Patents

Literature

67results about How to "Realize full inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

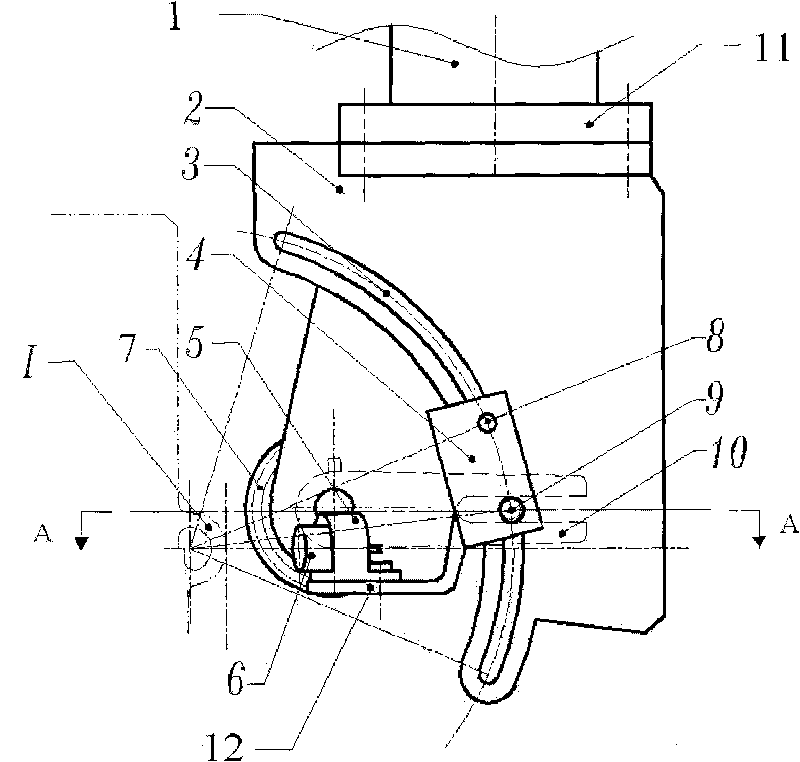

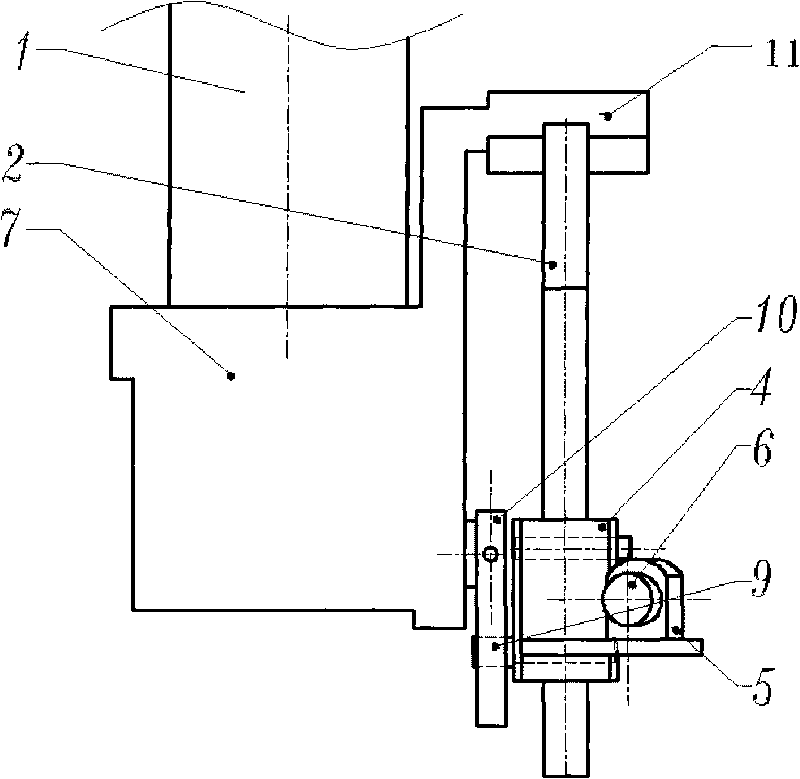

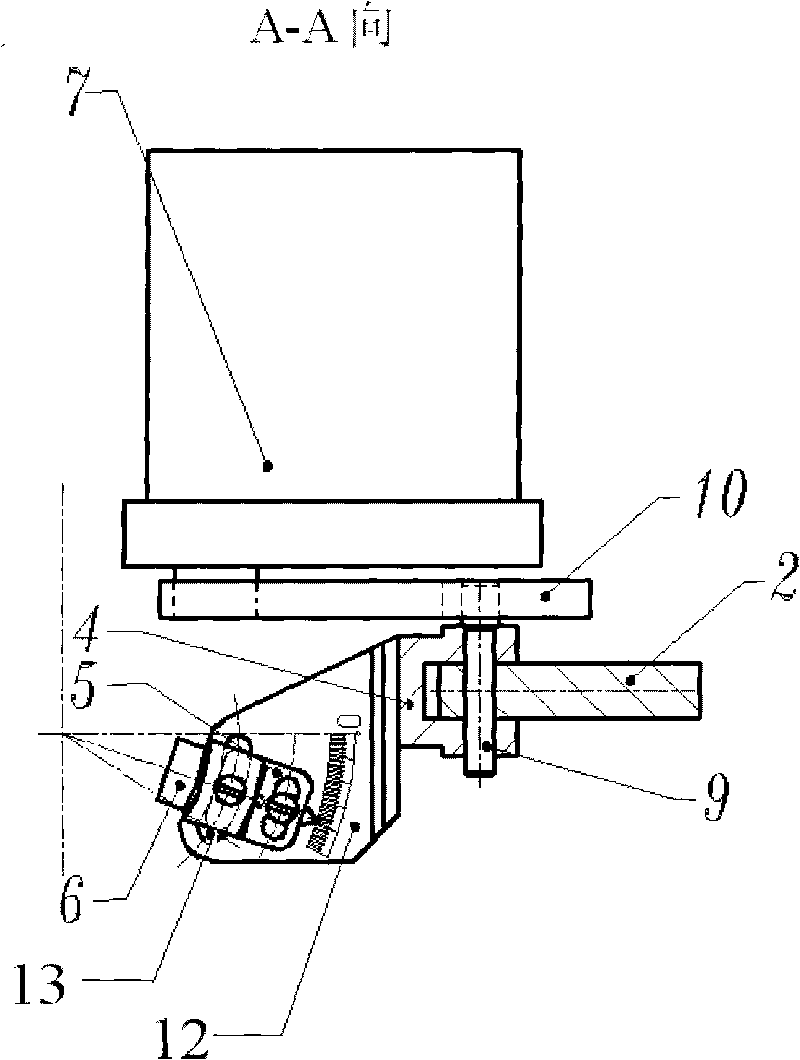

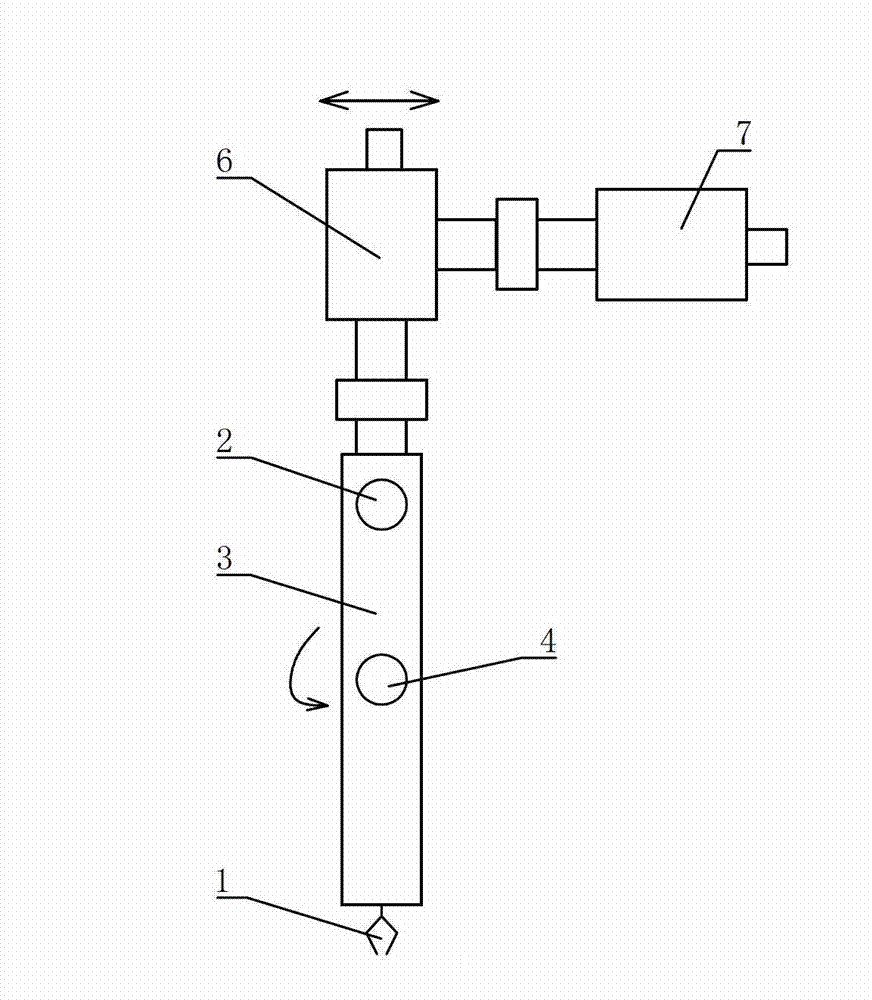

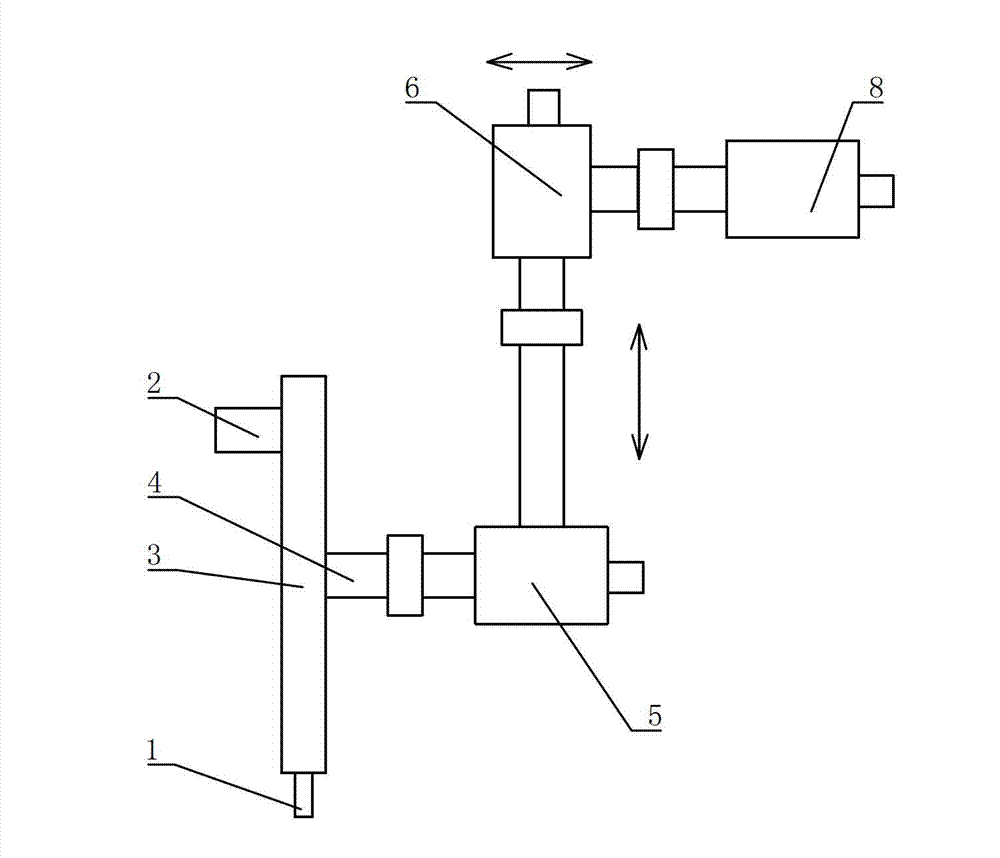

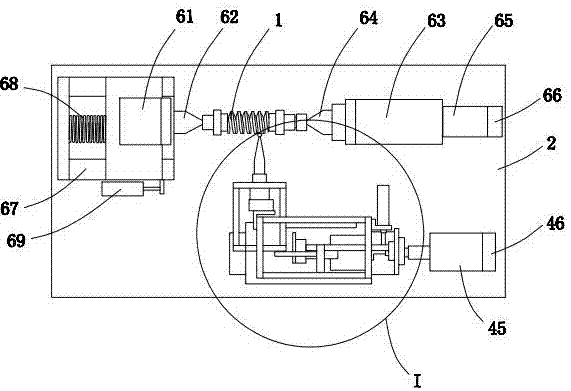

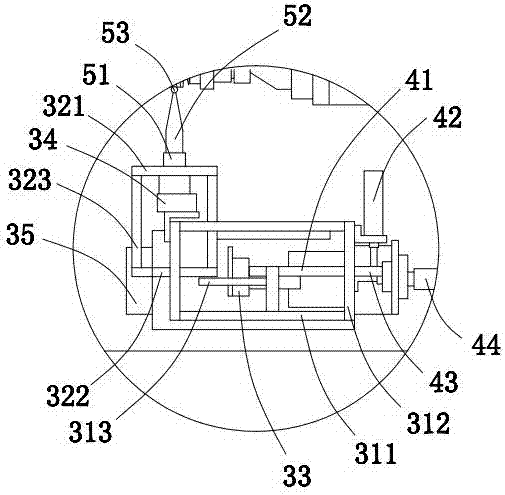

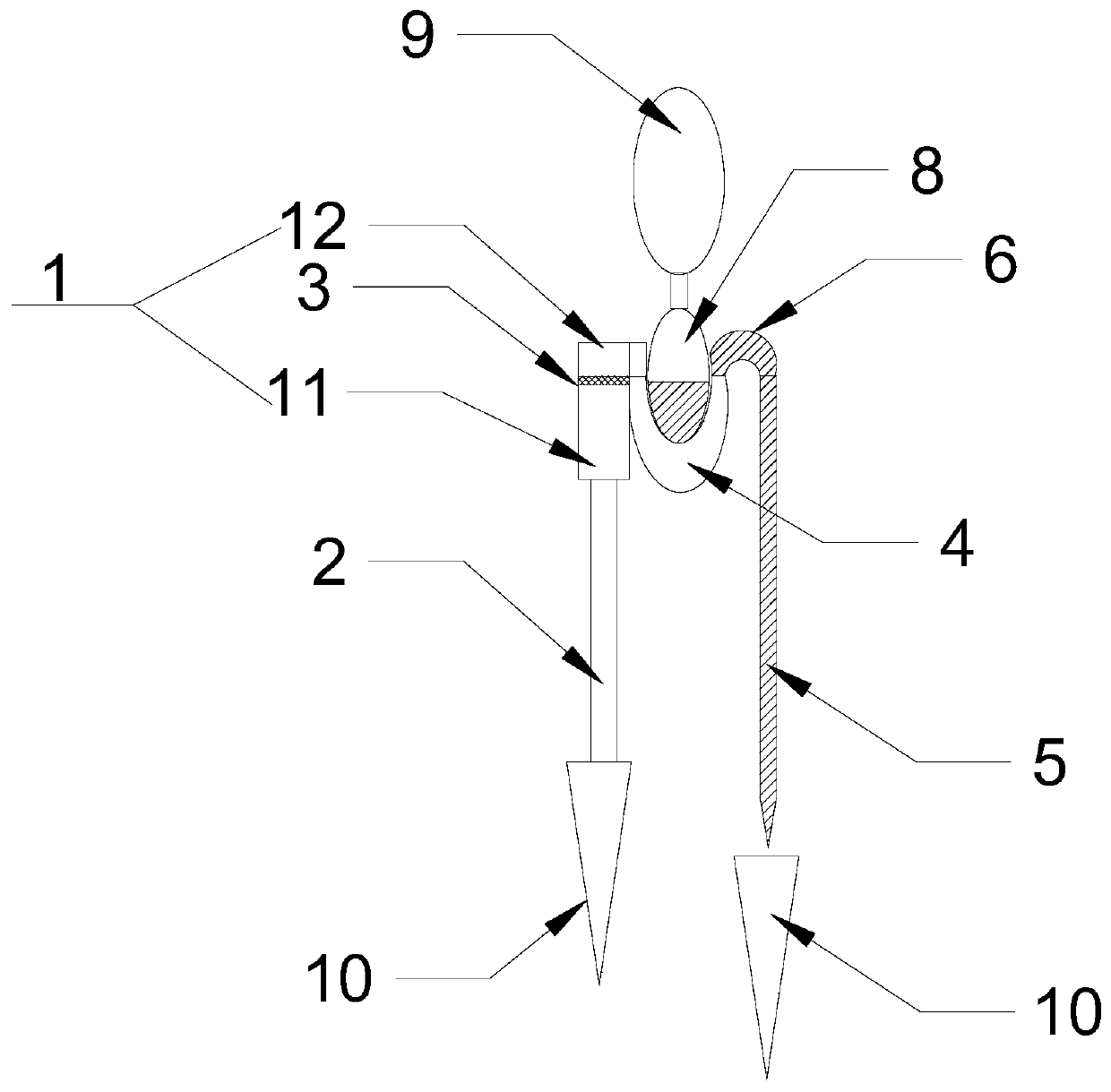

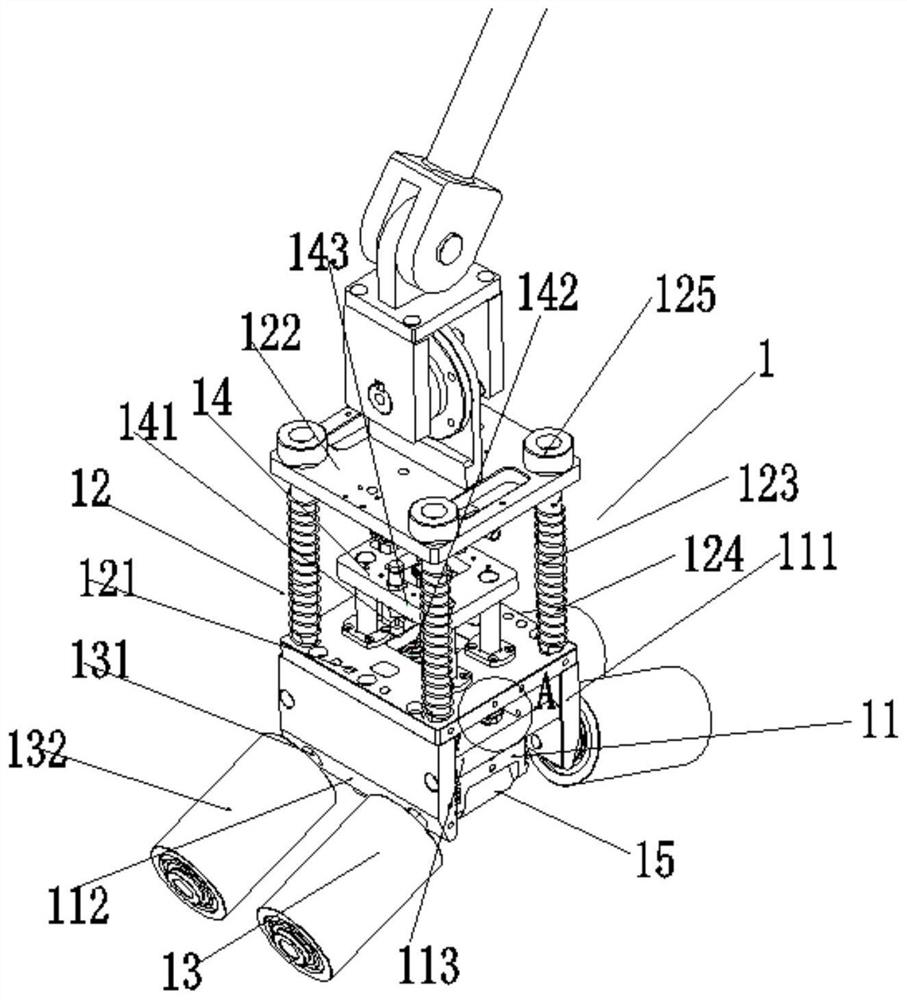

Probe swinging mechanism for performing ultrasonic detection on omega welding line of control bar driving mechanism

ActiveCN101762637AEasy to adjust the incident angleEasy to adjustMaterial analysis using sonic/ultrasonic/infrasonic wavesGear driveElectric machine

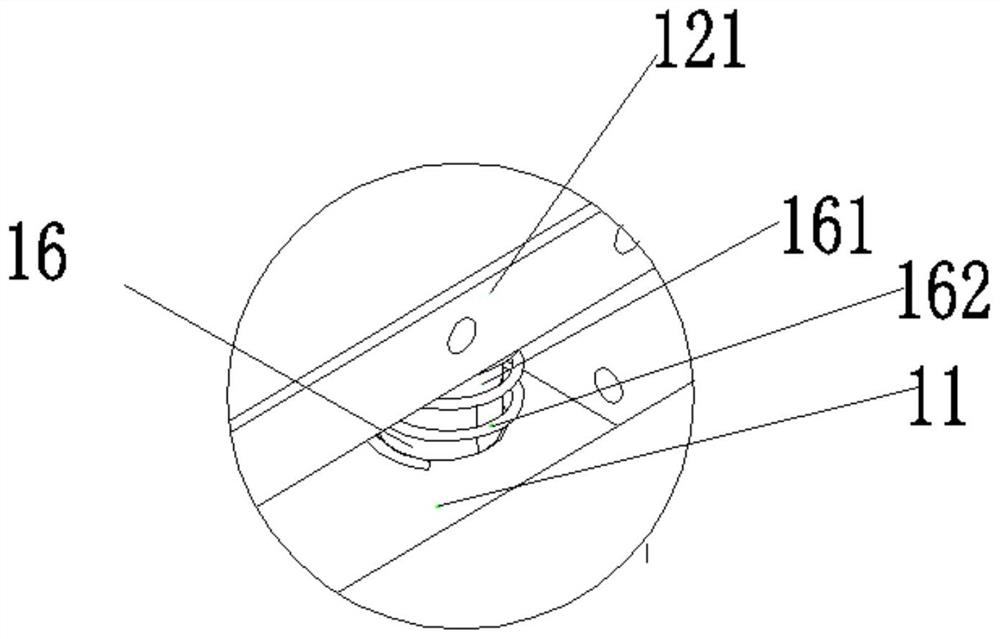

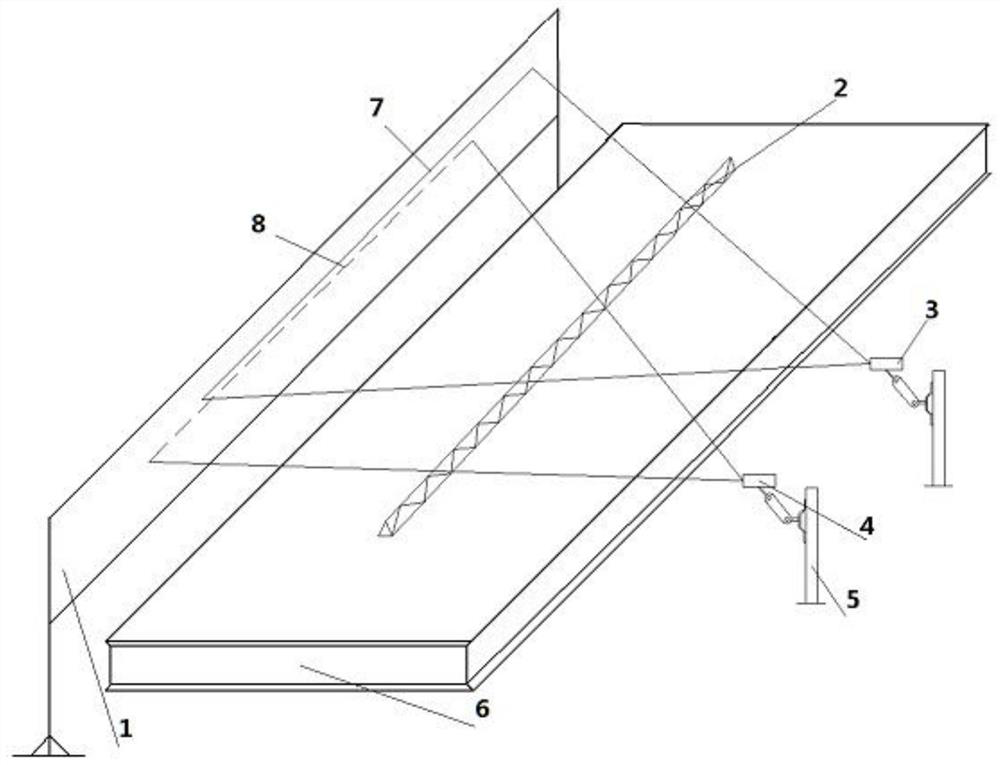

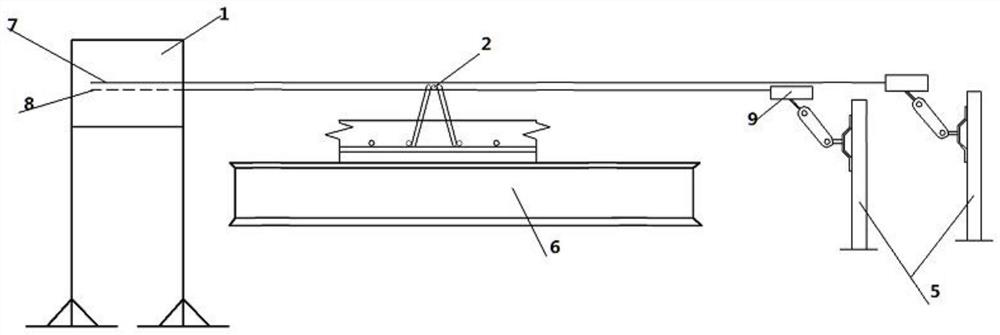

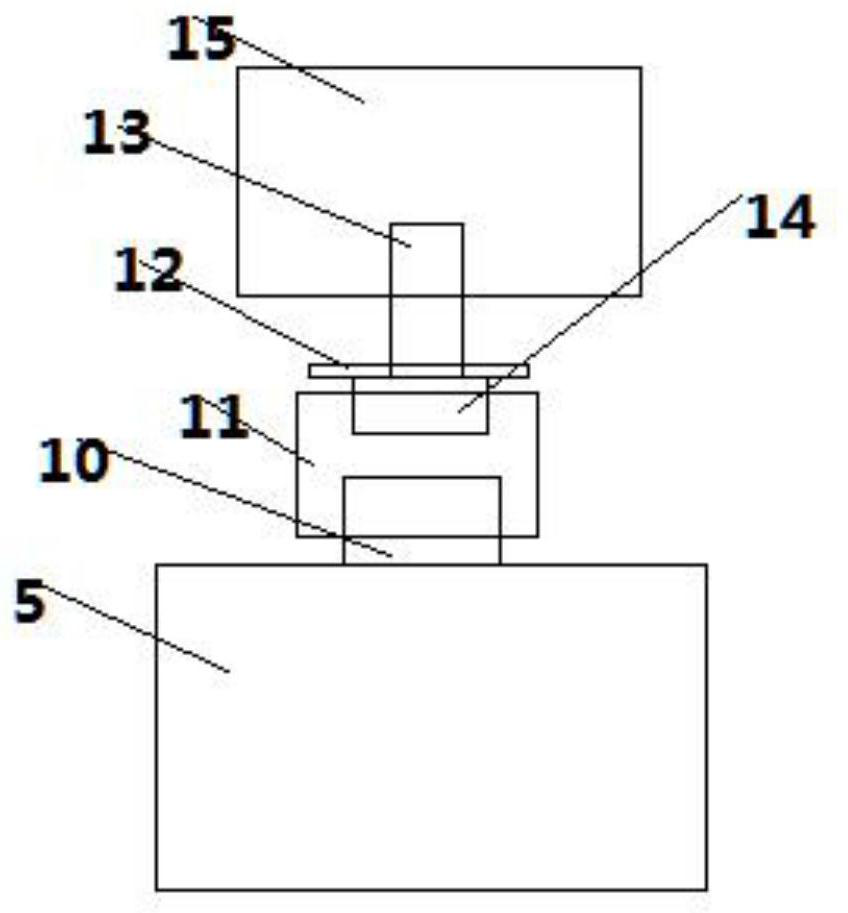

The invention belongs to a swinging mechanism, which and particularly discloses a probe swinging mechanism for performing ultrasonic detection on an omega welding line of a control bar driving mechanism. The mechanism comprises a servo motor, a gear driving mechanism, a guide rail plate and a probe swinging block, wherein the gear driving mechanism is connected with an the output shaft of the servo motor; the guide rail plate is arranged on the gear driving mechanism; the probe swinging block is arranged on the guide rail plate; the guide rail plate is provided with an arc-shaped guide rail slide groove; and the probe swinging block is arranged on the arc-shaped guide rail slide groove through a sliding pin and a shift rod, and is provided with an arc-shaped groove. A probe clamping device for clamping an ultrasonic probe is arranged in the arc-shaped groove. An The output shaft of the driving mechanism is fixed on and fixedly connected with a shift fork. The front end of the shift fork is used for clamping the shift rod, the shift rod and the probe swinging block are driven by the shifting of the shift fork, and slide along the arc-shaped guide rail slide groove, and then the ultrasonic probe is driven to rotate around the omega weld. The invention can perform continuous ultrasonic overall check around the omega weld.

