexavalent chromium polluted soil and underground water

ActiveCN104624632AComplete restorationEfficient removalWater contaminantsContaminated soil reclamationSodium BentoniteInjection equipment

The invention discloses a remediation method for hexavalent chromium polluted soil and underground water. The remediation method comprises the following steps: step (10): putting a pile machine in place; step (20): independently injecting acidified bentonite slurry loaded with active carbon powder and bentonite slurry loaded with zero-valent iron powder into the ground by using stirring and injection equipment and stirring; step (30): detecting the reduction effect of hexavalent chromium in the soil and the underground water; step (40): injecting bentonite and industrial waste alkali mixed slurry; and step (50): detecting the remediation effect of hexavalent chromium and trivalent chromium. By virtue of the remediation method, remediation chemicals can be in direct and sufficient contact with the soil and the underground water to react, so that the hexavalent chromium in the soil and the underground water can be completely reduced; meanwhile, an indissolvable stable compound is formed by the trivalent chromium and the useless loss of the remediation chemicals can be reduced; the potential of hydrogen of a stratum is balanced; and the remediation method is suitable for the large-area hexavalent chromium polluted stratums different in potential of hydrogen and moisture content.

Owner:SOUTHEAST UNIV

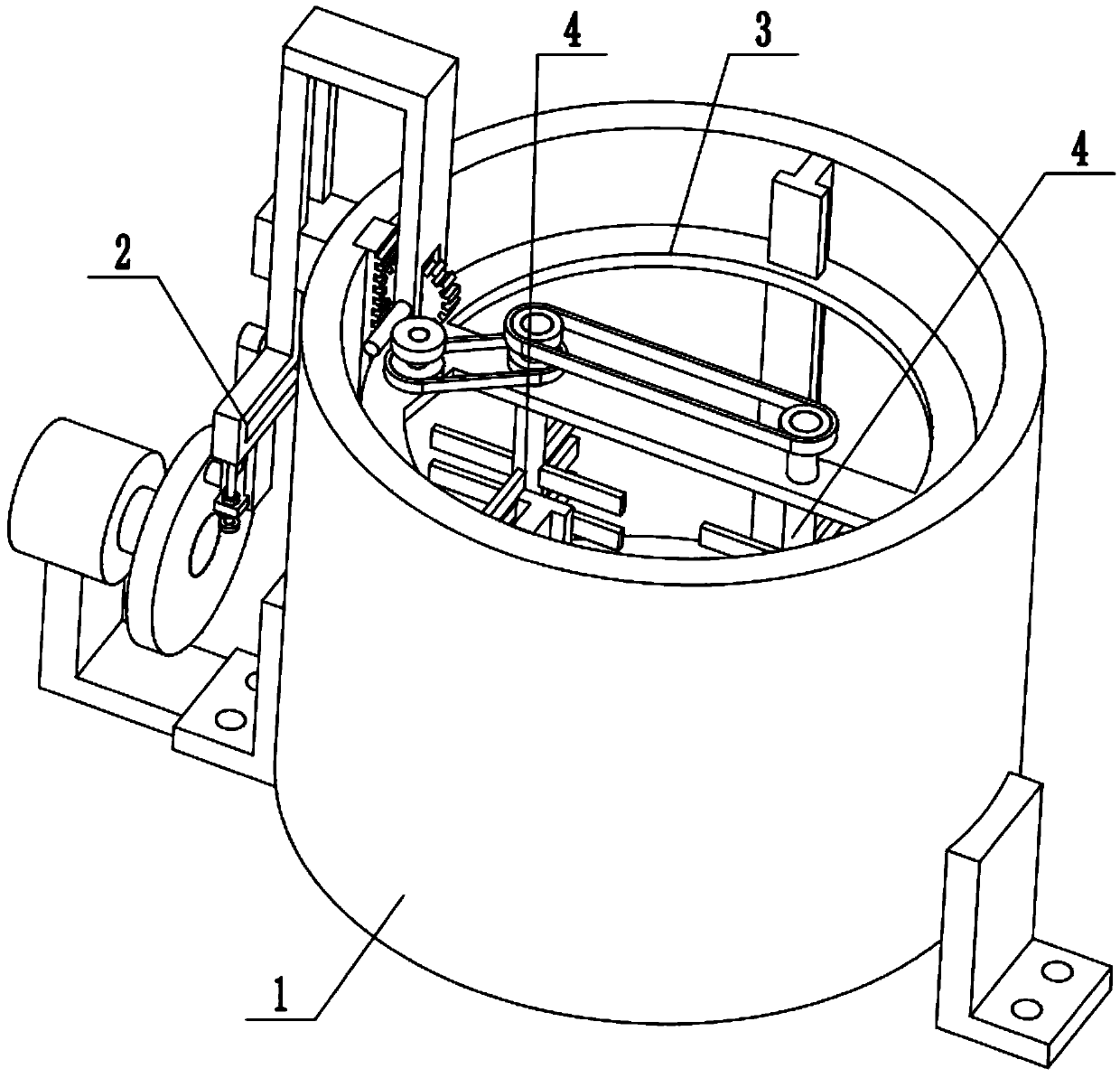

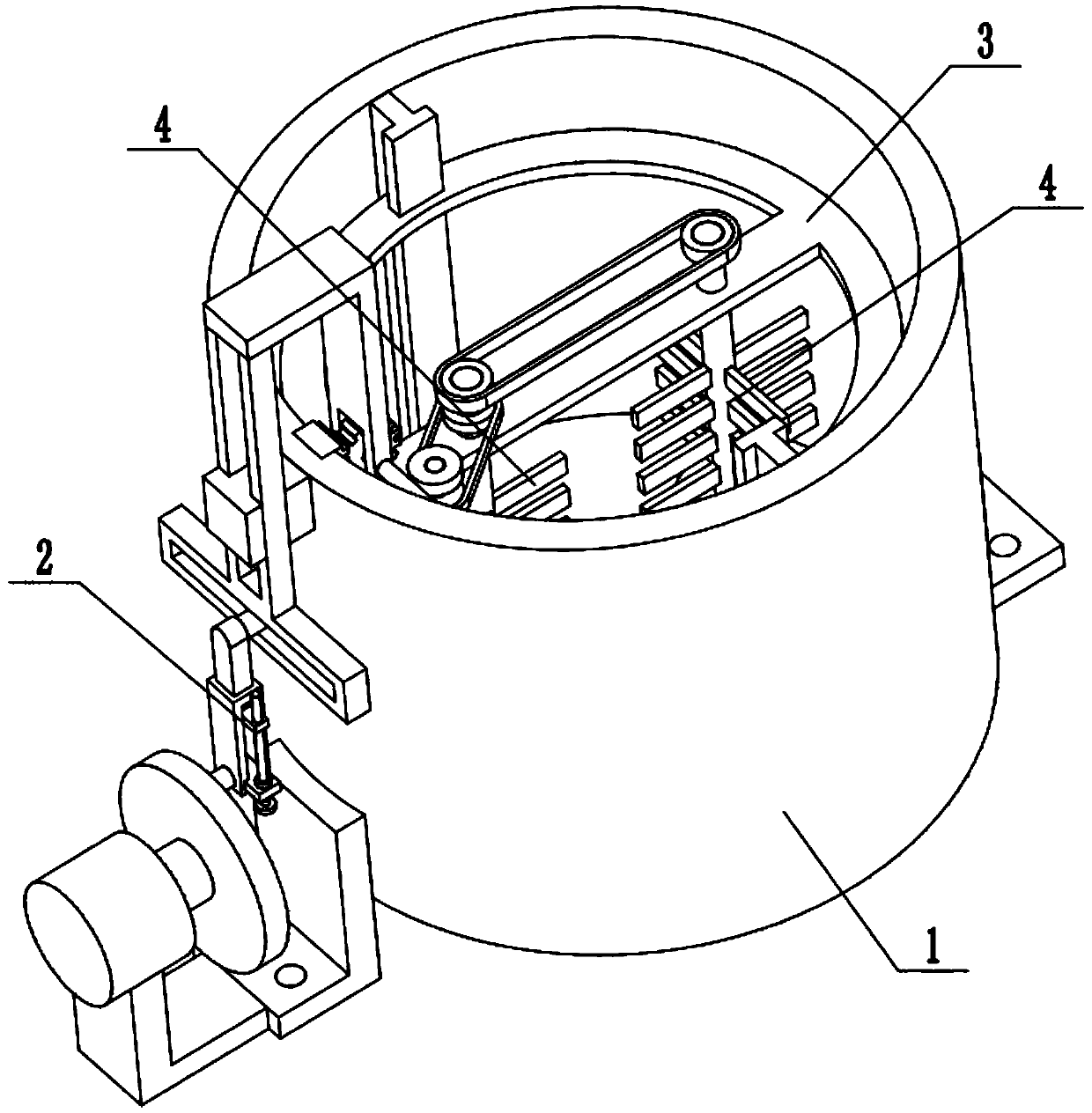

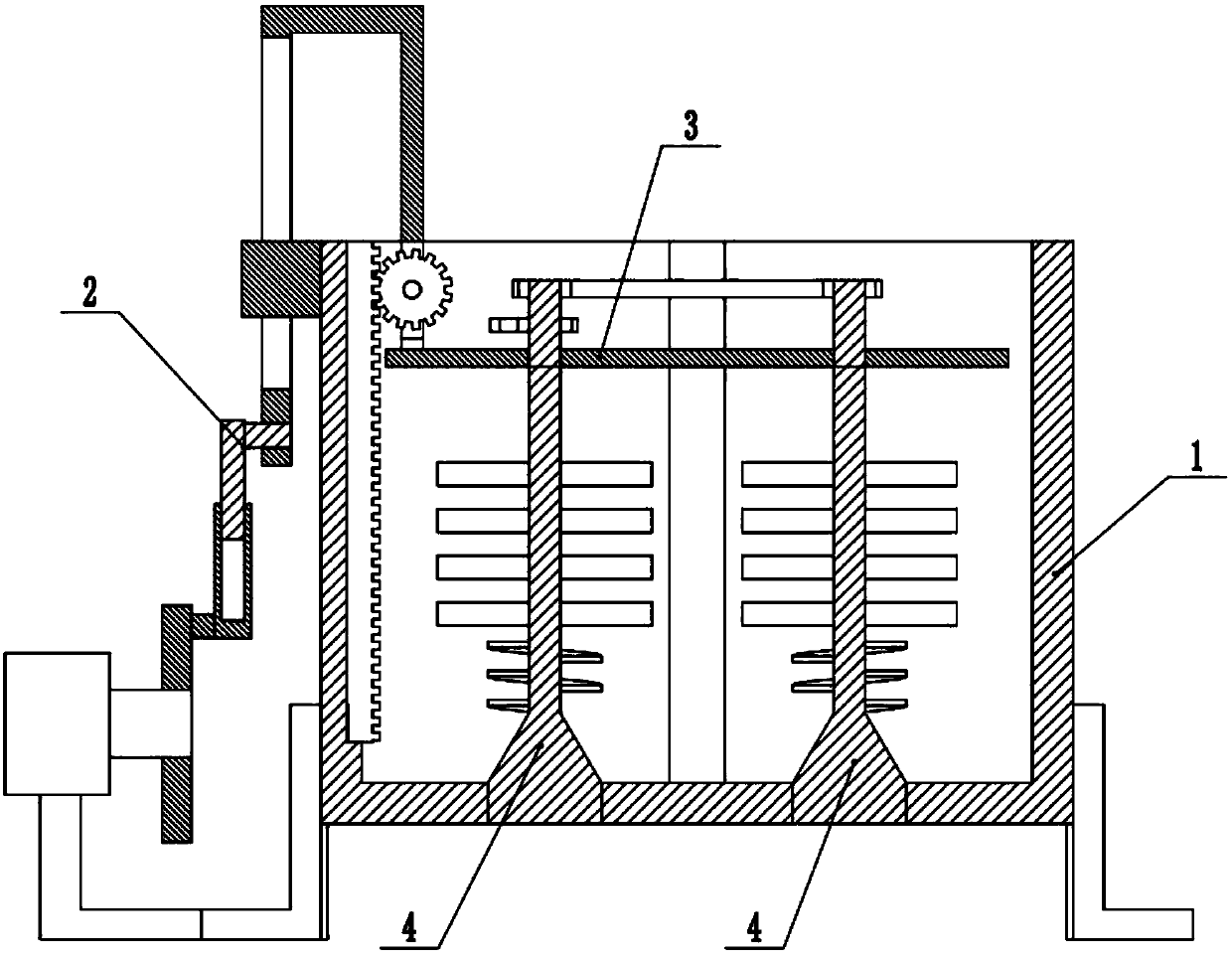

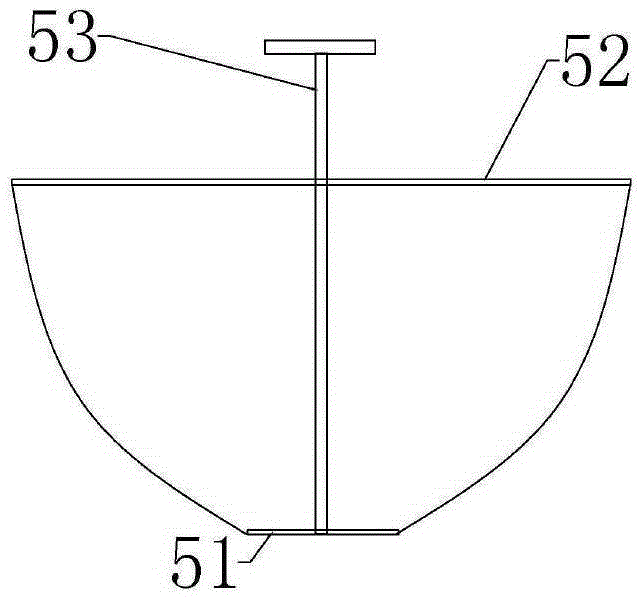

Intermittent feeding device for animal husbandry ingredients

InactiveCN109621783AWell mixedStir wellFeeding-stuffRotary stirring mixersAdditive ingredientEngineering

The invention relates to the field of ingredient mixing equipment, in particular to an intermittent feeding device for animal husbandry ingredients. The lower end of an intermittent discharging control mechanism is fixedly connected to the outer end of the lower end of an intermittent discharging barrel, the middle end of the intermittent discharging control mechanism is fixedly connected to the outer end of the upper end of the intermittent discharging barrel, the inner end of the intermittent discharging control mechanism is in meshed transmission connection with the inner side of the intermittent discharging barrel, and the inner end of the intermittent discharging control mechanism is fixedly connected to an upper and lower reciprocating sliding base which is slidably connected to theinterior of the intermittent discharging barrel, and the upper and lower reciprocating sliding base is in meshed transmission connection with the intermittent discharging control mechanism. Accordingly, various feed intermittent feeding equipment for animal husbandry is capable of conducting preliminarily mixing and high in work efficiency, the amount of feed can be adjusted according to the demand or the characteristics of the feed, then the subsequent mixing efficiency is changed, and energy consumption is saved.

Owner:张掖市金农源生物科技有限公司

Chopped glass fiber sizing agent for bulk molding compounds (BMC) for reinforcing thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

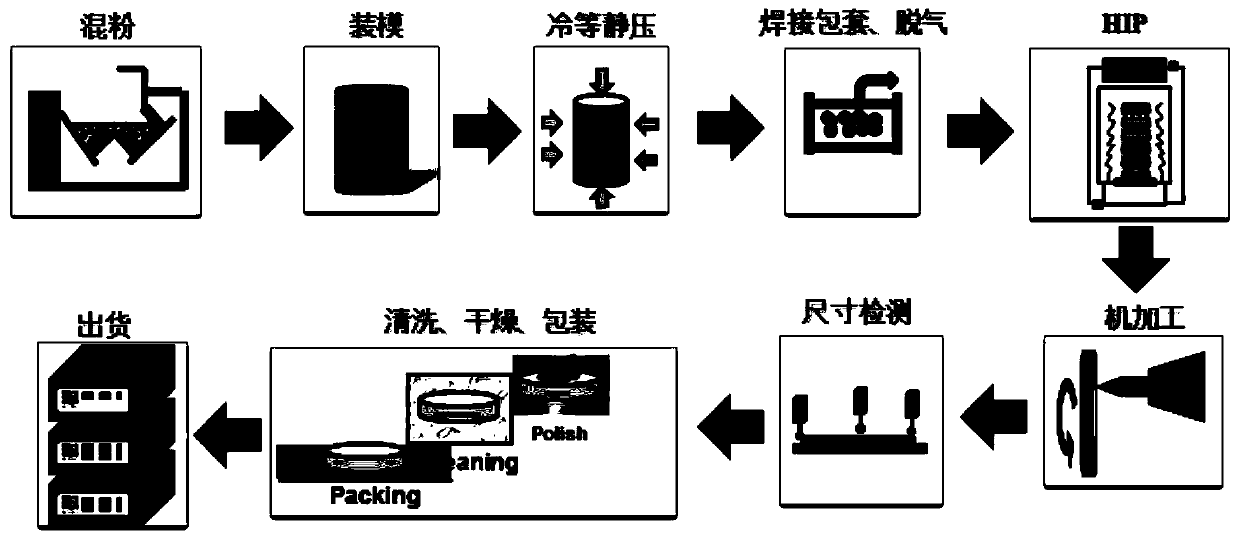

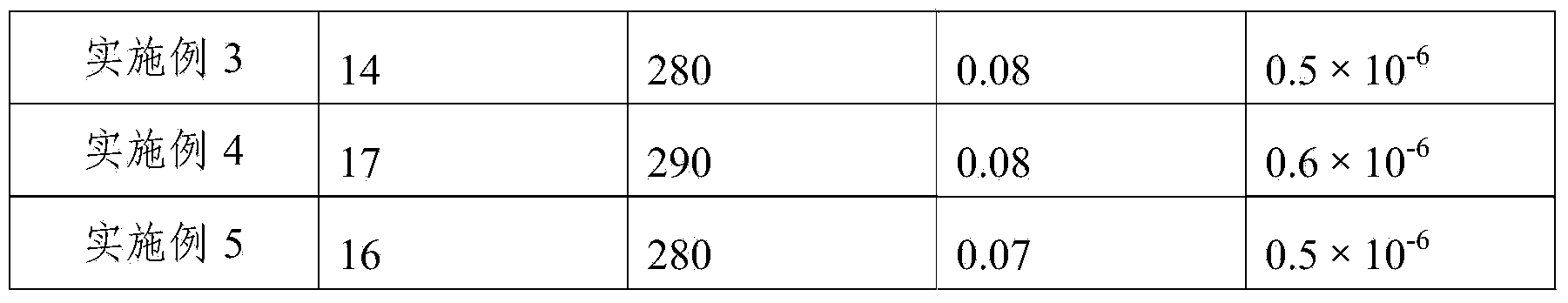

Tantalum-silicon alloy sputtering target material and preparation method thereof

InactiveCN110952064AUniform structureAvoid direct contactTransportation and packagingMetal-working apparatusSilicon alloyTantalum

