Numerical-control detection device for bearing-keeping-device rivet separating force

A bearing retainer and detection equipment technology, applied in force/torque/work measuring instruments, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as low precision and slow detection, and achieve stable operation of equipment , cost reduction, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The embodiments are described below with reference to the drawings. The embodiments shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configuration shown in the embodiments below are not limited to the invention described in the claims. Necessary for the solution.

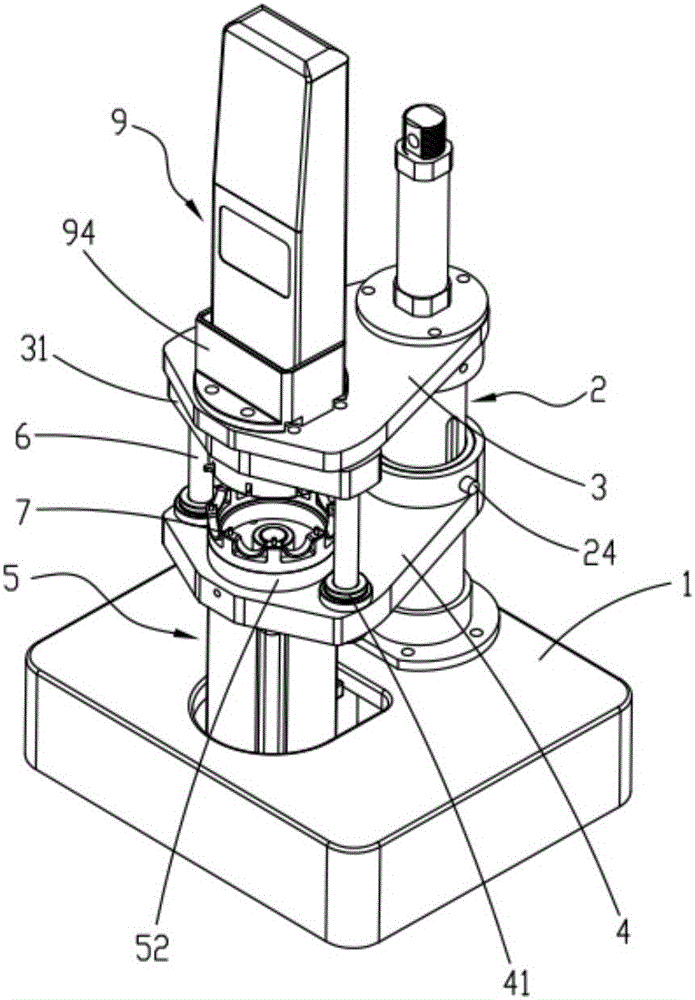

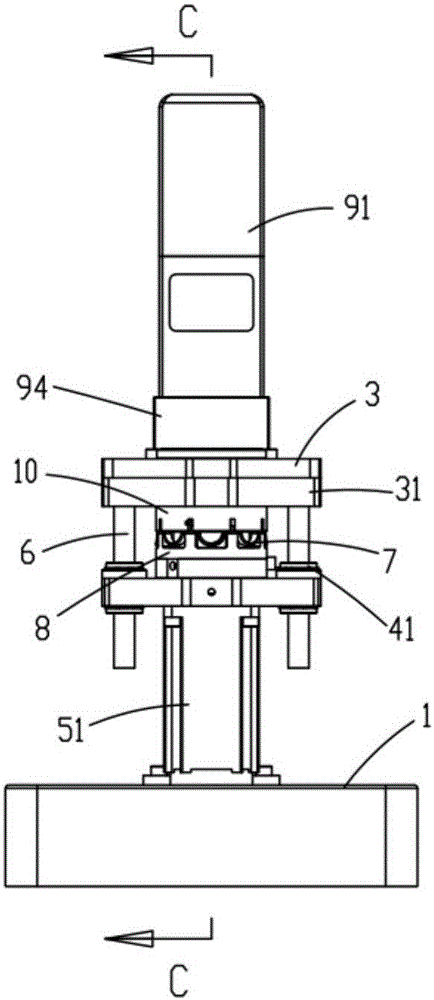

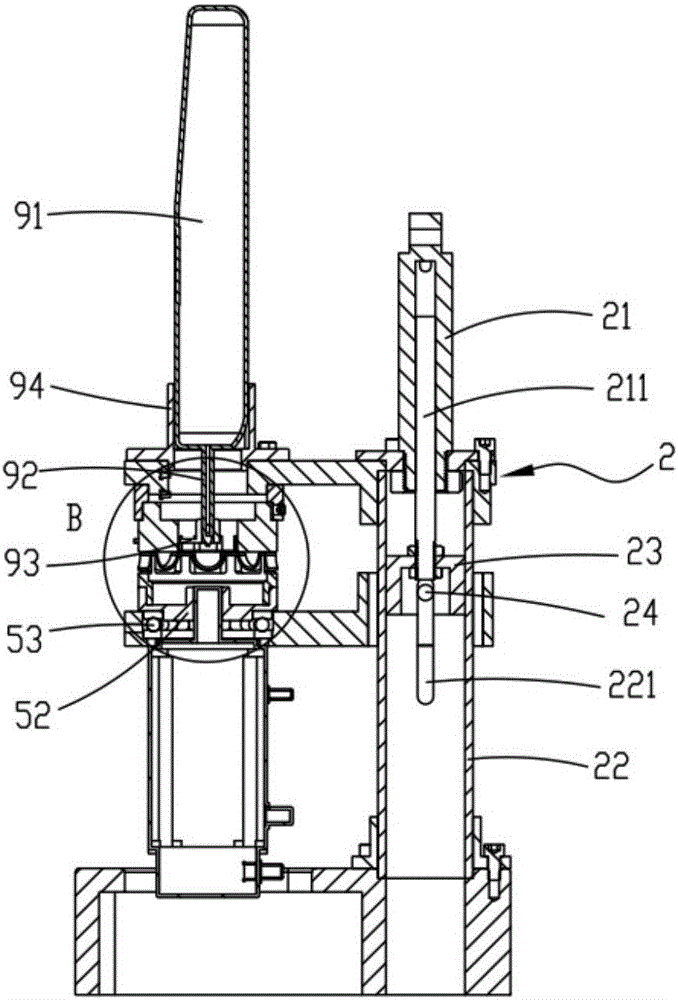

[0036] Such as figure 1 As shown, a numerical control detection device for rivet disengagement force of a bearing holder includes a base 1, a lifting mechanism 2, an upper molded part 3, a lower molded part 4, a rotating mechanism 5, and a torque detection mechanism 9. The lifting mechanism 2 is installed vertically On the base 1, one ends of the upper molded part 3 and the lower molded part 4 are sequentially installed on the lifting mechanism 2, and the other end is connected by two symmetrical guide posts 6, such as figure 2 As shown, the lower mold pressing part 4 is provided with a lower mold 8 for positioning the tested holder 7....

Embodiment 2

[0046] Such as Picture 9 As shown, the components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The second embodiment and figure 1 The difference in the first embodiment shown is that the pressure measuring rod 93 in this embodiment includes a vertical fixing part 931 sleeved on the end of the measuring rod 92 and at least one horizontal pressure measuring part 932. The parts 932 are fixed to the side wall of the vertical fixing part 931 by corresponding reinforcement parts 933. The number of the horizontal pressure measuring parts 932 on the pressure measuring rod 93 can be set according to the number of rivets on the holder 7 under test. , And cooperate with the numerical control programming to control the rotation angle of the rotating cylinder 51, so as to be suitable for measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com