Owner:CHINA NUCLEAR POWER OPERATION TECH

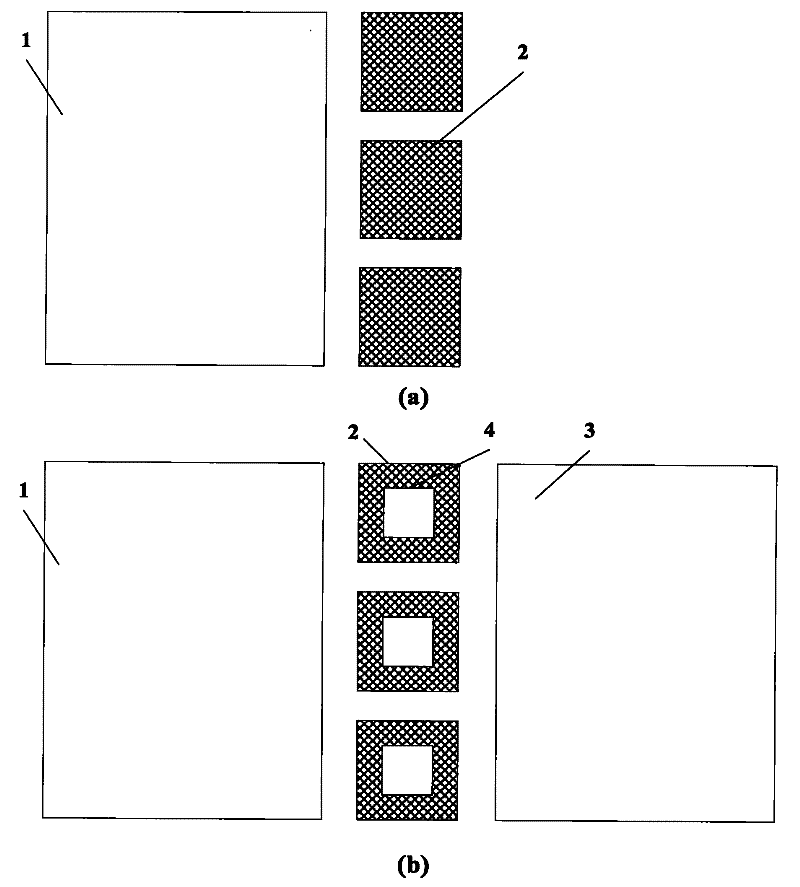

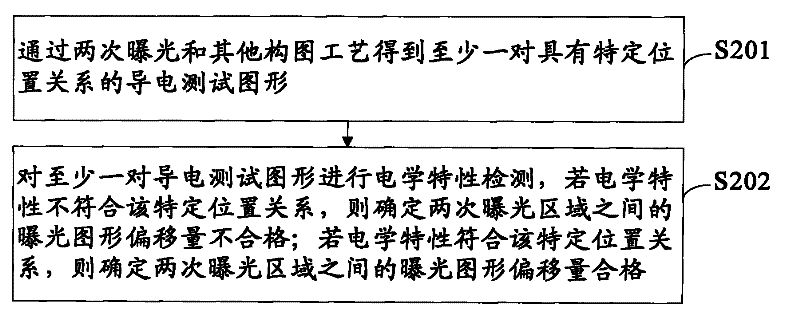

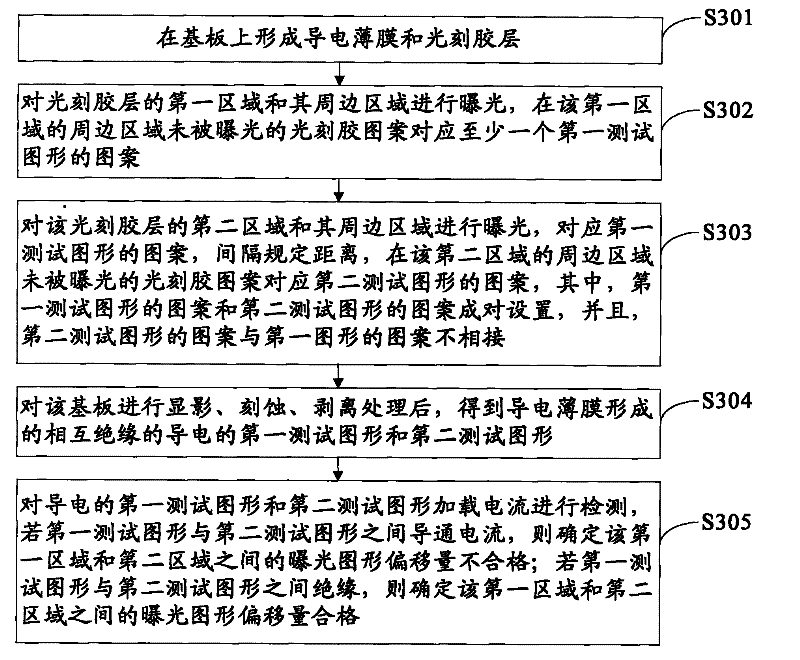

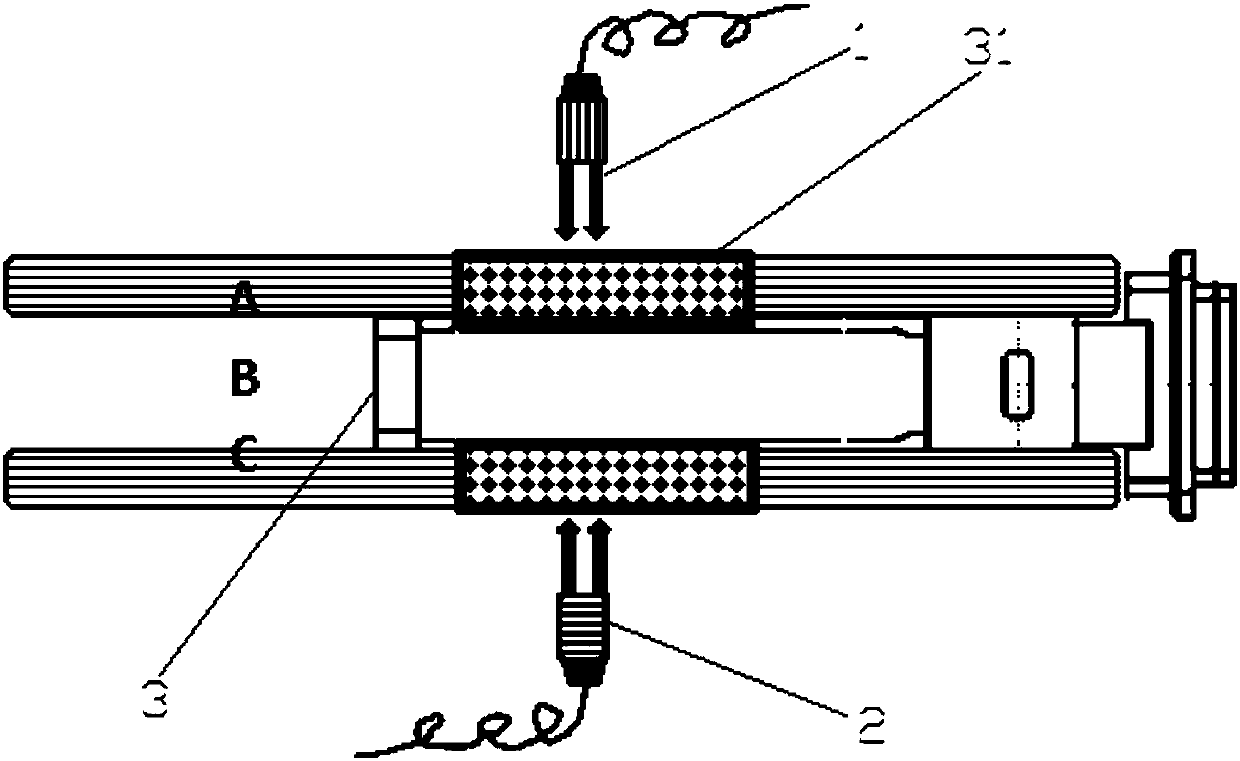

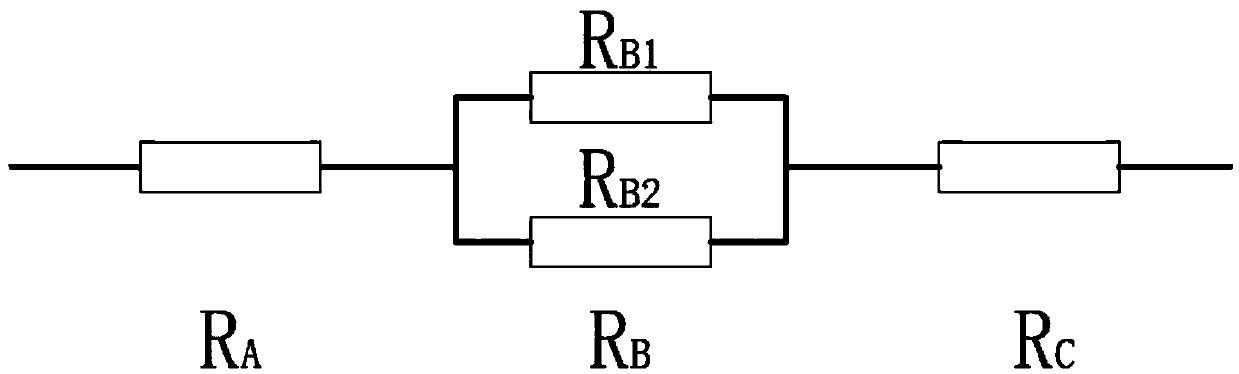

Detection method for pattern offset between exposure areas and test pattern

InactiveCN102243443ARealize full inspectionImprove bad detection rateElectric/magnetic position measurementsSemiconductor/solid-state device manufacturingFault detection rateDetection rate

The invention provides a detection method for the pattern offset between exposure areas and a test pattern, capable of rapidly and real-time detecting the pattern offset between exposure areas, as well as increasing the fault detection rate and yield. The method comprises the following steps of: obtaining at least one pair of conductive test patterns with a specific position relationship by two times of exposure and other picture composition techniques; performing an electric characteristic detection to the at least one pair of conductive test patterns, if the electric characteristic is not accord with the specific position relationship, then determining that the exposure pattern offset between the two times of exposure areas is unqualified; if the electric characteristic is accord with the specific position relationship, then determining that the exposure pattern offset between the two times of exposure areas is qualified. The method of the invention is used for the detection of the pattern offset between exposure areas.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

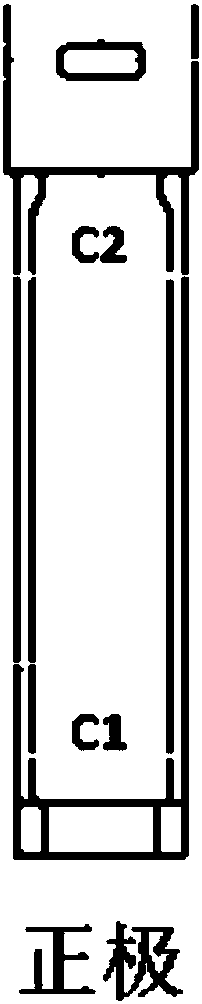

Detection method for detecting false welding of electric core tab

InactiveCN107783056AThe detection process is simpleRealize full inspectionElectrical testingElectrical batteryTest sample

The invention provides a detection method for detecting the false welding of an electric core tab. The method comprises the steps of 1) respectively contacting the positive and negative probes of a battery tester with weldmasks on the two sides of the positive / negative tab of an electrical core so as to obtain the test internal resistance value of the positive / negative tab of the electrical core;2) comparing the test internal resistance value of the positive / negative tab of the electrical core with a standard internal resistance value; if the test internal resistance value of the positive / negative tab of the electrical core is smaller than or equal to the standard internal resistance value, judging that the positive / negative tab of the electrical core is qualified. According to the methodfor detecting the false welding of the electric core tab, the test internal resistance value of the positive / negative tab of the electrical core is compared with the standard internal resistance value, and then whether the positive / negative tab of the electrical core is qualified or not can be judged. The detection process is simple and convenient. Meanwhile, the full inspection of electrical core tabs can be realized. Test results can be fed back in time. Meanwhile, test samples are prevented from being damaged.

Owner:ETRUST POWER ETP GRP LTD

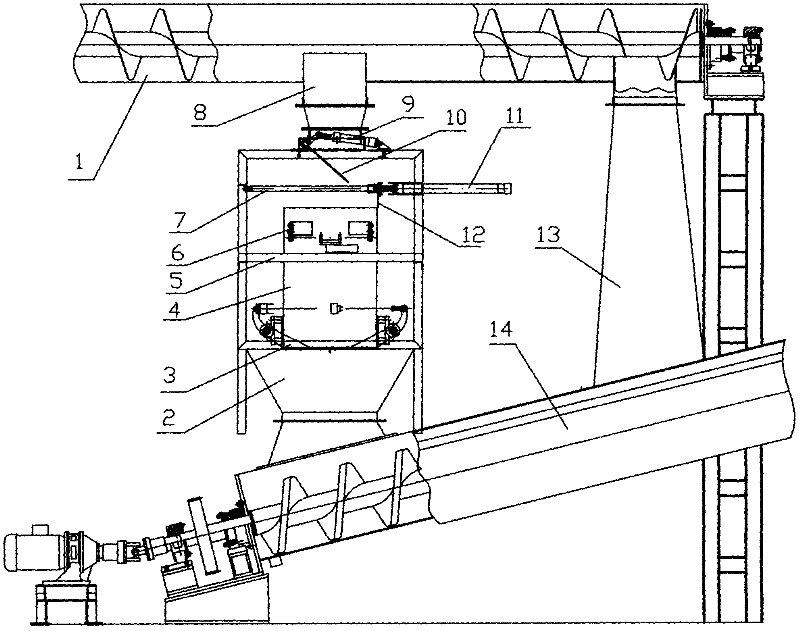

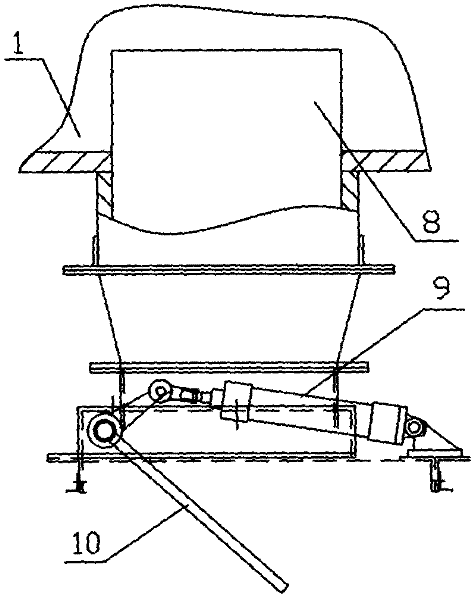

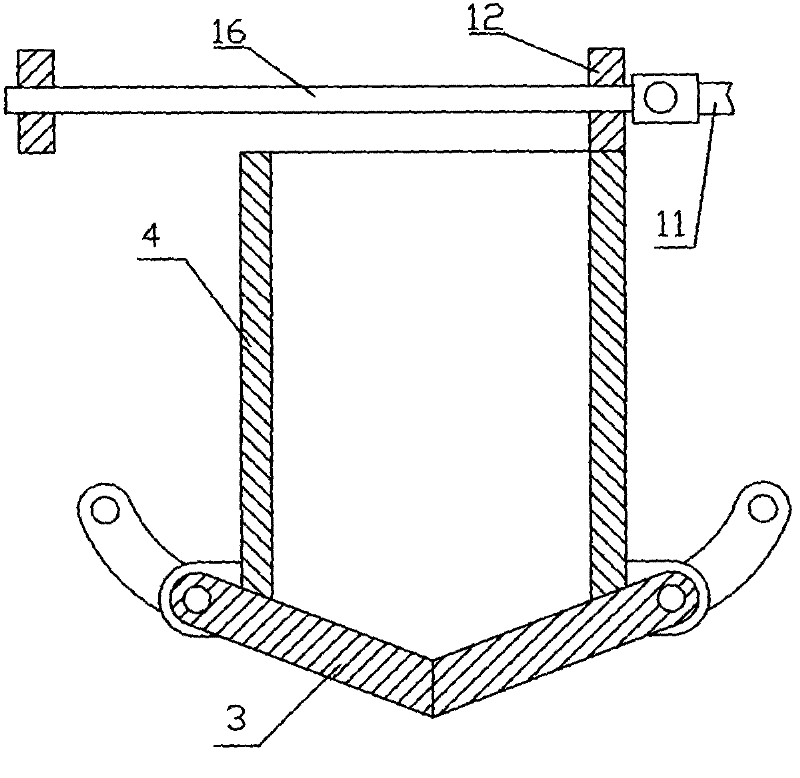

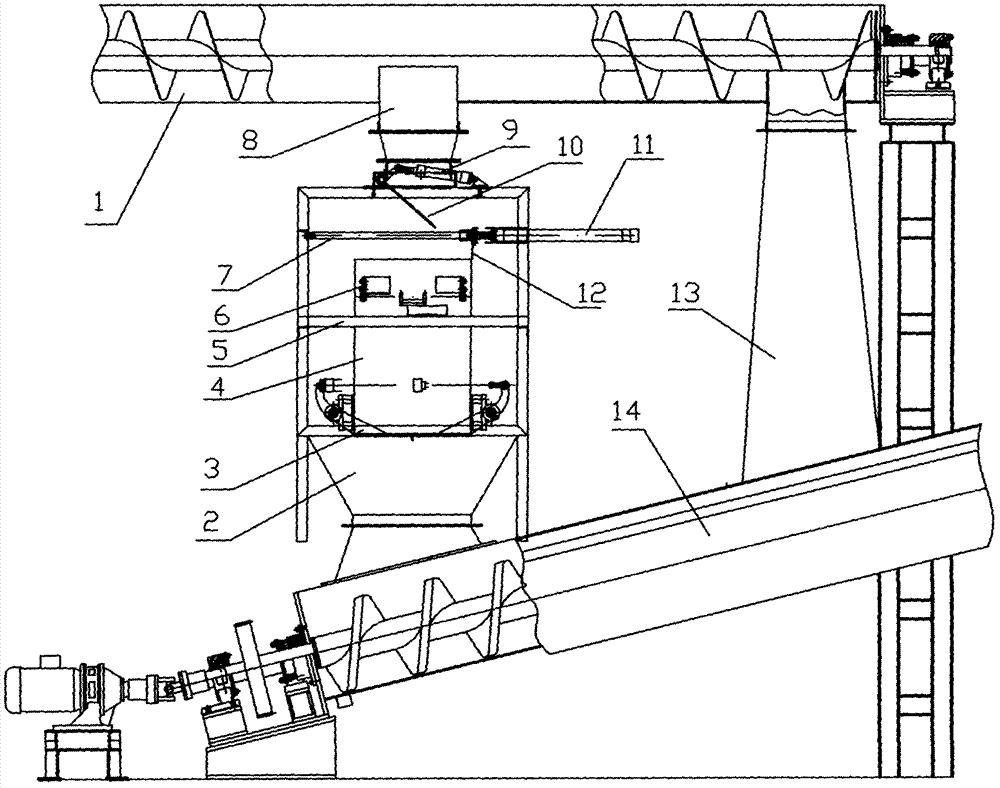

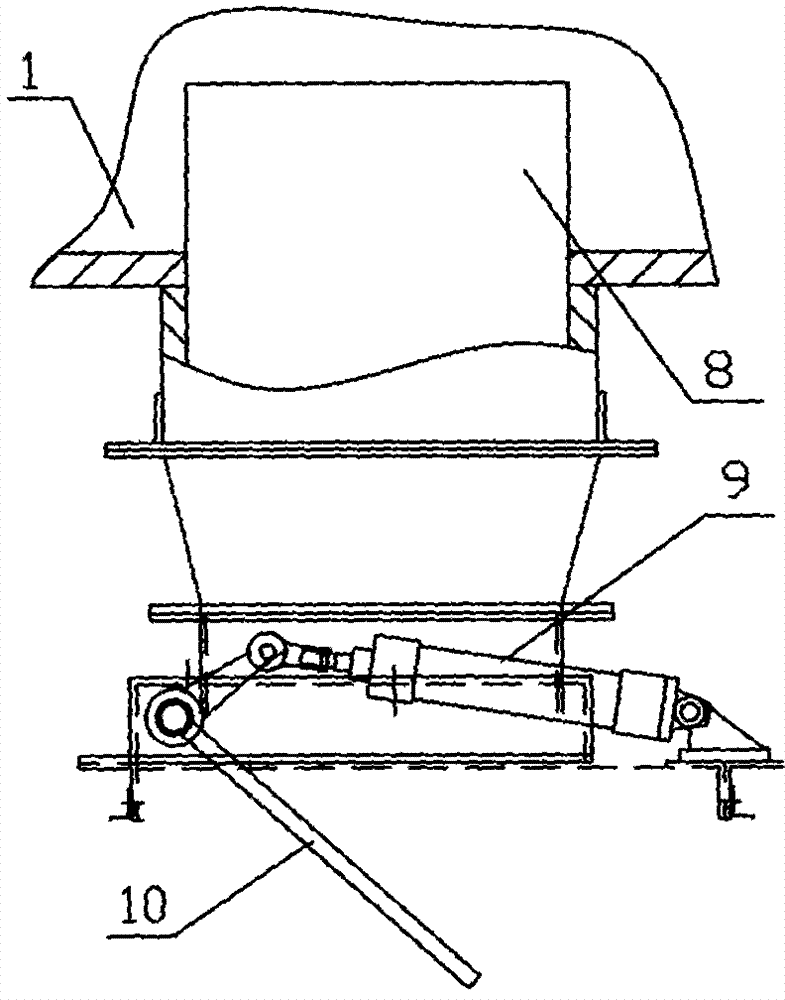

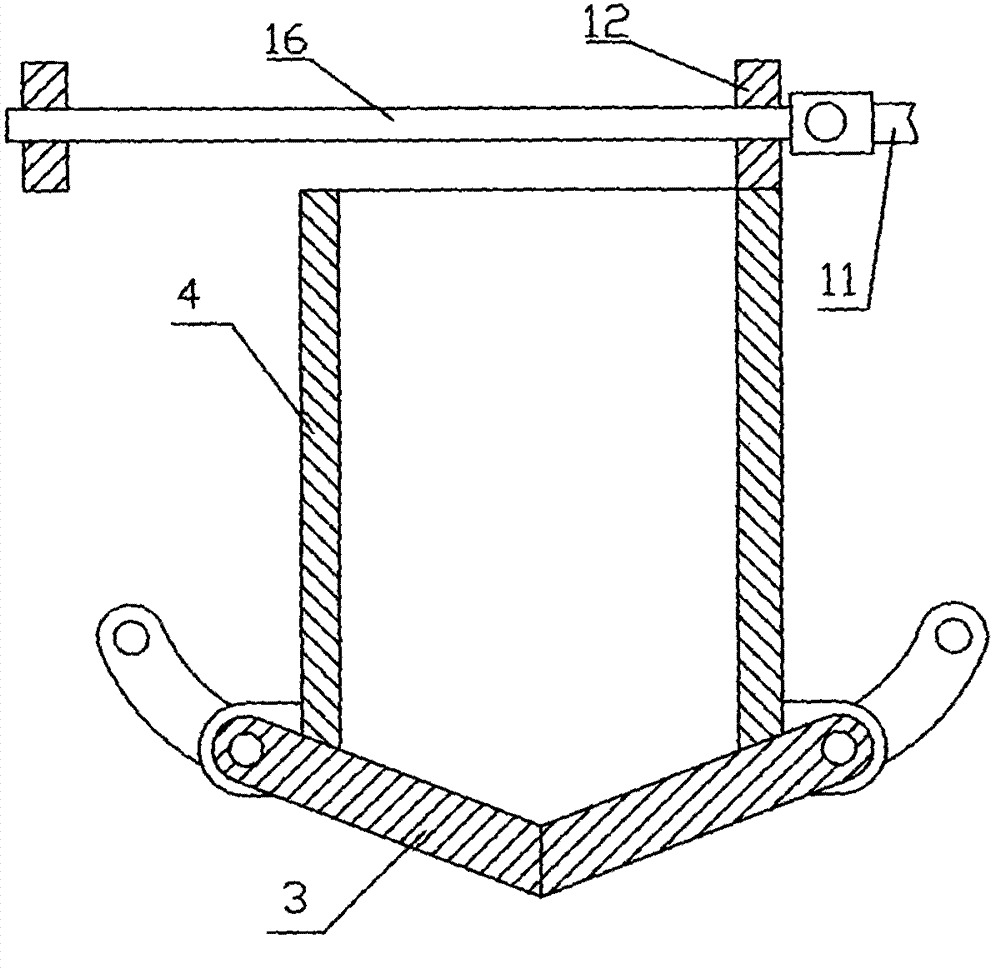

Method and device for automatically detecting powder material accumulation density

ActiveCN102175566ADetectiveFunctionalSpecific gravity measurementControl systemProgrammable logic controller

The invention relates to a method and a device for automatically detecting powder material accumulation density, relating to a device for detecting powder (granular) material accumulation density. The method comprises the following steps of: (1) connecting a material dividing hopper with an original spiral conveyer pipe; (2) opening a material dividing valve at the lower part of the material dividing hopper so that materials fall to a material weighing hopper supported by a weighing sensor; (3) scraping stacks at the top of the material weighing hopper through a material pushing scraping plate driven by a material pushing cylinder; (4) transmitting weight information of the material weighing hopper to a PLC (programmable logic controller) control system for calculating, comparing and displaying by the weighing sensor; (5) opening a material discharging valve at the lower part of the material weighing hopper so that the materials fall to a material receiving hopper and enter to a secondary spiral conveyer; and (6) pushing the materials falling from the material receiving hopper to be combined with the materials falling from an original spiral conveyer material discharging tube and sending to next procedure together by the secondary spiral conveyer. The device disclosed by the invention has the advantages of automatic identifying function, high accuracy, fast speed and high efficiency; and the device is capable of realizing full check, and effectively controlling the product quality.