The invention relates to a tantalum-silicon alloy sputtering target material and a preparation method thereof. The preparation method comprises the steps: (1) tantalum powder and silicon powder are mixed; (2) a mixture is loaded into a mold, and the mold is sealed; (3) the sealed mold is subjected to cold isostatic pressing treatment, and a tantalum-silicon blank is obtained; (4) the obtained tantalum-silicon blank is subjected to degassing treatment; (5) a degassed casing is subjected to hot isostatic pressing treatment at 1050-1350 DEG C, and a tantalum-silicon alloy sputtering target material crude product is obtained; and (6) the tantalum-silicon alloy sputtering target material is obtained by machining. According to the preparation method, oxidation of the silicon powder is effectively prevented, the product purity is guaranteed, the prepared tantalum-silicon alloy sputtering target material can further reach the density of 99% or above, the requirements of uniform density and internal organization structure of the tantalum-silicon alloy sputtering target material are met, a more excellent performance guarantee is provided for subsequent sputtering use, and the characteristicsof simple process, convenient operation and short production cycle are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

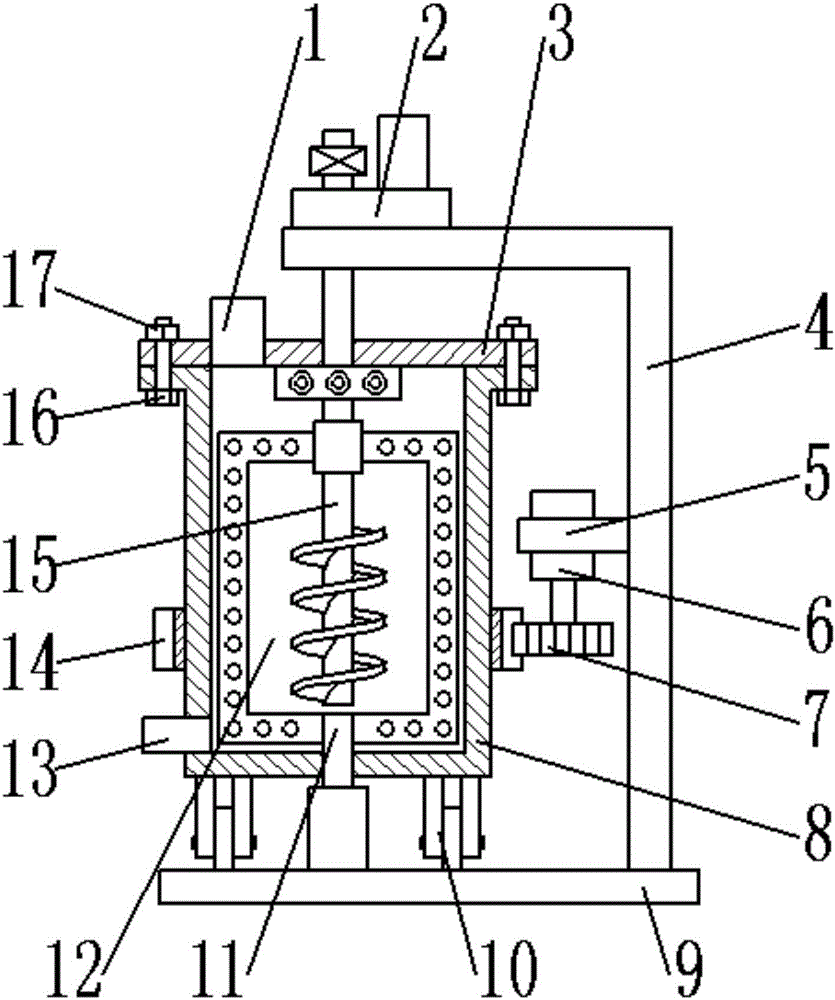

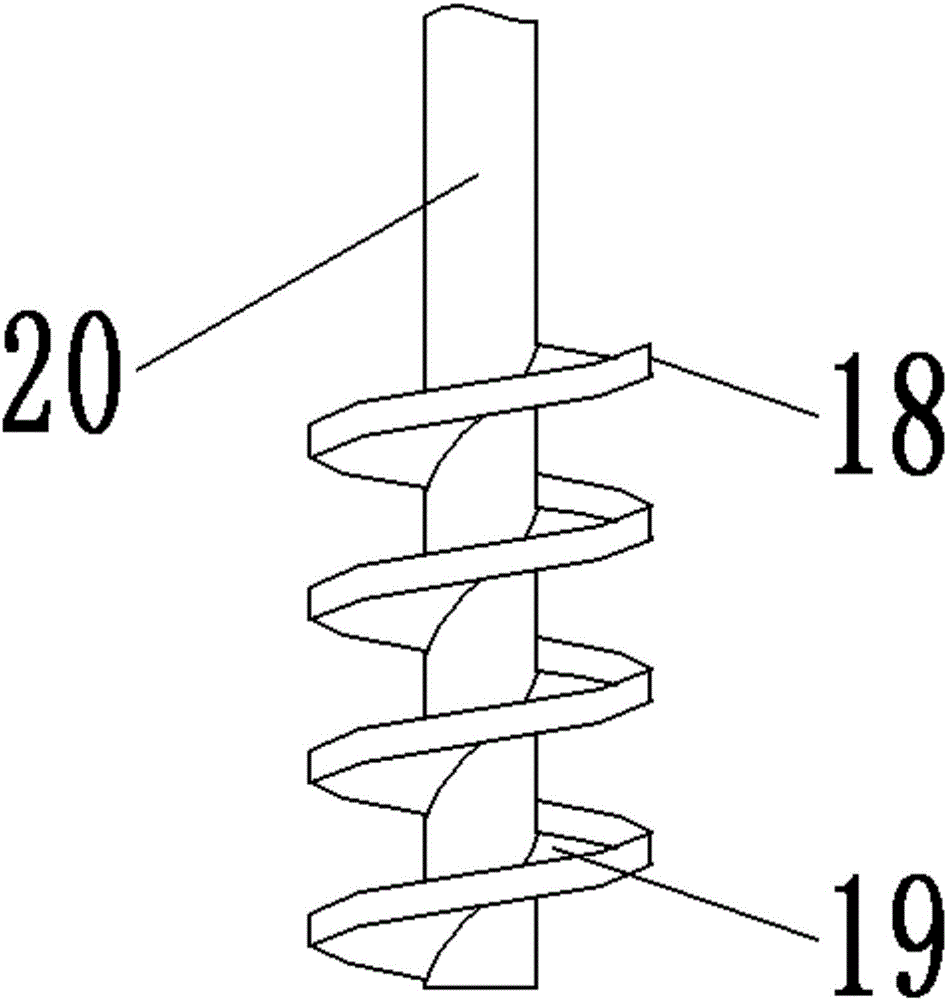

Efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering

InactiveCN106582389AEnsure mixing uniformityMixing uniformity does not existRotating receptacle mixersRotary stirring mixersElectric machineryRaw material

The invention provides efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering. The efficient stirring and mixing equipment comprises a tank body; a stirring cavity is formed in the tank body, an upper cover is installed on an opening formed in the top of the tank body, and four sets of rollers are installed on the lower surface of the tank body; the rollers are installed in a sliding groove formed in a base plate, a support is installed at the end of the base plate, and the vertical portion of the support is fixedly connected with a second motor through a fixing plate; a liquid feeding device is installed on the upper surface of the horizontal portion of the support, the liquid feeding device is composed of a transmission box, a first motor, a liquid feeding pipe, a connecting pillar and a spraying disc, and a first stirring device and a second stirring device are installed in the stirring cavity. According to the efficient stirring and mixing equipment of the solid-liquid raw materials for chemical engineering, through the liquid feeding device, the spraying area and speed of liquid materials are enlarged, so that the liquid materials make sufficient contact with solid materials; through the first stirring device, circulating stirring and mixing of the materials are achieved, so that the spraying speed of the liquid materials is improved; and through arrangement of the second stirring device, the materials are further stirred and mixed.

Owner:郑州吉音动漫科技有限公司

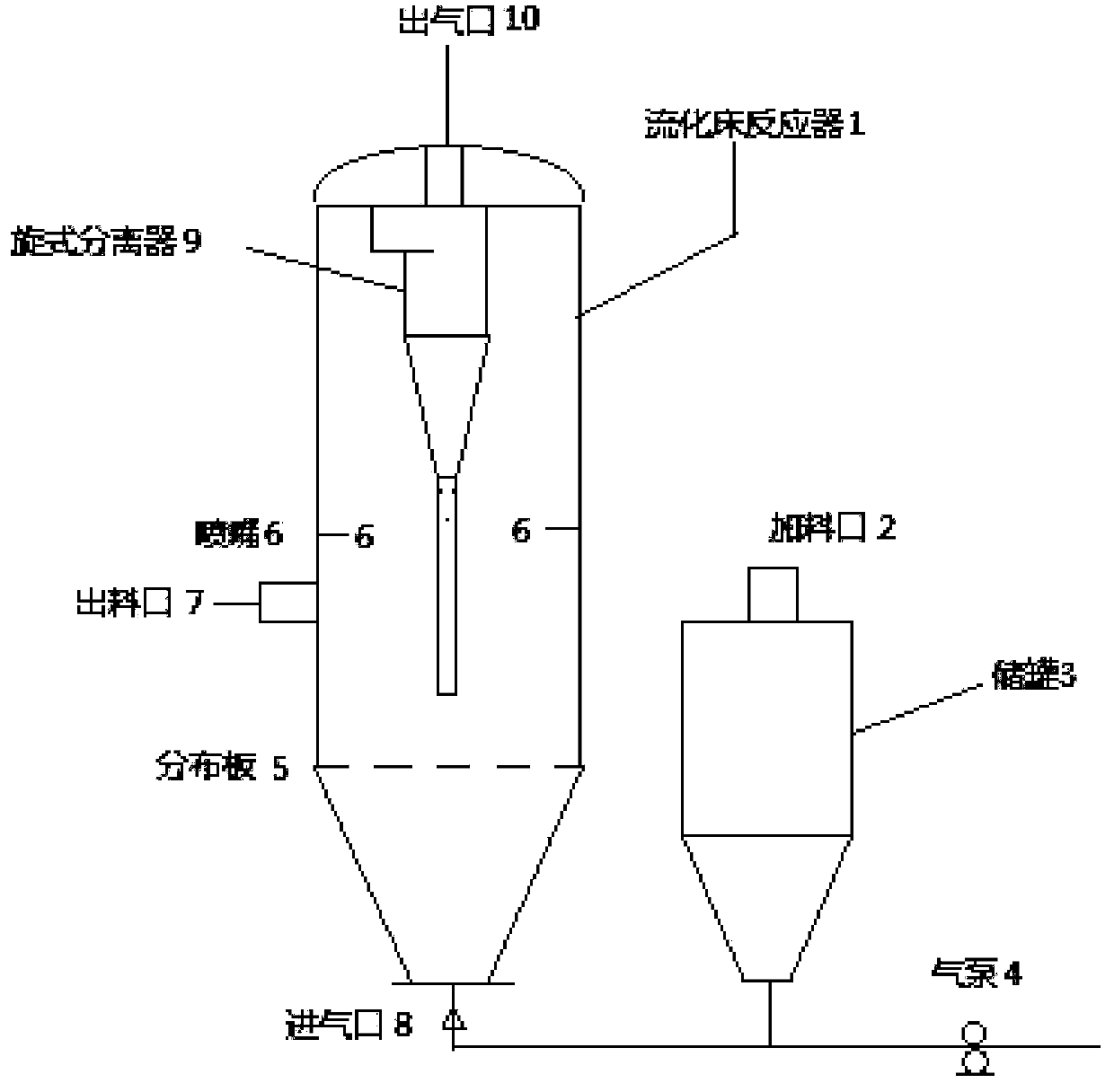

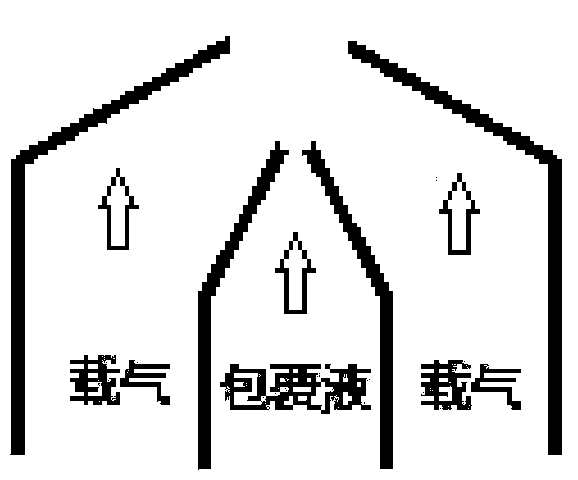

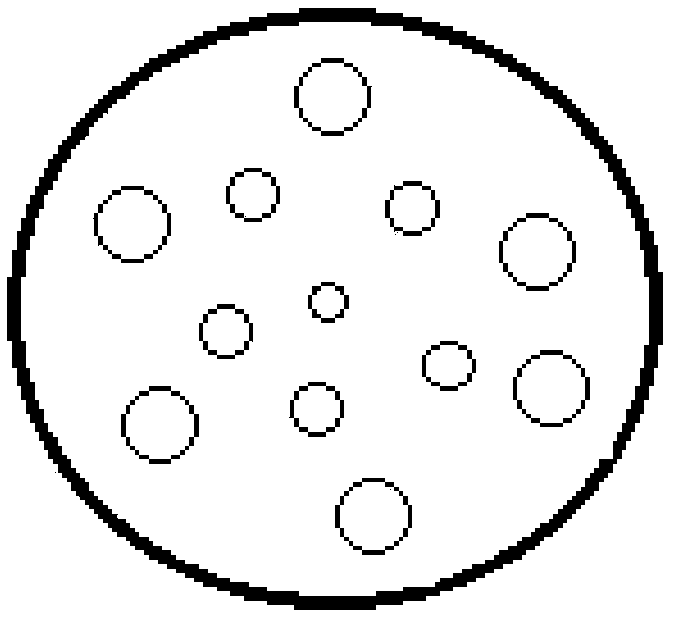

Coated modified electrode material and preparation method thereof

ActiveCN109585797AAchieve hybridMaintain coating uniformityCell electrodesSecondary cellsMaterials scienceElectrode material

The invention discloses a coated modified electrode material and a preparation method thereof. The method comprises the following steps of spraying a coating liquid into a fluidized bed reactor through a nozzle of a fluidized bed to be mixed with an electrode material which is in a fluidized state, so that coating of the electrode material by a coating material precursor is realized; and then carrying out sintering to obtain the coated modified electrode material which consists of the electrode material and a coating material which coats the surface of the electrode material. By further optimizing the component connection relation of the fluidized bed and the structural design of a gas distribution plate and the nozzles, the coating uniformity can be improved, the coating process can be simplified, the coating process cost is lowered, and the cycling performance of the electrode material is improved, and meanwhile, the problems of influence caused by an abnormal fluidization phenomenonand blocking of the nozzles during working are solved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

