Concrete production system and production method thereof

A production system and concrete technology, applied in chemical instruments and methods, clay preparation equipment, mixing operation control, etc., can solve the problems of prolonging concrete mixing time, uneven mixing of concrete, and low quality grade of concrete, so as to shorten the mixing time, The effect of uniform size and improved quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

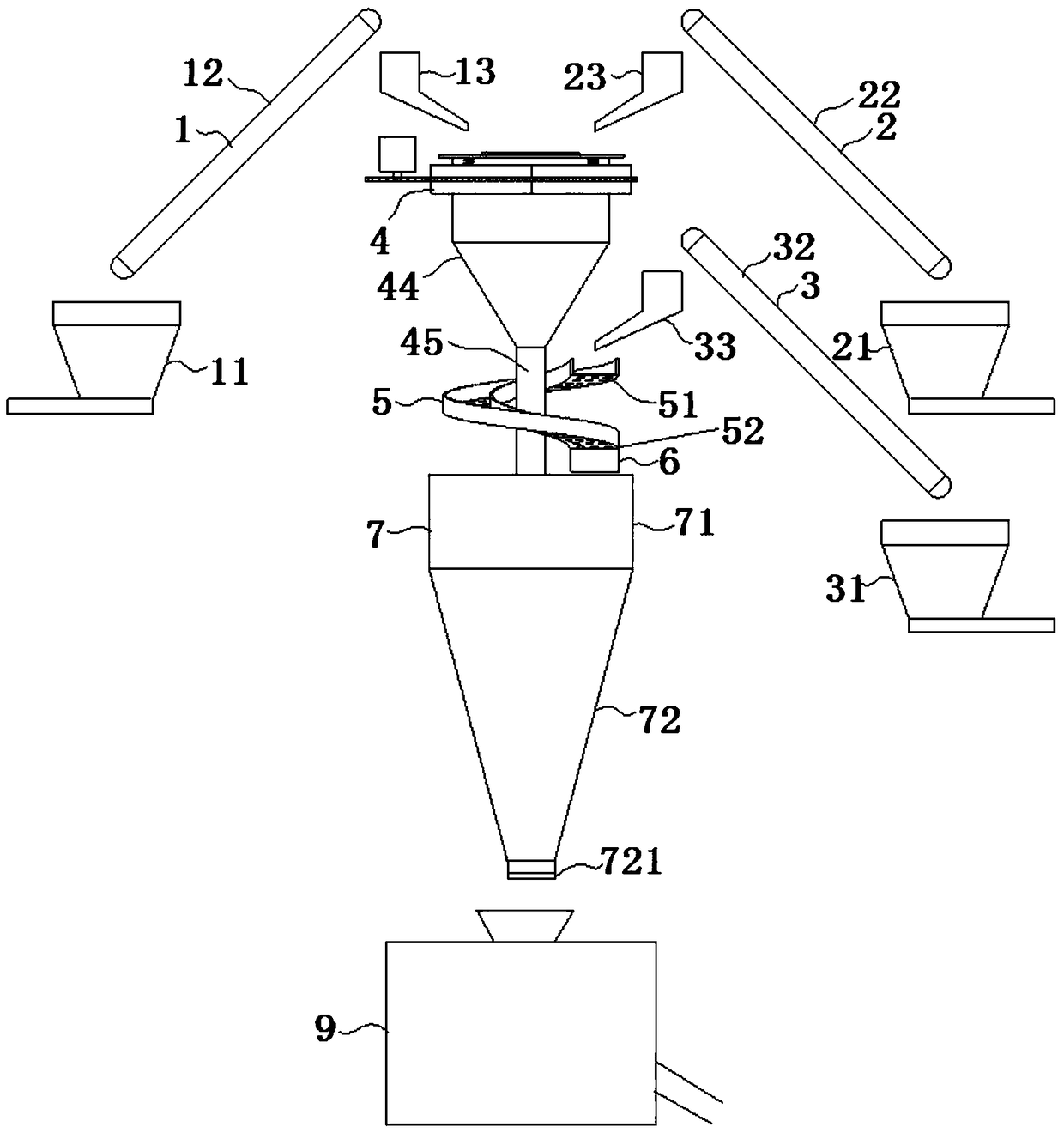