Owner:青海海西东诺化工有限公司

Device for detecting dynamic balance of hub of assembly line

InactiveCN102778334AOmit attitude switchingOut of manual operationStatic/dynamic balance measurementHorizontal transmissionDynamic balance

The invention discloses a device for detecting the dynamic balance of a hub of an assembly line. The device is characterized by comprising a horizontal transmission mechanism, a positioning mechanism, a main shaft mechanism and a marking mechanism, wherein the horizontal transmission mechanism has a horizontal travelling function; the positioning mechanism is arranged at the upstream end of the horizontal transmission mechanism; the main shaft mechanism is vertically and upwards arranged on the horizontal transmission mechanism and is provided with a locking mechanism and a processing system; and the marking mechanism is positioned on the side of the horizontal transmission mechanism; the locking mechanism is driven to rotate by a clamping and fixing hub; and the processing system is used for detecting an unbalance point of the hub. The initial position of the hub is determined at the positioning mechanism; the hub is horizontally conveyed to the main shaft mechanism through the horizontal transmission mechanism; the hub is rotated under the driving of the main shaft mechanism in the manner of a fixed shaft; the unbalance point is marked by the marking mechanism; and the hub departs from the main shaft mechanism and is conveyed away through the horizontal transmission mechanism. In the whole process, a hub rotating shaft is kept vertical, the posture of the hub rotating shaft is not changed, and the main shaft mechanism is meanwhile provided with a control and processing system and is integrated with the marking mechanism in the same device, so that manual operation is completely eliminated, and the device is suitable for the assembly line and can realize full detection.

Owner:厦门宣凯福瑞贸易有限公司

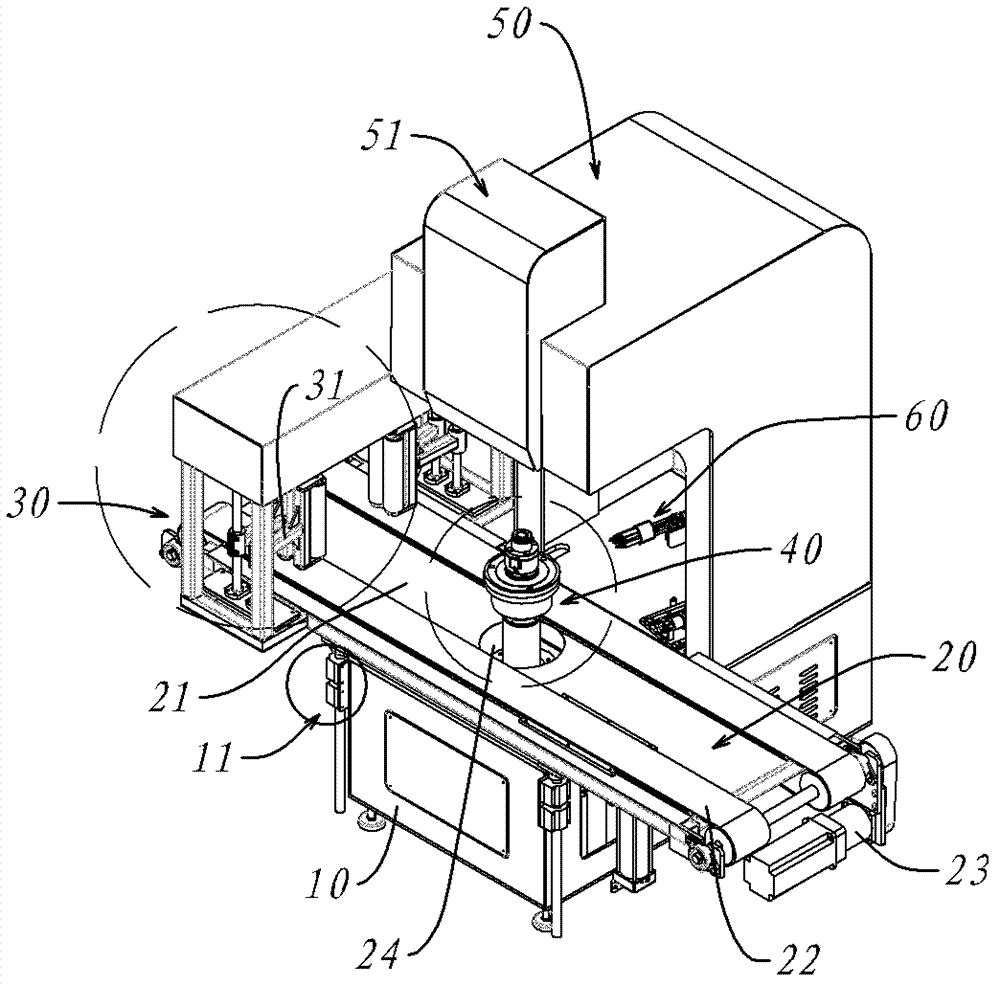

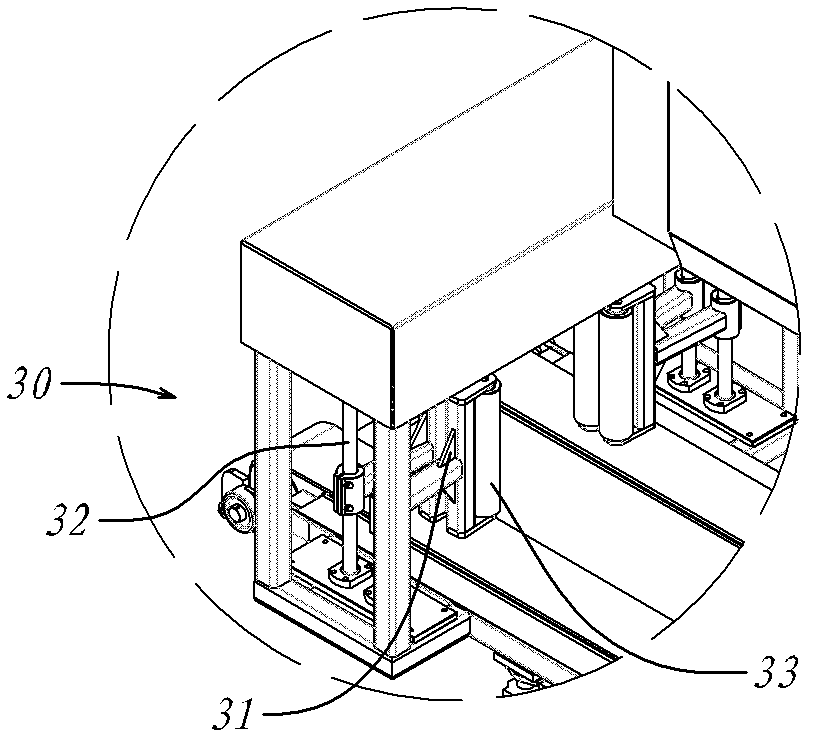

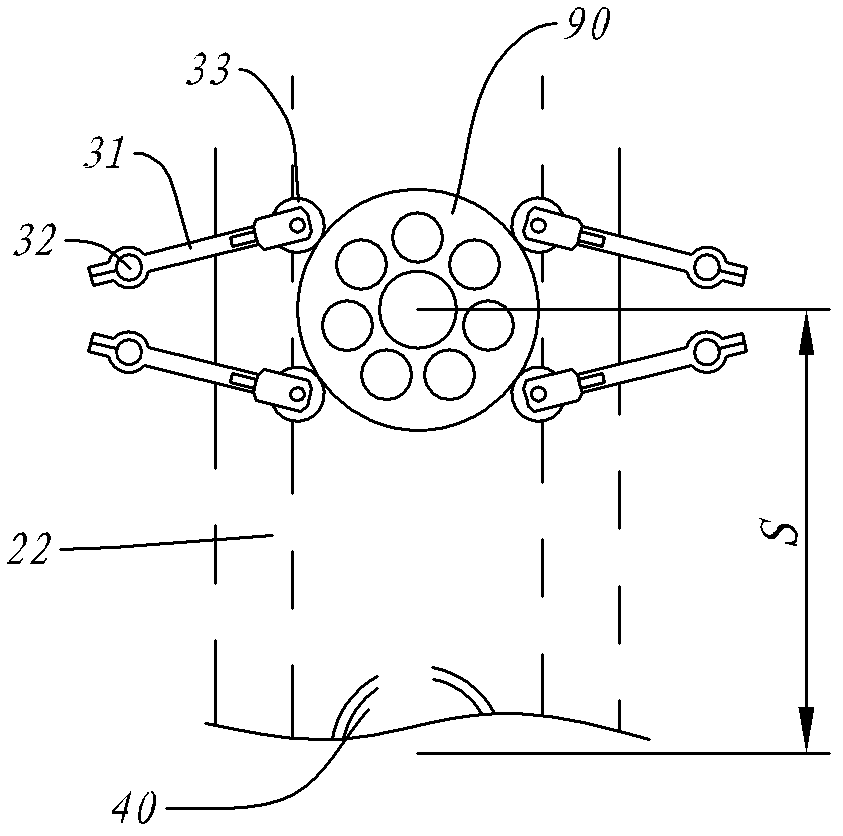

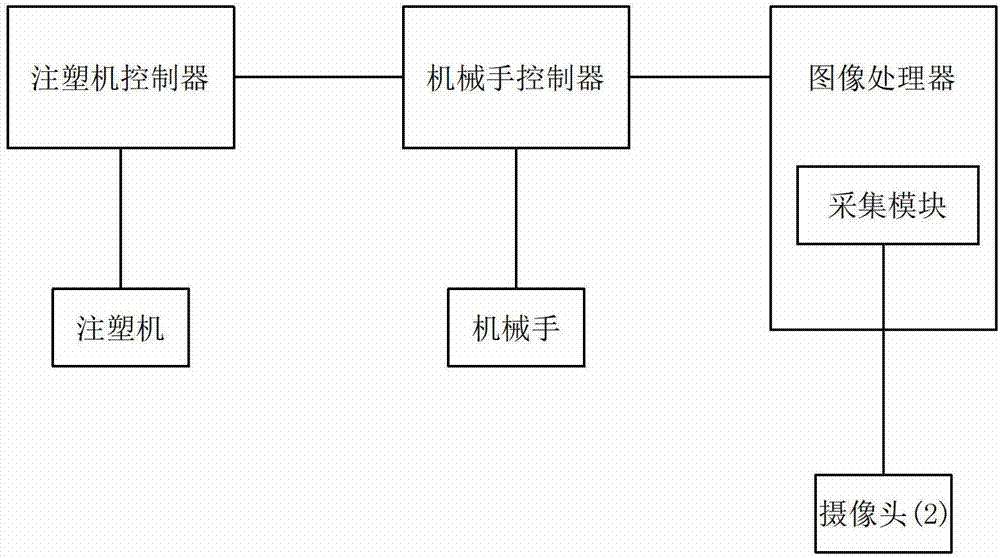

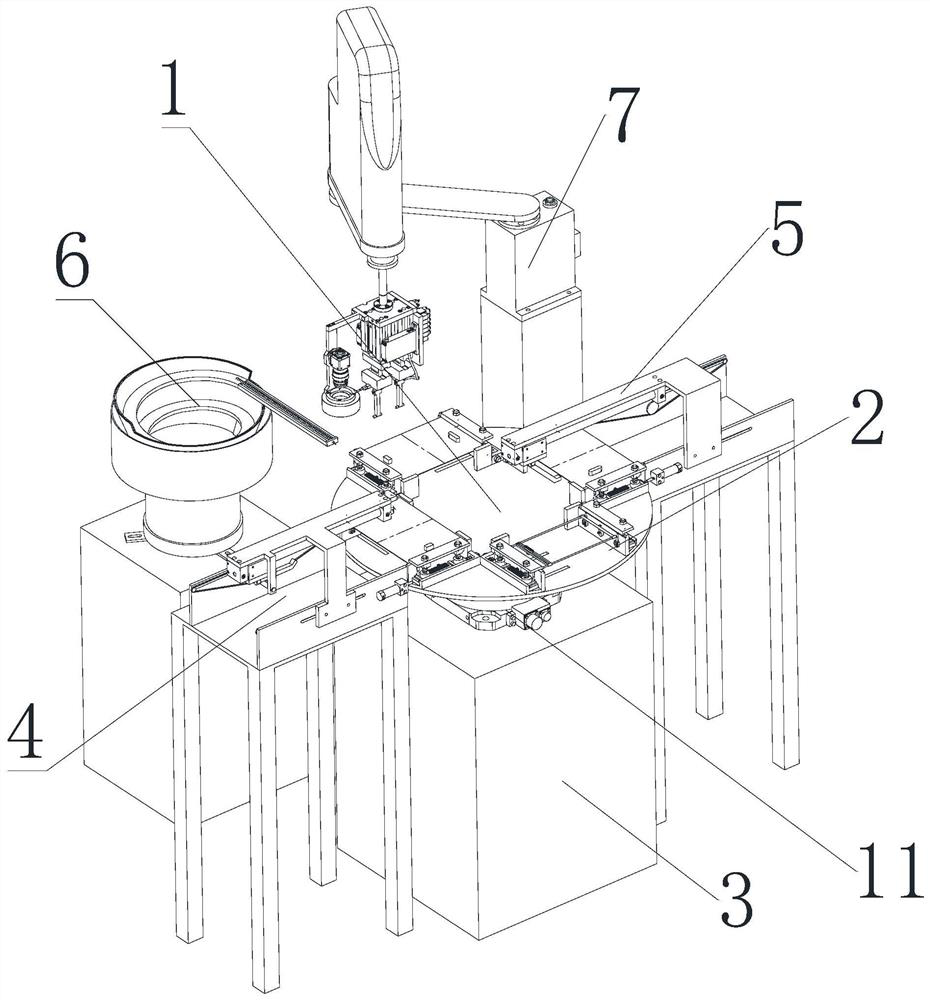

Multifunctional manipulator device for injection molding machine and quality full-inspection method for injection products

The invention relates to a multifunctional manipulator device for an injection molding machine. The device comprises manipulators with freedom degrees in at least the x direction, the y direction and the z direction and a control system, wherein product fixtures and cameras are arranged on the manipulators; the control system comprises a manipulator controller and an image processor; the manipulators are connected onto the manipulator controller electrically; and the image processor is connected with the cameras and the manipulator controller electrically. The invention further relates to a quality full-inspection method for injection products. Product quality grades are obtained after an injection product surface image shot by the camera is processed by the image processor; then the manipulators perform quality grade shunting for products of different quality grades; and processes for taking workpieces and detecting, which are completed in two steps in the conventional injection production, are integrated into one step for completion, so that the production efficiency of an enterprise can be improved substantially, the full inspection of the quality of large-scale products is achieved, the quality of outgoing products is guaranteed, and the comprehensive competitiveness of the enterprise is improved. The device and the method are suitable for injection production and detection.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

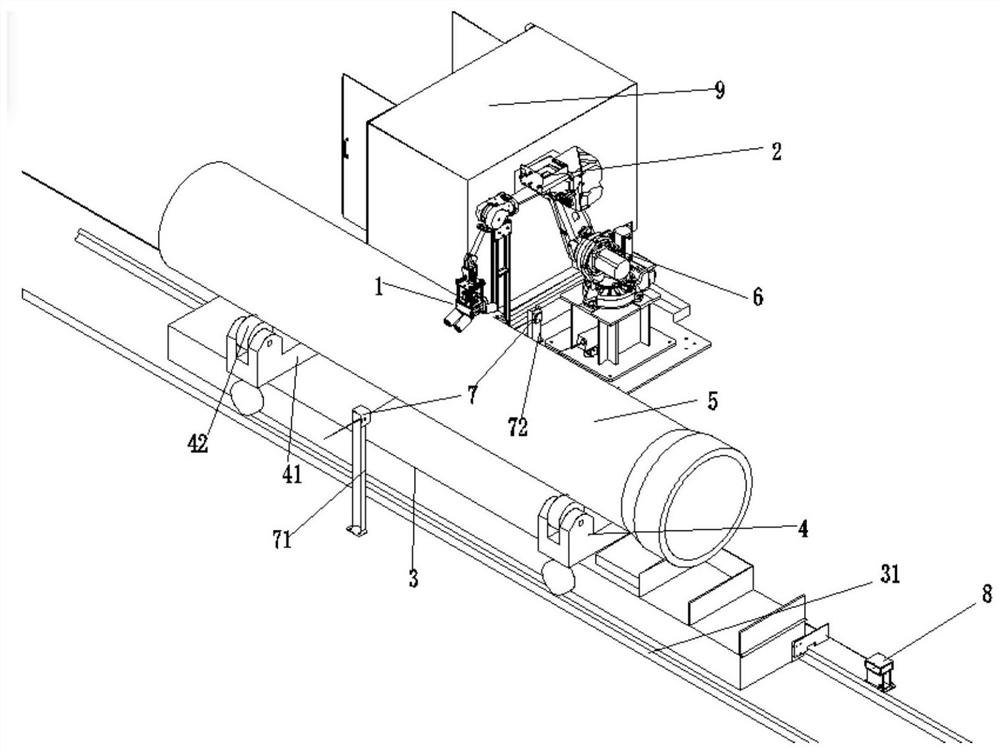

Automatic detection device for M-value of worm and runout of tooth surface

ActiveCN108007295ARealize full inspectionImprove detection accuracyMechanical measuring arrangementsEngineeringMechanical engineering

The invention belongs to the technical field of detection devices, and discloses an automatic detection device for an M-value of a worm and the runout of a tooth surface. The automatic detection device comprises a workbench, wherein the workbench is provided with a clamping unit used for clamping the worm and a measuring unit used for measuring the M-value of the worm and the runout of the tooth surface, the measuring unit comprises a contact portion, a measurement portion, a moving base and a measurement control portion, the contact portion is connected with the measurement portion, the measurement portion is arranged on the moving base, the measurement control portion is connected with the moving base, and the measurement control portion can control the measurement portion and the contact portion to move along a direction parallel to a clamping axis of the worm and a radial direction of the worm so as to enable the contact portion to be contacted with the tooth surface of the worm toperform measurement. The automatic detection device abandons a method of manually detecting the M-value, and improves the detection accuracy through refined component setting. Meanwhile, the automatic detection device is mechanically operated in the whole process, can realize full detection for the M-value of the worm, avoids the risk of manual wrong detection and missed detection and improves the detection efficiency at the same time.

Owner:ZHUZHOU ELITE ELECTRO MECHANICAL

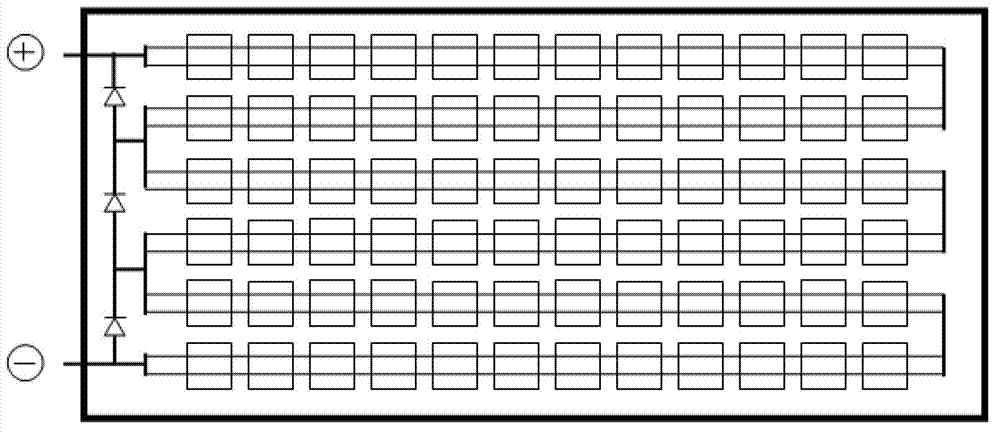

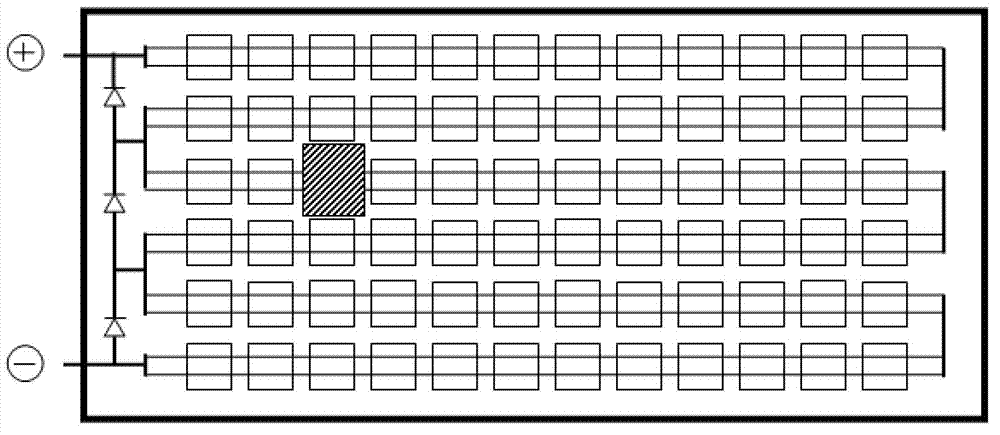

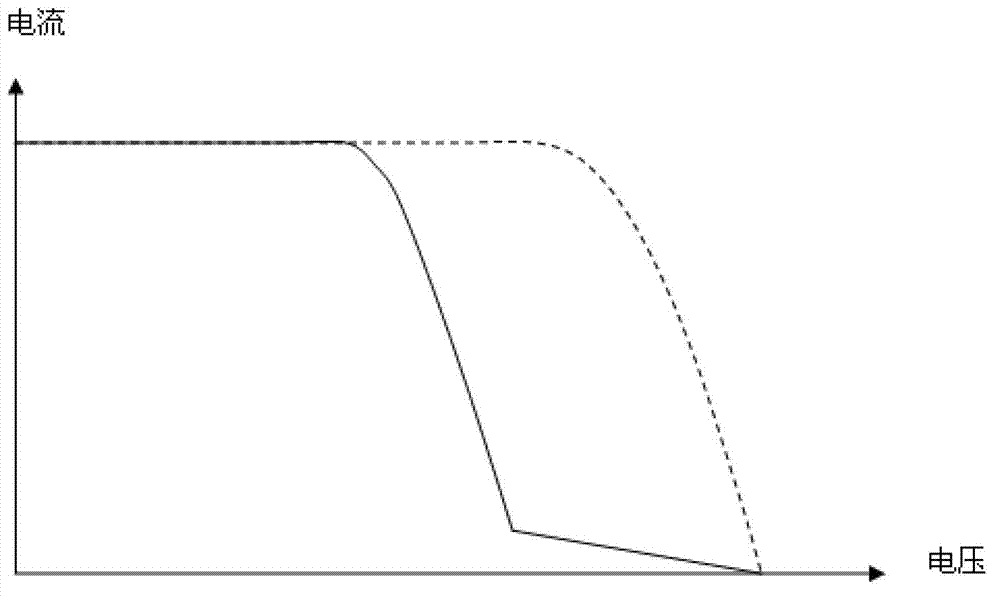

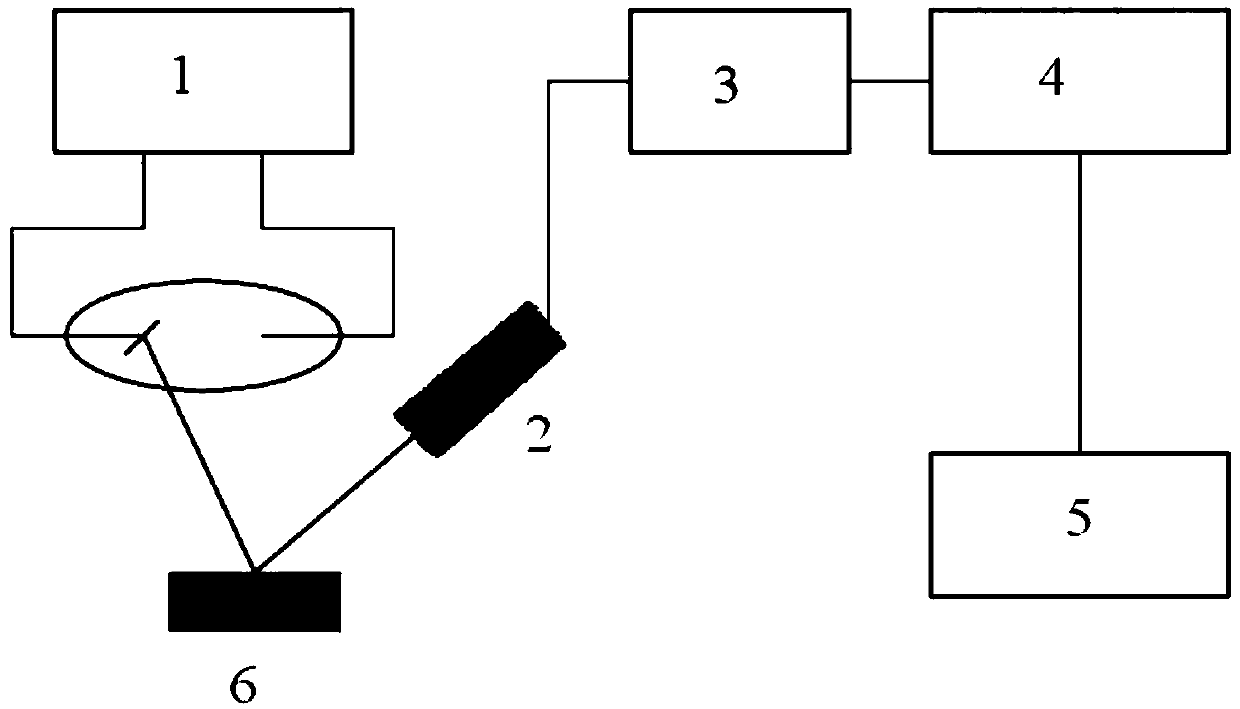

Battery pick-out equipment for hot-spot test of photovoltaic components

ActiveCN102928762ARealize full inspectionImprove tolerancePhotovoltaic monitoringPhotovoltaic energy generationData acquisitionEngineering

The invention relates to battery pick-out equipment for a hot-spot test of photovoltaic components. The battery pick-out equipment comprises a machine frame and is characterized in that baffle guide rails and photovoltaic component guide rails are mounted on a machine frame, a photovoltaic component support frame is mounted on the photovoltaic component guide rails and can move along the photovoltaic component guide rails; steady-state light sources and a plurality of light sources in array distribution are mounted on the machine frame above the photovoltaic component support frame; one or more group of baffle components are mounted between the steady-state light sources and the photovoltaic component support frame; the baffle components comprise baffle supports of which the two ends are arranged on the baffle guide rails, and the baffle supports can move along the baffle guide rails; a plurality of baffles capable of shielding the steady-state light sources are arranged on the baffle supports; a space for placing photovoltaic components is formed between the baffles and the photovoltaic component support frame; and a data acquisition circuit is mounted at one end of the machine frame. The battery pick-out equipment only requires measurement of the reverse dark-state leakage current of batteries, and can achieve multi-way monitoring at the same time, thereby greatly speeding up the test.