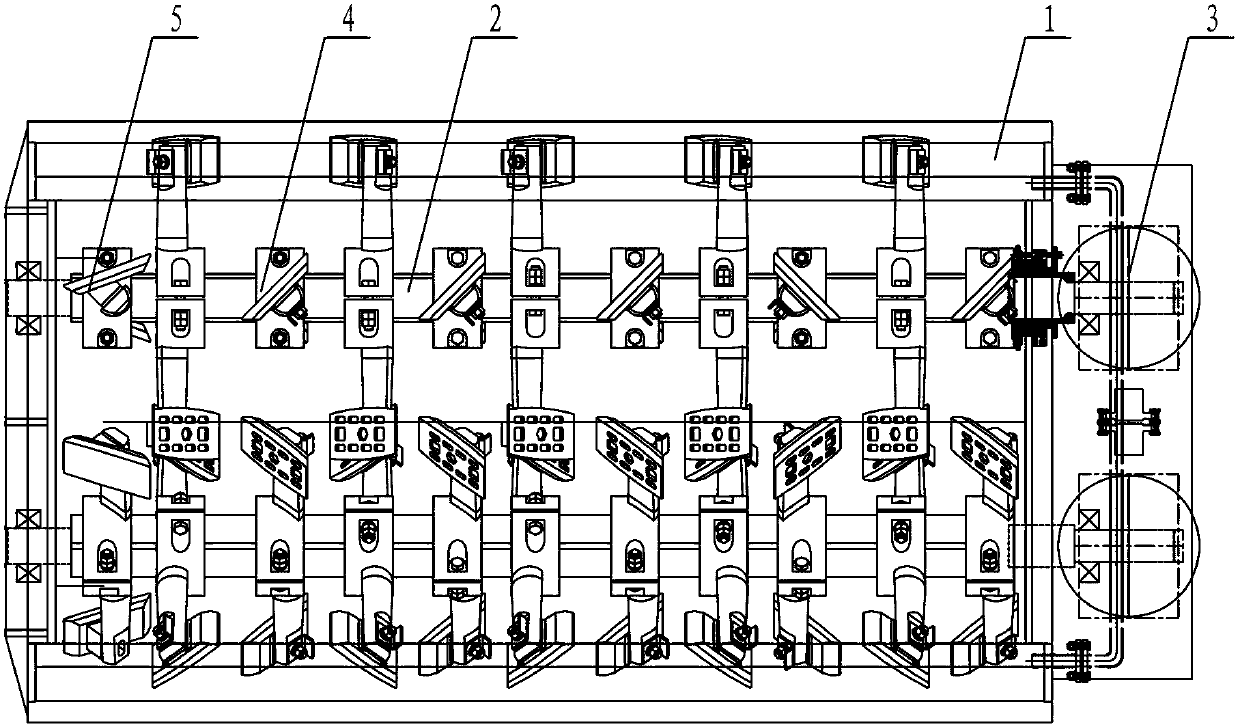

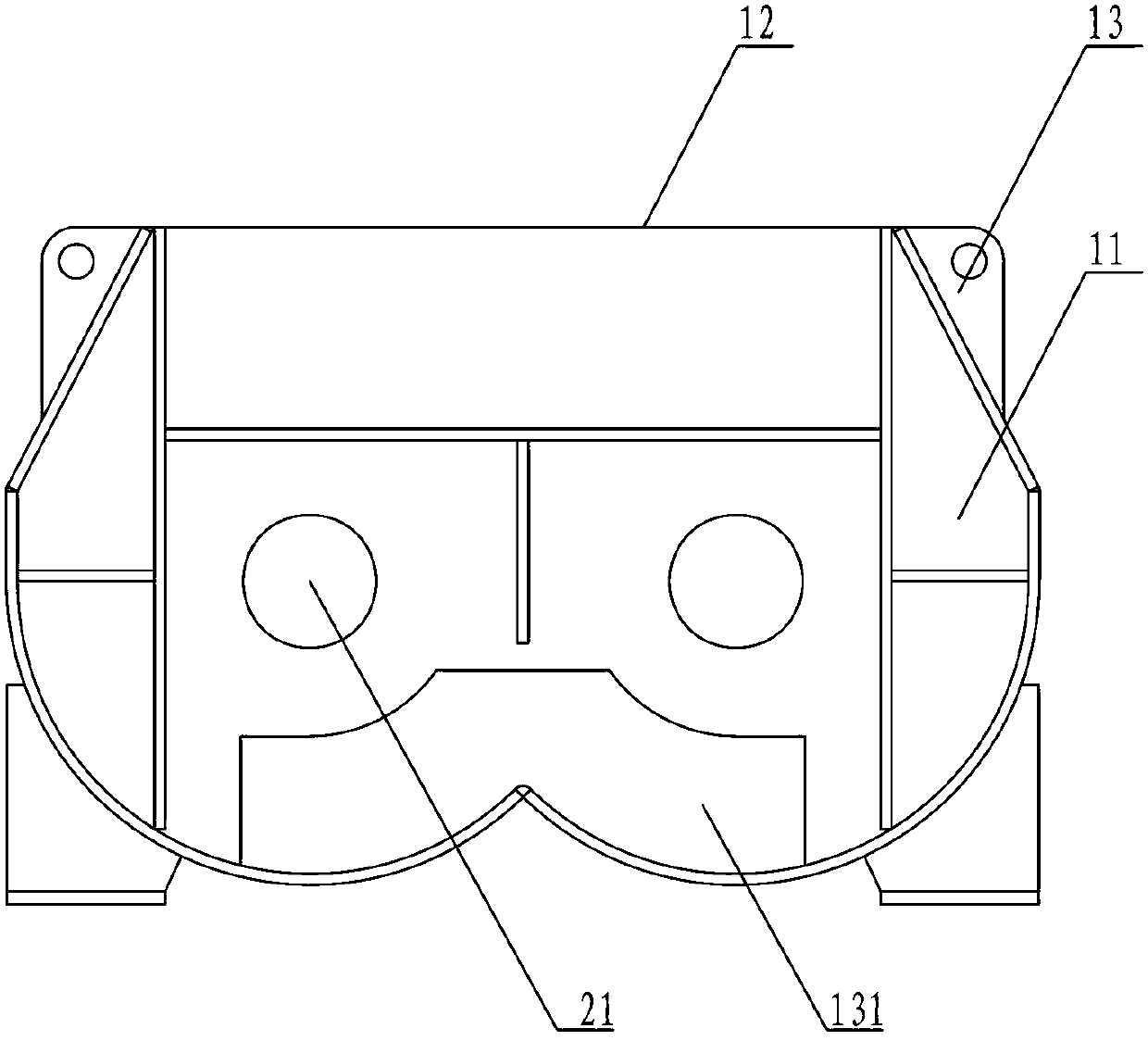

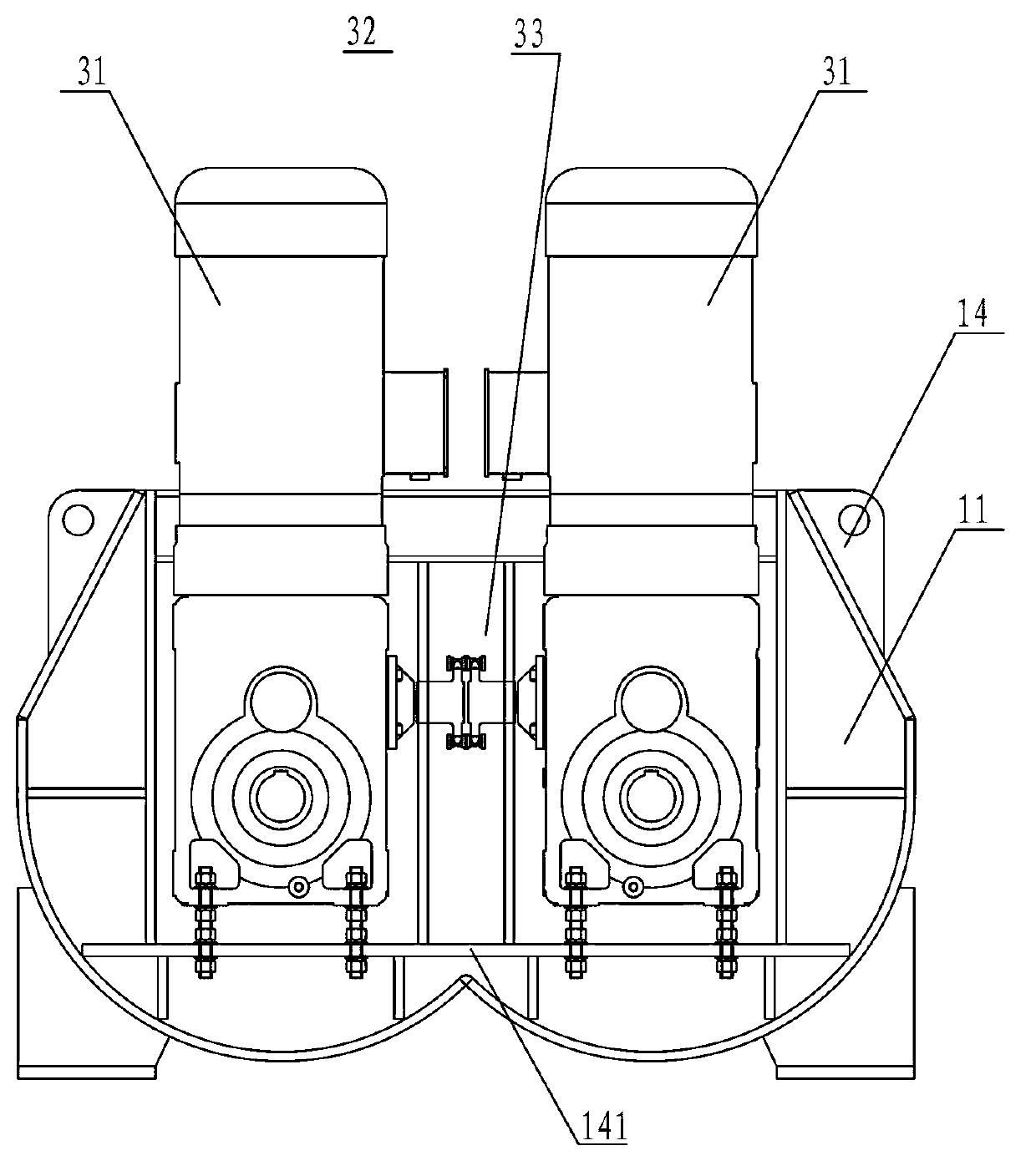

Continuous double-horizontal-shaft forced mixer for asphalt and concrete

ActiveCN103128854AYield easily achievedImprove transmission efficiencyDischarging apparatusMixing operation control apparatusContinuous mixingMechanical engineering

The invention belongs to the technical field of asphalt and concrete mixing, and particularly relates to a continuous double-horizontal-shaft forced mixer for asphalt and concrete. The continuous double-horizontal-shaft forced mixer for the asphalt and the concrete comprises a mixing tank provided with a feeding port and a discharging port, two mixing shafts which are arranged in the mixing tank in a parallel mode, a driving device which drives the mixing shafts to rotate synchronously and reversely, a plurality of groups of mixing units and a material scraping unit. Each mixing unit comprises mixing arms and blades, wherein the mixing arms are mounted on the mixing shafts in an opposite mode, the blades are mounted on the mixing arms and comprise a feeding blade and a returning blade, and the feeding blade and the returning blade are the same in structure and size and opposite in mounting direction. The material scraping unit comprises a group of mixing arms which are arranged in an opposite mode, and material scraping blades which are connected on the mixing arms, wherein an acute included angle is formed between each material scraping blade and a side plate of the mixing tank. According to the bituminous mixture mixer, namely the continuous double-horizontal-shaft forced mixer for the asphalt and the concrete, the methods of continuous grading feeding, continuous mixing and continuous discharging are used, and the output of the bituminous mixture mixer can reach 100-1,000 tons per hour.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Blockage-resistant pervious concrete as well as preparation method and application thereof

ActiveCN106186943AOptimize component contentEnsure small porosityCeramicwareSuspended particlesWater flow

The invention provides blockage-resistant pervious concrete. The water glue ratio of the blockage-resistant pervious concrete is 0.28-0.38. The blockage-resistant pervious concrete is prepared from the following components in parts by weight: 22-30 parts of silicate cement, 34-42 parts of macadam, 24-32 parts of quartz sand, 2-5 parts of pulverized coal ash, 3-6 parts of micro powder of ore residues, 0.3-0.5 part of modified polypropylene fibers, 1-3 parts of redispersible latex powder, 1-2 parts of a water reducing agent and water. According to the blockage-resistant pervious concrete disclosed by the invention, the pervious principle of conventional concrete with macropore is changed, the perviousness of the concrete is improved by using functional material components namely the modified polypropylene fibers, and the macadam and the quartz sand are matched for use, so that the small pore rate of the concrete is guaranteed, the modified polypropylene fibers and the small pores of the concrete are utilized for perviousness, and massive suspending particles or organic fine particles are prevented from entering large pores to block the pores along with water currents; and the modified polypropylene fibers are used and are effectively combined with other components in the pervious concrete, so that the perviousness of the pervious concrete is further improved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Infiltration agent of chopped glass fiber for reinforcing cement

The invention discloses an infiltration agent of chopped glass fiber for reinforcing cement. The infiltration agent comprises the following components by weight percent: (1) 0.2-1.5% of coupling agent which is combination of 3-amino propionic triethoxy silane and 3-methacryloyloxyethyl propyl trimethoxysilane; (2) 3.0-30.0% of a film-forming agent, which is crosslinked polyacrylic dispersion or combination of crosslinked polyacrylic acid dispersion and a bisphenol A epoxy emulsion with medium-high molecular weight, wherein the molecular weight of the epoxy resin in the bisphenol A epoxy emulsion with medium-high molecular weight is 1200-6000; (3) 0.01-2.0% of a nonionic lubricant; (4) 0.05-1.0% of organic antistatic agent; (5) 0.1-2% of pH value modifier; (6) 63.5-96.64% of deionized water. A glass fiber yarn produced by using the infiltration agent has the advantages of being good in bundling property, easy to chop, and resistant to alkaline corrosion of cement, the produced cement product is high in mechanical strength, and the product is bright and clean in appearance.

