Graphene modified vinyl acetate-maleic anhydride copolymer flame-retardant leather retanning agent preparation method

A vinyl acetate and graphene modification technology, applied in the field of leather chemicals, can solve the problems of weak double bond reactivity and low degree of copolymerization, and achieve the effects of improving quality grade, improving conductivity and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

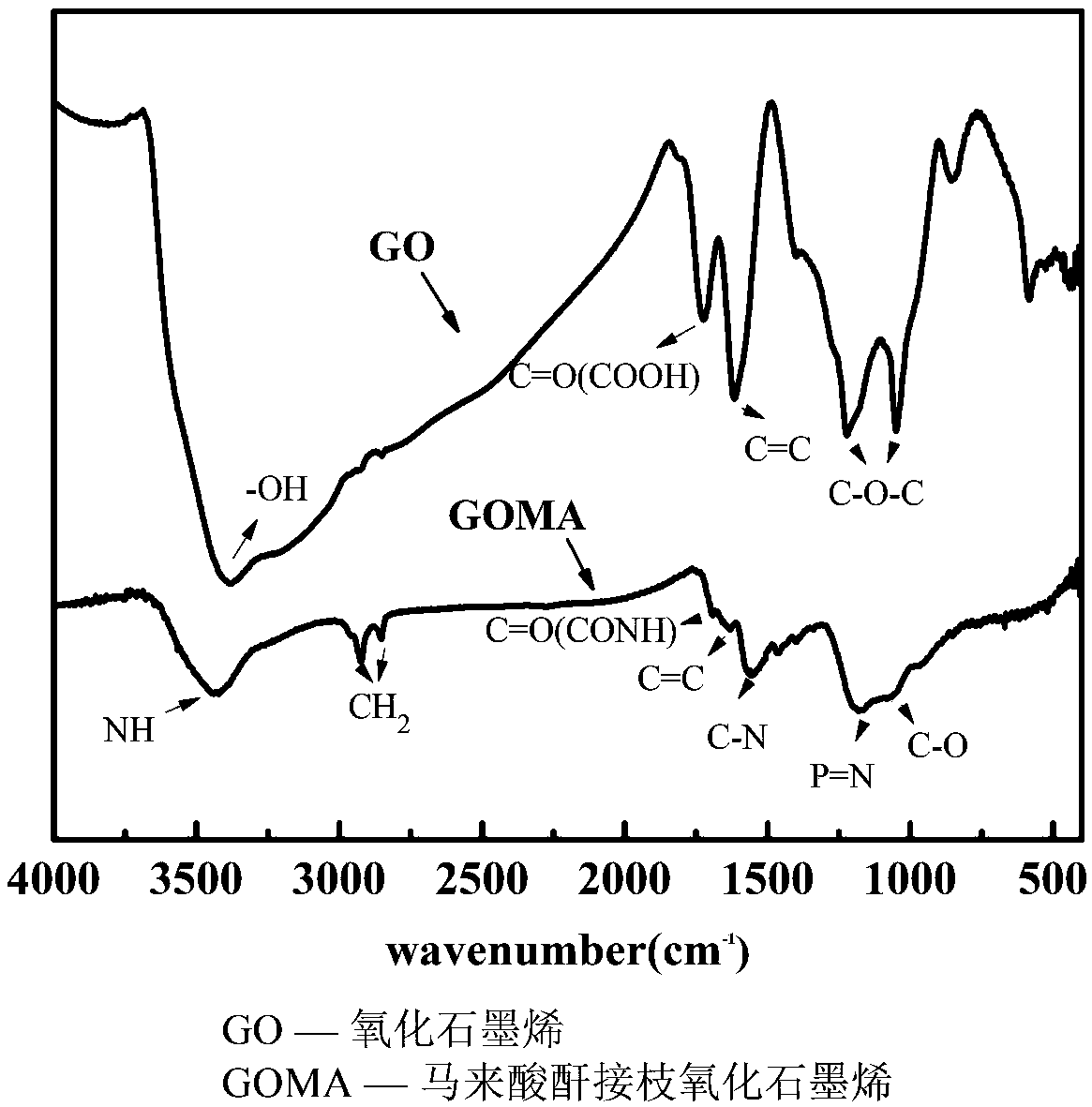

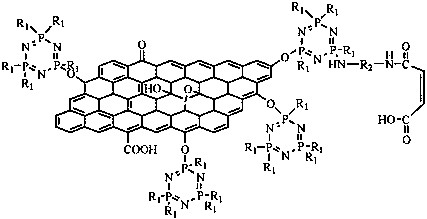

[0026] (1) Preparation of maleic anhydride grafted graphene oxide, in parts by weight

[0027] Add 1 part of graphene oxide and 150 parts of tetrahydrofuran into a 500 mL round-bottomed flask equipped with nitrogen protection device, mechanical stirring and constant pressure dropping funnel, and ultrasonically disperse for 1.0 h; add 6.0 parts of triethylamine, and use 10 Add 3.5 parts of hexachlorocyclotriphosphine cyanide dropwise into the reaction solution, react at 60 °C for 4-6 h, filter under reduced pressure, wash with absolute ethanol, and dry in vacuum; mix the dried product with 150 parts of tetrahydrofuran and ultrasonically disperse Add it back into the device, then add 3.0 parts of ethylenediamine and 6.0 parts of triethylamine dropwise to the system, react at room temperature for 2 h, filter under reduced pressure, wash with absolute ethanol, and dry in vacuum; then dry the product and 150 parts of tetrahydrofuran Mix and ultrasonically disperse and add to the de...

Embodiment 2

[0032] (1) Preparation of maleic anhydride grafted graphene oxide, in parts by weight

[0033]Mix 1 part graphene oxide with 150 parts N,N - Dimethylformamide was added to a 500 mL round bottom flask equipped with a nitrogen protection device, mechanical stirring and a constant pressure dropping funnel, ultrasonically dispersed for 1.0 h; 6.0 parts of triethylamine was added, and 10 parts of N,N - 3.5 parts of hexachlorocyclotriphosphorus cyanide diluted in dimethylformamide were added dropwise to the reaction solution, reacted at 60°C for 4-6 h, filtered under reduced pressure, washed with absolute ethanol, and dried in vacuum; the dried product and 150 parts of N,N -Dimethylformamide is mixed and ultrasonically dispersed and re-added to the device, and then 3.7 parts are added dropwise to the system 1,3 - Propylenediamine and 6.0 parts of triethylamine, reacted at room temperature for 2.5 h, filtered under reduced pressure, washed with absolute ethanol, and dried in vacuum;...

Embodiment 3

[0038] (1) Preparation of maleic anhydride grafted graphene oxide

[0039] Mix 1 part graphene oxide with 150 parts N,N - Dimethylacetamide was added to a 500 mL round bottom flask equipped with a nitrogen protection device, mechanical stirring and a constant pressure dropping funnel, ultrasonically dispersed for 1.0 h; 4.7 parts of pyridine was added, and 10 parts of N,N - 3.5 parts of hexachlorocyclotriphosphorus cyanogen diluted in dimethylacetamide were added dropwise to the reaction solution, reacted at 60°C for 4-6 h, filtered under reduced pressure, washed with absolute ethanol, and dried in vacuum; the dried product and 150 parts of N,N -Dimethylacetamide was mixed and ultrasonically dispersed and re-added to the device, and then 3.7 parts were added dropwise to the system 1,3 - Propylenediamine and 4.7 parts of pyridine, reacted at room temperature for 2.5 h, filtered under reduced pressure, washed with absolute ethanol, and dried in vacuum; then the dried product an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com