Owner:WUXI INSPECTION TESTING & CERTIFICATION INST

X-ray-based metal surface infiltrated layer thickness non-destructive detection device and method

InactiveCN109556541ARealize full inspectionImprove work efficiencyUsing wave/particle radiation meansNon destructiveDisplay device

The present invention provides an X-ray-based metal surface infiltrated layer thickness non-destructive detection device and method. The device comprises an X-ray generator, an X-ray detector, an amplifier, a data processing storage module and a display. The method comprises: producing sample pieces with different infiltrated layer thicknesses, using the device for calculation to obtain the infiltrated layer element content of the sample pieces, accurately measuring the infiltrated layer thicknesses of the sample pieces by using a scanning electron microscopy method, and establishing a data sheet corresponding to the infiltrated layer element content and the infiltrated layer thicknesses; and using the device to obtain the infiltrated layer element content of a to-be-detected test piece, and performing interpolation calculation in the pre-calibrated data sheet corresponding to the infiltrated layer element content and the infiltrated layer thicknesses to obtain the infiltrated layer thickness of the to-be-detected test piece. Compared with the existing infiltration layer inspection method, by using the method provided by the present invention, the infiltrated layer thickness of thediffusion aluminized layer can be quickly detected without destroying the test piece, full inspection of the product can be realized, and the working efficiency is greatly improved.

Owner:汪诚 +2

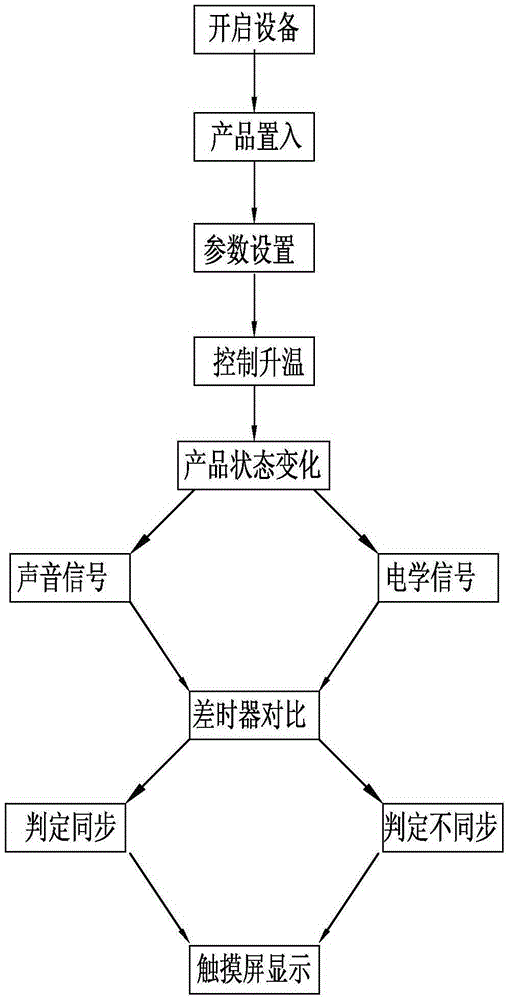

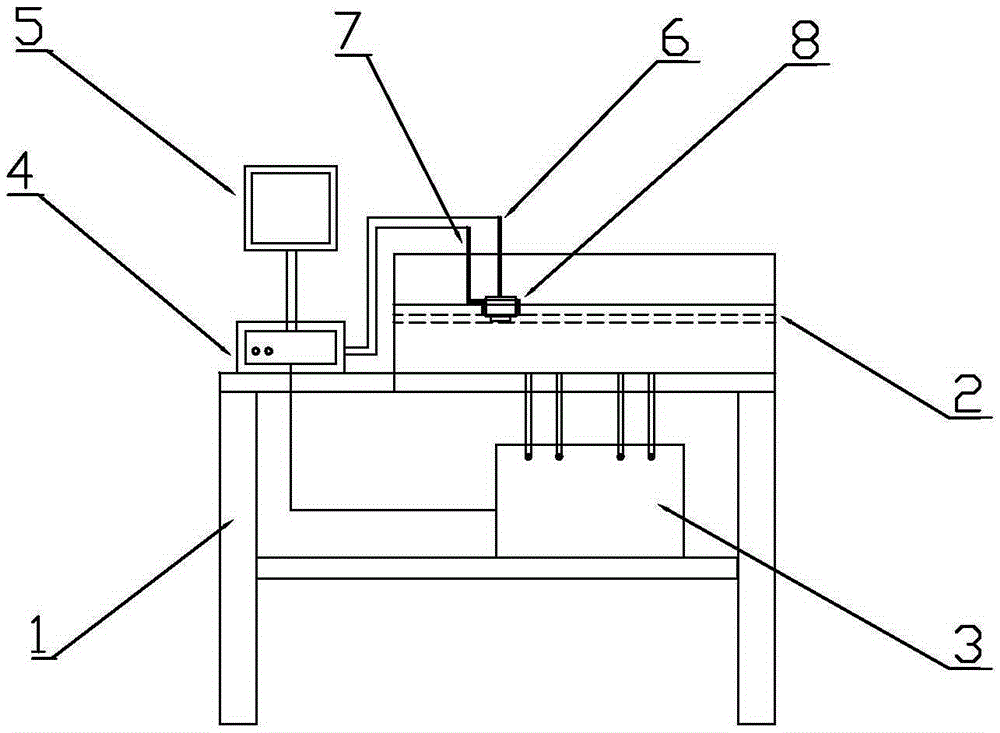

Single-circuit snap action temperature controller synchronization test method

ActiveCN105259893AReduce labor intensityRealize full inspectionElectric testing/monitoringTemperature controlElectricity

The invention discloses a single-circuit snap action temperature controller synchronization test method, which comprises synchronization test equipment and synchronization test procedures. The synchronization test method uses the synchronization test equipment, and carries out a synchronization test on a tested product according to the synchronization test procedures. The synchronization test equipment comprises a test frame, a test box, a temperature control device, PLC processor, a touch display screen, an electric signal line, an acoustic signal line and a tested product. The test method comprises an initial state, a temperature control state, a dynamic state, signal acquisition, time-differential comparison and a test result. According to the invention, the closed test box is designed, time difference analysis is carried out on circuit signals and acoustic signals, the signal reception time difference is quantified by using a time-differential device, and a synchronization characteristic of a temperature controller is accurately judged; the labor intensity is reduced, and the level of the product quality is improved; and indexes required by a customer are ensured to be reached through voluntarily adjusting the judgment time difference standard, and rising in product defective rate caused by overhigh synchronization standards is avoided at the same time.

Owner:LIGHTCOUNTRY CHANGSHU

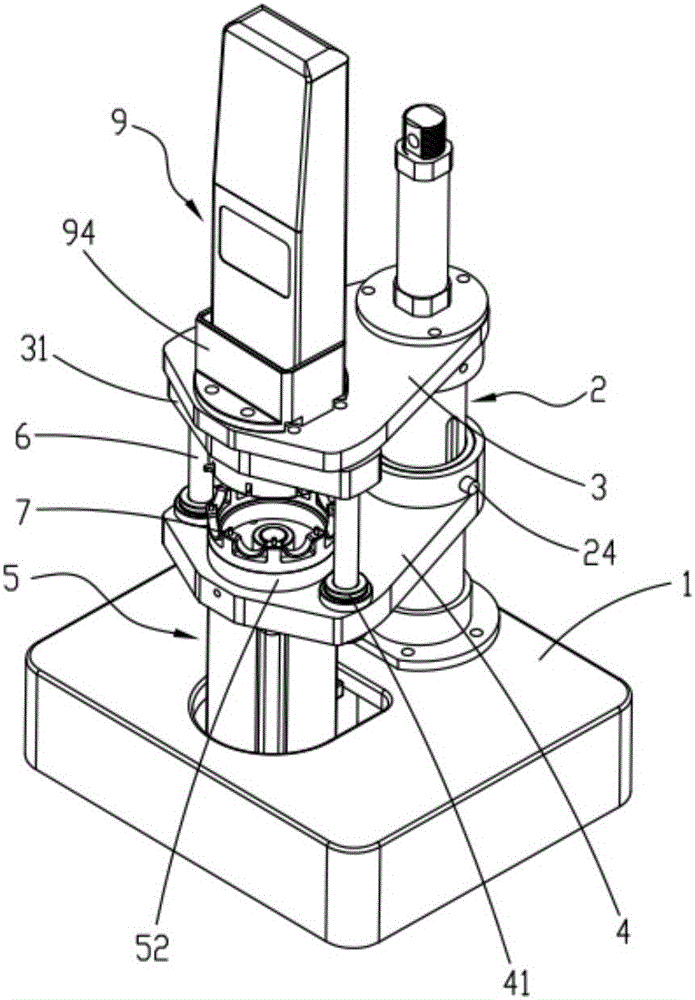

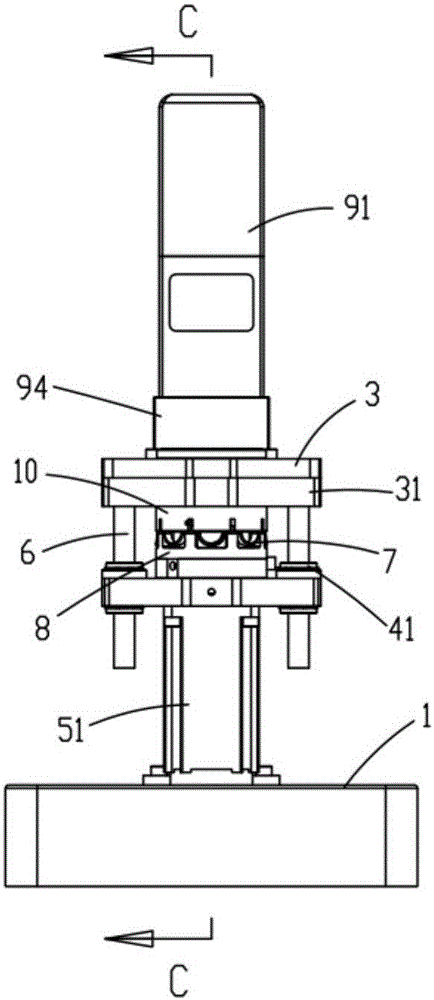

Numerical-control detection device for bearing-keeping-device rivet separating force

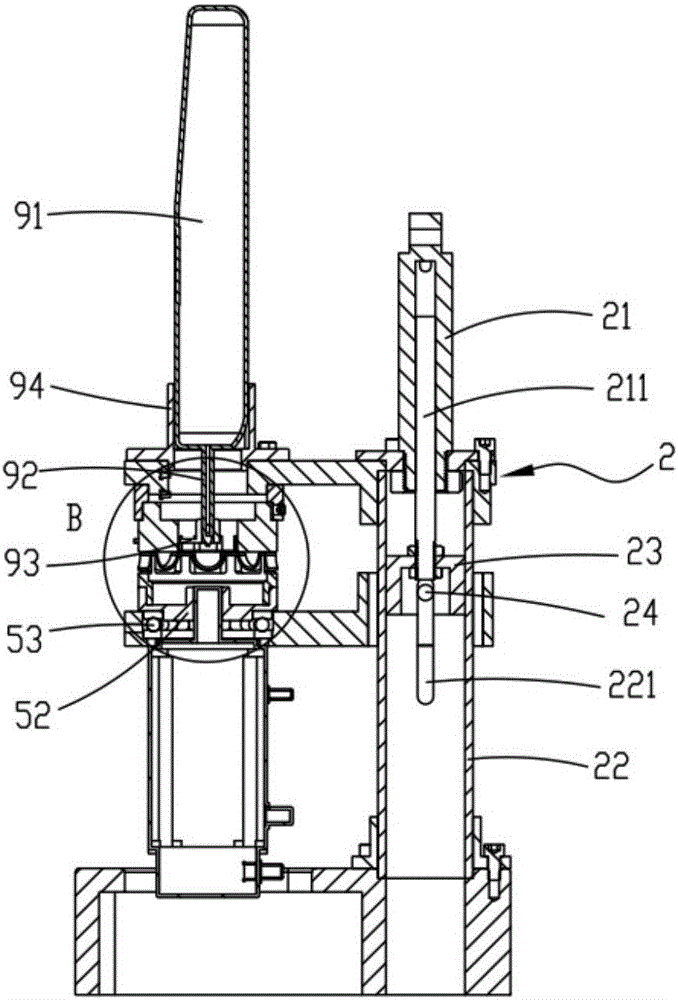

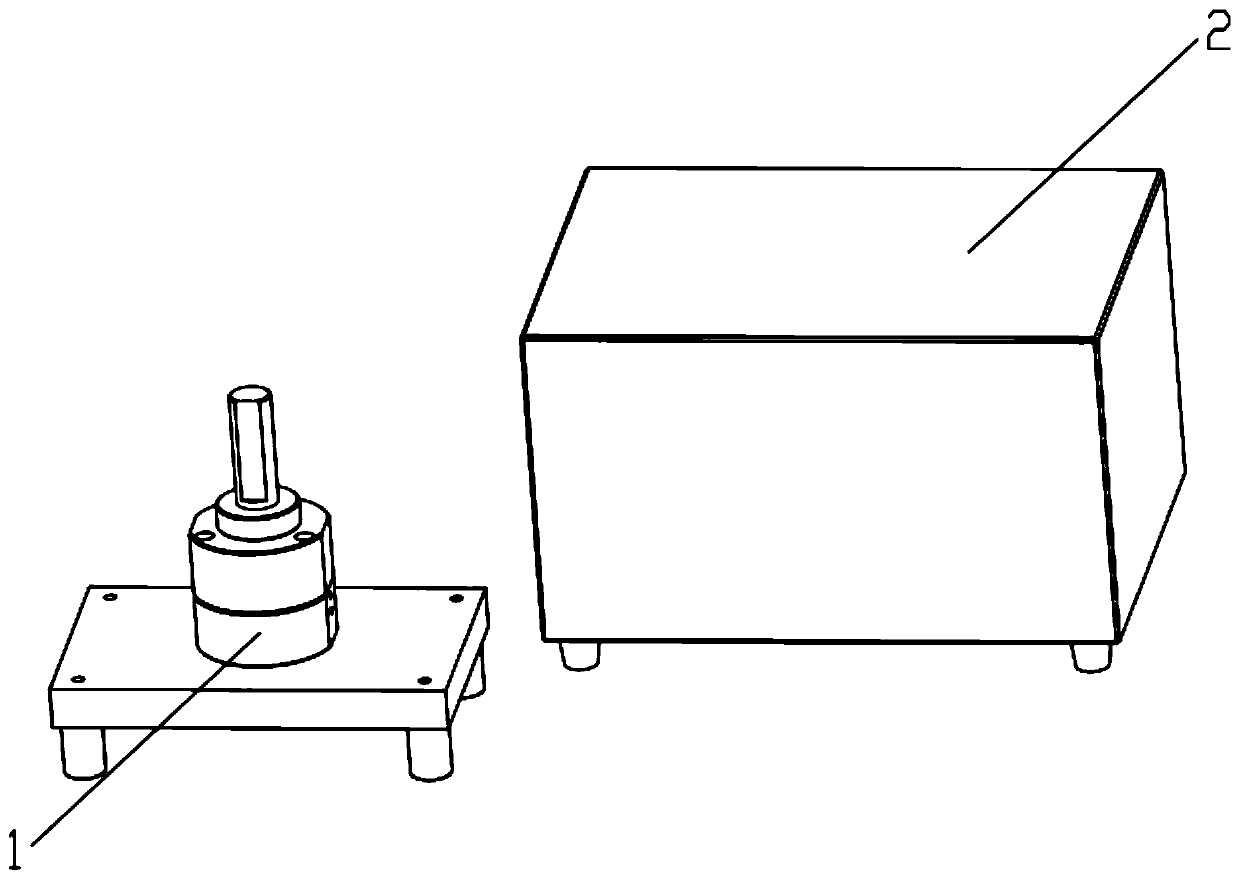

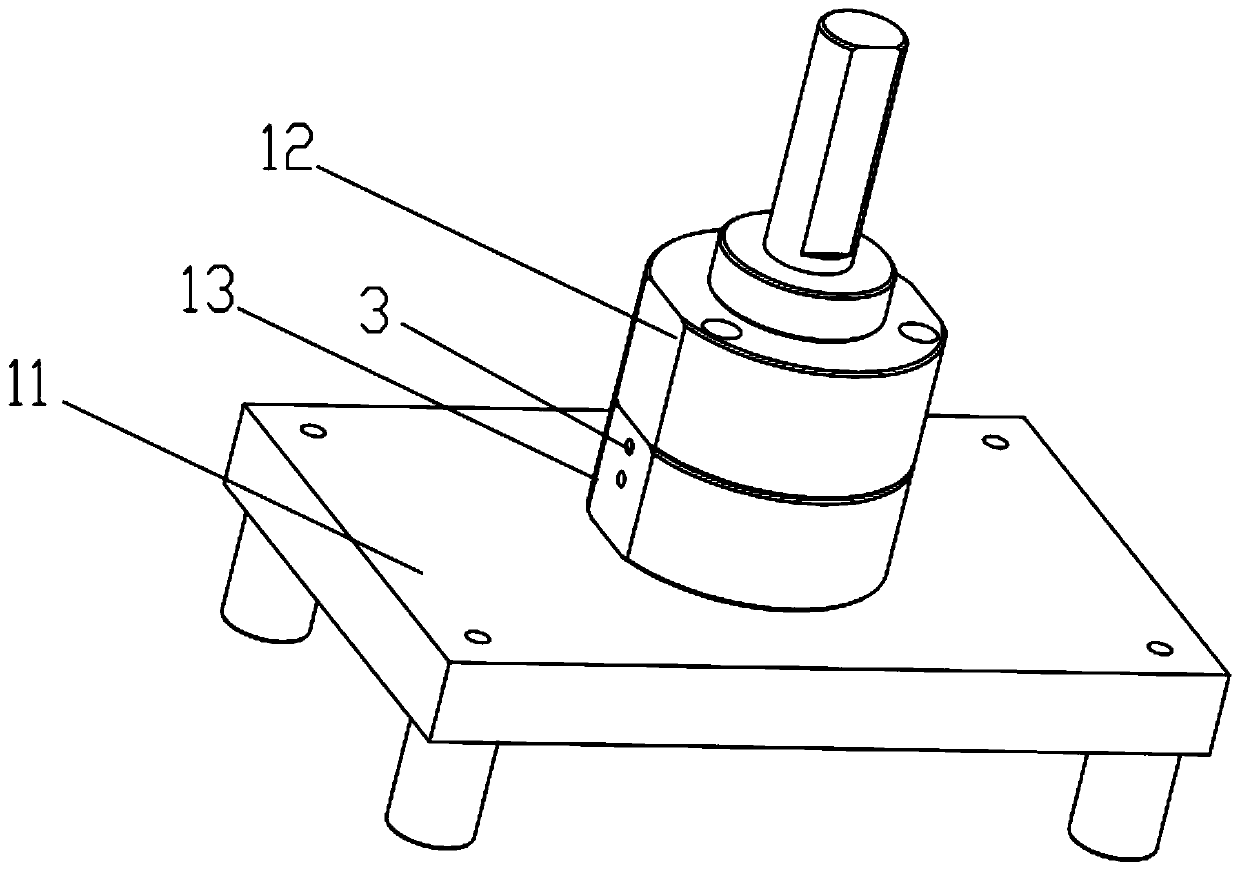

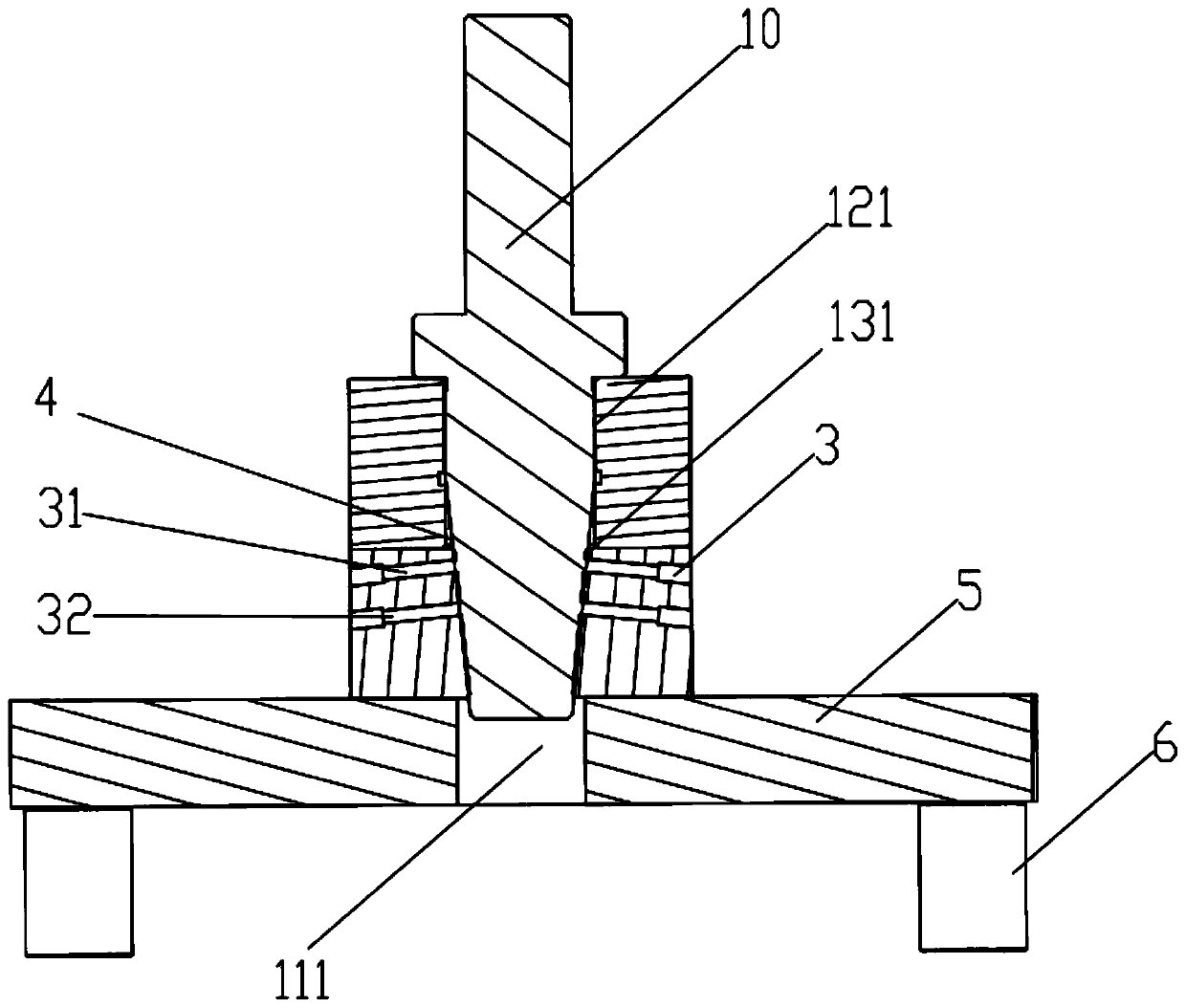

InactiveCN105973707AAccurate measurementImprove detection efficiencyMaterial strength using tensile/compressive forcesApparatus for force/torque/work measurementNumerical controlMeasuring instrument

The invention relates to a numerical-control detection device for bearing-keeping-device rivet separating force. The numerical-control detection device comprises a base, a lifting mechanism, an upper mold pressing piece, a lower mold pressing piece, a rotating mechanism and a torque detection mechanism. The lifting mechanism is vertically installed on the base, the upper mold pressing piece and the lower mold pressing piece are sequentially installed on the lifting mechanism, a lower pressing mold is arranged on the lower mold pressing piece, and the lifting mechanism drives the lower pressing mold to vertically move; the torque detection mechanism comprises a torque measuring instrument and a measuring bar, a pressure measuring bar is installed at the tail end of the measuring bar, an upper pressing mold corresponding to the lower pressing mold is arranged on the lower surface of the upper mold pressing piece, and a plurality of positioning grooves for positioning the pressure measuring bar are formed in the upper pressing mold, and correspond to rivets on a detected keeping device placed on the lower pressing mold one by one. According to the numerical-control detection device, the pressure measuring bar on the torque detection mechanism is matched with the lifting mechanism, the moment separating force, in the static state, of a riveting part of the detected keeping device is detected, the lower pressing mold is driven by the rotating mechanism to rotate, and the detection accuracy and the detection efficiency are improved.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

Check tool for pneumatic detection of taper angle and detection method

InactiveCN110715624AEase of judging eligibilityDetection speedUsing fluid meansCrankStructural engineering

The invention relates to a check tool for pneumatic detection of a taper angle and a detection method. The check tool comprises a detection device and a measurer, wherein the detection device is connected with the measurer and comprises a base, a cushion sleeve and a taper sleeve, the taper sleeve is arranged on the base, a conical hole is formed in the taper sleeve, air holes are formed in a sidesurface of the conical hole and are respectively arranged in an upper part and a lower part of the conical hole, axial lines of the air holes are perpendicular to a bus of a measured conical surface,the cushion sleeve is arranged above the taper sleeve, the cushion sleeve and the taper sleeve are coaxially arranged, and a through hole is formed in the cushion sleeve and communicates with the conical hole. By the check tool for pneumatic detection of the taper angle and the detection method, the taper angle of a crank shaft can be accurately detected, and whether a product is qualified or notis conveniently judged; and moreover, the detection speed can be increased, the check tool is suitable for mass detection, and complete inspection of the product is achieved.

Owner:CHONGQING MEIXIN YINGSHEN MACHINERY CO LTD

Method and device for automatically detecting powder material accumulation density

InactiveCN102175566BImprove accuracyImprove efficiencySpecific gravity measurementControl systemProgrammable logic controller

The invention relates to a method and a device for automatically detecting powder material accumulation density, relating to a device for detecting powder (granular) material accumulation density. The method comprises the following steps of: (1) connecting a material dividing hopper with an original spiral conveyer pipe; (2) opening a material dividing valve at the lower part of the material dividing hopper so that materials fall to a material weighing hopper supported by a weighing sensor; (3) scraping stacks at the top of the material weighing hopper through a material pushing scraping plate driven by a material pushing cylinder; (4) transmitting weight information of the material weighing hopper to a PLC (programmable logic controller) control system for calculating, comparing and displaying by the weighing sensor; (5) opening a material discharging valve at the lower part of the material weighing hopper so that the materials fall to a material receiving hopper and enter to a secondary spiral conveyer; and (6) pushing the materials falling from the material receiving hopper to be combined with the materials falling from an original spiral conveyer material discharging tube and sending to next procedure together by the secondary spiral conveyer. The device disclosed by the invention has the advantages of automatic identifying function, high accuracy, fast speed and high efficiency; and the device is capable of realizing full check, and effectively controlling the product quality.