Owner:JUSHI GRP CO

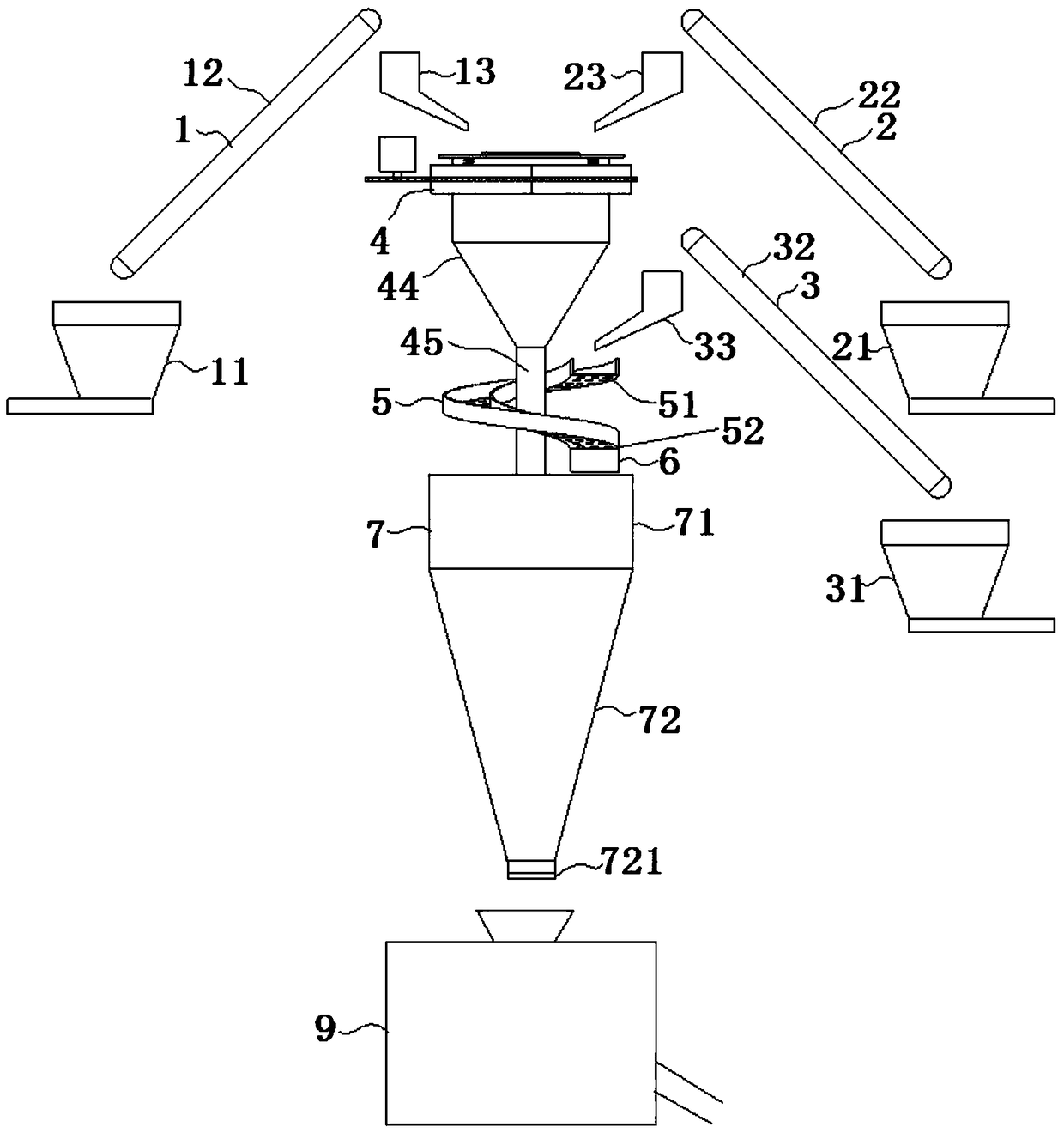

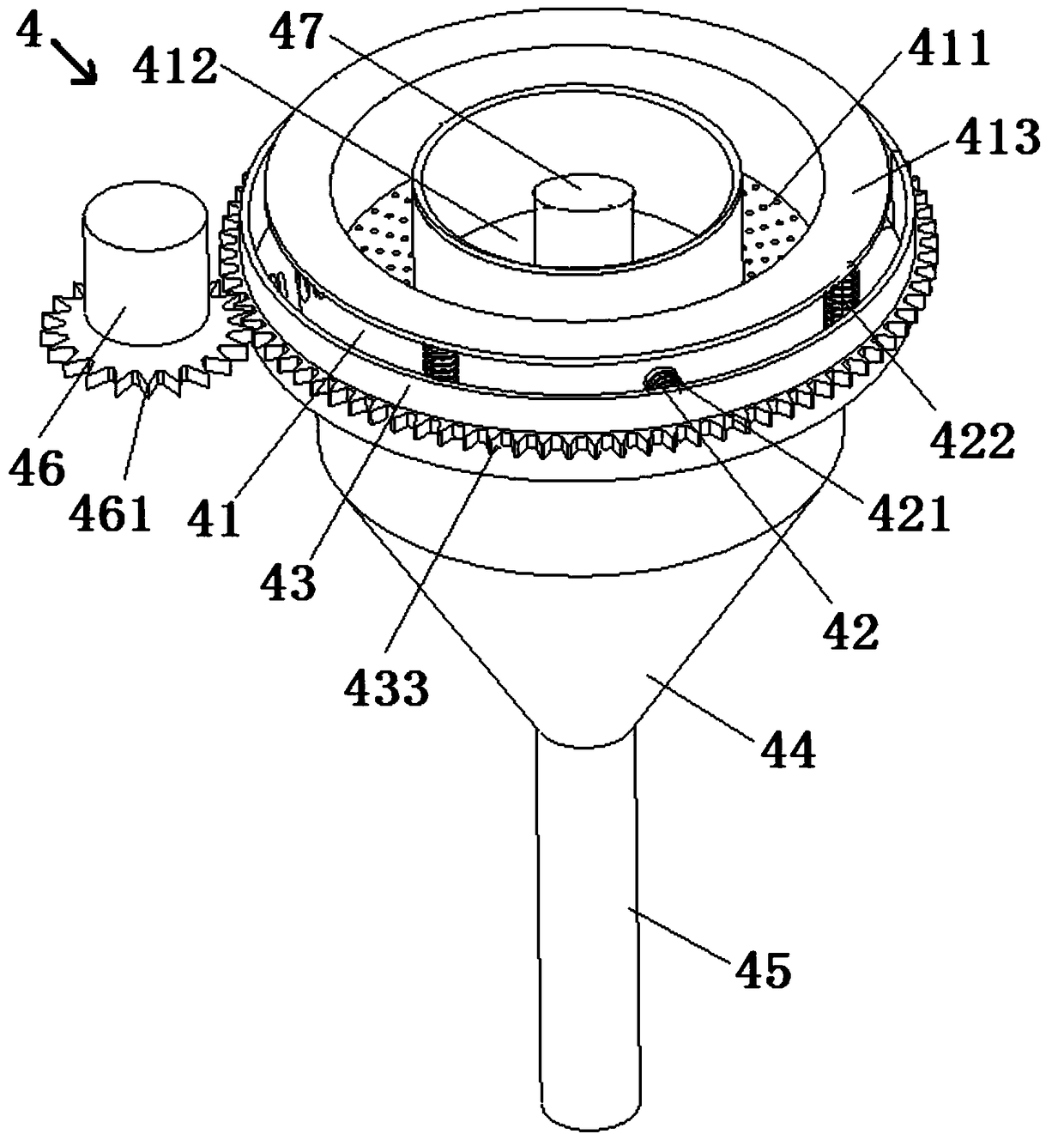

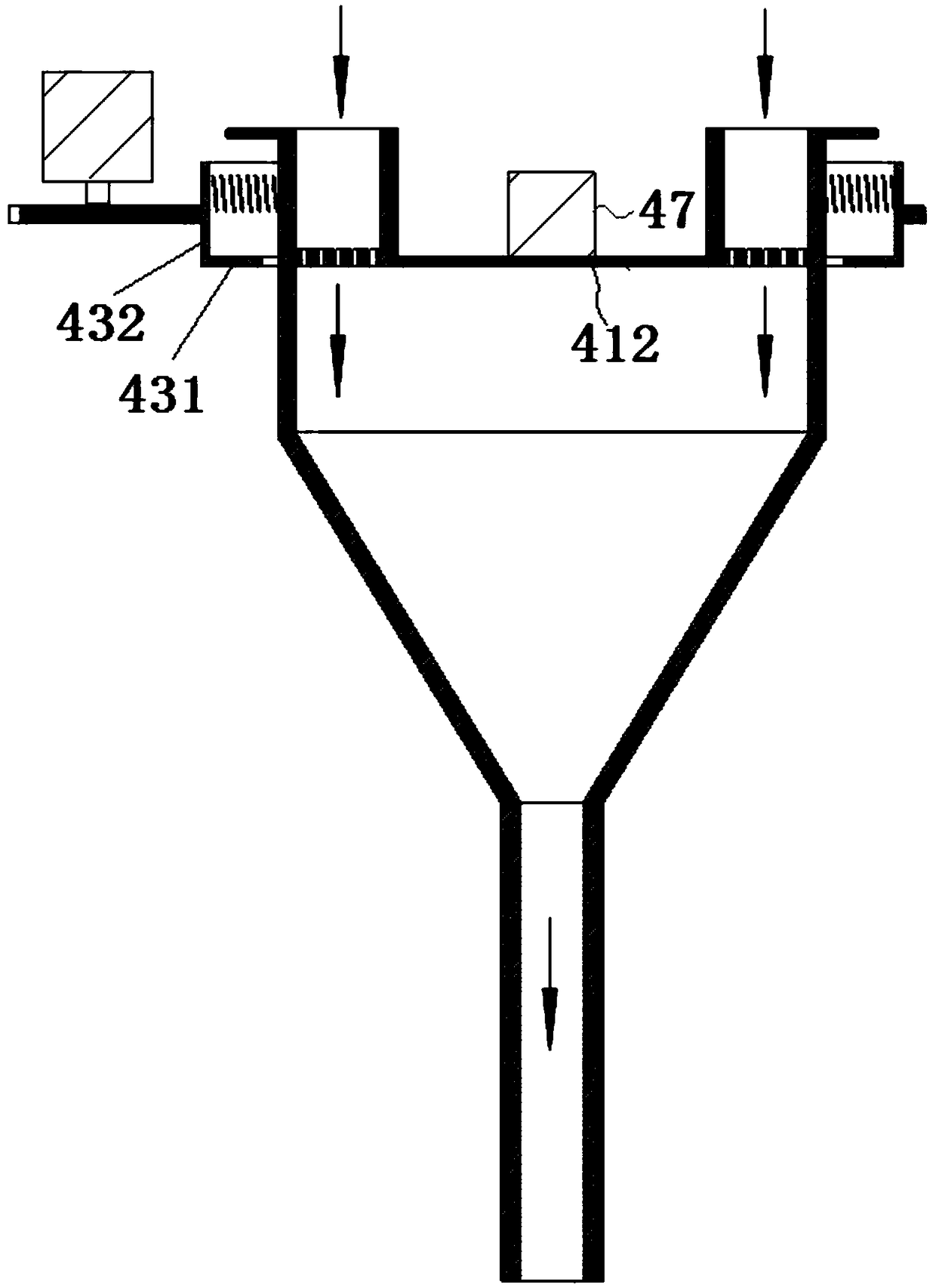

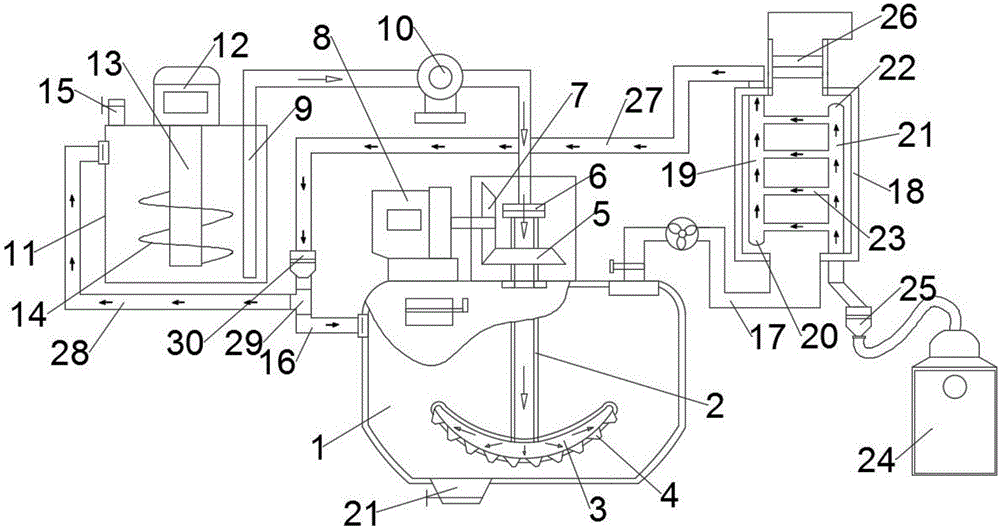

Concrete production system and production method thereof

ActiveCN109366742AImprove the quality levelShorten mixing timeMixing operation control apparatusPretreatment controlMaterials scienceRaw material

The invention discloses a concrete production system and a production method thereof. The concrete production system comprises a sand feeding device, a cement feeding device, a gravel feeding device,a sand-cement mixing device, a gravel screening spiral material guide groove, a sand-cement-gravel mixing device and a concrete mixer; the sand feeding device can supply raw material sand required byconcrete to the sand-cement mixing device, the cement feeding device can supply raw material cement required by the concrete to the sand-cement mixing device, and the sand-cement mixing device can mixthe supplied sand with the supplied cement; and the gravel feeding device can be used for screening raw material gravel required by the concrete through the gravel screening spiral material guide groove and then supplying the gravel to the sand-cement-gravel mixing device, the sand-cement-gravel mixing device can be used for mixing the mixed sand and cement with the gravel, and then the mixture is stirred by the concrete mixer to form the concrete. According to the concrete production system and the production method thereof, the mixing uniformity of all the raw materials required by the concrete is ensured, and the quality grade of the concrete is improved.

Owner:江西信源建材科技集团有限公司

Anti-oxidation chemical industrial raw material processing and blending device

InactiveCN106823966AEnsure mixing uniformitySolve the cumbersome complexityRotary stirring mixersTransportation and packagingNitrogenProcess engineering

The invention discloses an anti-oxidation chemical industrial raw material processing and blending device. The anti-oxidation chemical industrial raw material processing and blending device comprises a raw material blending tank, a blending and stirring rotating shaft is vertically inserted in an inner cavity of a tank body of the raw material blending tank along the central axis; the inner part of an arc-shaped stirring paddle is also set into a hollow structure, and a plurality of liquid spraying through holes are uniformly formed in the bottom side surface of the arc-shaped stirring paddle; an outer cavity nitrogen induction tube is vertically arranged in a position of the right side edge of an inner cavity of a gas heating chamber; a hot gas eduction pipe is vertically arranged in a position of the left side edge of the inner cavity of the gas heating chamber; the top end of the hot gas eduction tube is guided out of the top side wall of the gas heating chamber, and the end part of a tube body is integrally connected with a cyclic hot nitrogen conveying tube. According to the anti-oxidation chemical industrial raw material processing and blending device disclosed by the invention, the mixing uniformity of a whole additive is ensured, the tedious and complicated performance of a traditional blending agent in an addition process is solved, an assistance function is provided for preparation by a filled inert gas-nitrogen, and the preparation rate of raw materials is enhanced.

Owner:六安市智奇工业设计有限公司

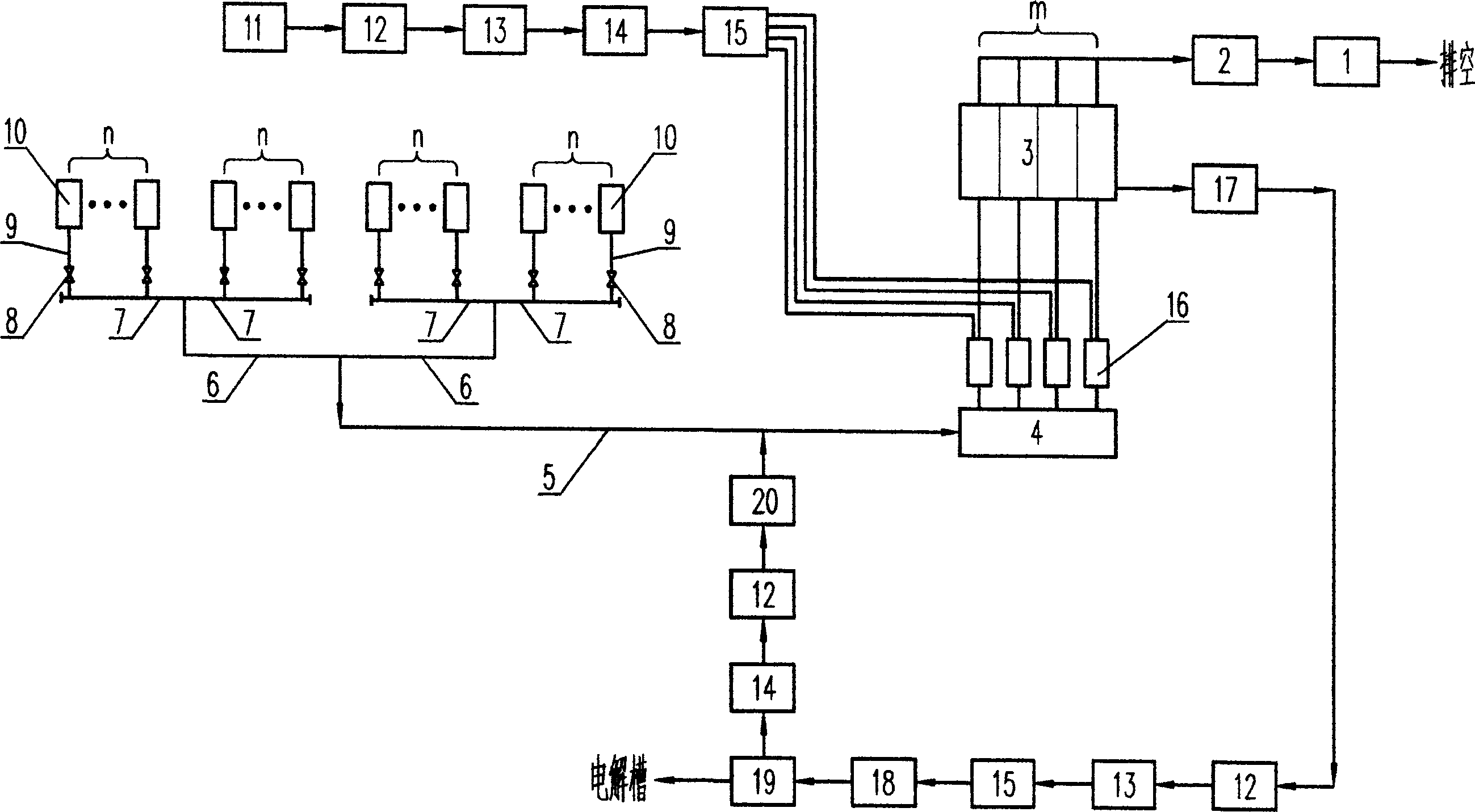

Process for purifying fluorine contg. flue-gas for aluminium electrolysis

ActiveCN1831201AUniform exhaustImprove mixing uniformityDispersed particle separationAluminium electrolysisEngineering

The invention discloses a purify technology of aluminum electrolyzing FI contained smoke that makes the smoke from electrolyzing FI passing through smoke evacuation branch pipe, smoke evacuation secondary main pipe, smoke evacuation main pipe and smoke evacuation total pipe spraying to impulse purifying filterer. Before coming into the filterer, the two steps material feeding would be taken and take adsorption reaction, and taking filtering and separating in the filterer. One section of the separated alumina containing FI could be used as the raw material to make electrolytic tank, and some would be return to the total pipe to mix with hydrogen fluoride. The purified smoke would be sent to air. The invention has short process, high efficiency, low power consumption, high reliable, no secondary pollution, etc.

Owner:GUIYANG AL-MG DESIGN & RES INST

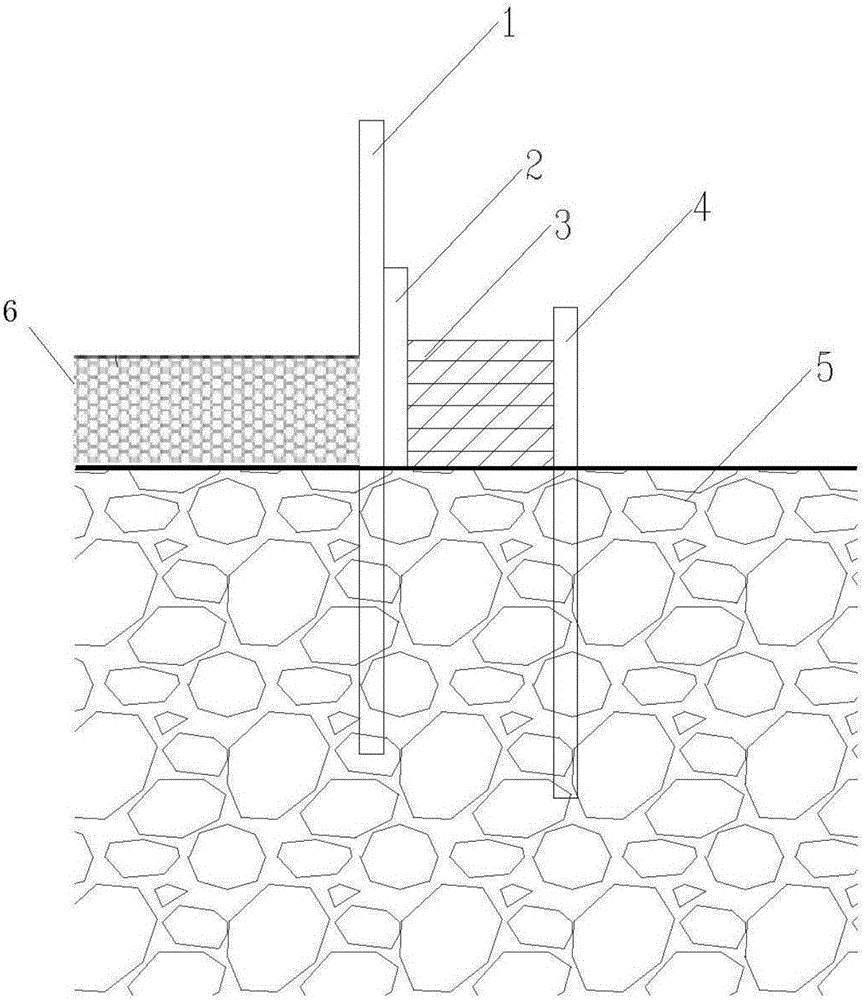

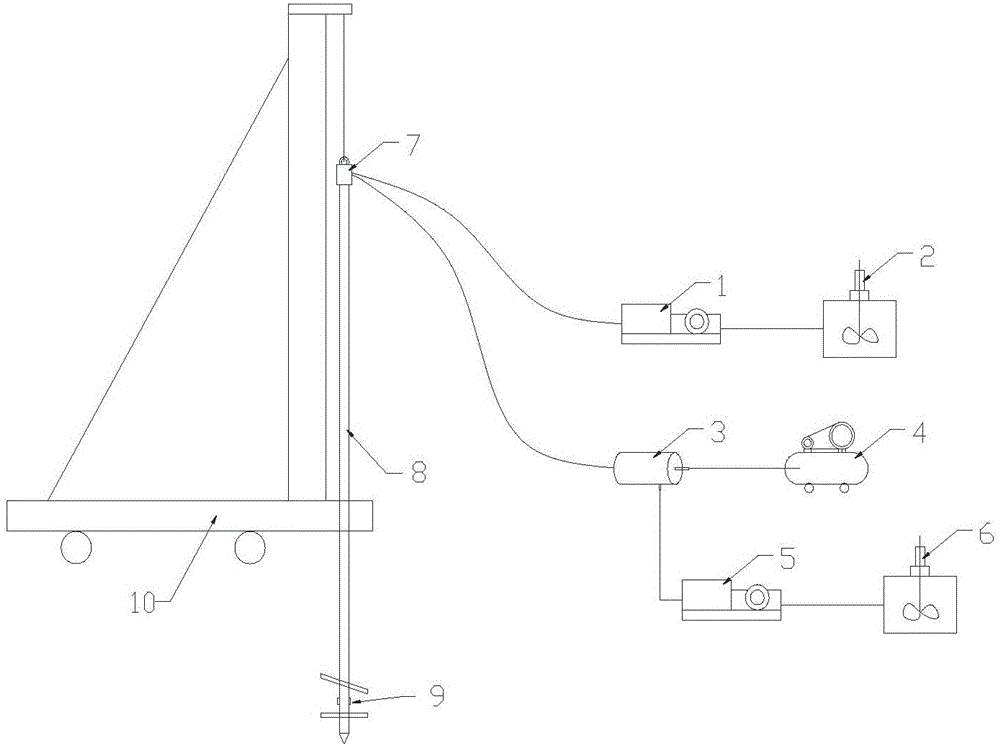

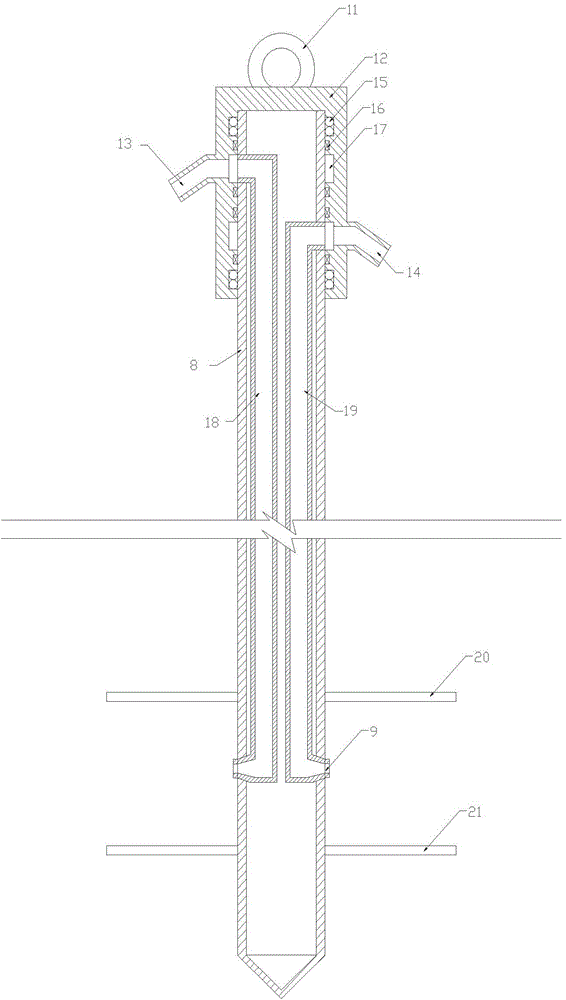

Technical method for improving quality of deep cement soil mixing piles using compressed air foam

