Detection method for detecting false welding of electric core tab

A detection method, a technology of tab welding, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of long test time, false welding, poor timeliness, etc., and achieve the effect of simple and convenient detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

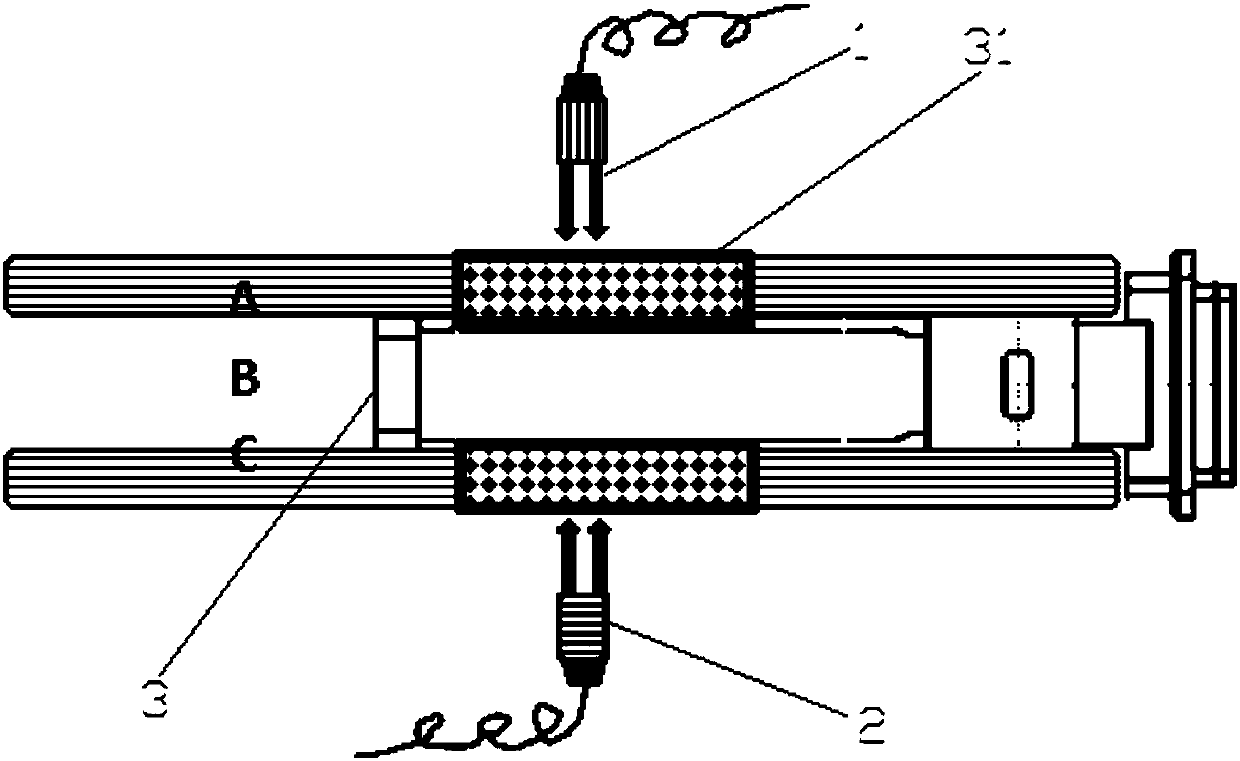

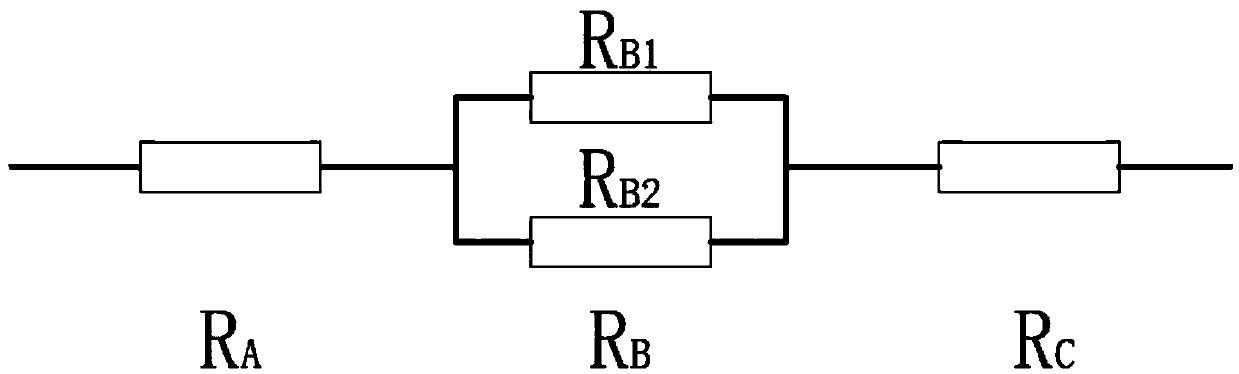

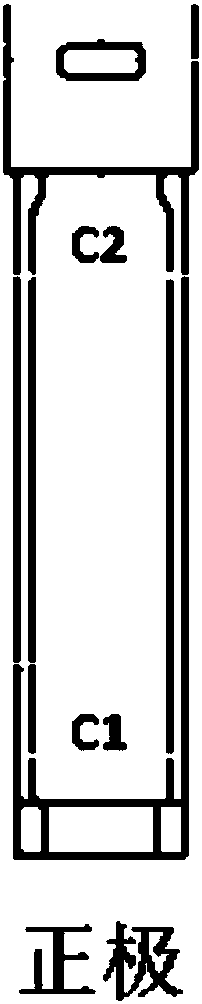

[0033] A method for detecting false welding of battery tabs, comprising the following steps:

[0034] 1) Touch the positive probe and negative probe of the battery tester to the solder marks on both sides of the positive / negative side tabs of the battery cell to be tested, and obtain the test internal resistance value of the positive / negative side tabs of the battery cell to be tested.

[0035] 2) Compare the test internal resistance value of the positive / negative side tab of the cell to be tested with the standard internal resistance value of the positive / negative side tab of the battery cell. If the test internal resistance value is less than or equal to the standard internal resistance value, judge The tabs on the positive / negative side of the cell to be tested are qualified products. If the test internal resistance value is greater than the standard internal resistance value, it is judged that the tab on the positive / negative side of the cell to be tested is a substandard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com