Owner:青海海西东诺化工有限公司

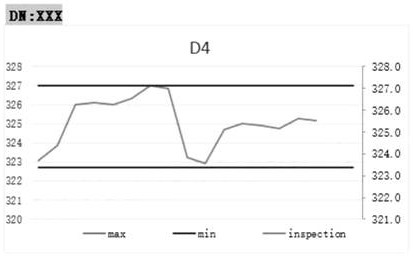

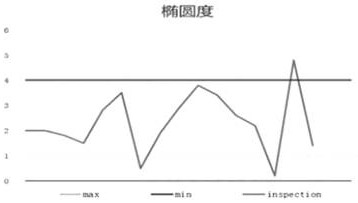

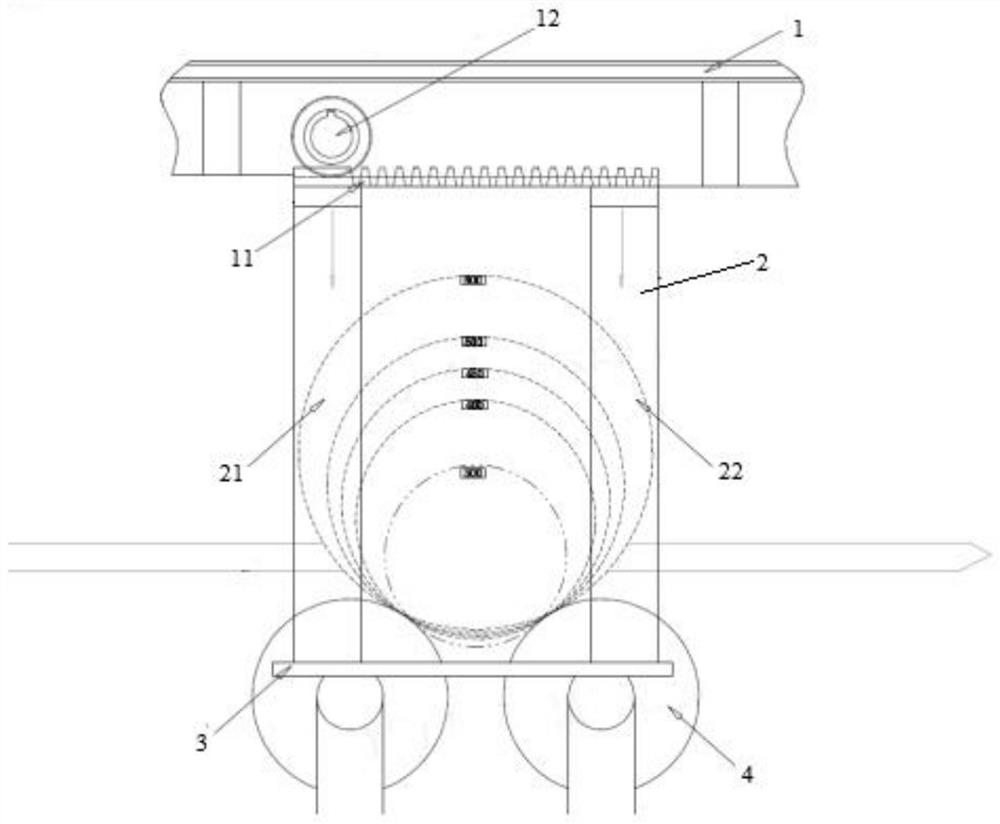

Device and method for detecting ovality and diameter of large-diameter spheroidal graphite cast pipe

PendingCN114739302AImprove detection accuracyRealize full inspectionUsing optical meansGraphiteDiameter measurement

The invention discloses a large-diameter spheroidal graphite cast pipe ovality and diameter detection device and a detection method thereof, and belongs to the technical field of spheroidal graphite cast pipe diameter measurement. The device comprises a fixing support and a sensor assembly, the sensor assembly is assembled on a support body of the fixing support, the sensor assembly is composed of a first sensor and a second sensor, and the first sensor and the second sensor are arranged in parallel at an interval; the ductile iron pipe is placed between the measurement ranges of both the first sensor and the second sensor. The cast pipe detection range can be expanded, all cast pipe models at present are covered, the detection precision of the sensor assembly is higher than that of a caliper and a measuring tool, full detection is achieved, the diameter and ovality are calculated through software according to data detected and collected by the sensor assembly, production is fed back in real time, and a quality report is generated. Unqualified products are processed through background data, the maximum outer circle and the minimum outer circle of the cast pipe are found out in time and fed back to a rounding station, and the production efficiency is improved.

Owner:SAINT GOBAIN PIPELINE SYST +1

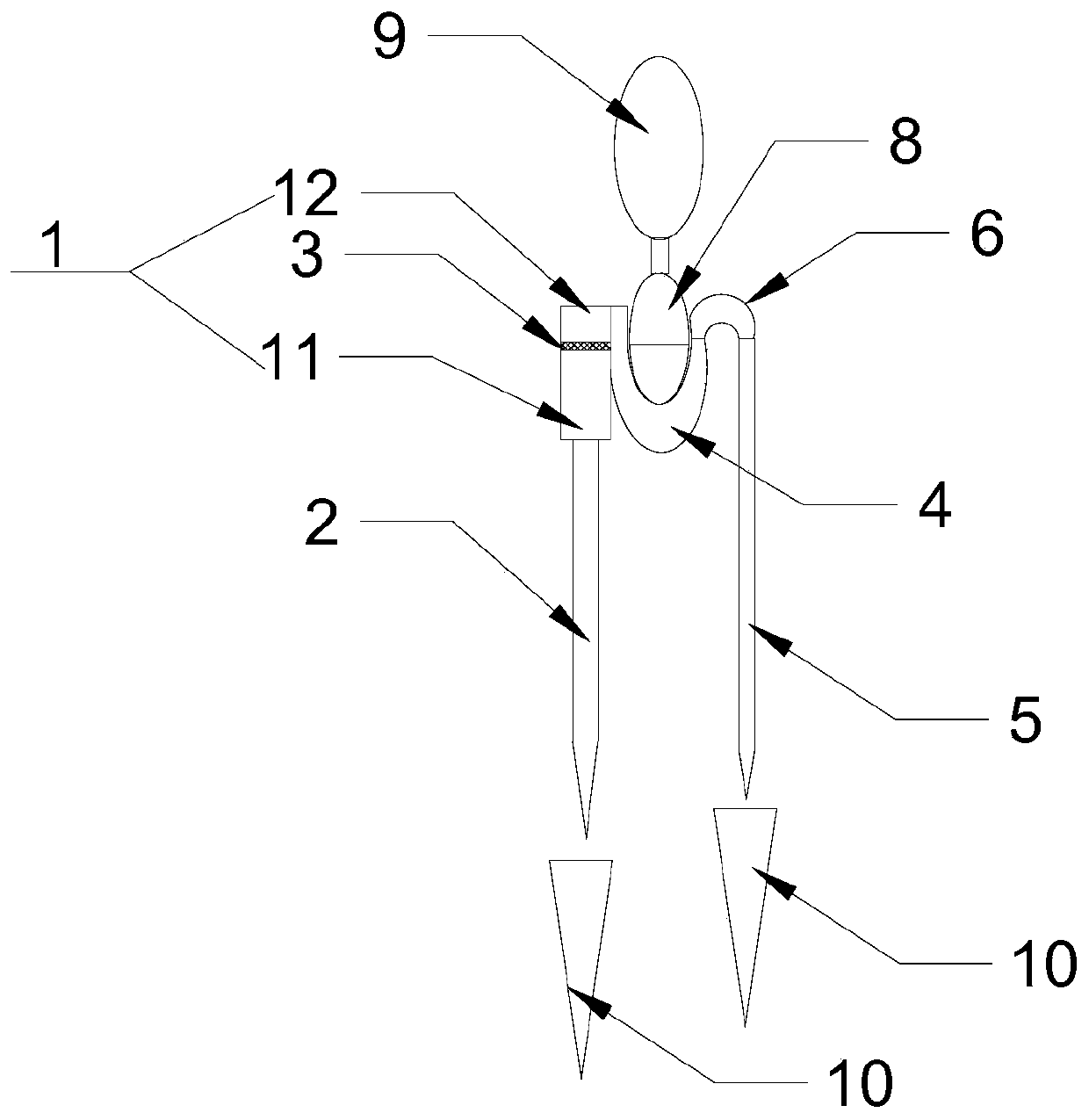

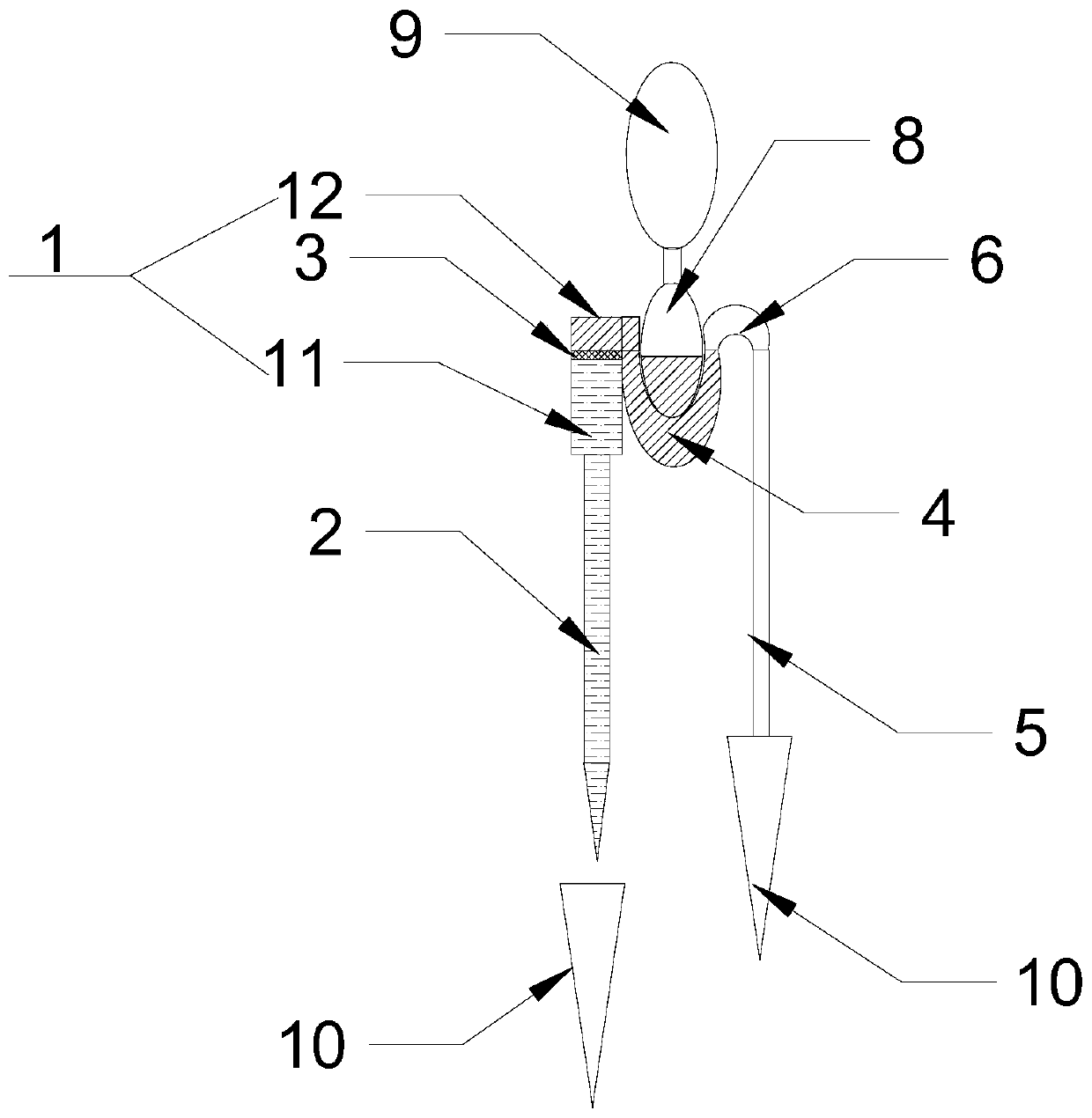

Quantitative sample injector for blood separation

PendingCN111413186AHigh precisionEasy to operatePreparing sample for investigationWhole blood unitsBlood separation

The invention relates to the technical field of medical apparatus and instruments, in particular to a quantitative sample injector for blood separation which comprises a sample suction tube of which atop part is provided with an accommodating space, a filter membrane which is used for dividing the accommodating space into a stock solution area and a filtrate area, a U-shaped pipe of which the bent pipe part is arranged downwards, wherein one end of the U-shaped pipe is communicated to the filtrate area, and the other end of the U-shaped pipe is connected with a sample adding pipe; a liquid storage bag which is arranged between the two straight pipe sections of the U-shaped pipe, wherein an inlet is formed in one side, close to the sample suction pipe, of the liquid storage bag; a pluggingpiece which is used for plugging the open end of the sample suction pipe or the sample adding pipe, wherein a negative pressure unit is arranged on the liquid storage bag and used for generating negative pressure to enable a whole blood sample to enter the U-shaped pipe after being filtered by a filter membrane at the top of the sample suction tube, and the whole blood sample is discharged from the sample adding tube after the negative pressure unit applies pressure. The quantitative sample injector for blood separation not only can filter red blood cells, but also can quantitatively inject samples.

Owner:芜湖森爱驰生物科技有限公司

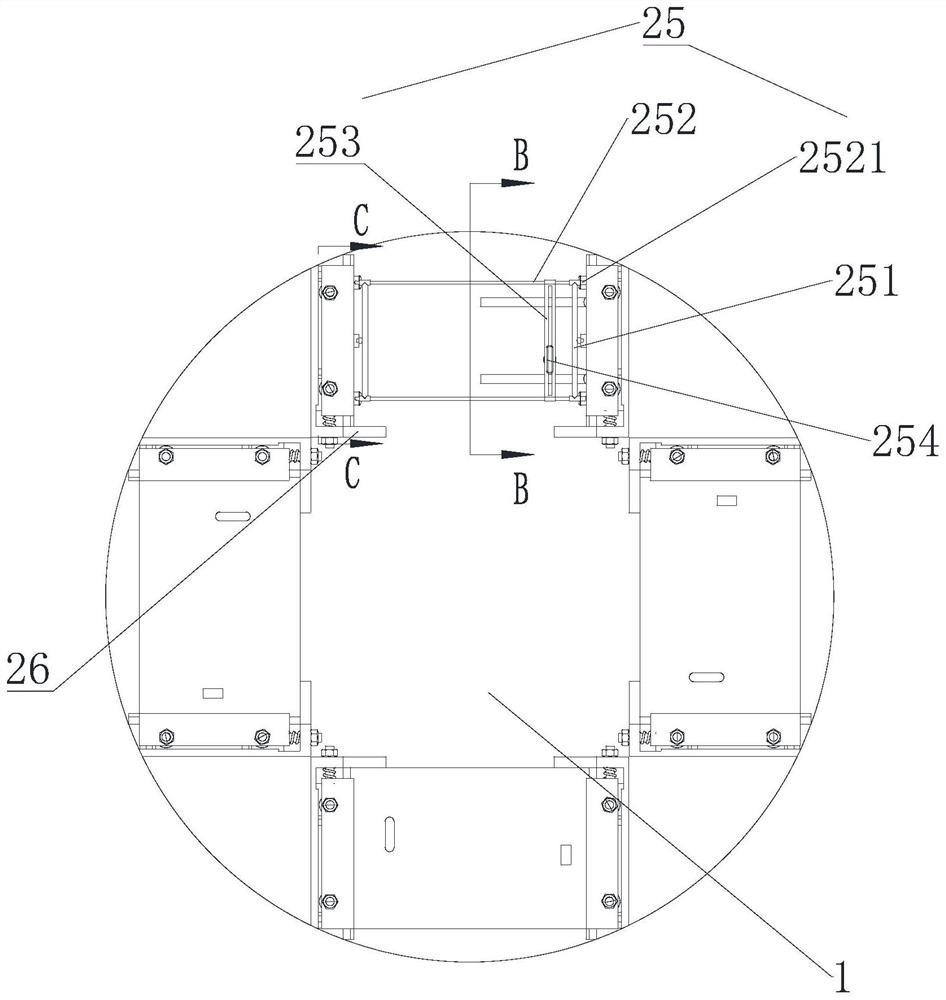

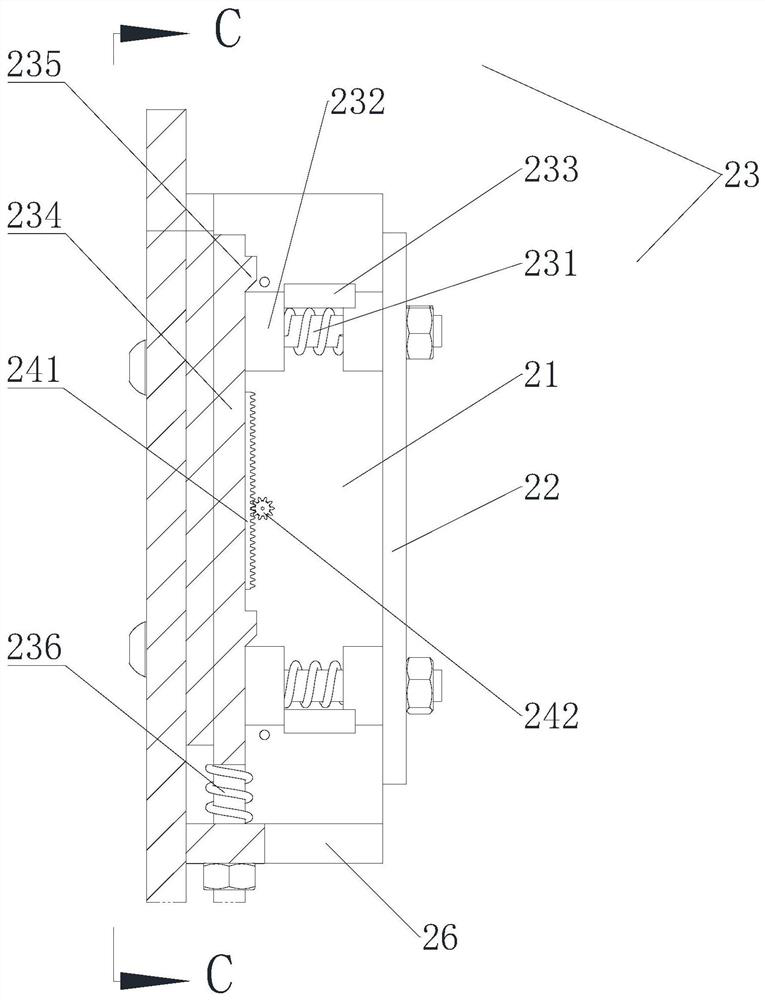

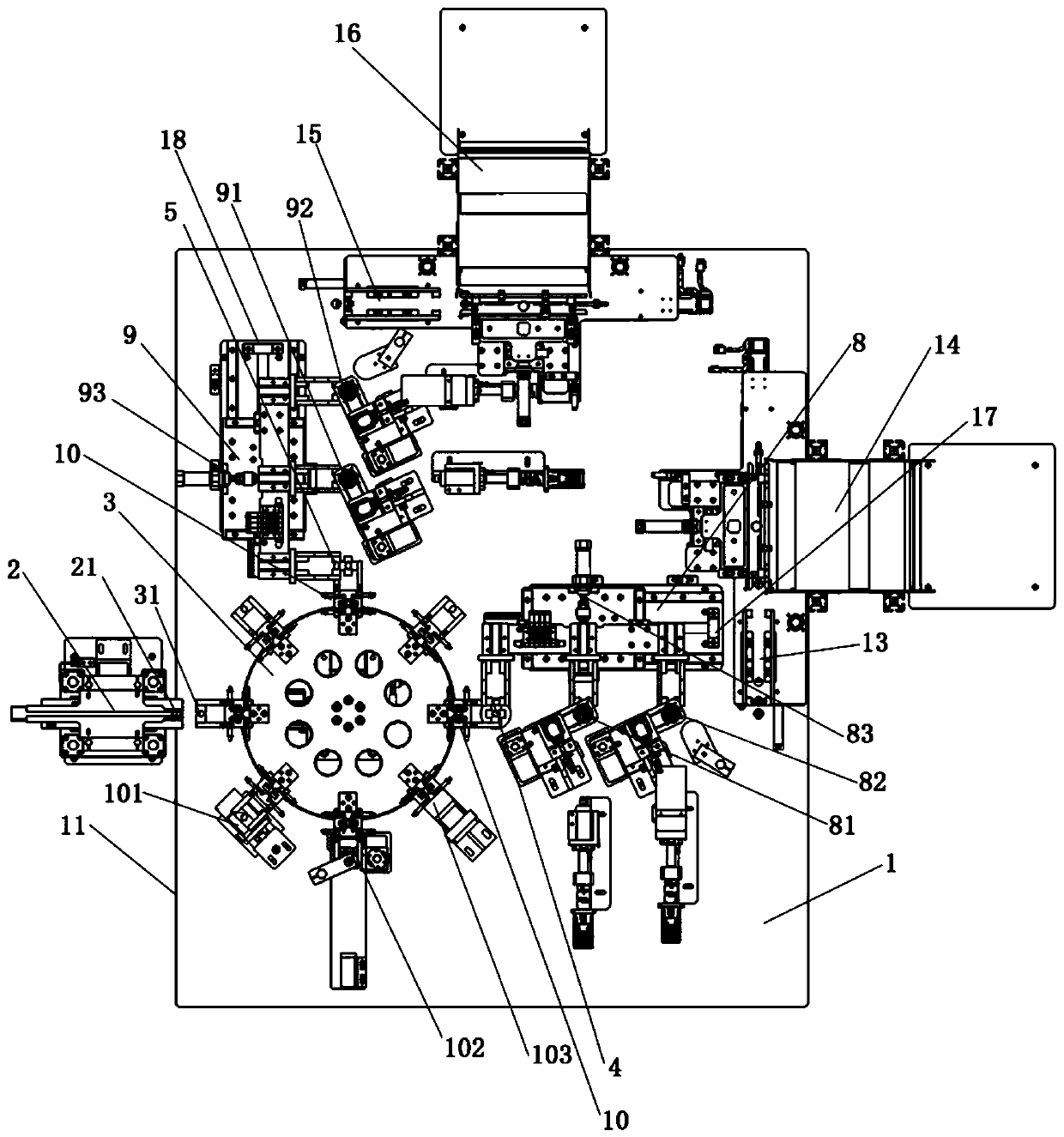

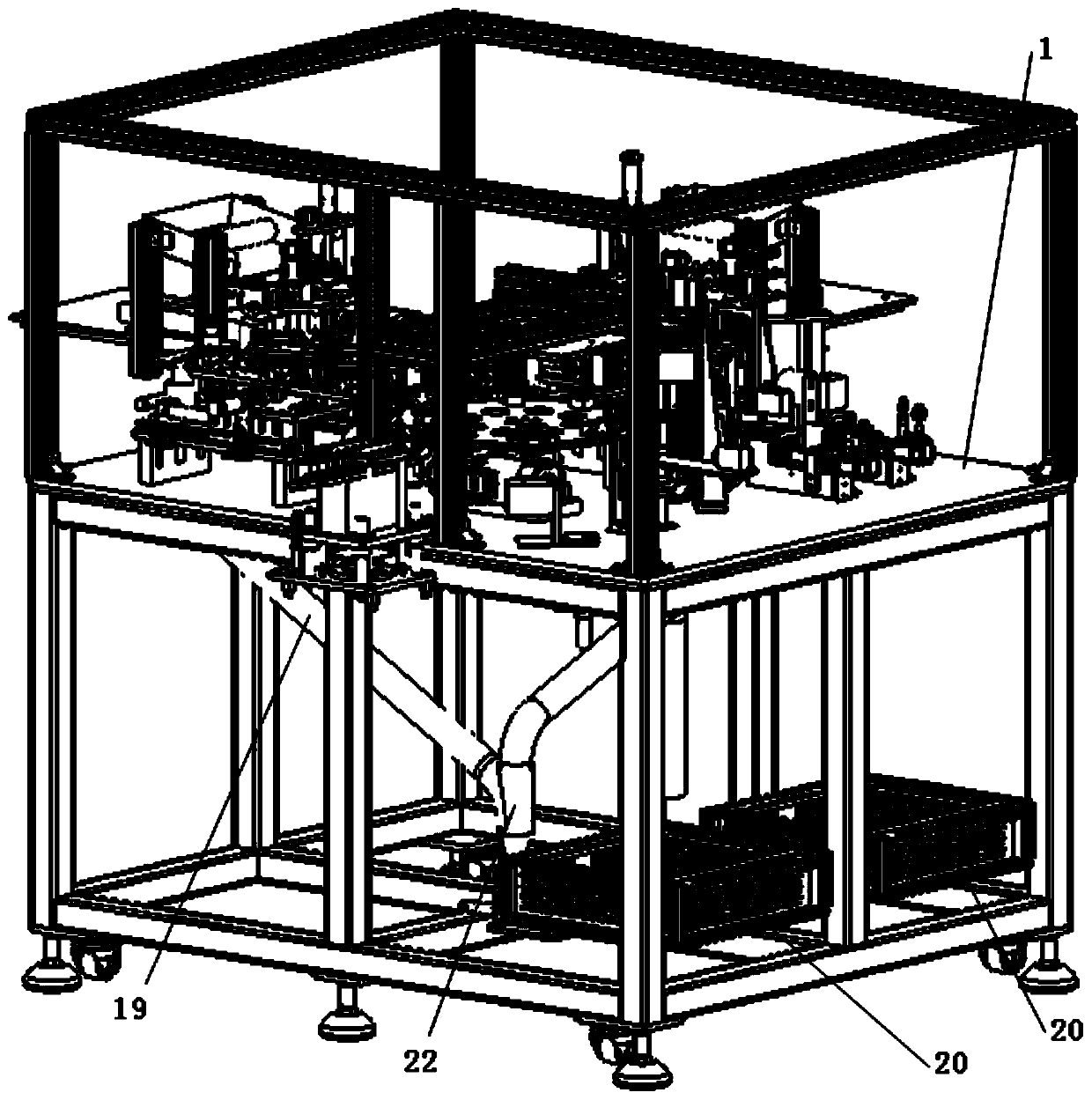

Fuse tube plug-in mounting device

PendingCN112291945ARealize fully automatic insertionEnsure insertion reliabilityPrinted circuit assemblingPrinted circuit aspectsPressure curveForce sensor

The invention discloses a fuse tube plug-in mounting device, which comprises a turntable, wherein a plurality of groups of tool clamps for fixing PCBs are arranged on the turntable, a board feeding connection mechanism, a plug-in mounting mechanism and a board discharging connection mechanism are respectively arranged on the outer side of the turntable along the rotating direction of the turntable, an opening and closing mechanism is arranged in each tool clamp, the opening and closing mechanisms automatically open the tool clamps when the PCBs enter or exit from the tool clamps, and the PCBsare pressed after being in place. According to the fuse tube plug-in mounting device, full-automatic plug-in mounting of a fuse tube is achieved, and the labor cost is reduced; full inspection of themodel of the fuse tube is realized, and material mixing is avoided; and a plug-in pressure sensor is designed to monitor plug-in pressure in real time and compare pressure curves to ensure plug-in reliability of the fuse tube.