InactiveCN104631446AImprove construction qualityImprove construction efficiencyBulkheads/pilesSoil mixingCement grout

The invention provides a technical method for improving quality of deep cement soil mixing piles using compressed air foam, and on the basis of a 'guniting-stirring' technology in conventional deep cement soil mixing pile machine, a foam injection system is added. Cement grout and the compressed air foam pass through a double-channel rotating joint and a double-channel drill stem and are finally ejected into soil simultaneously through a nozzle in the side face of a drill. The compressed air foam assists the guniting and the stirring of the cement mixing drill, on one hand stirring resistance of the drill in a sand soil layer is reduced, on the other hand, drill adhesion in cohesive soil is reduced. According to the technical method, cement adding amount and uniformity of the stirring can be guaranteed, so that the quality of the cement soil mixing piles is improved.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

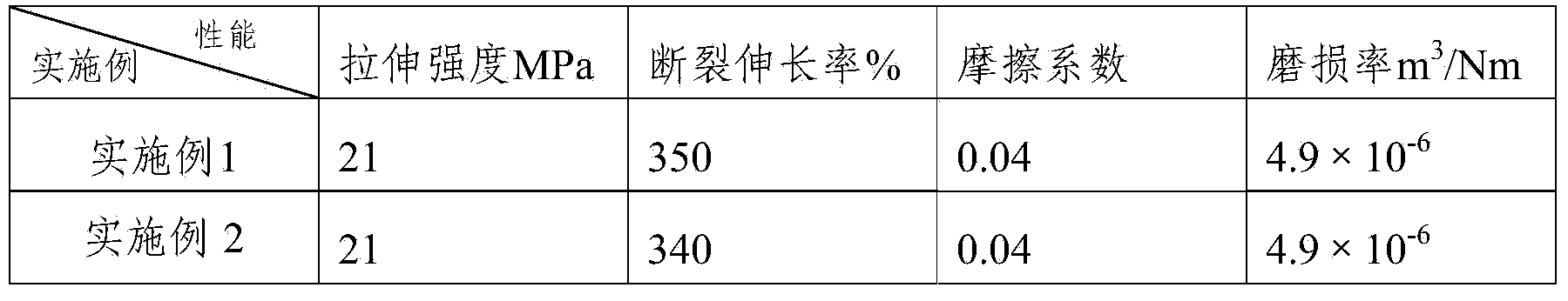

Preparation method of dispersion resins filled with polytetrafluoroethylene

The invention relates to a preparation method of dispersion resins filled with polytetrafluoroethylene. The preparation method comprises the following steps: 1) adding surfactants to polytetrafluoroethylene emulsion with specific gravity of 1.04-1.08g / cm<3>, and mechanically stirring the materials uniformly, wherein the addition of the surfactants is 0.3-0.5% of the weight of polytetrafluoroethylene solid in the emulsion; 2) adding graphite and / or carbon black to the polytetrafluoroethylene emulsion obtained in the step 1), and mechanically stirring the materials; 3) adding electrolyte to carry out chemical and mechanical cohesion, wherein the electrolyte is alkaline or acid and the rotating speed is 1-3 times that in the step 2). The preparation method provided by the invention is simple and practicable and can ensure the mixing uniformity of the filler in the base material. The conductivity and mechanical properties of products are controlled by adjusting the addition of the filler. The preparation method has multiple purposes.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

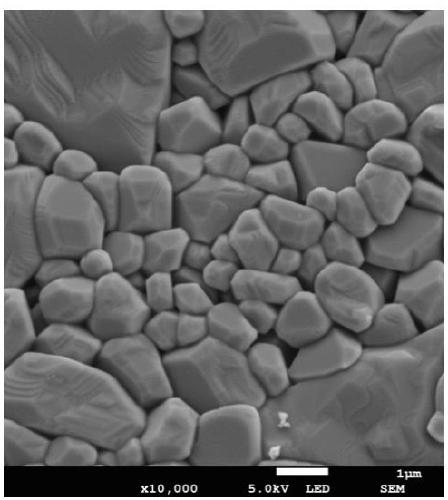

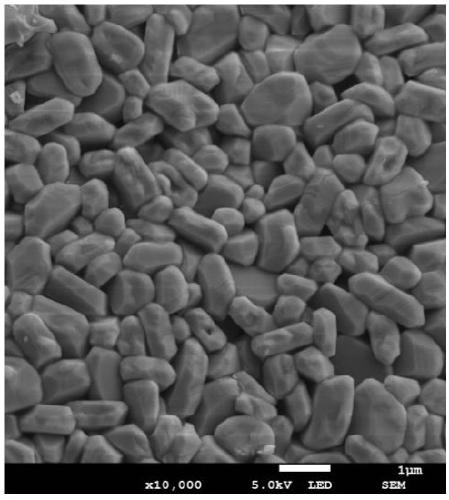

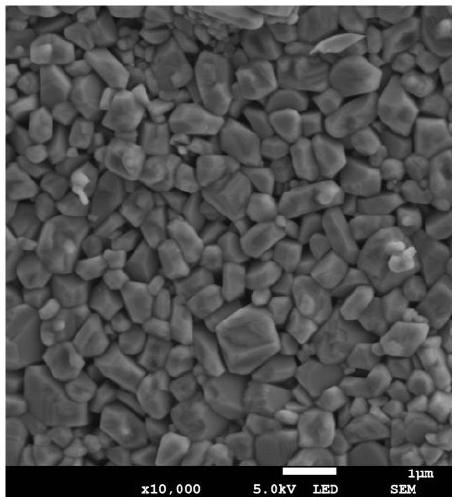

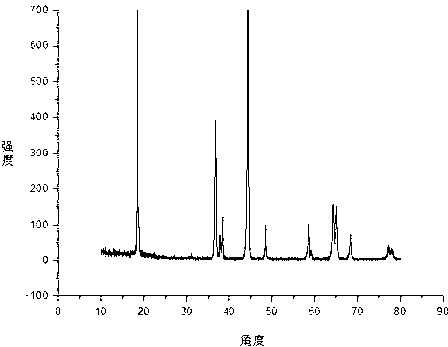

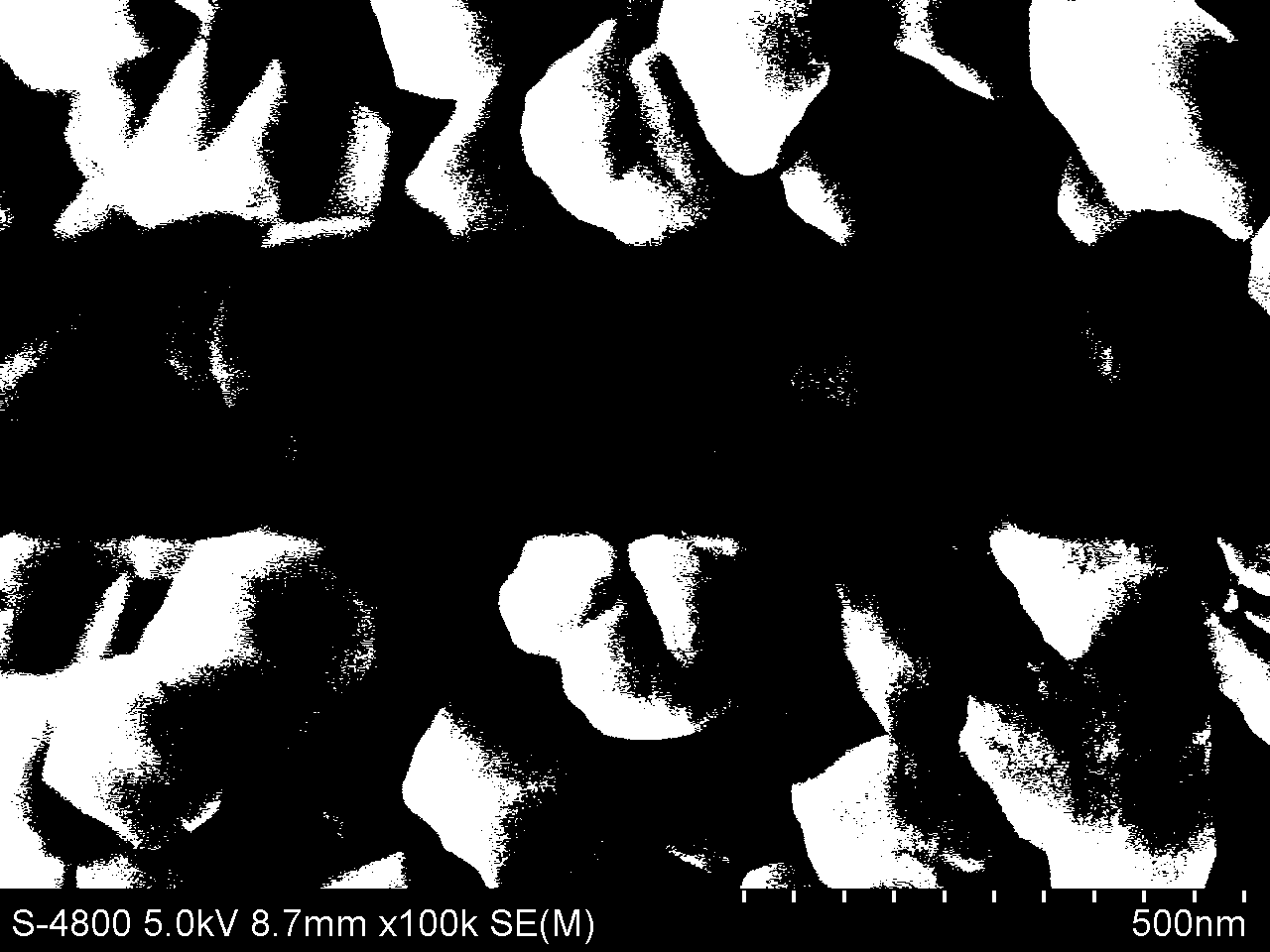

Nanocrystal ceramic corundum abrasive material and preparation method thereof

ActiveCN109231970ALower sintering temperaturePromote migrationOther chemical processesCompressive strengthNanometre

The invention relates to a nanocrystal ceramic corundum abrasive material and a preparation method thereof, and belongs to the field of ceramic corundum abrasive materials. The nanocrystal ceramic corundum abrasive material is prepared from the following components of Al2(SO3)3.18H2O and additives, wherein the additives comprise a dispersant, a liquid composite sintering additive and an Al2O3 (aluminum oxide) sol crystal seed. The preparation method of the nanocrystal ceramic corundum abrasive material comprises the following steps of adding the liquid composite sintering additive and the Al2O3 sol crystal seed into an Al2(OH)3 gel precursor; performing uniform ball milling, and drying by stages, so as to obtain a dry gel; crushing the dry gel, granulating, and screening, so as to obtain gel particles meeting the particle size requirement; calcining the gel particles by sections, cooling along with a furnace, and screening, so as to obtain the ceramic corundum abrasive material with different particle sizes. The invention also discloses a preparation method of the Al2O3 sol seed crystal and the prepared ceramic corundum abrasive material. The nanocrystal nanocrystal ceramic corundum abrasive material has the advantages that by introducing the Al2O3 sol crystal seed, the defects of difficulty in introducing of solid-state nanocrystal seeds and nonuniform mixing are overcome, andthe uniform mixing of the raw materials and additives is guaranteed; the microtopography with fine and uniform crystal seed size is realized, and the compressive strength and grinding property are improved.

