Online thickness measurement system for high-temperature cast pipe and using method of online thickness measurement system

A detection system and technology for casting pipes, which are applied in measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of reducing the defective rate of casting pipes, low detection efficiency, and inability to meet the quality monitoring needs of large-scale production lines. , to avoid the effect of subsequent stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

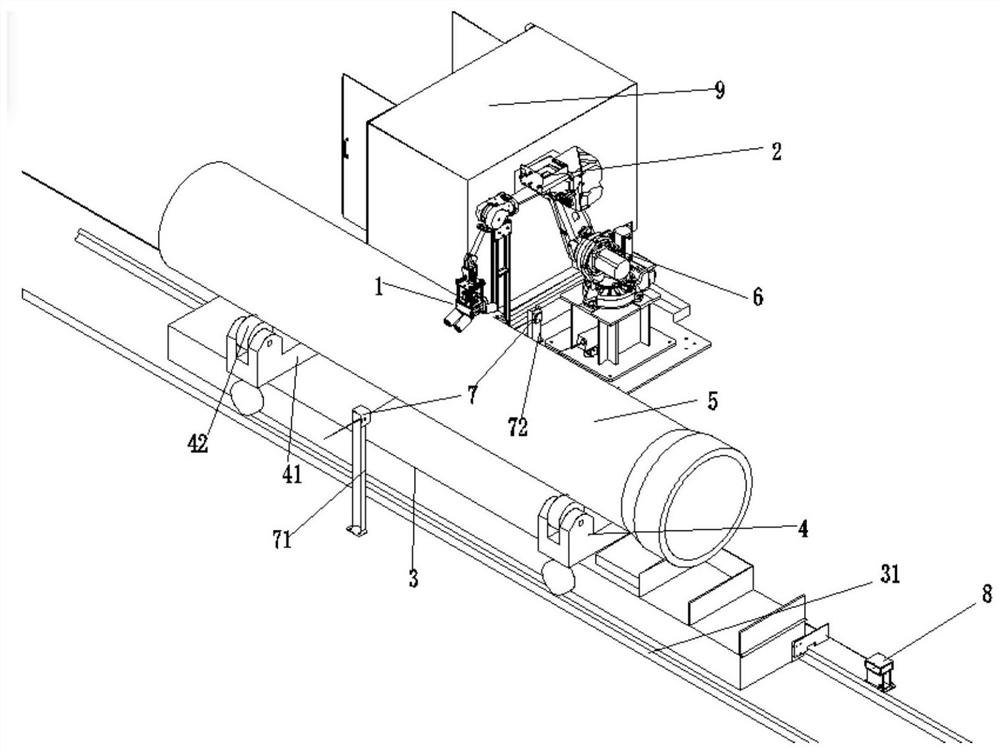

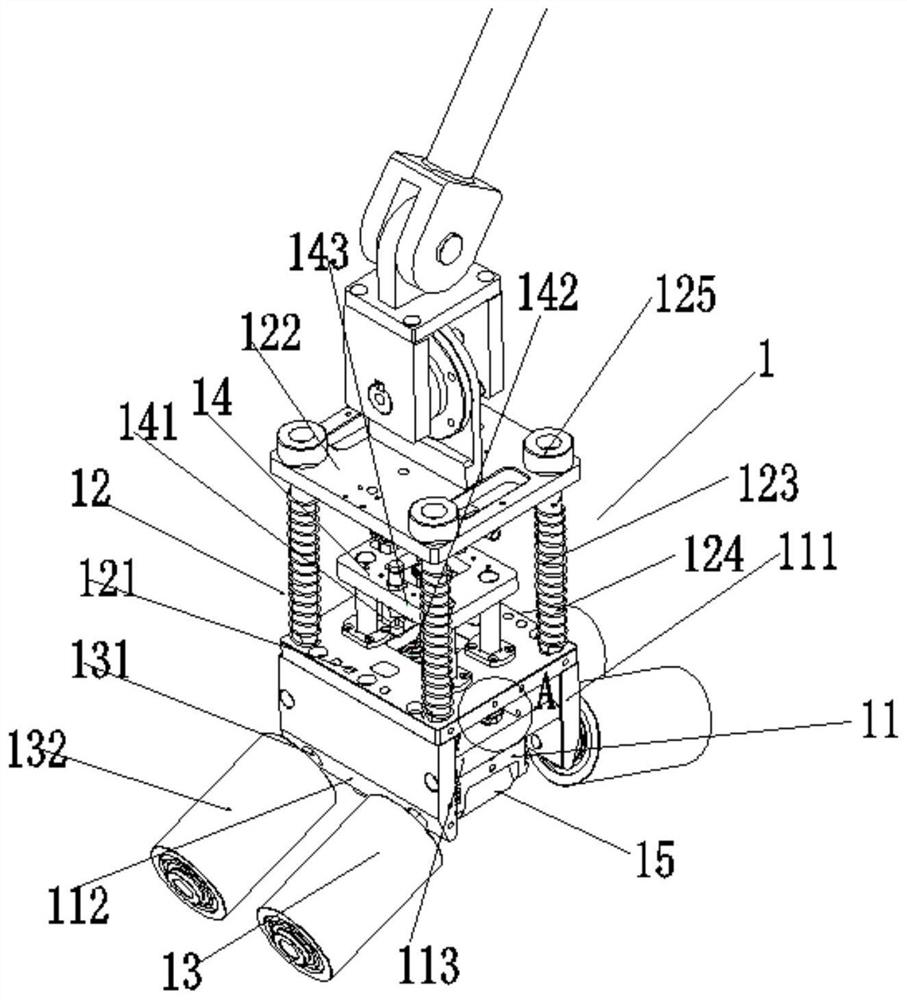

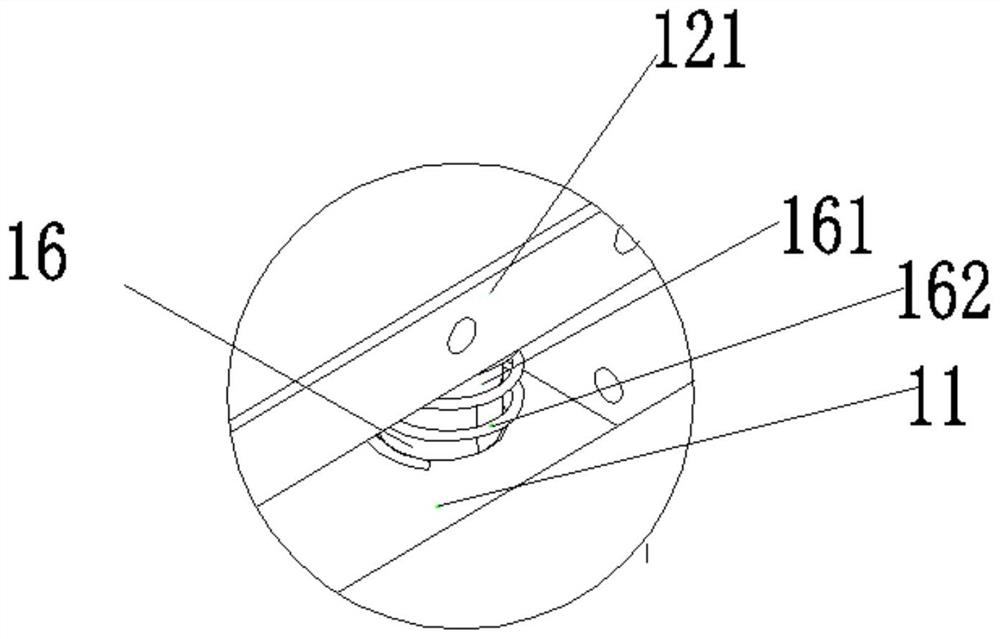

[0034] An on-line thickness measuring system for high-temperature cast pipes, comprising a pipe transport vehicle 3 arranged at the exit of a casting machine and a detection system arranged on the moving line of the pipe transport vehicle 3; the detection system includes a wall thickness detection mechanism; the The wall thickness detection mechanism includes a probe 1-1 assembly, and the probe 1-1 assembly includes a detection probe 1-1; the invention discloses a thickness measurement system for high-temperature cast pipe 5 online, and the setting of the pipe transportation vehicle 3 , it can facilitate the placement of the cast pipe 5 after it is taken out of the casting machine, and it is also convenient for subsequent transportation and transportation. In addition, the pipe transport veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com