Owner:GREE ELECTRIC APPLIANCES CHONGQING +1

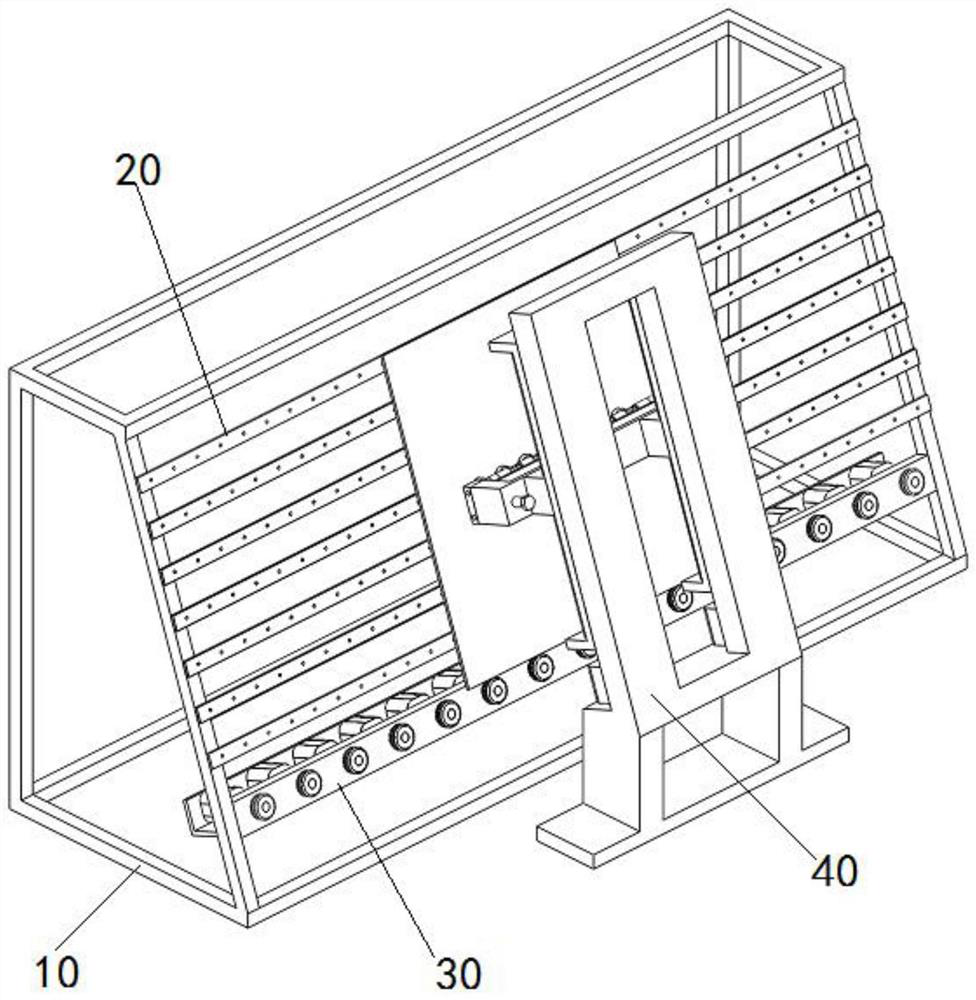

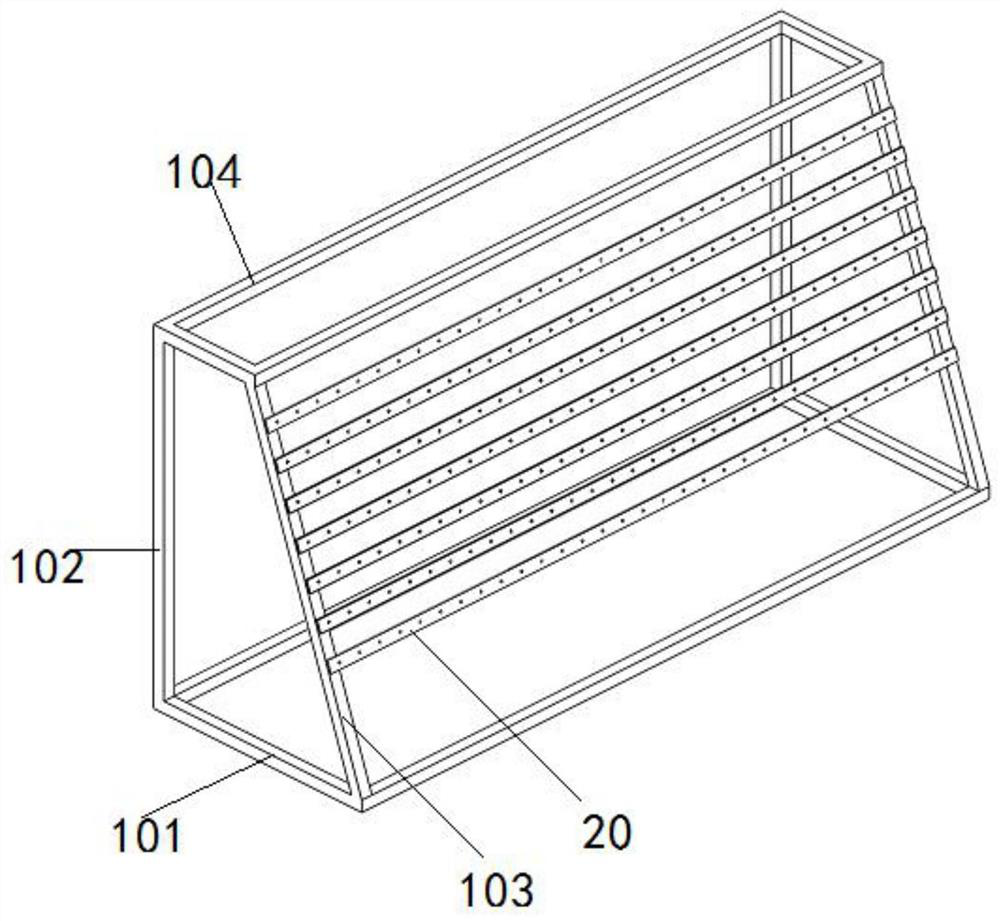

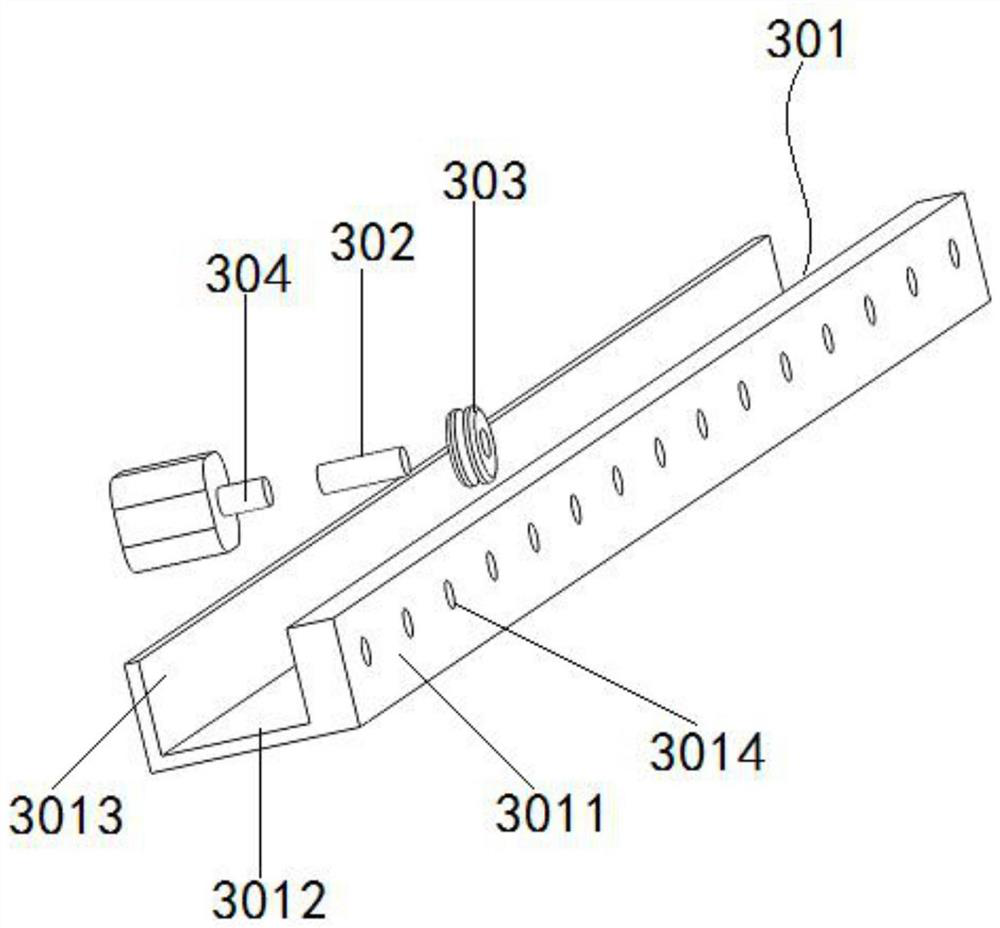

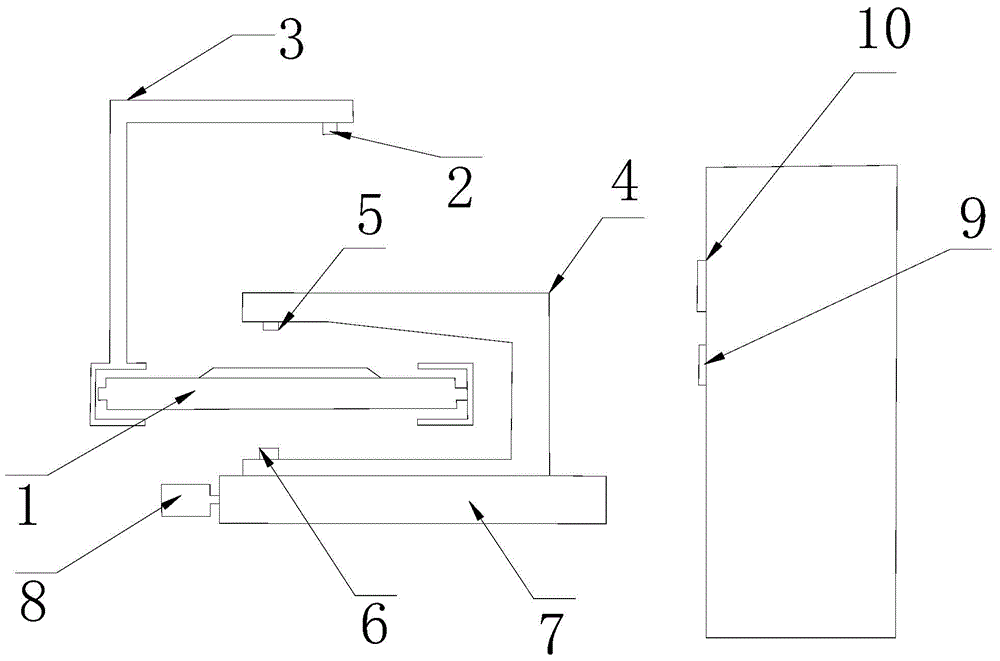

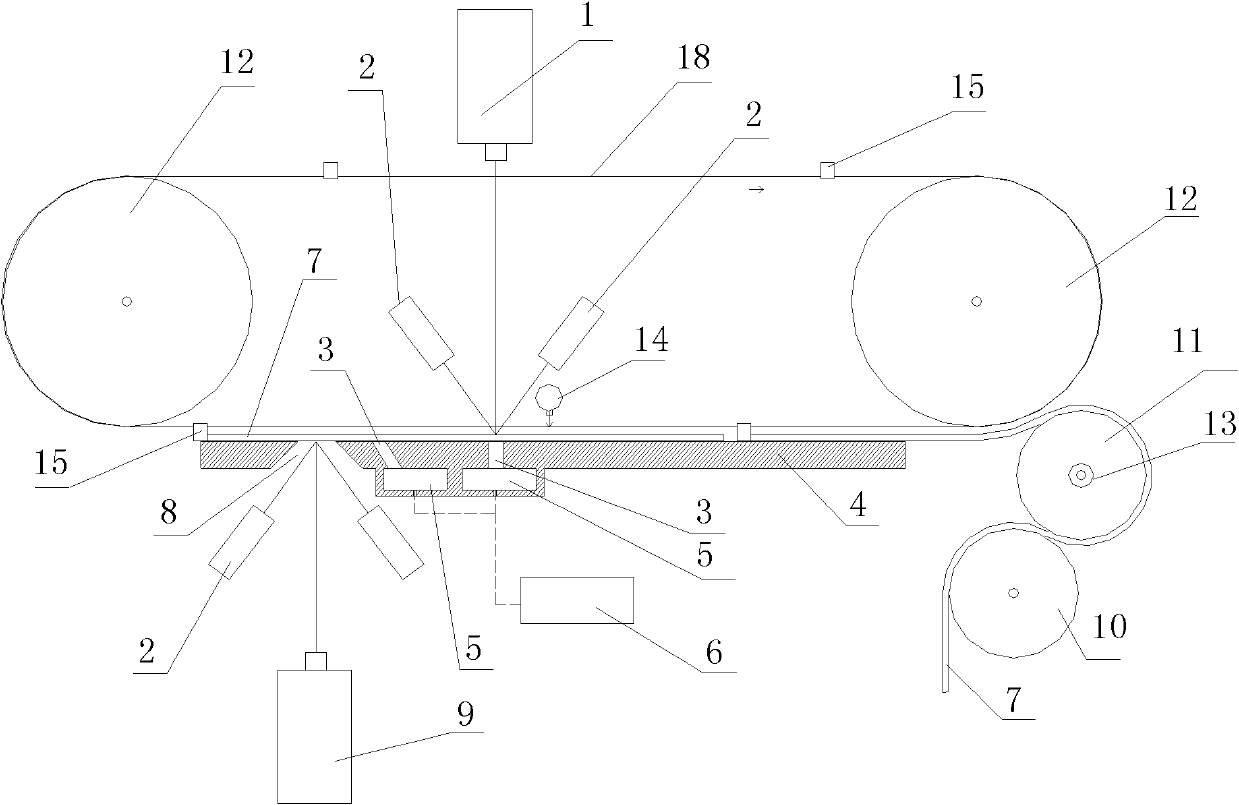

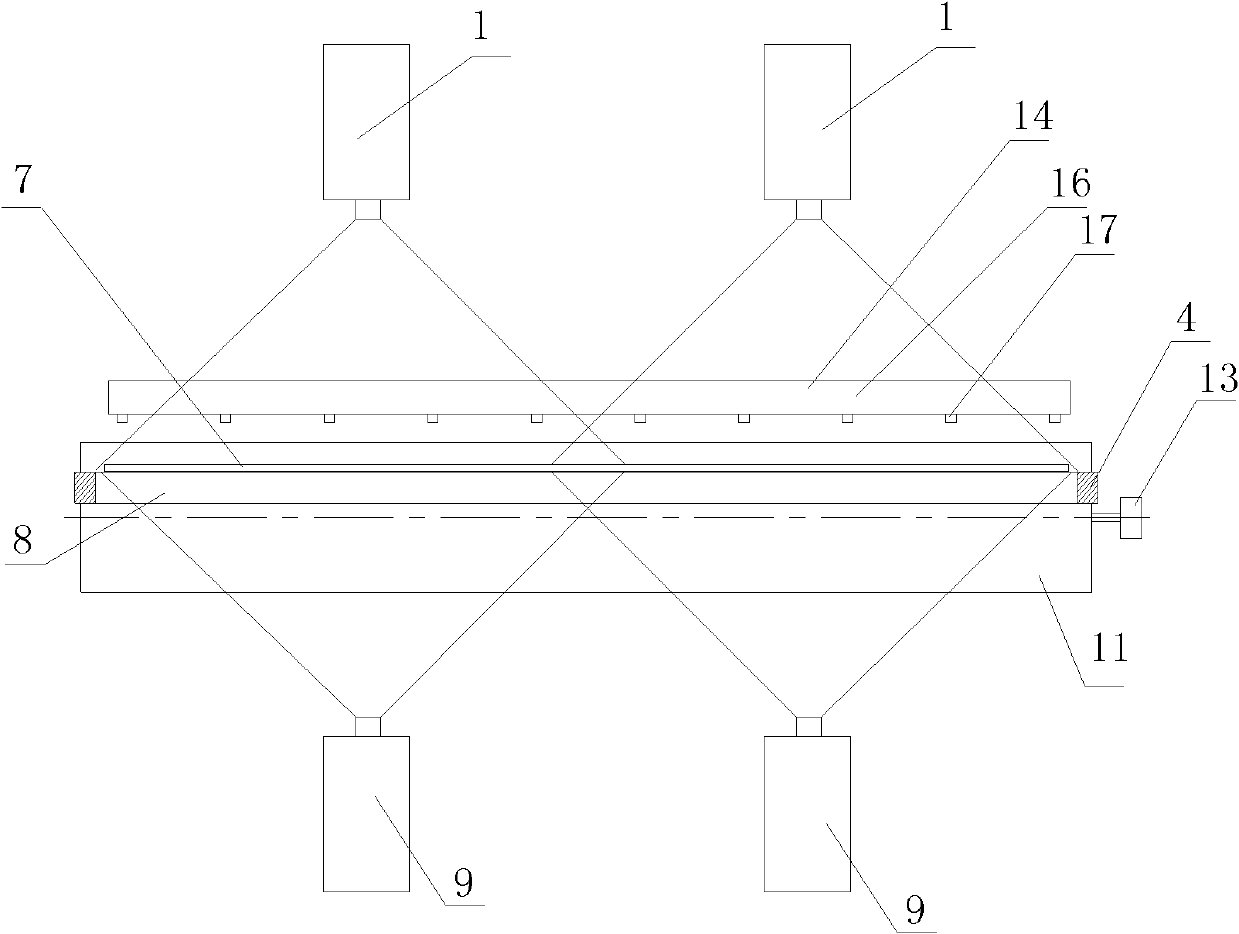

Plate buckling deformation online detection device based on longitudinal scanning

ActiveCN113340224AImprove measurement efficiencyRealize full inspectionUsing optical meansLaser probeStructural engineering

The invention discloses a plate buckling deformation online detection device based on longitudinal scanning. The plate buckling deformation online detection device comprises a transmission frame and air floating cushion rods evenly distributed on the front face of the transmission frame, a roller transmission mechanism is arranged at the bottom end of the front face of the transmission frame, and a detection installation frame is installed in the middle of the front face of the transmission frame; the detection mounting frame comprises a detection mounting inclined plate which is obliquely distributed, a mounting bottom plate fixedly connected with the bottom end of the roller transmission mechanism is arranged at the bottom end of the detection mounting inclined plate, and a mounting top plate fixedly connected with the top end of the transmission frame is arranged at the top end of the detection mounting inclined plate; a lifting adjusting mechanism is longitudinally arranged in the middle of the inner surface of the detection mounting inclined plate, and a probe mounting mechanism is transversely mounted in the middle of the lifting adjusting mechanism. According to the invention, the laser probe is transversely arranged along the product transmission direction, the surface distance of the product is measured by moving along the longitudinal direction, whether the warping of the product is qualified or not is determined through specification judgment in combination with the finally formed product surface 3D distribution diagram, the measurement efficiency is high, and the full inspection of the product is realized through on-line one-by-one inspection of the product.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

Online section scanner of tyre surface

ActiveCN105043291AQuality improvementRealize full inspectionUsing optical meansDisplay deviceEngineering

The invention relates to an online section scanner of a tyre surface. The device is mounted a conveying roller which is cut in fixed length, and comprises a photoelectric sensor, a first support, a second support, a servo motor, a controller and a display, the photoelectric sensor is arranged over the conveying roller via the first support, a first laser thickness measuring sensor and a second laser thickness measuring sensor are respectively arranged at the two ends of the second support, and placed over and under the conveying roller respectively, a transmission mechanism is arranged under the second support, one end of the transmission mechanism is connected with the servo motor, the first laser thickness measuring sensor, the second laser thickness measuring sensor and the photoelectric sensor are connected with the controller, and the controller is connected with the servo motor and the display. The scanner can realize comprehensive detection, the whole detection process does not need manual work, the detection time is shortened, and the quality of the tyre surface is improved.

Owner:HANGZHOU CHAOYANG RUBBER

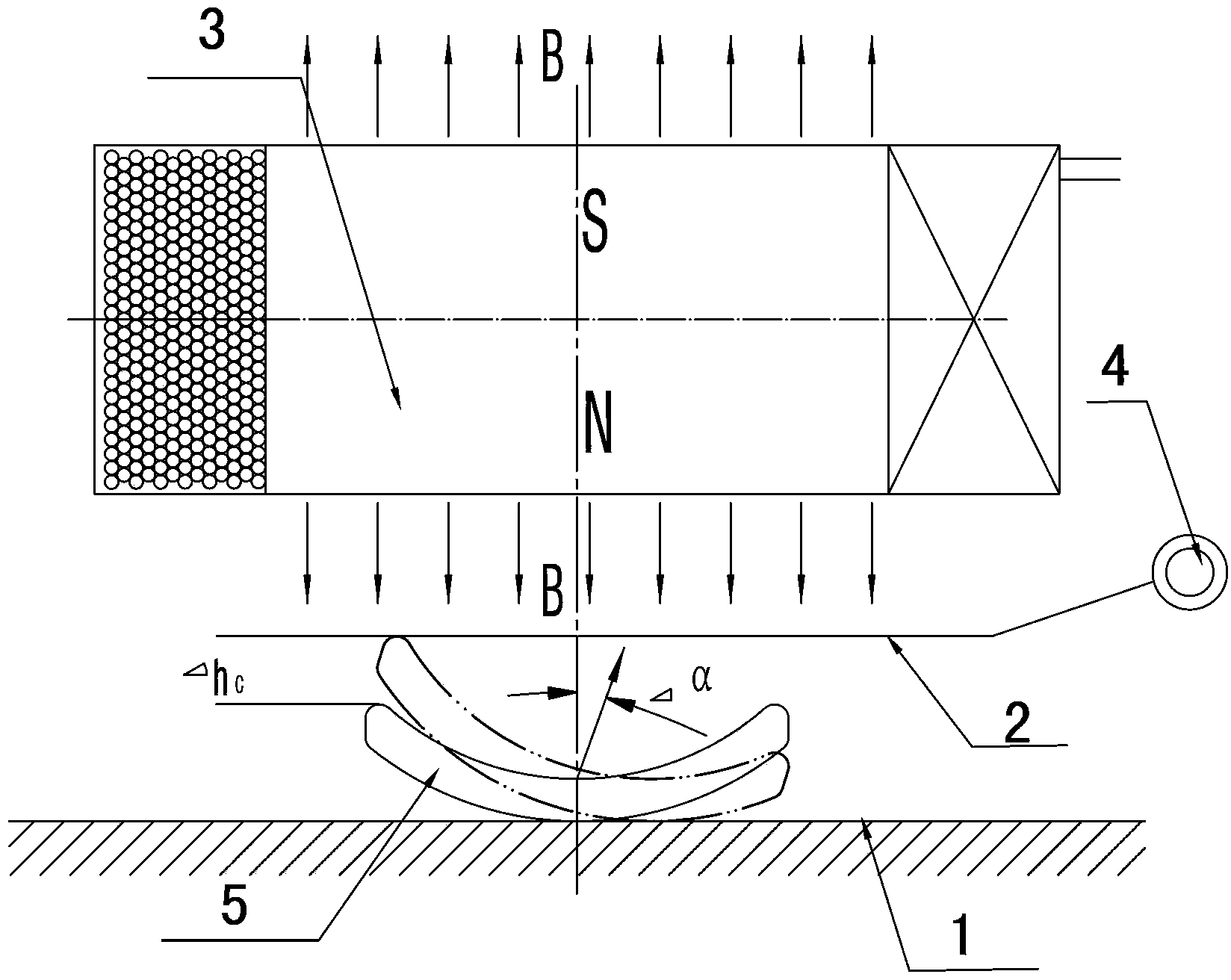

Method for detecting magnetization direction of non-magnetized anisotropic magnetic steel

ActiveCN104020425ARealize continuous automatic detectionRealize full inspectionMagnetic property measurementsElectrical resistance and conductanceMagnetic anisotropy

The invention discloses a method for detecting magnetization direction of non-magnetized anisotropic magnetic steel. According to the method, non-magnetized anisotropic magnetic steel which has correct magnetization direction and has the same specification with magnetic steel to be detected is used as first standard magnetic steel and non-magnetized anisotropic magnetic steel which has incorrect magnetization direction and has the same specification with the magnetic steel to be detected is used as second standard magnetic steel; reactance and resistance are respectively detected by the adoption of an eddy current inspection instrument; resistance of the magnetic steel is taken as a horizontal coordinate and reactance of the magnetic steel is taken as a vertical coordinate to make an impedance plane diagram of the magnetic steel; an oval area is delimited in the impedance plane diagram to be used as a magnetization direction qualified area according to a position marked as the first standard magnetic steel and a position marked as the second standard magnetic steel in the impedance plane diagram; and detection of magnetization direction of the magnetic steel is converted to detection of position of the magnetic steel in the impedance plane diagram. The method provided by the invention has advantages as follows: continuous automatic detection of the magnetic steel in a non-magnetic environment is realized; detection efficiency is high; costs are low; full inspection of mass production can be realized; and detectivity of the detection is high.

Owner:NINGBO YUNSHENG +4

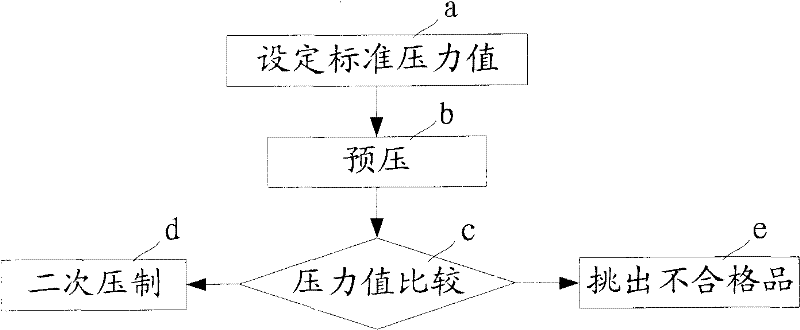

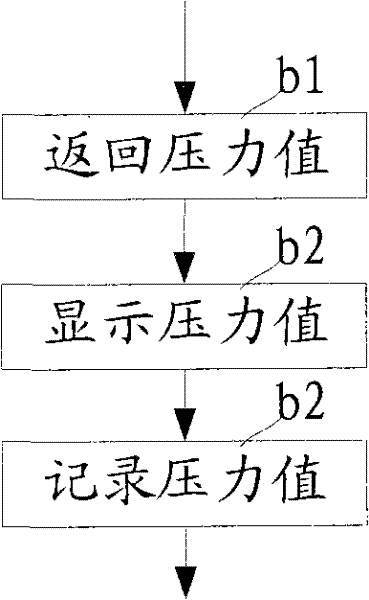

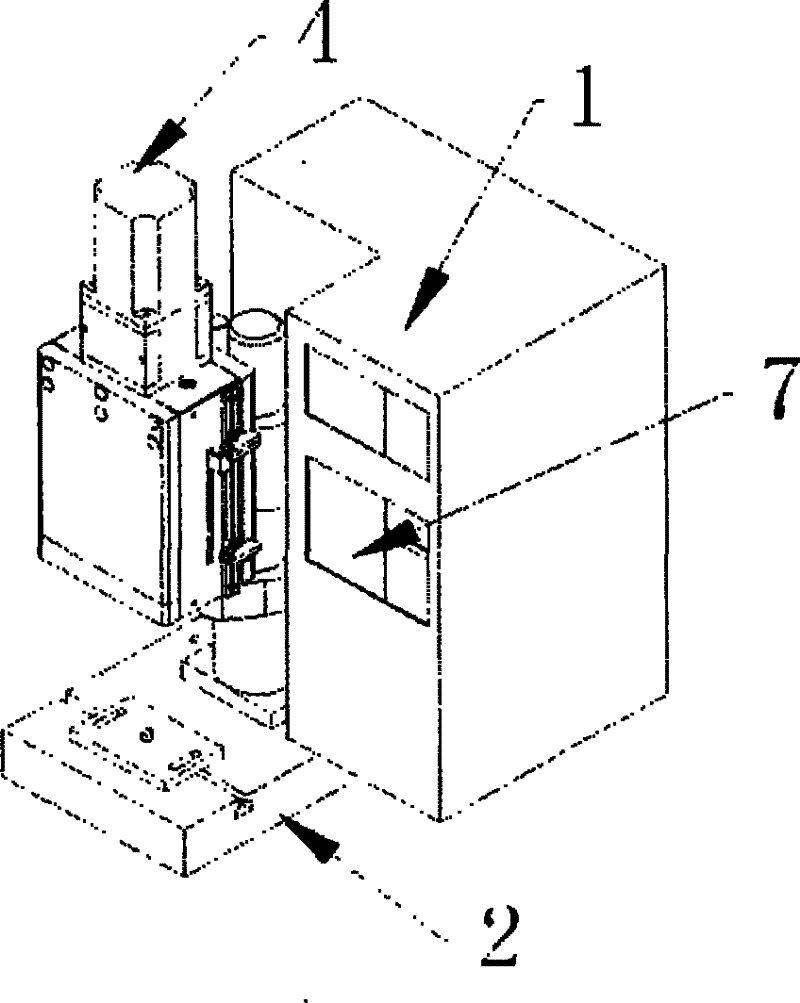

Pressfit method and equipment capable of measuring interference force

InactiveCN102189393ADisengagement force achievedRealize full inspectionMetal working apparatusPressesEngineeringElectrical and Electronics engineering

The invention relates to a pressfit method and pressfit equipment capable of measuring interference force, in particular to a press working method and press working equipment. The method comprises the following steps of: setting the standard pressure value required by a finished product; pre-pressing a part, measuring the current pressure value during pre-pressing, and comparing the pressure value measured during pre-pressing and the standard pressure value; when the pressure value measured during the pre-pressing reaches the standard pressure value, pressing for the secondary time; and when the current pressure value does not reach the standard pressure value, finishing processing. In the pressfit method and the pressfit equipment capable of measuring the interference force, defective products which cannot reach the breakout effort can be picked up in the production process; during pressing, the part is pressed to a specific position for the first time, and the position is half or one third the total pressfit stroke; and according to the setting of different products, if the measured pressure value reaches the requirement of a product, the pressfit of a secondary step is performed, and the product is continuously pressed in place, so that the full inspection of the key index of the breakout effort is realized.