Owner:YICHUAN DONGFENG ABRASIVES

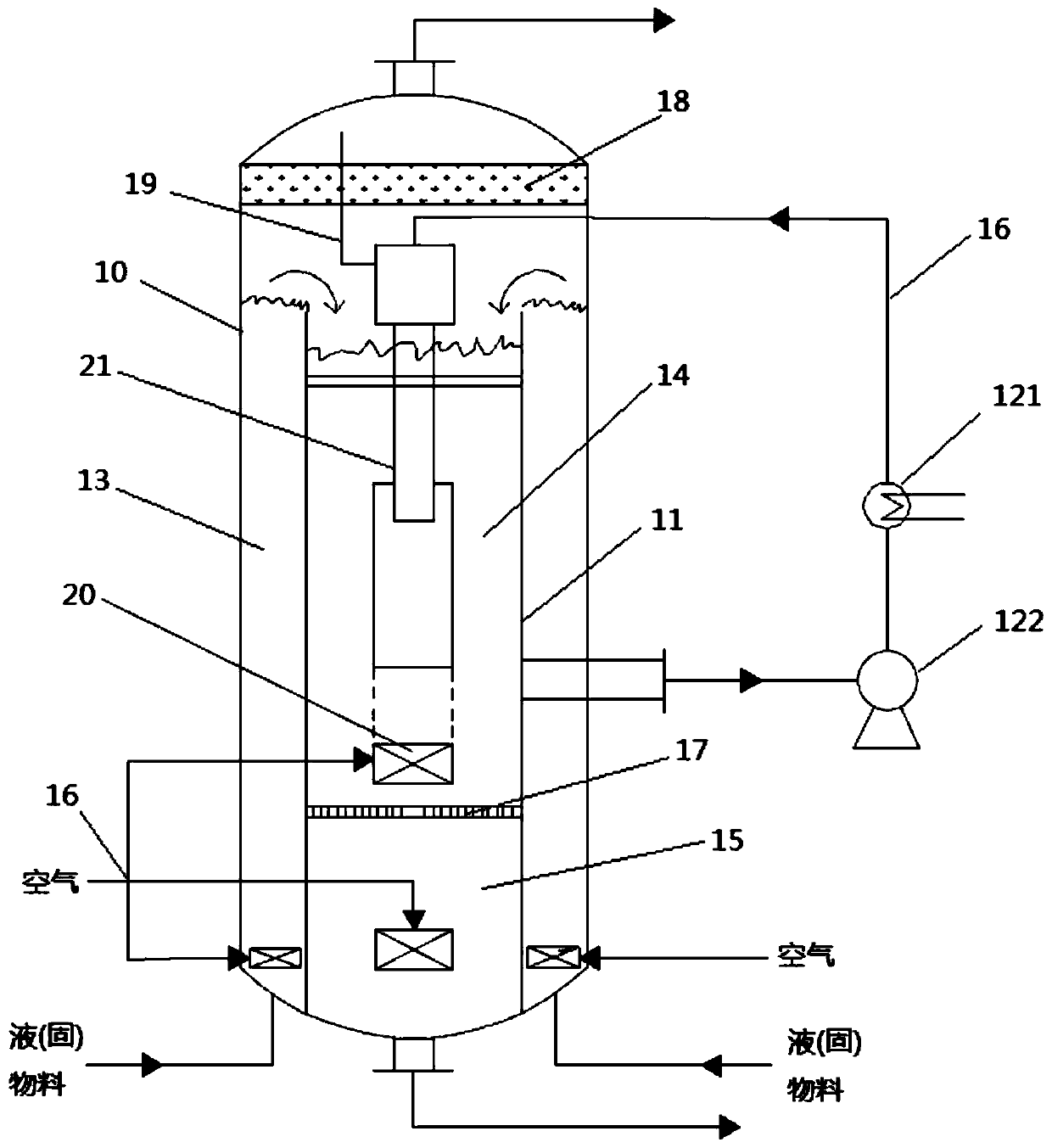

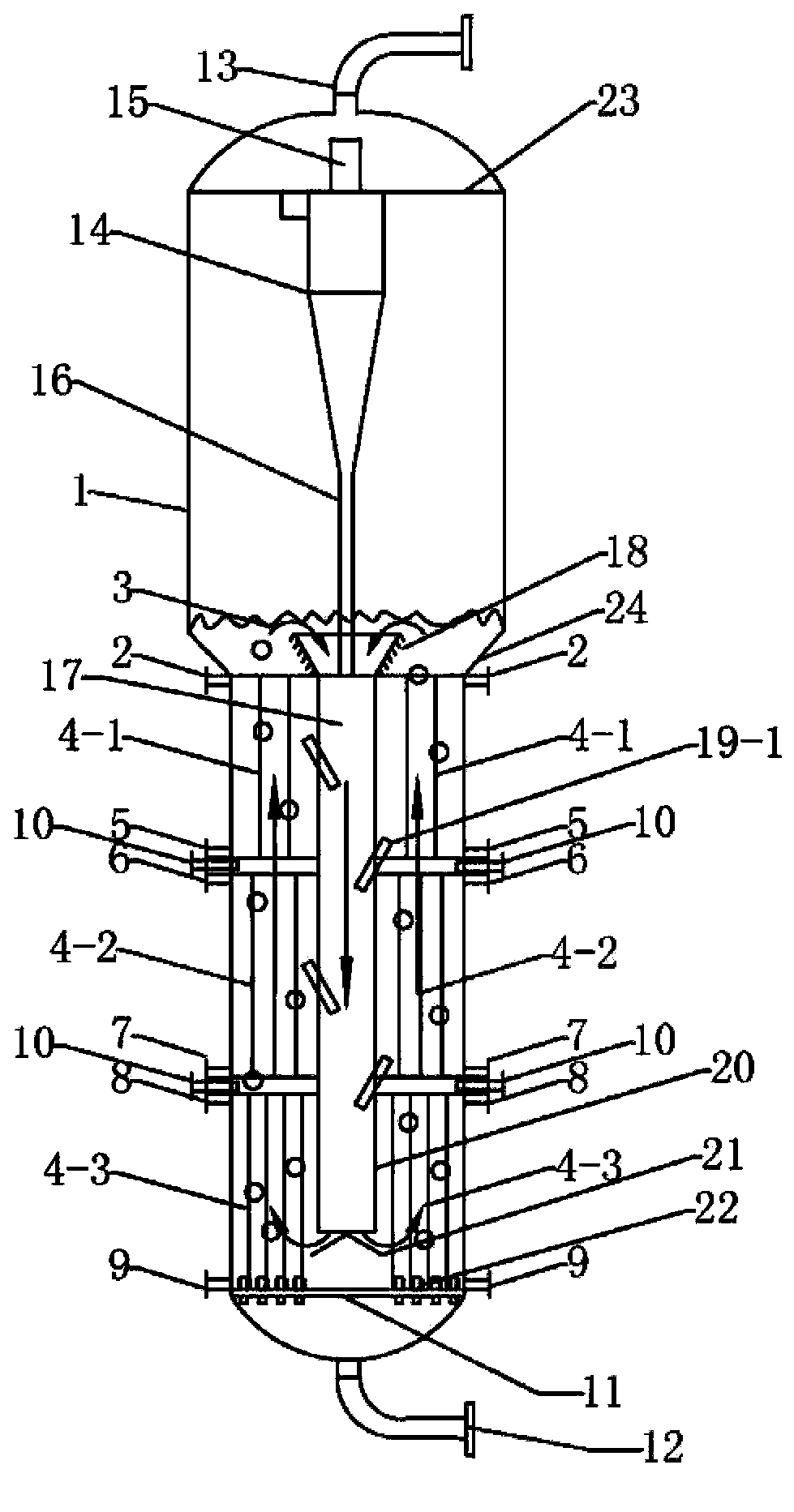

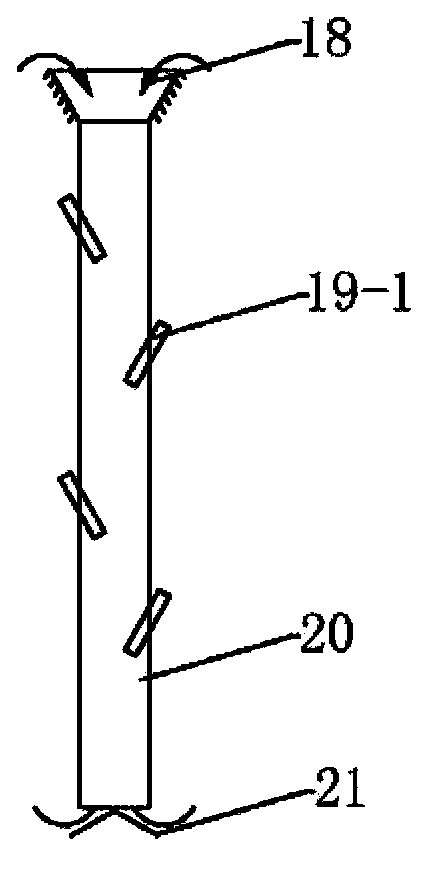

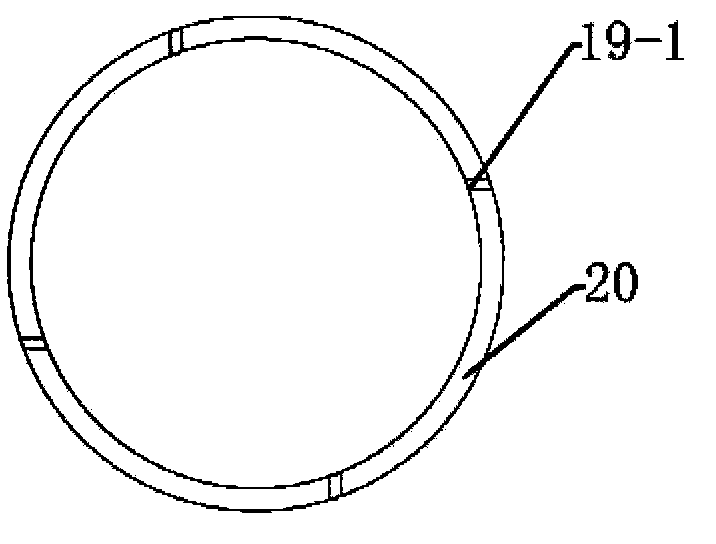

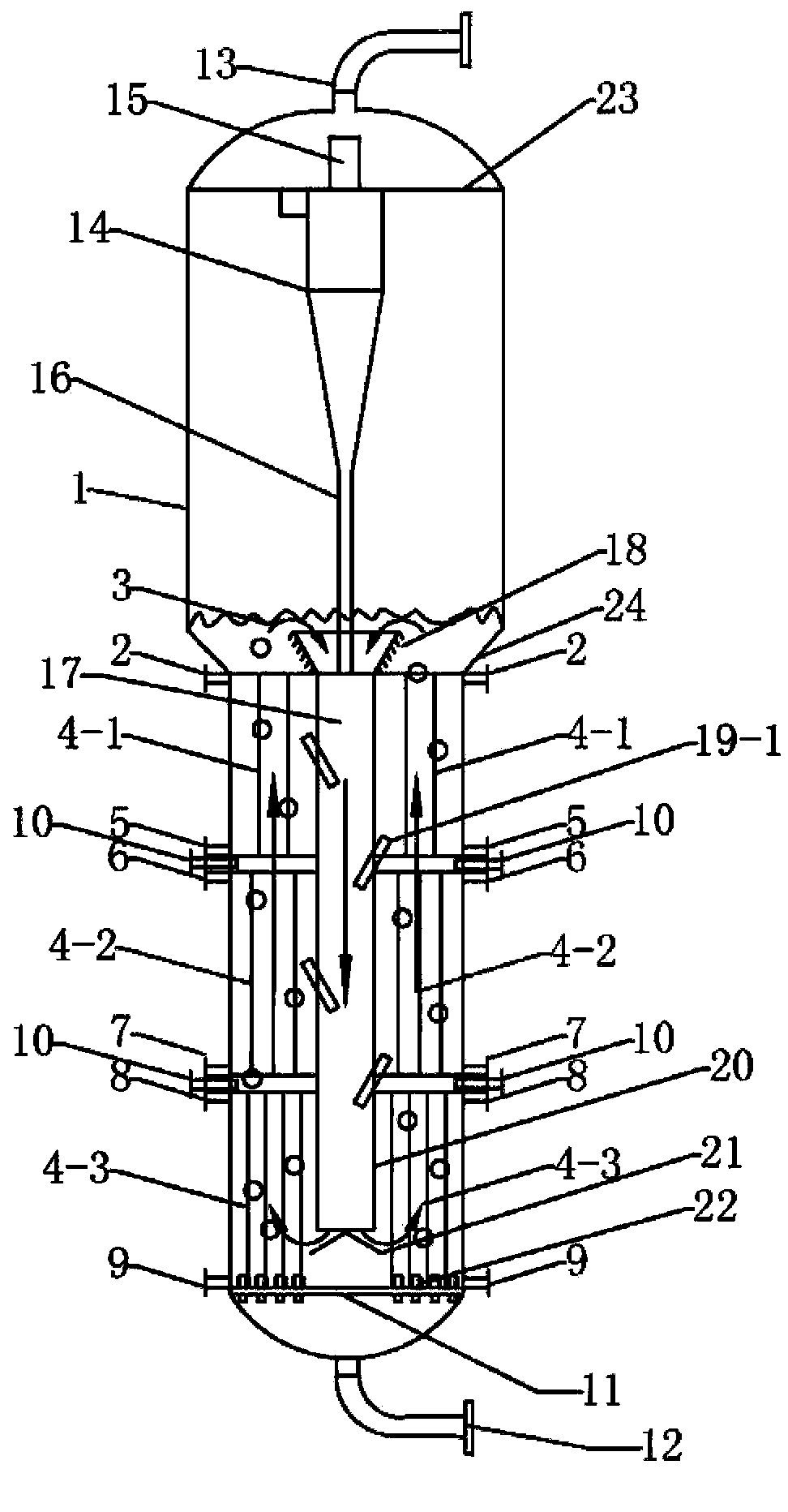

Built-in micro-interface unit enhanced reaction system for producing PTA through PX and process thereof

ActiveCN111389314ASolve the contradiction of not being able to withstand high temperature oxidation conditionsReduce energy consumptionLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationAcetic acidEthylic acid

The invention provides a built-in micro-interface unit enhanced reaction system for producing PTA through PX and a process thereof. The system comprises a reactor and a micro-interface unit arranged in the reactor. The reactor comprises a shell, an inner barrel concentrically arranged in the shell, and a circulating heat exchange device partially arranged outside the shell; wherein the bottom endof the inner cylinder is connected to the inner bottom surface of the shell in a closed manner, the top end of the inner cylinder is open, an area between the shell and the inner cylinder is a first reaction area, a second reaction area and a third reaction area are sequentially arranged in the inner cylinder from top to bottom, and the circulating heat exchange device is respectively connected with the inner cylinder and the micro-interface unit. According to the method, the problems that a large amount of reaction solvent acetic acid is wasted at high temperature and high pressure and a product TA cannot be taken out in time in the existing process of producing PTA through PX are effectively solved, so that the energy consumption is greatly reduced, an acetic acid solvent is saved, and the reaction efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

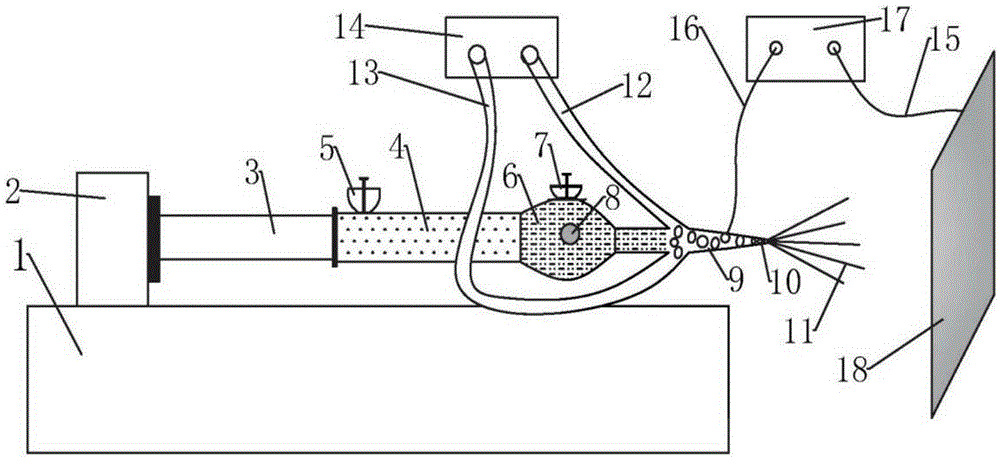

Air Bubble electrostatic spinning device

InactiveCN105274634AShorten the timeEnsure mixing uniformityFilament/thread formingEngineeringAir bubble

The invention provides an air bubble electrostatic spinning device. The air bubble electrostatic spinning device comprises a liquid storage tube, a mixing tube, an air bubble tube and an electrostatic generator; the liquid storage tube is connected with the mixing tube; the mixing tube is connected with the air bubble tube; the electrostatic generator is arranged at the tail end of the air bubble tube; a liquid adding groove is arranged above the liquid storage tube; a feeding groove is arranged above the mixing tube; a spinning solution and an additive can be added in a spinning process at any time; a mixing device is arranged in the mixing tube; air blowing tubes are arranged at two sides of the air bubble tube; after being injected into the liquid storage tube through the liquid adding groove, the spinning solution enters the mixing tube; the additive is added through the feeding groove; the spinning solution and the additive are mixed evenly; the mixture enters the air bubble tube; the spinning solution which forms air bubbles is converted into jet flows at the tail end of the air bubble tube through static electricity; the jet flows are ejected; and ultimately, nanofibers can be formed. Thus, spinning time after the spinning solution and the additive are mixed together can be shortened, and the uniform mixing and stability of the original spinning solution and the additive can be ensured.

Owner:SUZHOU UNIV

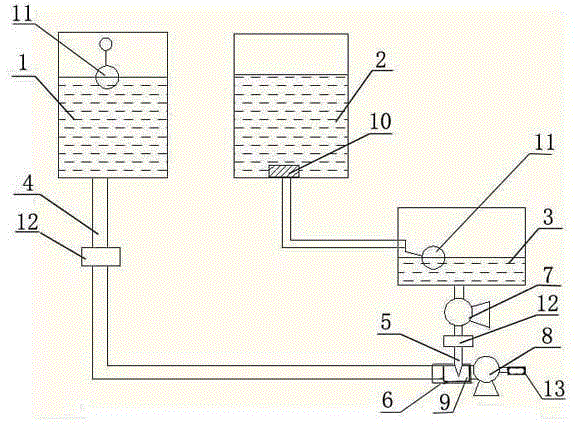

Emulsification device and emulsification method

InactiveCN105582828AAccurate ejection volumeAccurate control of ejection volumeFlow mixersMixing methodsEmulsionEngineering

The invention provides an emulsification device and an emulsification method. The emulsification device comprises a water tank, an emulsifier dispensing tank, a water pipe, an emulsifier conveyer pipe, a proportioner, an emulsifier pump and a transfer pump. The water tank is communicated with the proportioner through the water pipe. The emulsifier dispensing tank passes through the emulsifier pump through the emulsifier conveyer pipe to be communicated with a water distribution pipe of the proportioner. The emulsifier conveyer pipe is vertically inserted into the water distribution pipe in the inflow direction. An outlet end is positioned at the middle-lower part of the water distribution pipe, and diameter of the outlet end is small. An outlet of the proportioner is communicated with the transfer pump. Height in the vertical direction of the water tank and the emulsifier dispensing tank is higher than height of the proportioner. By the emulsification method, a uniformly-mixed emulsion can be prepared continuously. By the device and the method, continuous emulsification is realized, and the emulsification effect can reach the level of an emulsification homogenizer in the prior art. The device and the method have efficiency and emulsification quality, and have a good application prospect.

Owner:曾小强 +1

Method for carrying out slurry bed reaction

ActiveCN103962067APromote circulationEasy to separateLiquid hydrocarbon mixture productionChemical/physical processesSpray nozzleProduct gas

The invention relates to a method for carrying out a slurry bed reaction. The method comprises that: a) a gaseous component is introduced into a slurry bed reactor to make the gaseous component rise, concurrently a slurry is driven to rise along with the rising gaseous component, and the gaseous component reacts in the slurry; b) the gaseous product of the reaction and the unreacted gaseous component rise and leave a slurry bed layer (3), at least a part of the slurry enters a diversion pipe (17) from the upper portion opening of the diversion pipe (17), flows downward along the diversion pipe (17), outflows from the lower portion outlet of the diversion pipe (17), and enters an annular space, and at least a spraying nozzle sprays the gas, the liquid or the slurry; and (c) the steps (a) and (b) are repeatedly performed. With the method, the mass transfer and the heat transfer in the slurry bed reaction system can be promoted.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +3

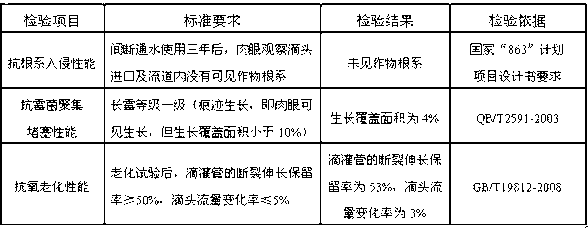

Special cooper root removing agent for underground drip irrigation, and production method thereof

ActiveCN102977442AImprove ductilityImprove corrosion resistanceClimate change adaptationWatering devicesSustainable developmentWater source

The present invention relates to a special cooper root removing agent for underground drip irrigation. The special cooper root removing agent comprises the following components, by weight, 40-50% of injection molding grade high density polyethylene, 15-20% of low density polyethylene, 18-25% of high pressure linear low density polyethylene, 0.25-0.3% of a biological aging inhibitor, 8-10% of copper powder and 3-5% of color masterbatch. The present invention further discloses a production method for the root removing agent. The finished product has excellent performances of root system intrusion blockage resistance, fungal accumulation blockage resistance, oxidation aging resistance and the like so as to provide far-reaching theoretical guidance and practical significances for promotion of China's underground drip irrigation technology researches and product industrialization developments, especially for containment of ecological environment deterioration in northwest drought areas and effective water source utilization, and achievement of sustainable economic and social development.