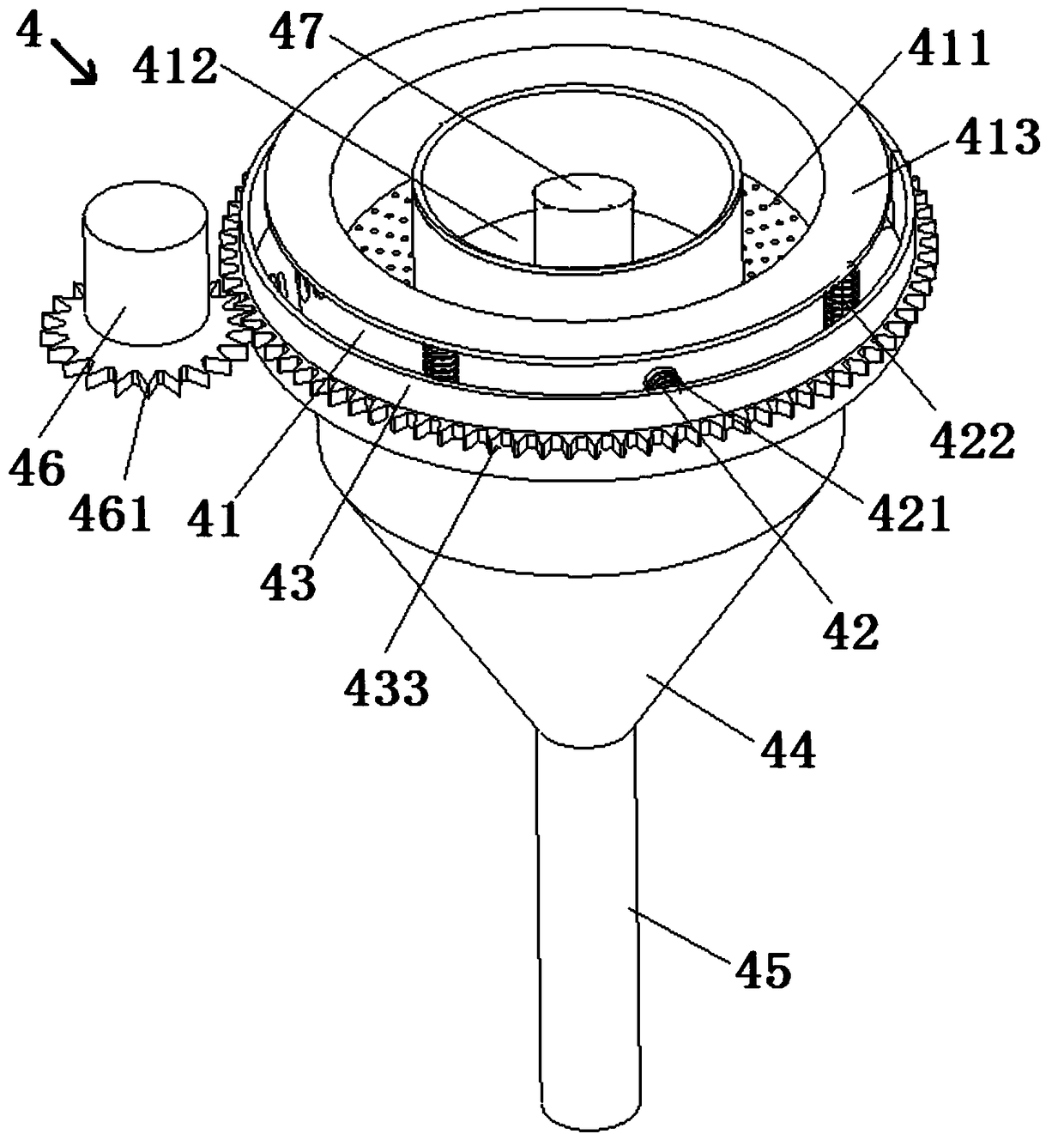

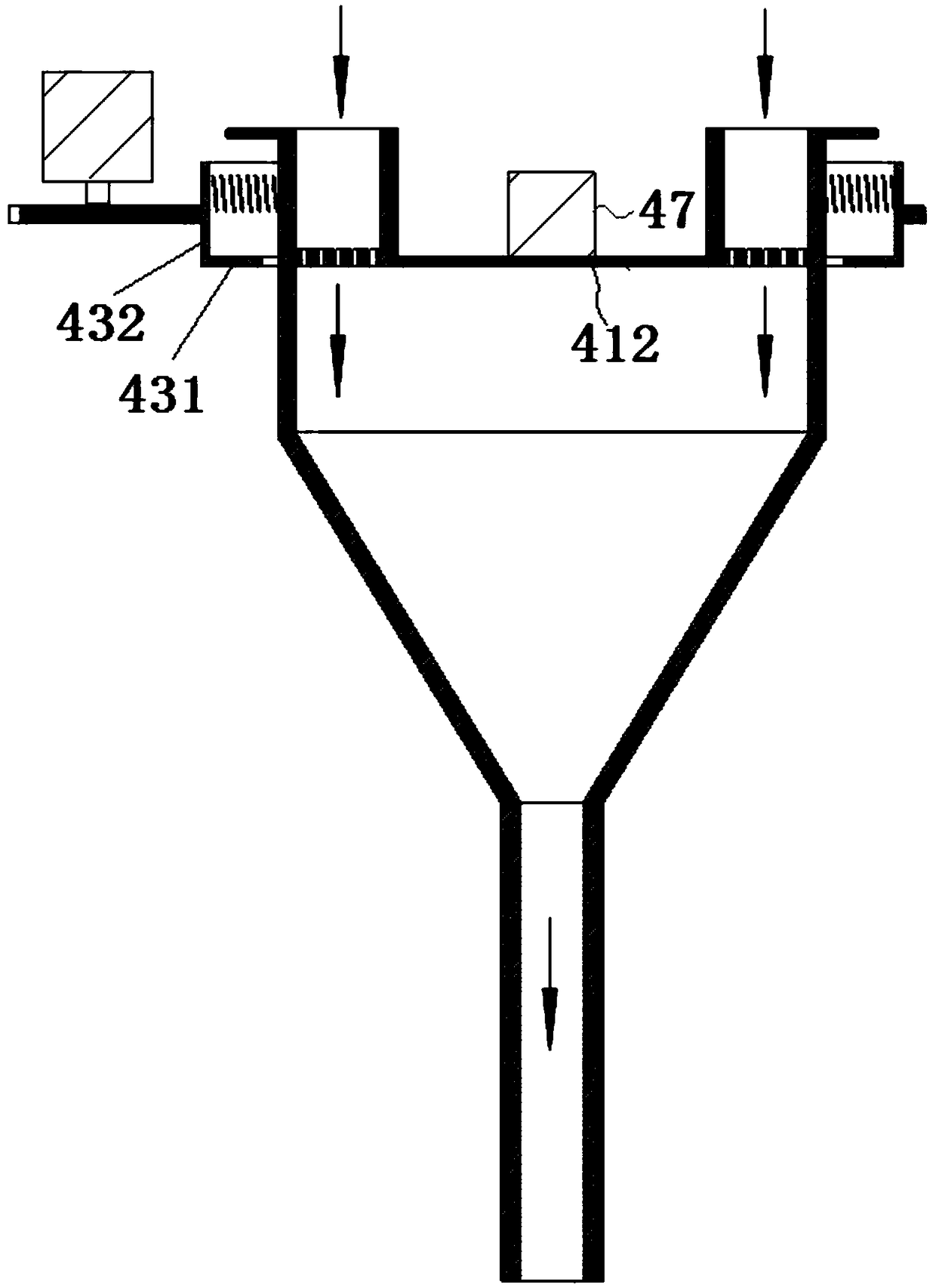

[0035] as attached figure 1 Shown, a kind of concrete production system comprises sand feeding device 1, cement feeding device 2, gravel feeding device 3, sand and mud mixing device 4, gravel screening screw guide chute 5, sand and mud gravel mixing device 7 and Concrete mixer 9; the sand feeding device 1 and the cement feeding device 2 are arranged symmetrically with respect to the sand and mud mixing device 4, and the sand feeding device 1 can supply the raw material sand required for concrete to the sand and mud mixing device 4, and the The cement supply device 2 can supply the raw material cement required for concrete to the sand and mud mixing device 4, and the sand and mud mixing device 4 can mix the supplied sand with the supplied cement; the sand and gravel mixing device 7 is arranged on the sand Just below the mud mixing device 4, the sand and mud mixing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com