Owner:张志嵩

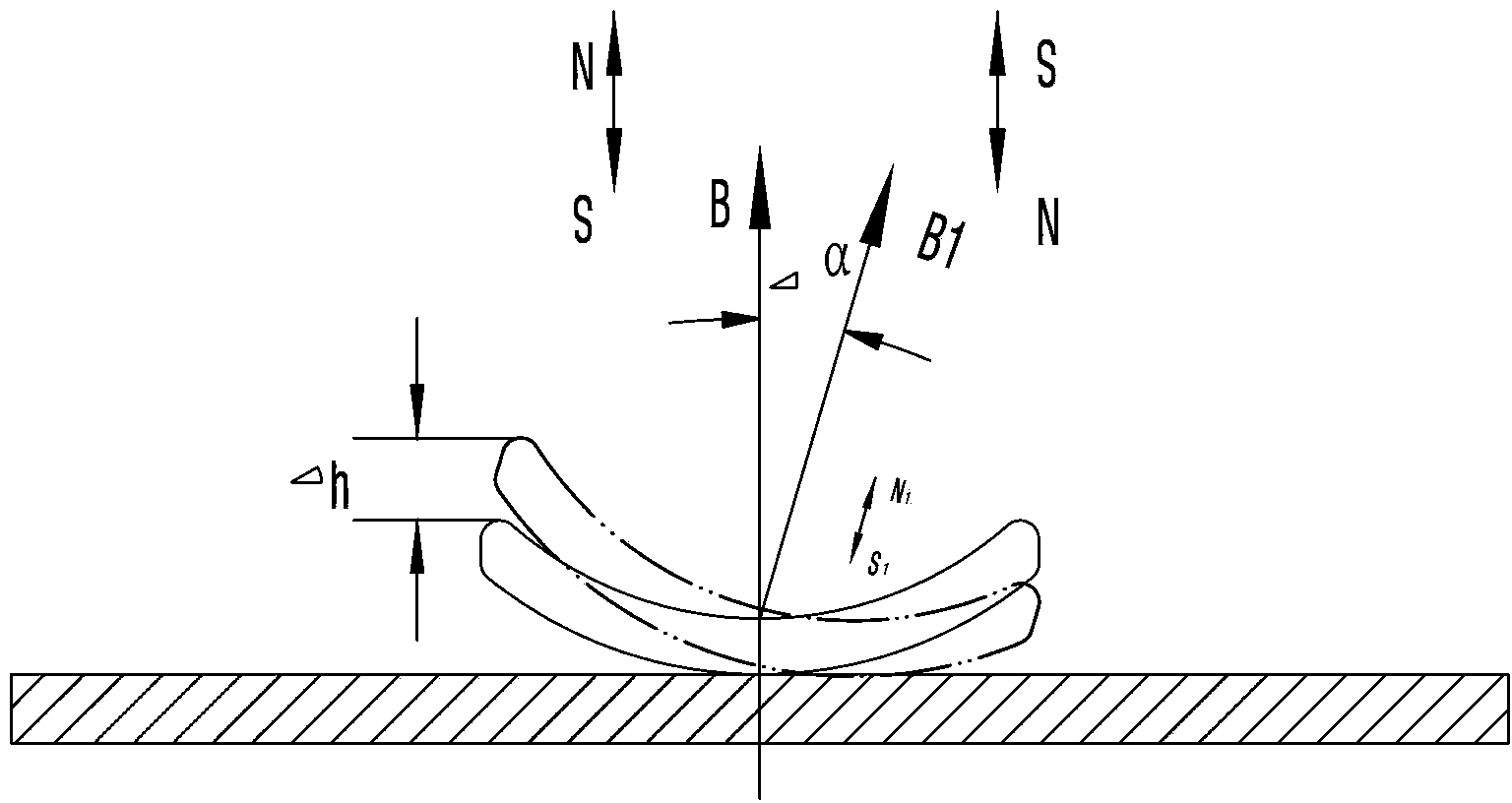

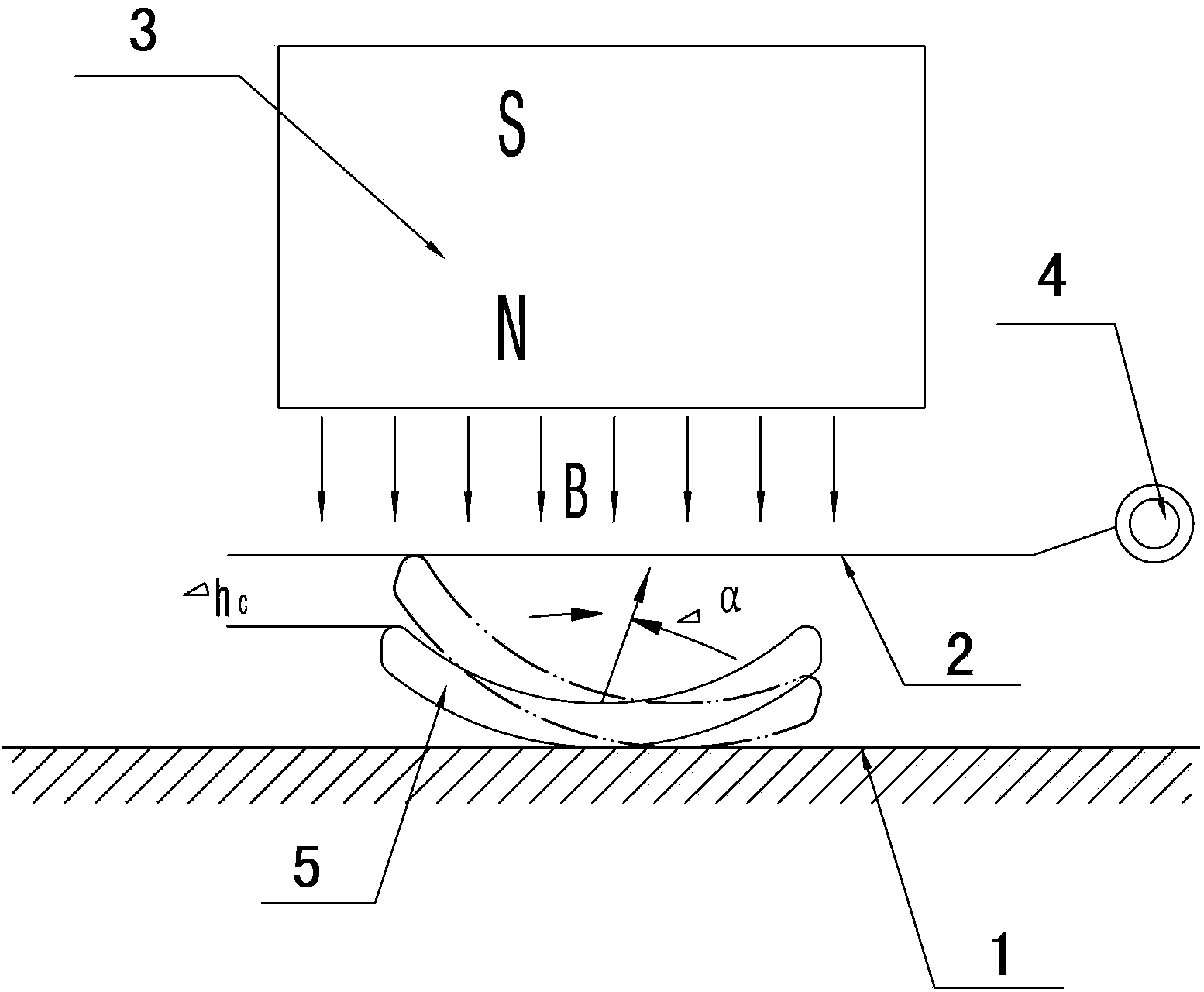

Method and device for measuring magnetic declination of tile-shaped magnet element

ActiveCN103412267ARealize full inspectionGuaranteed pass rateMagnitude/direction of magnetic fieldsMagnetic declinationMagnet

The invention discloses a method and device for measuring the magnetic declination of a tile-shaped magnet element. Firstly, the deflection height, relative to the datum line, of a datum component is detected under the action of a magnetic field, the deflection height, relative to the datum line, of the datum component serves as the detection datum, and then when a product to be detected is detected in the magnetic filed, the deflection height, relative to the datum line, of the product to be detected and the deflection height, relative to the datum line, of the datum component are compared to obtain whether the magnetic declination of the product to be detected is qualified. The method and device have the advantages that operation is simple, cost is low, the tile-shaped magnet element (after orientation forming) without magnetizing is detected, full detection of the magnetic declination of the tile-shaped magnet element can be achieved, and the percent of pass of the magnetic declination of the tile-shaped magnet elements of the whole batch is guaranteed.

Owner:NINGBO CANMANG TECH

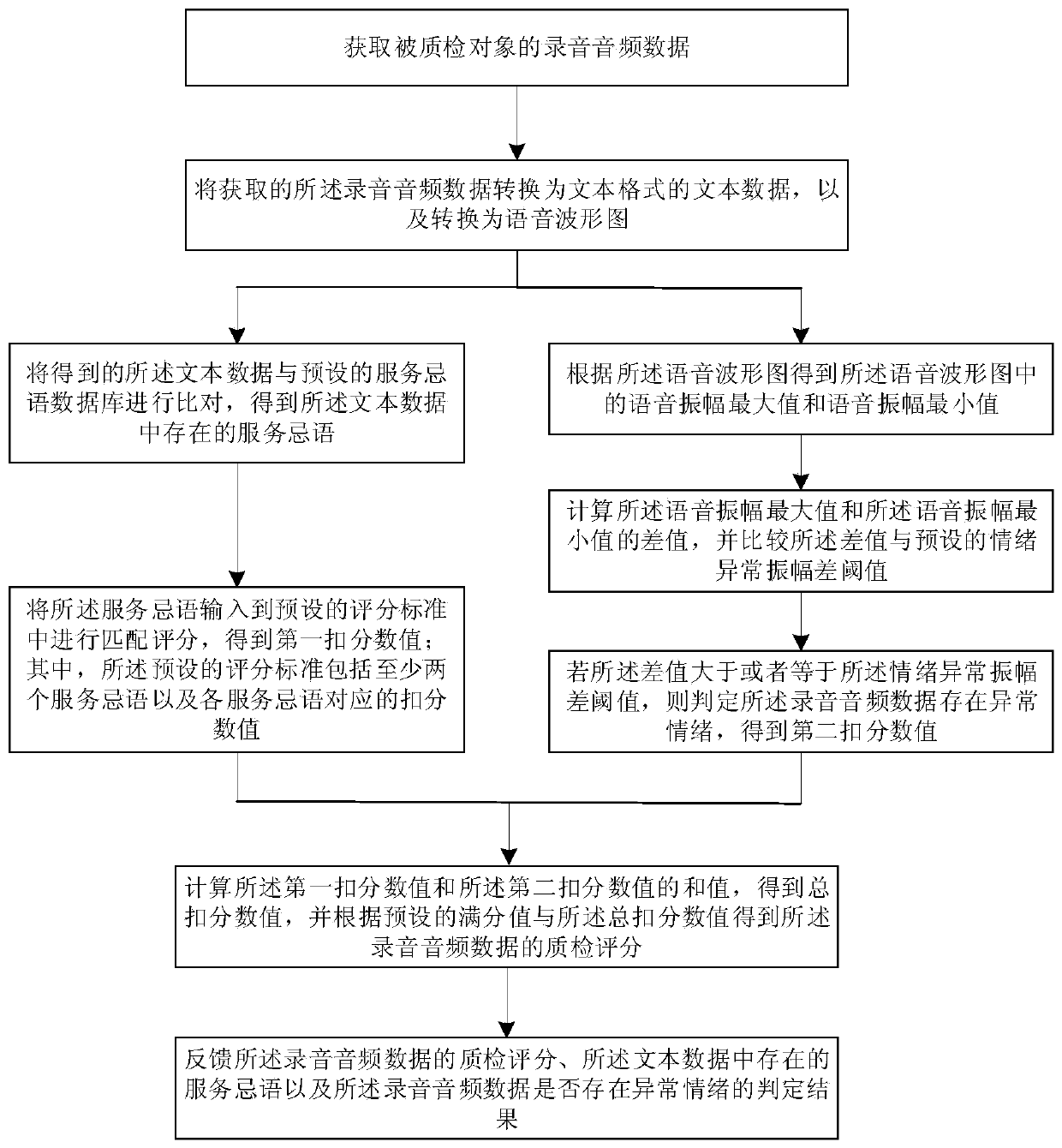

Dynamic extensible voice quality inspection scoring method

PendingCN111508529ADynamically scalable implementationGood effectSpeech analysisNatural language processingEngineering

The invention relates to a dynamic extensible voice quality inspection scoring method. The method comprises the steps of acquiring recording audio data of an object subjected to quality inspection, converting the acquired recording audio data into text data in a text format, converting the text data into a voice oscillogram, detecting service taboo languages according to the text data, generatinga first score deduction value; and detecting emotion abnormality according to the voice oscillogram, generating a second score deduction value, obtaining a quality inspection score of the recorded audio data according to the first score deduction value, the second score deduction value and the full score, and feeding back a judgment result of the quality inspection score, service taboo languages existing in the text data and whether the recorded audio data has abnormal emotion or not. The voice quality inspection scoring method is an automatic quality inspection scoring method, does not need to specially set quality inspection personnel, further avoids the problem of large quality inspection workload, reduces personnel investment cost, avoids loss of scoring fairness due to subjective judgment of the quality inspection personnel, and is relatively high in accuracy.

Owner:深圳航天科创实业有限公司

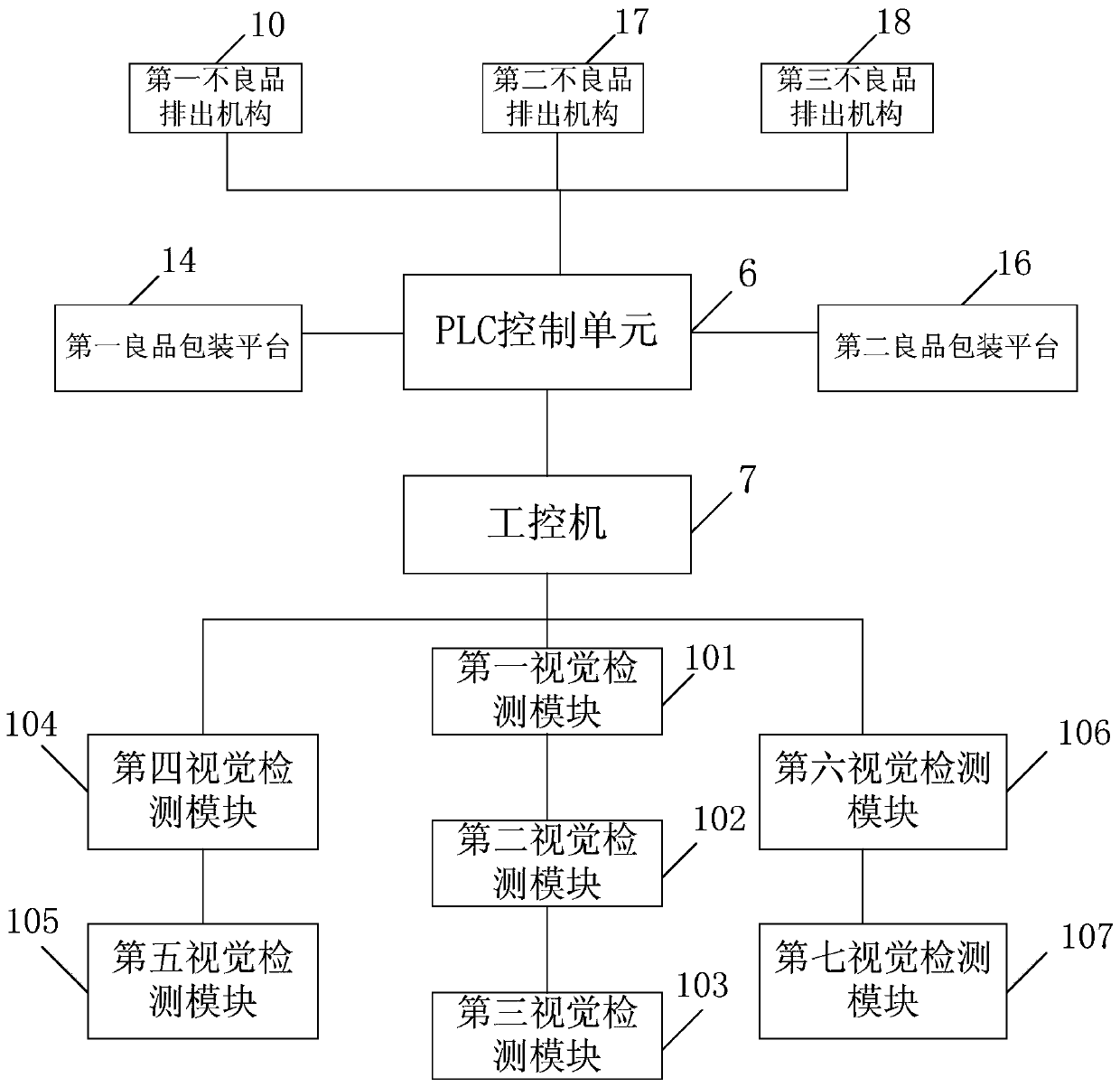

Automatic sorting machine for capacitor appearance

PendingCN109813724AImplement automatic detectionAvoid secondary damageOptically investigating flaws/contaminationSortingCapacitanceComputer module

The invention provides an automatic sorting machine for the capacitor appearance. The machine comprises a platform, a feeding mechanism, a division disc, a PLC control unit and an industrial personalcomputer; the feeding mechanism is fixed to the platform and used for conveying a capacitor; the division disc is rotatably fixed to the platform, a discharging port of the feeding mechanism faces thedivision disc, and a capacitor fixing assembly is arranged at the edge of the division disc at an interval of every quarter arc; a second vision detection module, a first separation mechanism, a second separation mechanism, a first vision detection module and a third vision detection module are arranged from the discharging port of the feeding mechanism; the three vision detection modules are used for detecting the capacitor appearance, and detection items of the three vision detection modules are different; the PLC control unit is used for controlling action of the feeding mechanism and usedfor controlling rotation of the division disc; data transmission connection between the industrial personal computer and the three vision detection modules is established, and the industrial personalcomputer is used for acquiring detection results of the detection items of the three vision detection modules in real time.

Owner:无锡立赫智能科技有限公司

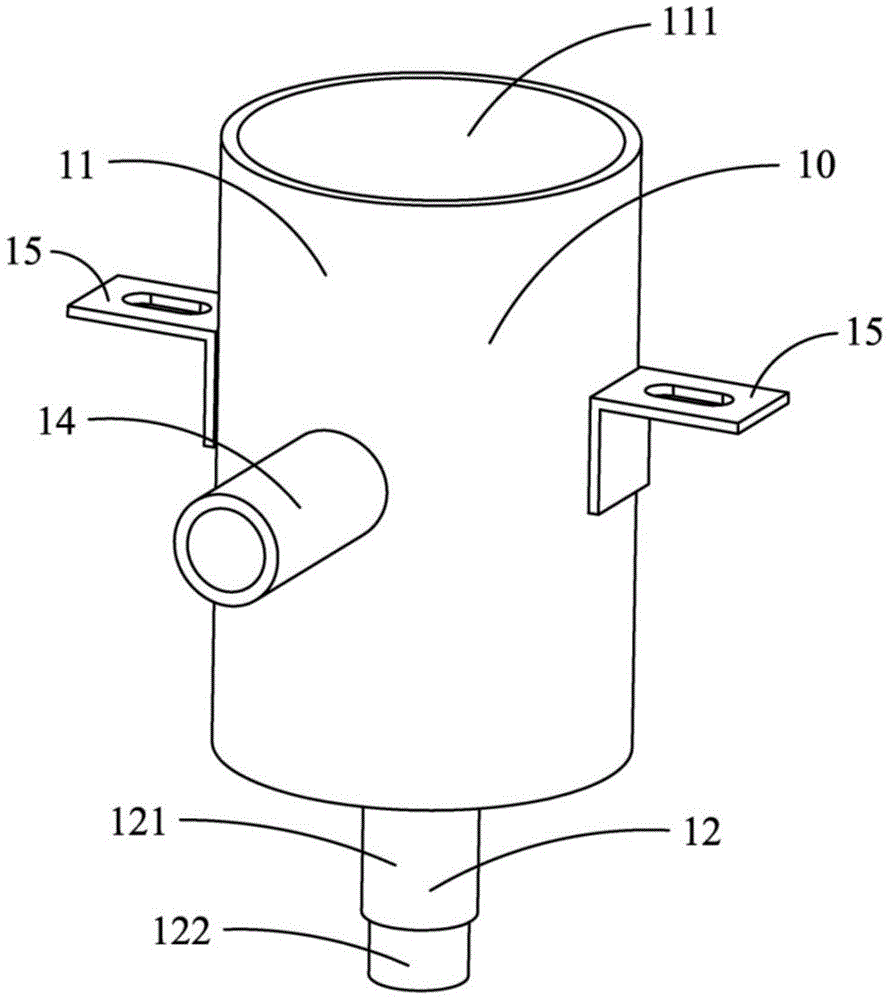

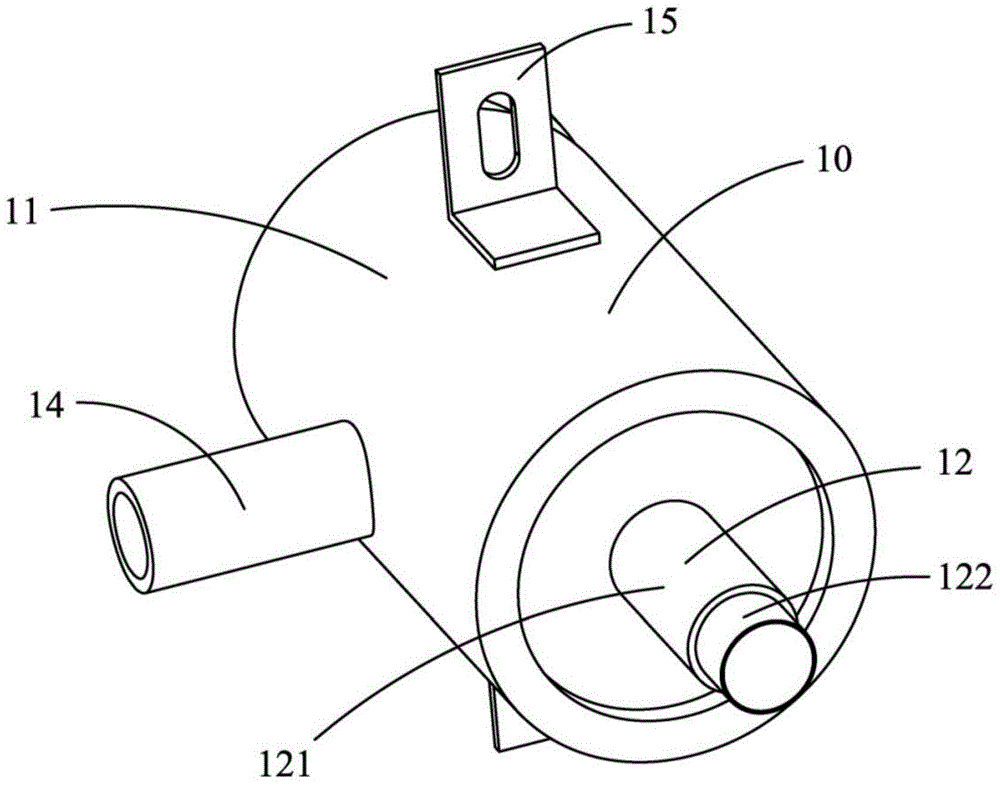

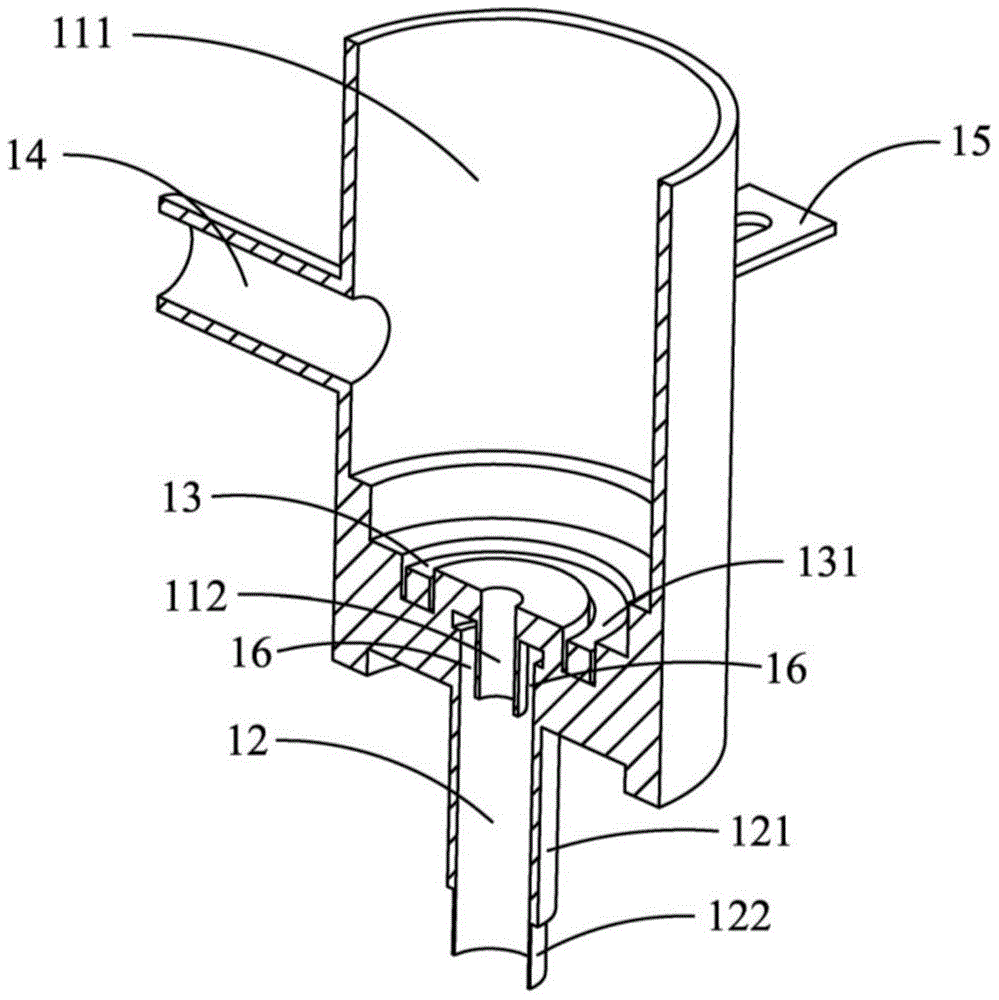

Online thickness measurement system for high-temperature cast pipe and using method of online thickness measurement system

PendingCN112525117ARealize full inspectionAvoid subsequent stackingUsing subsonic/sonic/ultrasonic vibration meansControl engineeringProcess engineering

The invention relates to the field of cast tube wall thickness detection equipment, and in particular, relates to an online thickness measurement system for a high-temperature cast pipe and a using method of the online thickness measurement system, wherein the online thickness measurement system comprises a pipe conveying vehicle arranged at an outlet of a casting machine and a detection system arranged on a moving line of the pipe conveying vehicle; the detection system comprises a wall thickness detection mechanism; the wall thickness detection mechanism comprises a probe assembly, and the probe assembly comprises a detection probe. The invention discloses the online thickness measurement system for high-temperature casting; the wall thickness of a cast pipe after the cast pipe is cast from a centrifugal casting machine can be immediately detected and the wall thickness data is immediately fed back to the casting machine for adjusting pouring parameters through the arrangement of thepipe conveying vehicle.