Owner:GANSU DAYU WATER SAVING +4

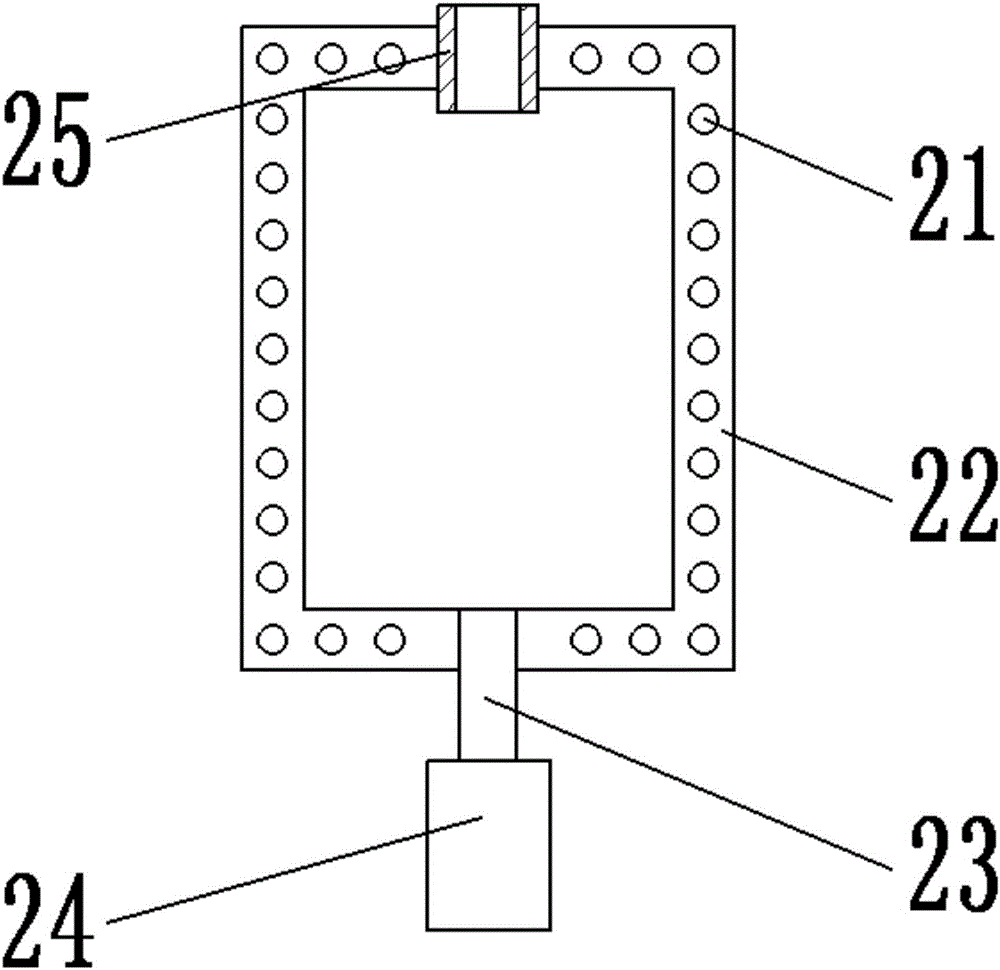

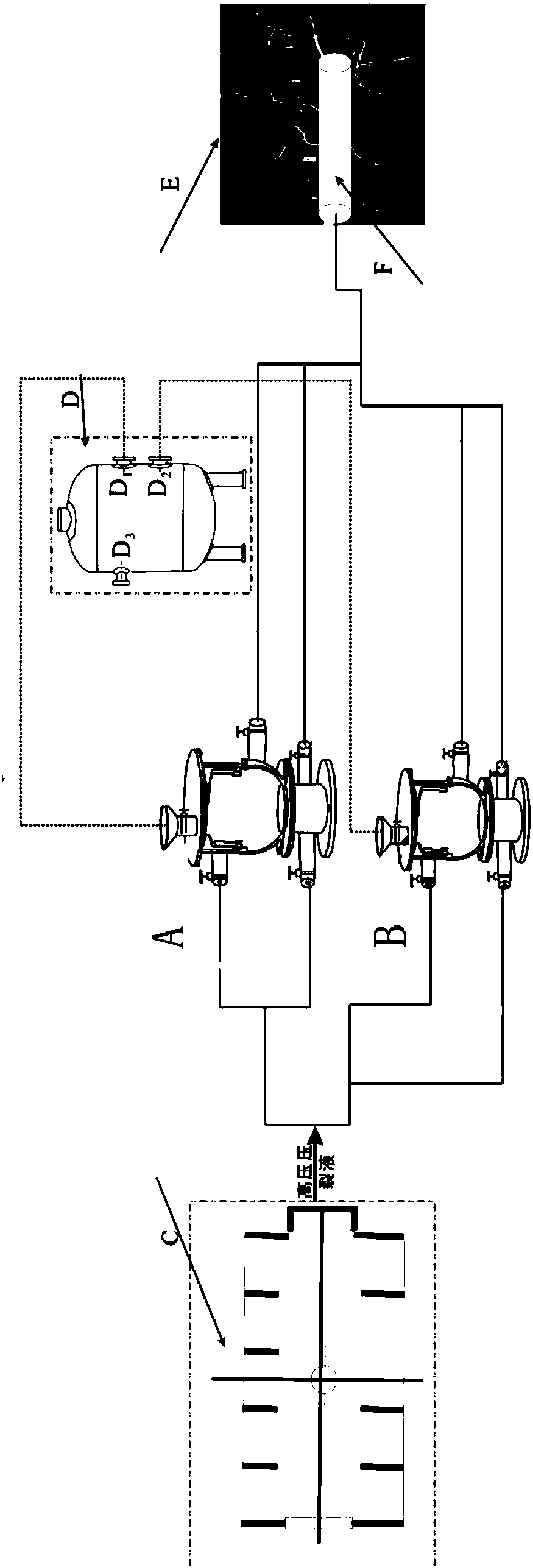

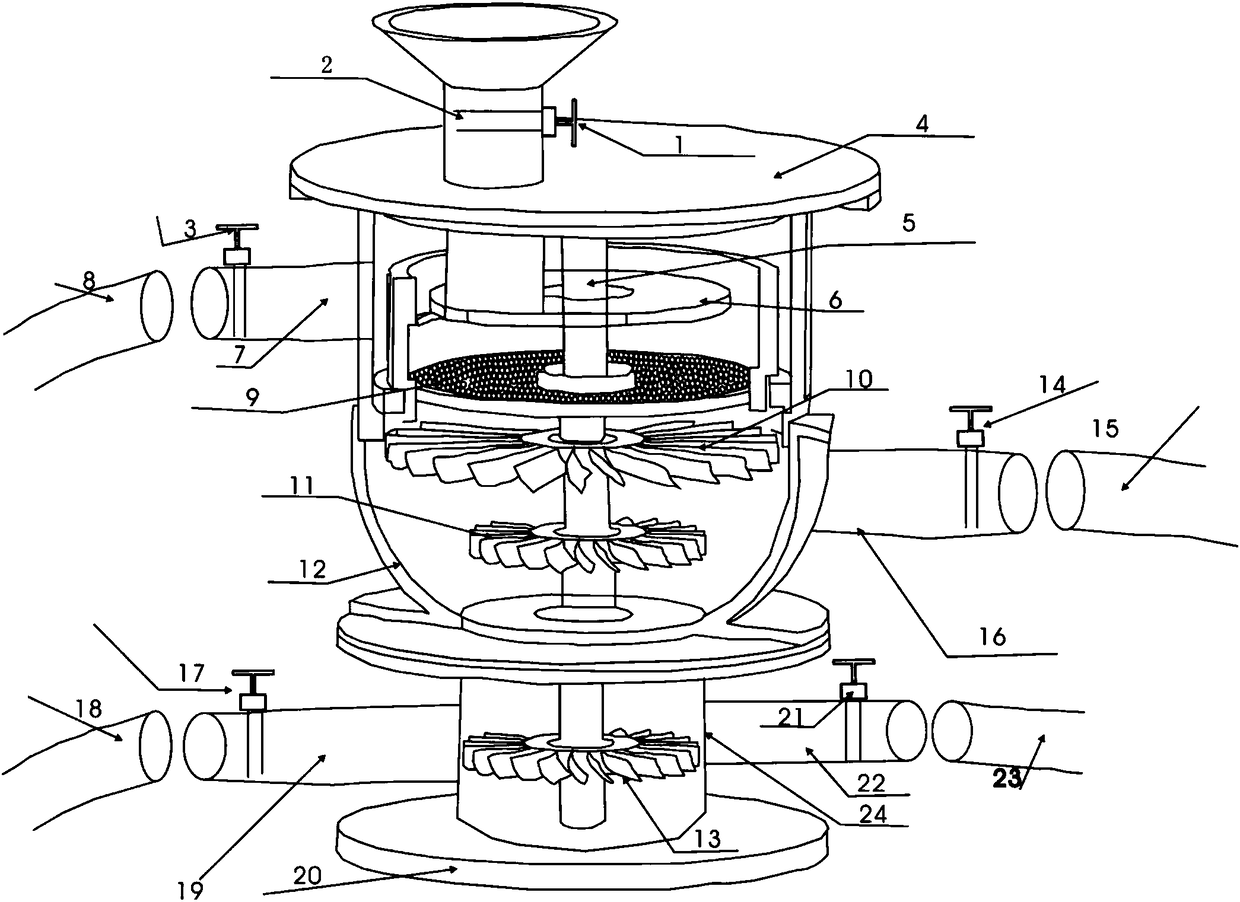

Coal mine downhole hydraulic fracturing high-pressure sealing continuous aggregate adding system and method

InactiveCN108397180AAdjustable openingAccurately control the ratioFluid removalGas removalFracturing fluidHydraulic fracturing

The invention provides a coal mine downhole hydraulic fracturing high-pressure sealing continuous aggregate adding system and method. The coal mine downhole hydraulic fracturing high-pressure sealingcontinuous aggregate adding system comprises at least one aggregate adding device, a high-pressure fracturing pump group and a pneumatic aggregate feeding tank. The pneumatic aggregate feeding tank isconnected to the aggregate adding device and can provide aggregate simultaneously. The pneumatic aggregate feeding tank further provides the aggregate in the aggregate feeding tank to a sand mixing system quantitatively at a fixed speed through a downhole air supply system. The high-pressure fracturing pump group is connected to the aggregate adding device to provide pressure. The aggregate adding device is connected to a fracturing hole in a coal seam of a fracturing object, and the continuous work of sand fracturing is realized in an alternate transmission mode. Therefore, high-pressure fracturing fluid is supplied by a large displacement and high-pressure fracturing pump group in the front-end downhole during the construction process, and is conveyed by two ways through high-pressure resistant pipes, the mixed power of aggregate and fracturing fluid is provided in one way; the other way enters an aggregate mixing chamber and is mixed with the aggregate, so that it is guaranteed that the fracturing fluid and the aggregate are evenly mixed, and the mixture ratio of the aggregate and fracturing is ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Preparation method of low-cost high-performance lost foam casting coating

The invention discloses a preparation method of a low-cost high-performance lost foam casting coating. The lost foam fireproof coating is prepared by taking 20-25% of quartz powder, 20-25% of bauxite and 50-60% of steel-making slag to prepare composite fireproof aggregate with the combination of a suspending agent, a binding agent and other auxiliary materials, and the components are in a synergistic effect. Under the condition that the cost of the fireproof aggregate is lowered and furthermore the overall cost of the coating is lowered, the high-performance lost foam casting coating which is high in fire resistance, suspension and air permeability is obtained.

Owner:遵义金业机械铸造有限公司

Preparation method of ternary cathode material

ActiveCN103227314AIncrease oxidation stateShort manufacturing timeCell electrodesNickel saltManganese

The invention discloses a preparation method of a ternary cathode material. The method includes: dissolving a lithium salt, a nickel salt, a manganese salt and a cobalt salt in an alcohol compound solvent according to certain mole ratio, then stirring them and introducing air or oxygen continuously, adding concentrated ammonia water or ammonia, raising the temperature to 80-120DEG C, and conducting roasting in a high temperature furnace at 800-950DEG C for 6-24h, thus obtaining submicron scale particles of the ternary cathode material LiNi1 / 3Mn1 / 3Co1 / 3O2, LiNi0.4Mn0.4Co0.2O2, LiNi0.5Mn0.3Co0.2O2 and LiNi0.7Mn0.15Co0.15O2. For the preparation method, as manganese ions and cobalt ions are subjected to pre-oxidation in a precursor preparation process, the oxidation states of manganese ions and cobalt ions in the precursor are improved, low temperature oxidation at 350-450DEG C is not needed, and the product preparation time is greatly shortened. The method does not introduce hetero-metal ions in the preparation process, and the preparation process is simple and fast. The prepared product particles are uniform in size, which ranges from 200 to 300nm, and the particles are uniformly dispersed.

Owner:嘉峪关大友嘉能精碳科技股份有限公司

Polycarboxylic acid hyper-dispersant for dispersing lithium iron phosphate precursor

ActiveCN102504127AEnsure mixing uniformityAvoid formingCell electrodesLithium iron phosphateOrganosolv

The invention discloses a preparation method of a polycarboxylic acid hyper-dispersant for dispersing lithium iron phosphate precursors, which comprises the following steps: firstly dissolving isoamylene alcohol polyoxyethylene ether in water, adding an oxidant solution, stirring uniformly; than dropwisely adding a mixed solution of a reducing agent and a chain transfer agent, and a comonomer solution respectively for polymerization; finally, adding an alkaline regulator for neutralization and curing so as to obtain the polycarboxylic acid hyper-dispersant for dispersing lithium iron phosphate precursors. Aiming at the characteristics that the system is weak acidic during the dispersion of lithium iron phosphate precursors and organic solvents such as ethanol and the like are used as a dispersing carrier, the hyper-dispersant prepared in the invention can effectively prevent electrode active materials in slurry from forming secondary aggregates, does not introduce impurity ions which are not contained in the precursors, thus ensures the mixing uniformity of the precursors, and further allows the preparation of lithium iron phosphate products with excellent performance.

Owner:NANJING RUIDI HIGH TECH

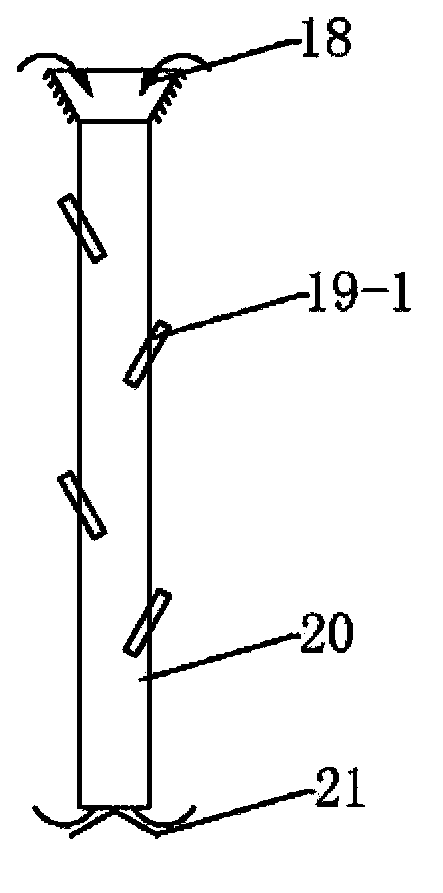

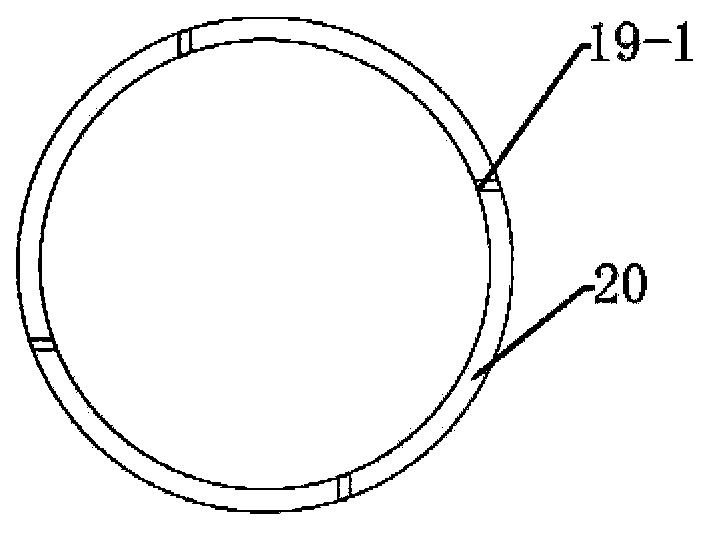

Slurry bed reactor

ActiveCN103962069APromote circulationEasy to separateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSpray nozzleProcess engineering

The present invention relates to a slurry bed reactor, which comprises a reactor housing (1) and parts arranged above the housing (1) or inside the housing (1), wherein the parts comprise an upper portion outlet (13 ), a diversion pipe (17) and a lower portion inlet (12), the diversion pipe (17) is vertically arranged in the housing and is provided for allowing a slurry bed slurry to inflow from the upper portion opening of the diversion pipe (17), the lower portion inlet (12) and a space positioned in the housing and provided for accommodating the slurry bed form a fluid communication, and the upper portion outlet (13) is provided for exporting a gas substance accommodated in the housing. The slurry bed reactor is characterized in that at least a spraying nozzle is arranged in the diversion pipe (17), and the opening direction of the spraying nozzle is downward or obliquely downward. The slurry bed reactor can be used for carrying out the slurry bed reaction such as the Fischer-Tropsch reaction so as to achieve efficient internal circulation in the reaction system.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +3

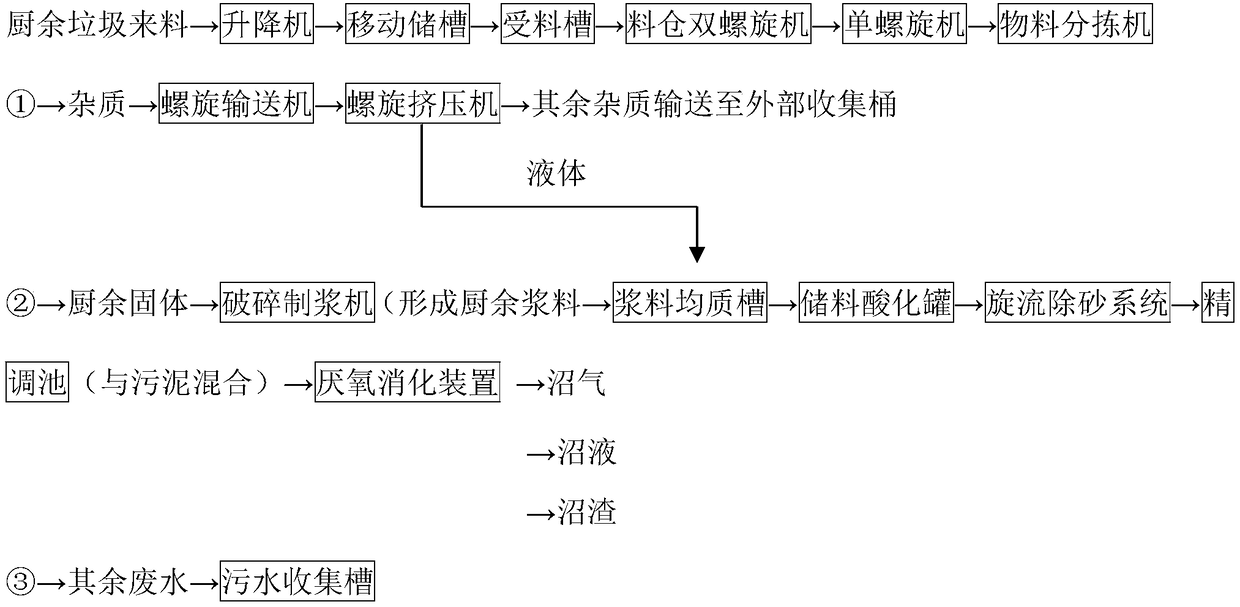

Kitchen waste disposal system and method

PendingCN109332366ASufficient alkalinityEnsure mixing uniformityWaste processingSolid waste disposalEnergy recoveryHandling system

The invention discloses a kitchen waste disposal system. The kitchen waste disposal system comprises a mobile storage tank. The lower portion of the movable storage tank is provided with a material receiving tank. The bottom of the material receiving tank is sequentially provided with a material bin double screw conveyor and a material bin single screw conveyor. An outlet of the material bin single screw conveyor is connected with a material sorting machine. The material sorting machine is connected with a screw conveyor and a crushing pulper. An outlet of the screw conveyor is connected witha screw extruder. The crushing pulper is sequentially connected with a pulp homogenizing tank, a material storage acidification tank, a cyclone degritting system, a fine adjustment tank and an anaerobic digestion tank. According to the system, kitchen waste is combined with sludge for disposal, the defect of shortage of organic matter of the sludge can be overcome, the ratio of carbon to nitrogencan be used for adjustment of microorganisms, the anaerobic fermentation efficiency and the gas production rate are increased, thus, the gas production efficiency is improved, the anaerobic digestioncost is reduced, the economic benefits of anaerobic digestion are increased, and the system becomes an important and effective means of efficient energy recovery.