Owner:WUHU XINXING DUCTILE IRON PIPES

A device for quickly measuring the height of prefabricated building laminated trusses

ActiveCN111707201BQuick measurementReduce the difficulty of measurementUsing optical meansFast measurementArchitectural engineering

This application belongs to the technical field of measurement of prefabricated building laminated trusses, specifically a device for quickly measuring the height of prefabricated building laminated trusses, including a laser device and a background board, the laser device is arranged in front of the truss, and the background The board is arranged behind the truss, and the laser device is matched with the background board. The application realizes the rapid measurement of the height of the laminated plate truss. The application reduces the difficulty of measuring the height of the laminated plate truss, improves the measurement accuracy and efficiency, improves the production efficiency and reduces the physical exertion of workers.

Owner:山东城开远大装配式建筑有限公司

Wine detection device

The invention relates to a wine liquid detection device. The wine liquid detection device comprises a wine receiving device, a sample tank for detecting a wine liquid, and a connecting pipe through which the wine receiving device and the sample tank are connected, wherein the sample tank comprises a basic body, the top of the basic body sinks inwards to form a liquid inlet groove, and the side part of the basic body sinks inwards to form a liquid outlet groove communicated with the liquid inlet groove; a first mounting groove and a second mounting groove are also formed in the basic body, are positioned on the same straight line and are respectively communicated with the liquid outlet groove, quartz window sheets are respectively arranged on the first mounting groove and the second mounting groove, a Raman spectrometer for detecting the wine liquid is also mounted in the first mounting groove, and a light trap for absorbing lasers in the sample tank is also mounted in the second mounting groove.

Owner:SUZHOU EUROPOD PRECISION INSTR TECH CO LTD

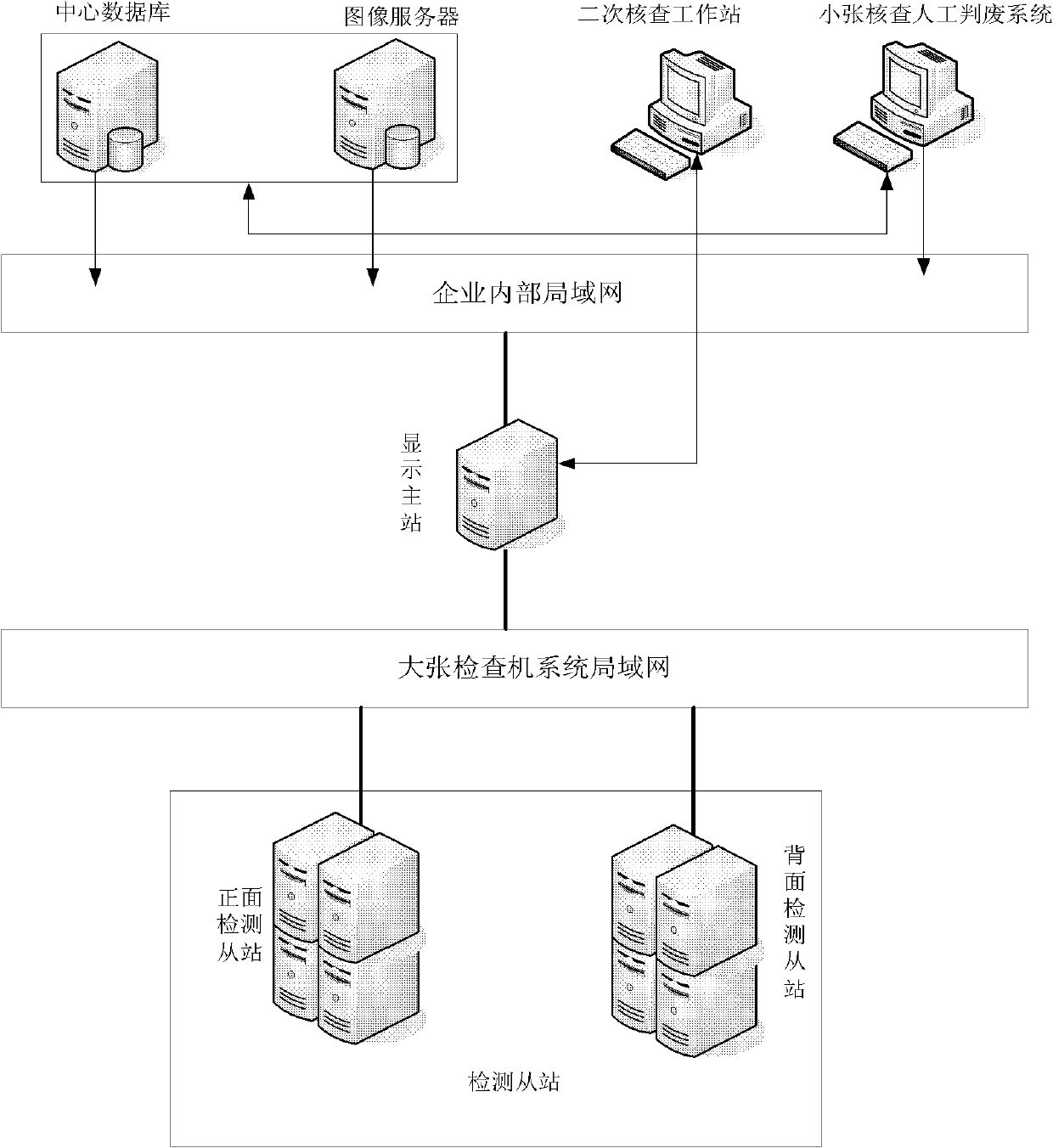

System and method for offline secondary detection and checking of machine detected data of large-piece checker

ActiveCN102236925BReduce workloadAvoid the risk of artificial leakage and serious wasteCoin testingFace detectionImage server

Owner:XIAN BANKNOTE PRINTING +2

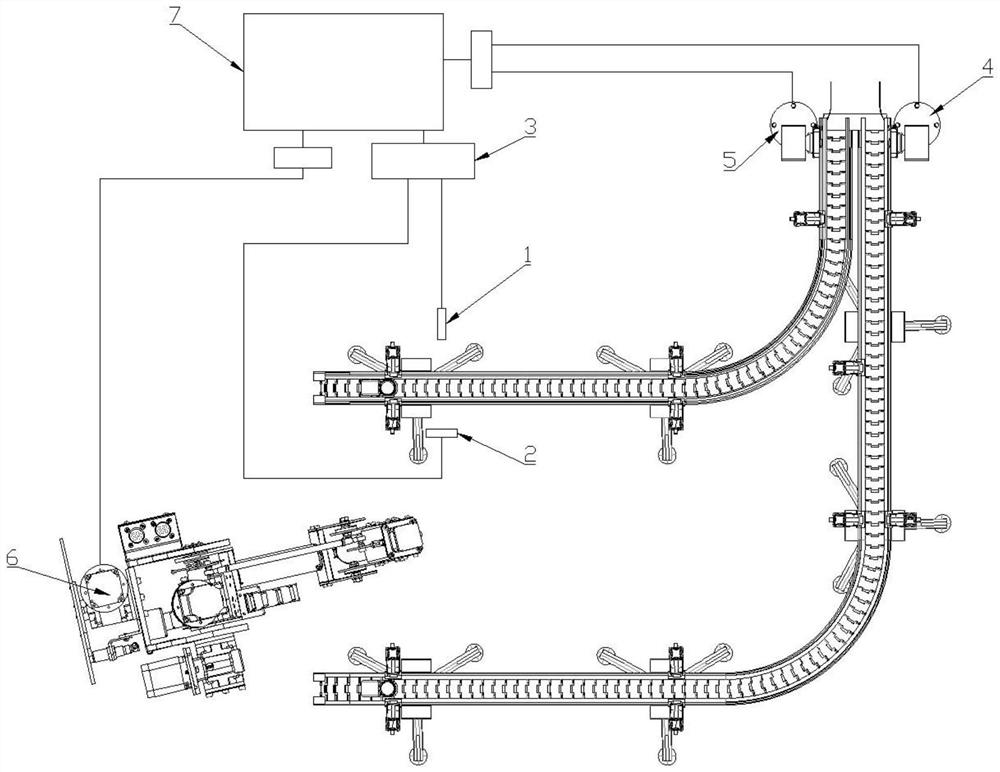

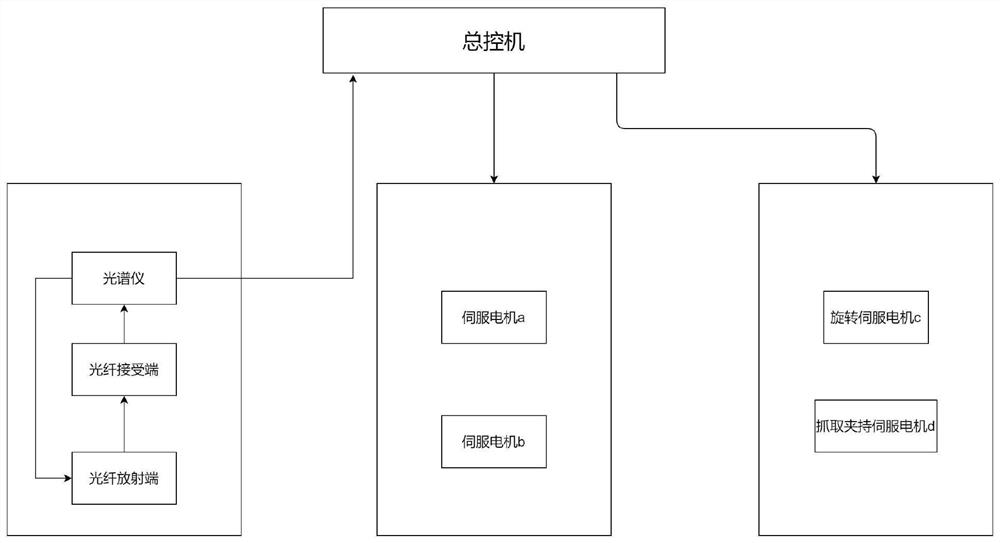

Optical fiber concentration detection system based on liquid medicines

InactiveCN112326555ARealize full inspectionFully automatedPhase-affecting property measurementsDual coreRefractive index

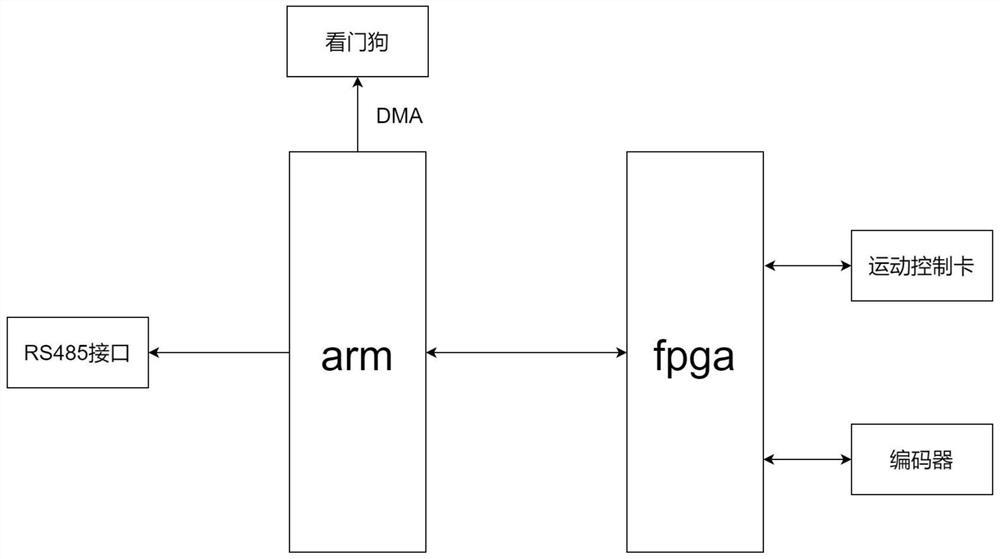

The invention discloses an optical fiber concentration detection system based on liquid medicines. The system comprises an optical fiber sensing and processing module, a parallel assembly line module,a sorting manipulator module and a master control machine, the optical fiber sensing and processing module comprises an optical fiber emitting end, an optical fiber receiving end and a spectrograph,the parallel assembly line module is composed of two assembly line conveying belts opposite in operation directions and further comprises a forward servo motor a and a reverse servo motor b, a rotaryservo motor c and a grabbing and clamping servo motor d are arranged in the sorting mechanical arm module, and the master control machine is a dual-core control machine designed based on arm and fpga.Compared with like systems in the prior art, the optical fiber concentration detection system has the advantages that the optical fiber concentration detection system utilizes the refractive index oflight for concentration, can realize full detection of a medicine solution on an assembly line, and can be directly brought into a technological process production line; and automatic and semi-automatic online process analysis can be realized by formulating personalized medicine detection and programming.

Owner:SHANDONG POLYTECHNIC COLLEGE

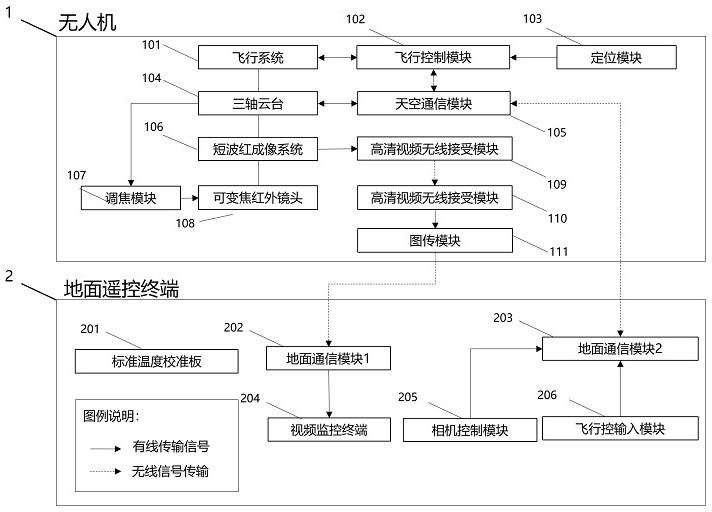

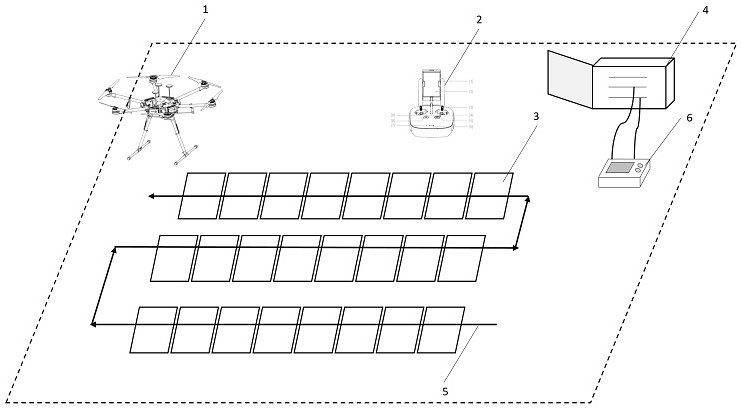

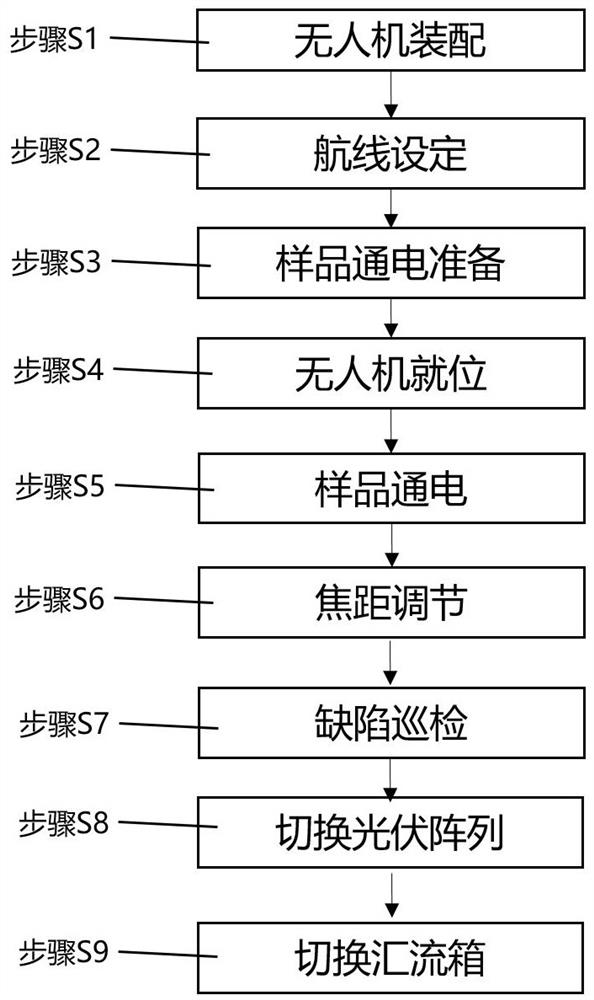

EL defect unmanned aerial vehicle inspection method for on-site evaluation of energy equipment

InactiveCN112822436AImprove test efficiencyRealize full inspectionTelevision system detailsColor television detailsUncrewed vehicleEngineering

The invention provides an EL defect unmanned aerial vehicle inspection method and system for on-site evaluation of energy equipment. The method comprises the steps of route setting, unmanned aerial vehicle assembling, sample electrifying, focal length adjusting, EL defect inspection and the like. The invention further provides an EL defect unmanned aerial vehicle inspection system for energy equipment field evaluation. The EL defect unmanned aerial vehicle inspection system integrates a multi-rotor unmanned aerial vehicle system, a high-sensitivity short-wave infrared system, a remote infrared lens focusing module and a high-definition infrared image wireless real-time transmission module. Compared with a conventional handheld EL testing system, the EL testing system is wide in application scene, high in testing efficiency and capable of monitoring the defect inspection condition on line in real time and avoiding damage to a sample wiring terminal. According to the method, the safety, the quality and the benefit evaluation efficiency of green assets formed by taking photovoltaic power stations as groups is improved, and the safety and quality of on-site construction and operation links in the whole life cycle of key equipment of the green assets are effectively guaranteed.

Owner:上海道口智能科技有限公司 +1

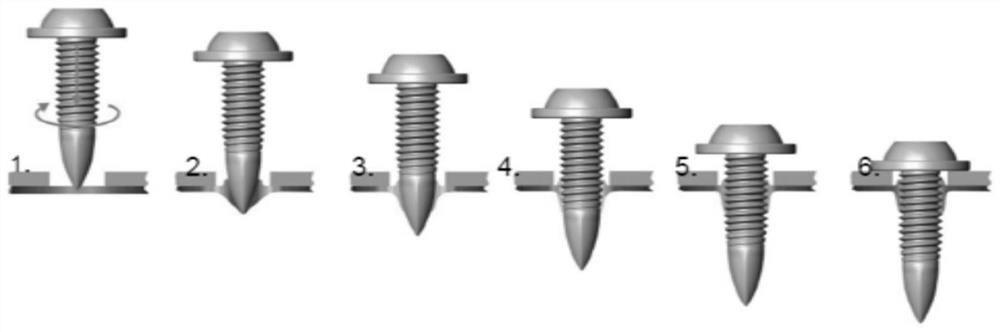

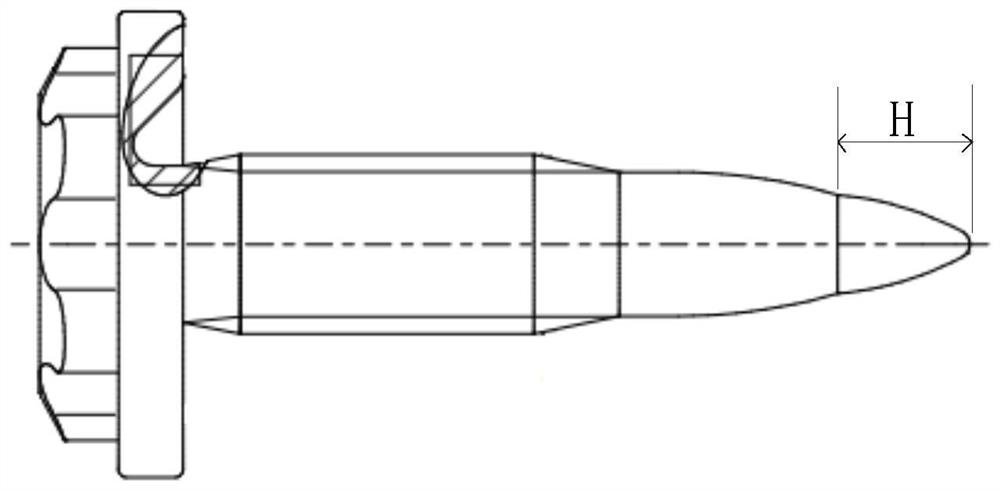

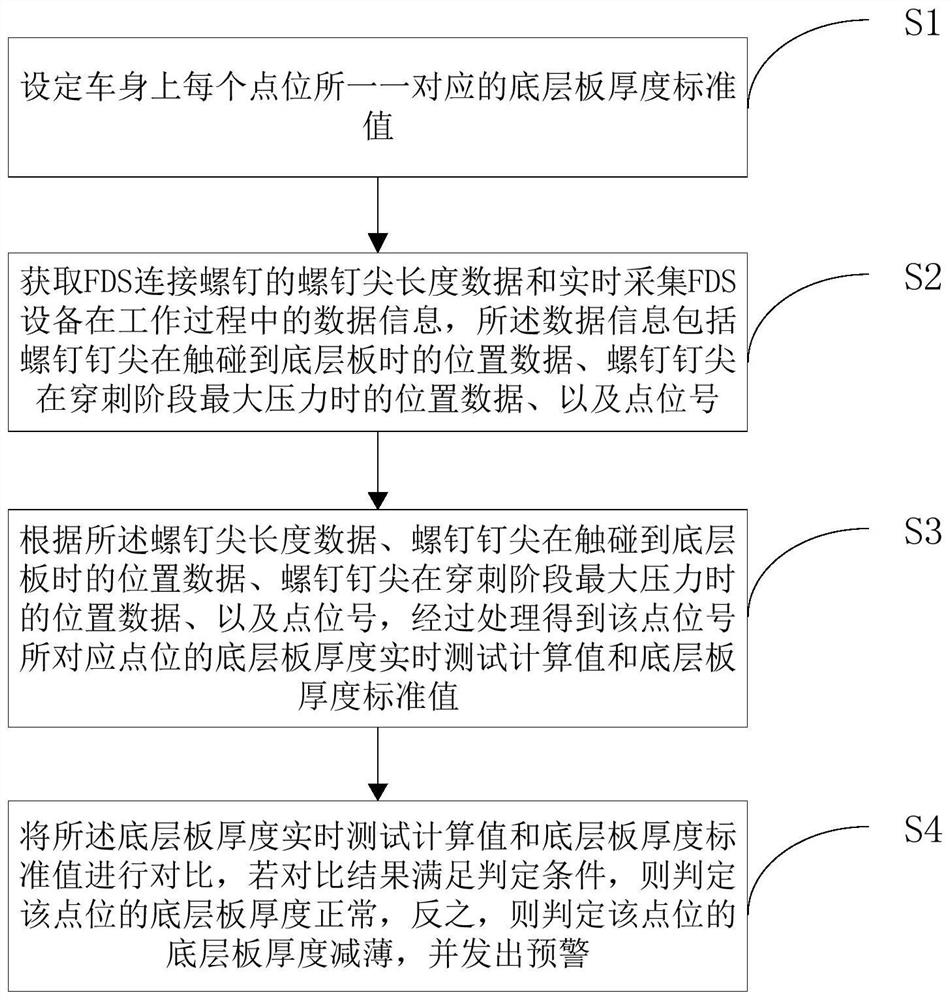

FDS bottom plate thickness judgment method and device, electronic equipment and storage medium

PendingCN112541707AReduce scrapReduce or even avoid scrappingOffice automationResourcesData informationEngineering

The invention discloses an FDS bottom plate thickness judgment method and device, electronic equipment and a storage medium. The judgment method comprises the following steps: a setting step: settinga bottom plate thickness standard value corresponding to each point location; an acquisition step: acquiring screw tip length data H and acquiring data information in the working process of the FDS equipment in real time, wherein the data information comprises position data L1 when the screw tip touches the bottom layer plate, position data L2 when the screw tip has the maximum pressure in the puncture stage, and a point position number; a processing step: according to the H, the L1, the L2 and the point location number, processing to obtain a real-time test calculation value and a standard value of the thickness of the bottom layer plate of the point location corresponding to the point location number; and a judgment step: comparing the real-time test calculation value with a standard value, if a judgment condition is met, judging that the thickness of the bottom plate of the point location is normal, and otherwise, judging that the thickness of the bottom plate of the point locationis reduced and giving an early warning. Whether the thickness of the bottom layer plate in the FDS process is reduced or not can be monitored in real time, and the quality problem in the production process can be found in time.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com