Owner:大连东泰有机废物处理有限公司 +1

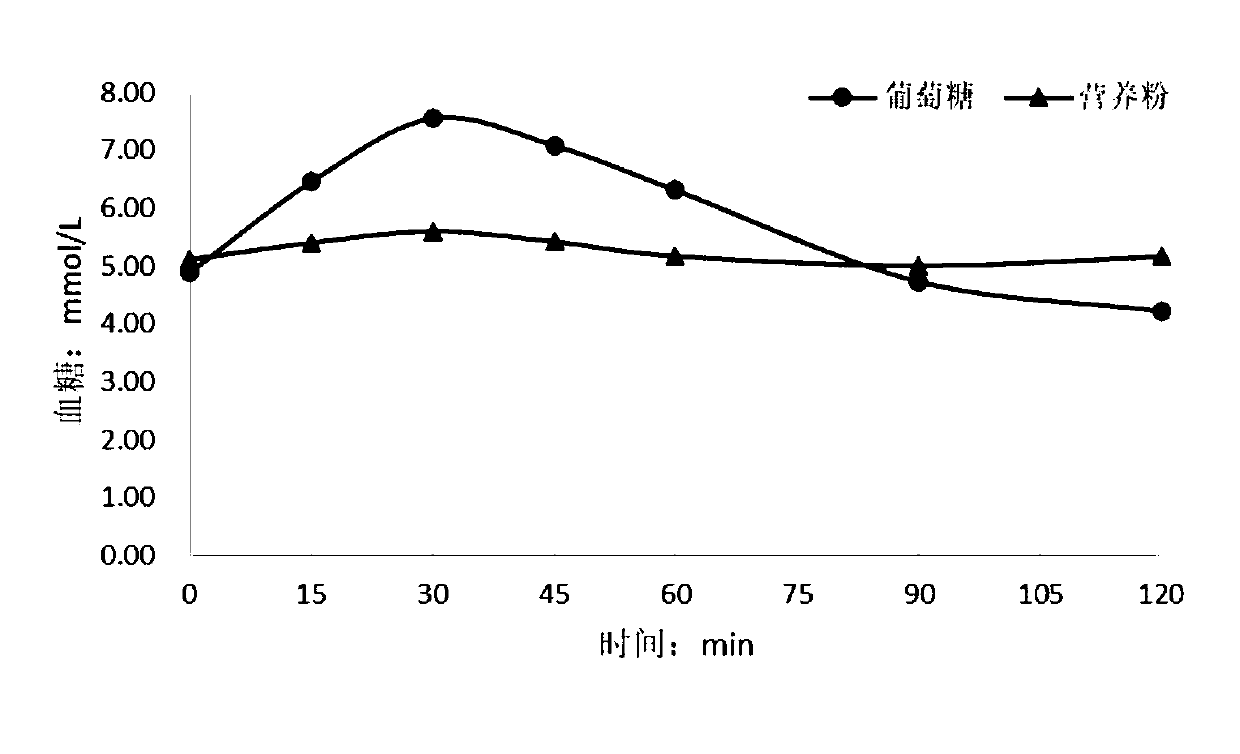

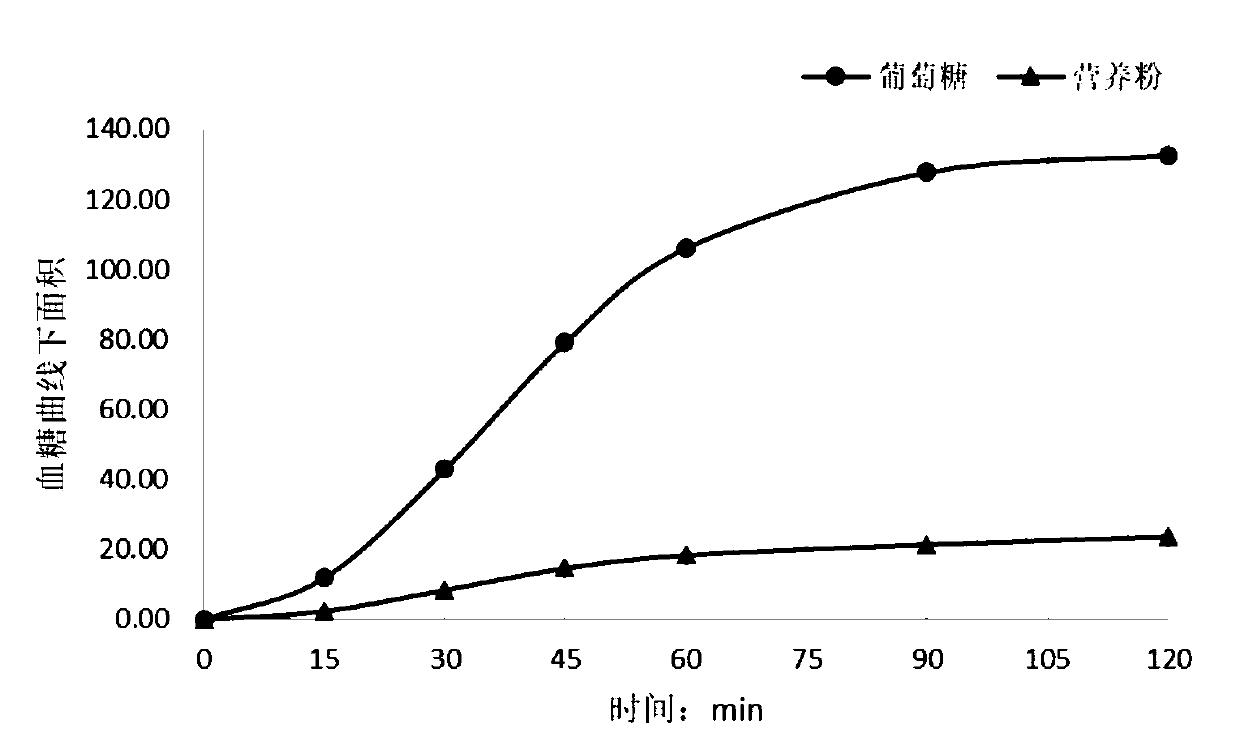

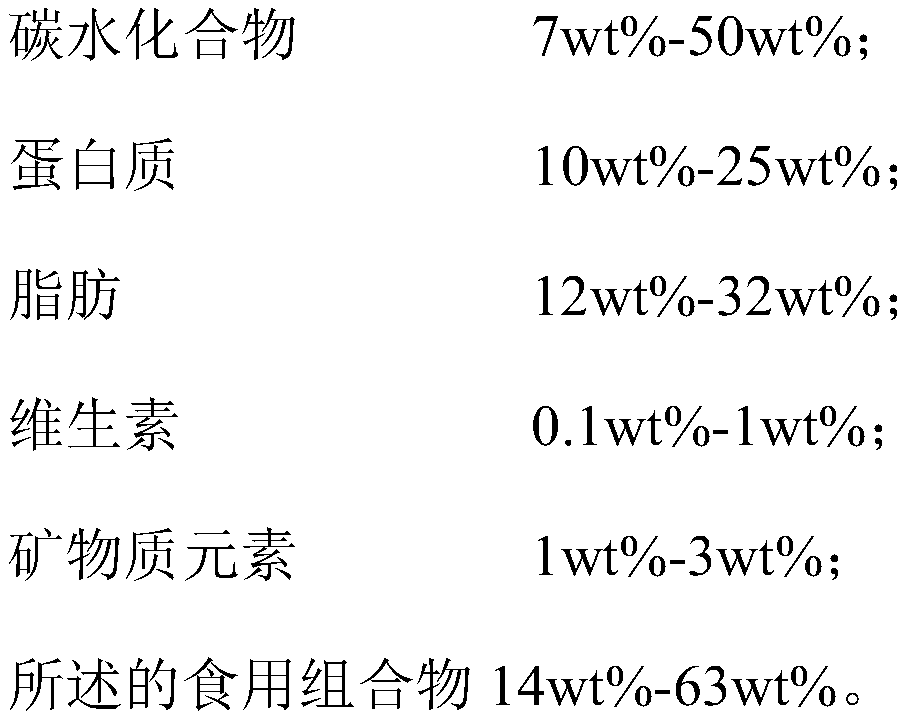

Edible composition, low glycemic index nutrition powder and preparation method thereof

ActiveCN111011862AImprove poor mobilityImprove liquidityFood processingNatural extract food ingredientsBiotechnologyLow glucose

The invention discloses an edible composition, a low glycemic index nutrition powder and a preparation method of the edible composition and the low glycemic index nutrition powder. The edible composition comprises the following components in parts by weight: 10-16 parts of isomaltulose and 4-9 parts of resistant dextrin; isomaltulose and resistant dextrin are adopted for compounding and using under a specific ratio, so that not only the liquidity of the prepared low glycemic index nutrition powder can be obviously improved, the quality uniformity of the nutrition powder is further improved, but also the brewing performance of the nutrition powder is improved, complete dissolving can be realized in a short nutrition powder brewing time period, no caking or precipitating is caused; and in addition, the taste and flavor of the nutrition powder can be improved, the preparation process is simple, and the raw materials are easily available, so that the nutrition powder with low GI, balancednutrition, good fluidity, good reconstituability and good flavor is suitable for patients with diabetes, and is prepared.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Precoated sand used for laser sintering and nano 3D printing technology and preparation method thereof

ActiveCN108296417AAffect qualityGuaranteed mixing effectAdditive manufacturing apparatusTransportation and packagingFiberSuperalloy

The invention relates to precoated sand and a preparation method thereof and in particular to the precoated sand used for a laser sintering and nano 3D printing technology and the preparation method thereof. The precoated sand used for the laser sintering and nano 3D printing technology comprises the following raw material components, in part by weight, 80-90 parts of silica sand, 30-45 parts of high-temperature alloy fiber, 6-8 parts of urotropin, 30-35 parts of resin, 30-35 parts of refractory clay, 30-50 parts of nano negative ion powders, 12-18parts of nano carbon powders and 5-8 parts ofoxalate. The toughness and the tensile strength of the precoated sand are improved by adding the high-temperature alloy fiber; the amount of pin holes and nitrogen holes, which are generated by a highgas evolution of the precoated sand, of a precoated sand casting to be printed can be reduced by using the high-strength and low-gas-volution resin; and the amount of free phenol in the precoated sand is reduced by adding the oxalate, so that the environment can be protected and the gas hole disadvantage of the casting can be reduced, and therefore the accuracy of 3D printing can be improved andthe surface quality of the casting can be guaranteed.

Owner:LIUZHOU LIUJING TECH CO LTD

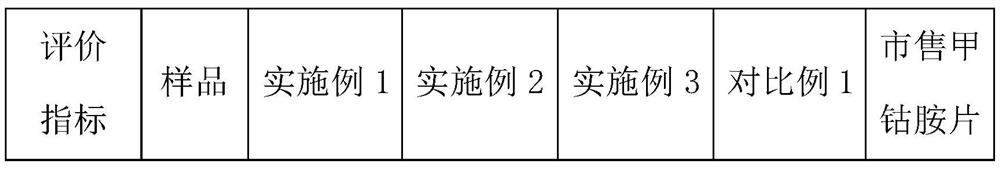

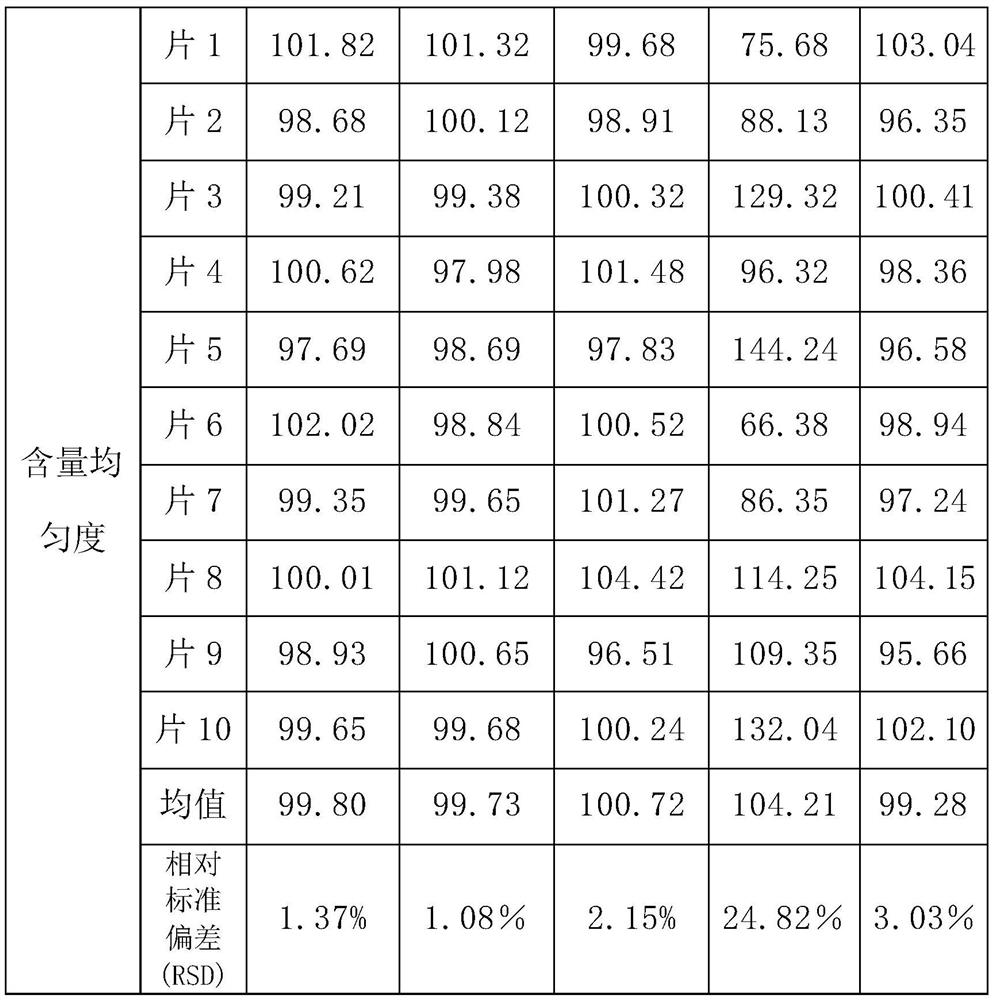

Mecobalamin tablet and preparation method thereof

PendingCN112022826AGood content uniformityImprove stabilityOrganic active ingredientsNervous disorderCelluloseFiber

The invention discloses a mecobalamin tablet and a preparation method thereof. The mecobalamin tablet comprises a plain tablet and a film coating layer; the mass ratio of the plain tablet to the filmcoating layer is 100:510; the plain tablet comprises the following components in percentage by weight: 0.5% of mecobalamin, 40% to 70% of directly-compressed lactose, 15% to 45% of micro-crystalline fiber, 0 to 15% of corn starch, 0 to 15% of pregelatinized starch, 0 to 2% of stearic acid and 0 to 2% of a lubricant; the film coating layer comprises the following components in percentage by weight:20% to 40% of hydroxypropyl methyl cellulose, 20% to 50% of polyethylene glycol; 10% to 35% of titanium dioxide; 1% to 15% of yellow iron oxide; and 1% to 15% of red iron oxide. The preparation method of the mecobalamin tablet disclosed by the invention is simple; a mecobalamin raw material medicine can be uniformly dispersed in a manner of sieving and mixing the mecobalamin raw material medicineand proper auxiliary materials; the phenomenon of aggregation of the raw material medicine is prevented by a mechanical force, the raw material medicine is fully adsorbed on the auxiliary materials,and then the raw material medicine is mixed with other auxiliary materials step by step to improve the content uniformity; The preparation method disclosed by the invention reduces the stability riskby adopting a powder direct-compression process, and further improves the stability of the preparation by adopting a high-shading-performance film coating material for coating.

Owner:湖北欣泽霏药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com